Production method of inflaming retarding hollow polyster fiber

A production method and polyester fiber technology are applied in the production field of functional hollow polyester, which can solve the problems of increasing the amount of flame retardants, adverse production efficiency, and reducing the quality of fiber products, so as to reduce the amount of flame retardants, improve labor productivity, The effect of streamlining the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

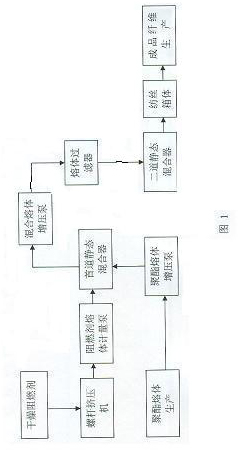

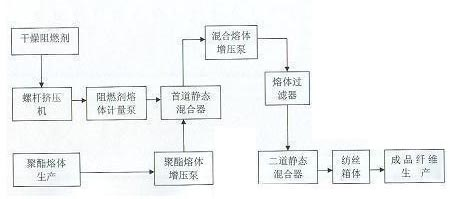

[0011] Below by specific embodiment and process flow chart figure 1 The present invention is further described, but this is not meant to limit the present invention. Its production process includes the following steps:

[0012] Polyester melt production. Polyester raw materials PTA (terephthalic acid) and EG (ethylene glycol) are evenly mixed at a molar ratio of 1.12:1, and then enter the first esterification reactor under the action of the catalyst ethylene glycol antimony, at a pressure of 75kPa, The temperature is 256°C and other process conditions, and the esterification reaction is carried out under the action of the stirrer without stopping, usually the esterification rate can reach 90%; then enter the second esterification reaction tank, and inject 0.3% (mass percentage) of extinction at the same time Agent TiO2, the esterification reaction is continued at a slight positive pressure of 67kPa and a slightly higher temperature than the first esterification, and the este...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com