Method for preparing guaiacol

A technology of guaiacol and reaction, which is applied in the field of guaiacol preparation, can solve the problems of difficult development of matching technology, high price of catechol, expensive life of catalyst, etc., to achieve improved product selectivity and low cost , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Preparation of supported solid acid catalyst: dissolving stannous chloride and / or niobium oxalate, bismuth nitrate, zirconium nitrate in 0.05mol / L dilute nitric acid solution respectively to obtain active component solution, the mass concentration of above-mentioned active component solution is 10 %, prepare aluminum nitrate into an aqueous solution with a mass concentration of 30%, mix the active component solution and aluminum nitrate solution evenly according to the ratio in Table 1, stir, and slowly add 25% ammonia water with the same mass as the active component solution at 70°C As a precipitating agent, it was added dropwise for 1 hour. After the dropwise addition, it was filtered and washed until the pH of the washing liquid was neutral, dried, and roasted at 773K for 6 hours. Catalyst raw powders loaded with different active components and different loads are prepared. The molded catalyst was obtained by extruding, and the active components and contents of the ca...

Embodiment 2

[0047] Dehydrogenation catalyst preparation:

[0048] Using the method of excessive volume impregnation, add a certain amount of light silicon dioxide and 300g water to the 5L round bottom flask, gradually add nickel nitrate, K 2 CO 3 , stannous chloride, stirred at 80°C for 3h, dried at 120°C for 12h after stirring, roasted at 400°C for 6h, extruded into a 3*3mm columnar catalyst, packed into a fixed bed reactor, 350°C, H 2 After reduction for 6 hours, the activated catalyst was obtained. The specific composition of the obtained dehydrogenation catalyst is shown in Table 2.

[0049] Table 2 Composition of different dehydrogenation catalysts

[0050]

[0051]

