Surface strengthening processing method for pinchbeck alloy

A surface strengthening and treatment method technology, which is applied in the field of copper-zinc alloy surface strengthening treatment, can solve the problems of hindering dislocation movement, low tensile plasticity, and difficulty in meeting the requirements of high-performance materials, so as to achieve the improvement of strength and plasticity and product quality. Stable and easy continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

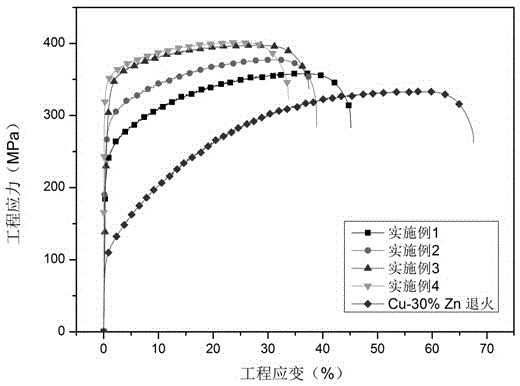

Embodiment 1

[0016] (1) Anneal the copper-zinc alloy sheet at a temperature of 800°C for 2 hours;

[0017] (2) The surface of the plate obtained in step (1) is polished, and the polished copper-zinc alloy plate (mass percentage is 30%, the thickness of the plate is 2mm) is subjected to surface nano-treatment in a liquid nitrogen environment, and the test frequency is 50Hz , the number of steel balls is 100, the diameter is 8mm, and the processing time is 5 minutes.

[0018] The prepared surface nano-copper-zinc sheet has high strength and good plasticity, the yield strength can reach 230Mpa, and the uniform elongation can reach 36%.

Embodiment 2

[0020] (1) Anneal the copper-zinc alloy sheet at a temperature of 850°C for 1 hour;

[0021] (2) The surface of the plate obtained in step (1) is polished, and the polished copper-zinc alloy plate (mass percentage is 30%, the thickness of the plate is 2mm) is subjected to surface nano-treatment in a liquid nitrogen environment, and the test frequency is 20Hz , the number of steel balls is 100, the diameter is 10mm, and the processing time is 15 minutes.

[0022] The prepared surface nano-copper-zinc sheet has high strength and good plasticity, the yield strength can reach 265Mpa, and the uniform elongation can reach 30%.

Embodiment 3

[0024] (1) Anneal the copper-zinc alloy sheet at a temperature of 825°C for 1.5 hours;

[0025] (2) The surface of the plate obtained in step (1) is polished, and the polished copper-zinc alloy plate (mass percentage is 30%, the thickness of the plate is 2mm) is subjected to surface nano-treatment in a vacuum environment, and the test frequency is 25Hz. The steel ball is 180, the diameter is 9mm, and the processing time is 20 minutes.

[0026] The prepared surface nano-copper-zinc sheet has high strength and good plasticity, the yield strength can reach 335Mpa, and the uniform elongation can reach 24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com