Embodiment 3

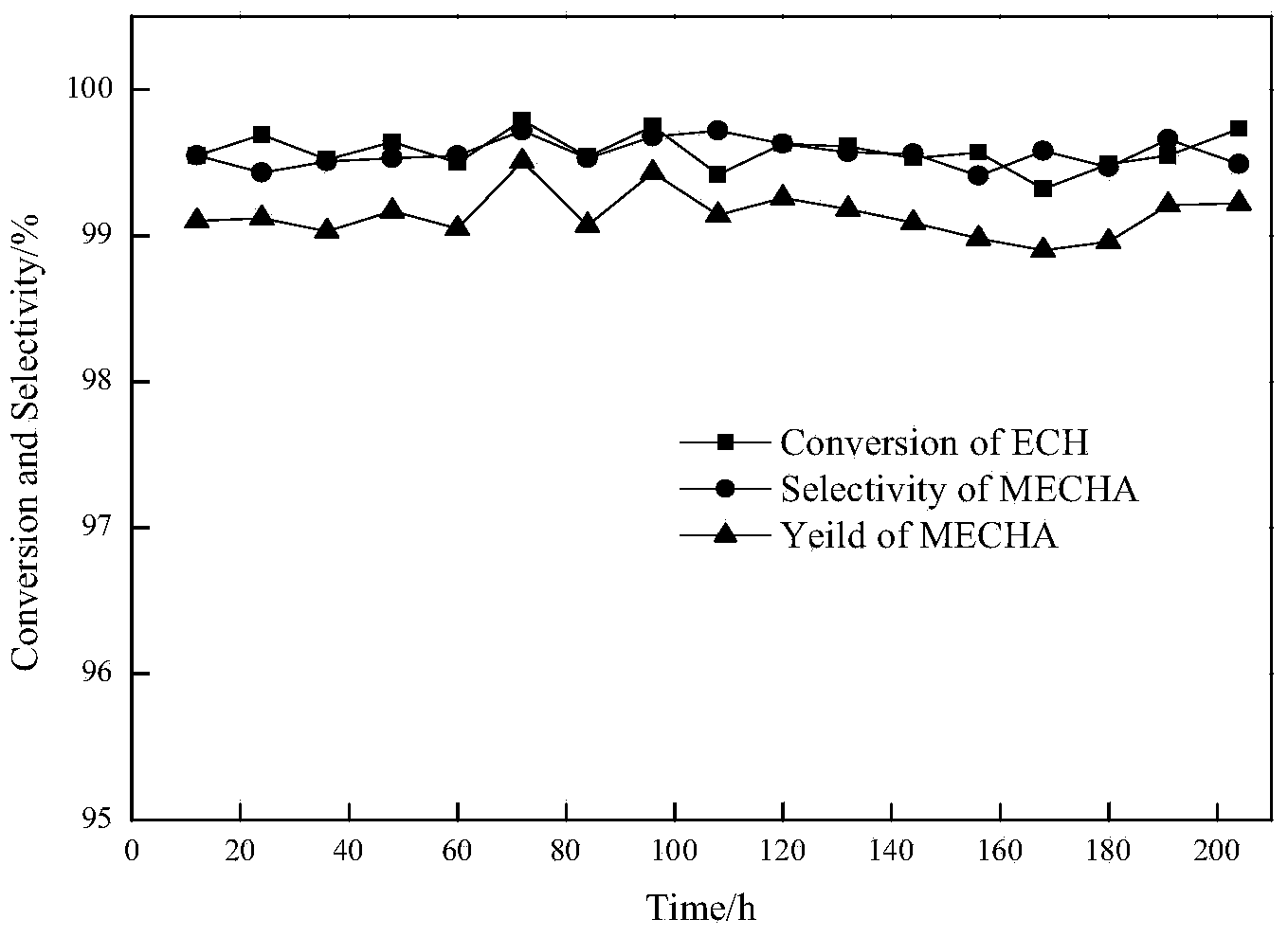

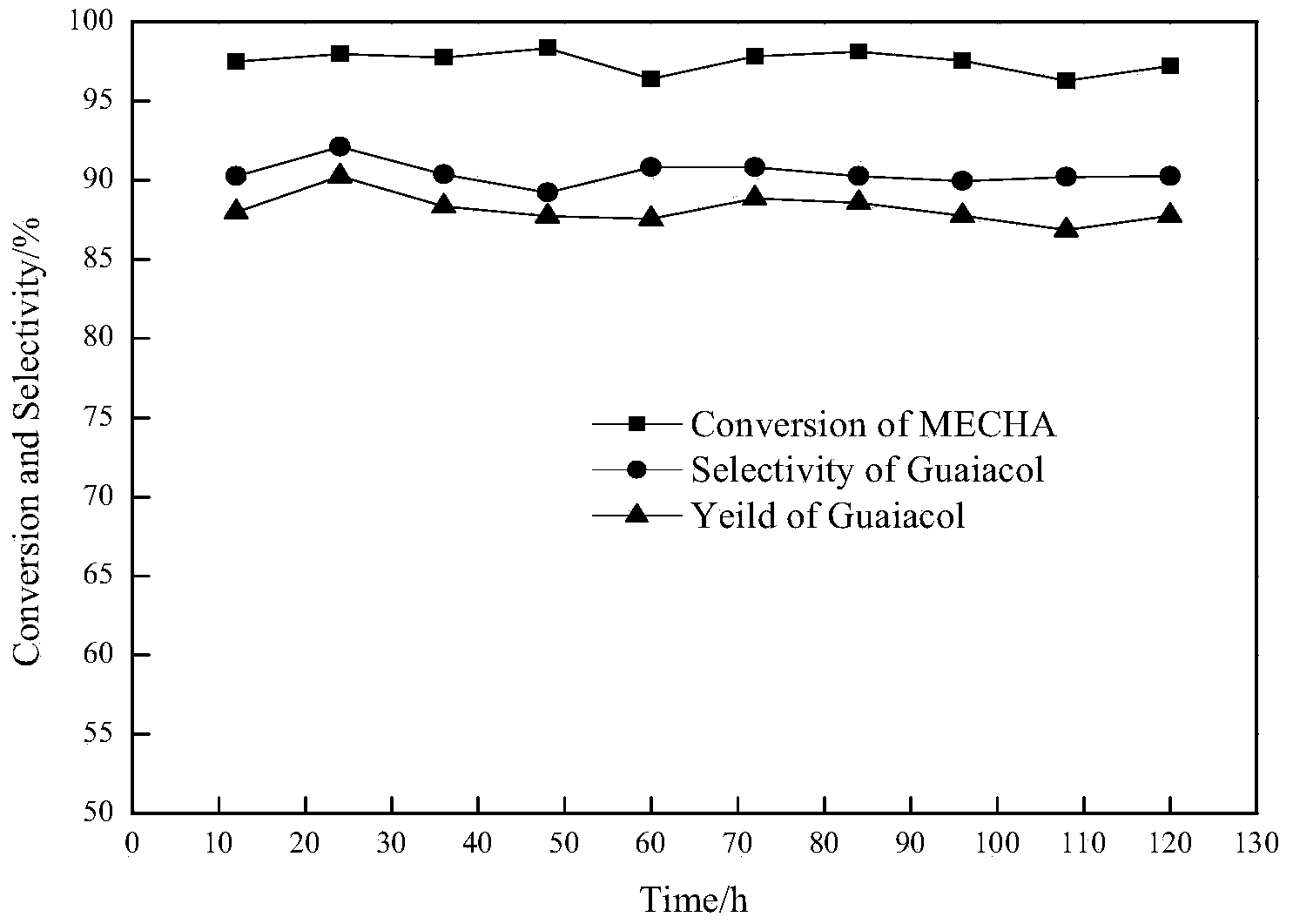

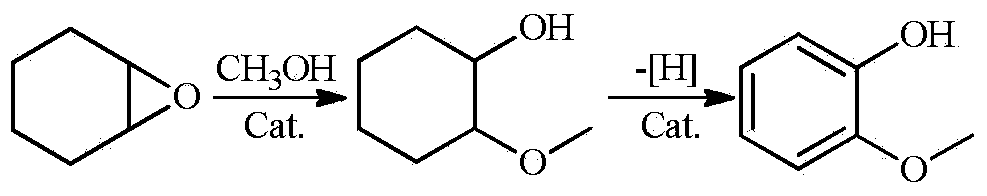

[0053] Ring-opening reaction of epoxycyclohexane alcohol: put epoxycyclohexane and methanol in a certain proportion, respectively, through the In a fixed-bed reactor for decomposing the catalyst, the reaction is continued under the protection of an inert gas. After the reaction is completed, methanol is distilled off under reduced pressure at a pressure of 0.2 bar, and o-methoxycyclohexanol is obtained at the bottom of the kettle; o-methoxycyclohexanol Dehydrogenation reaction: o-methoxycyclohexanol is diluted with nitrogen and passed through the 2 The fixed-bed reactor of activated dehydrogenation catalyst bed, the crude product adopts batch rectification process under normal pressure, and the theoretical plate number of rectification tower is 30, and first rectification extracts a small amount of by-product components, and the temperature of tower still 200°C, tower top temperature 170°C, pressure 0.1MPa, reflux ratio 1:1, to obtain a small amount of cyclohexanone, o-methoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com