Method for preparing one or more of silicon nano power, silicon nanowires and silicon nanotubes by electrochemical method

A nanotube and electrochemical technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., to achieve the effect of controllable shape, simple equipment, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

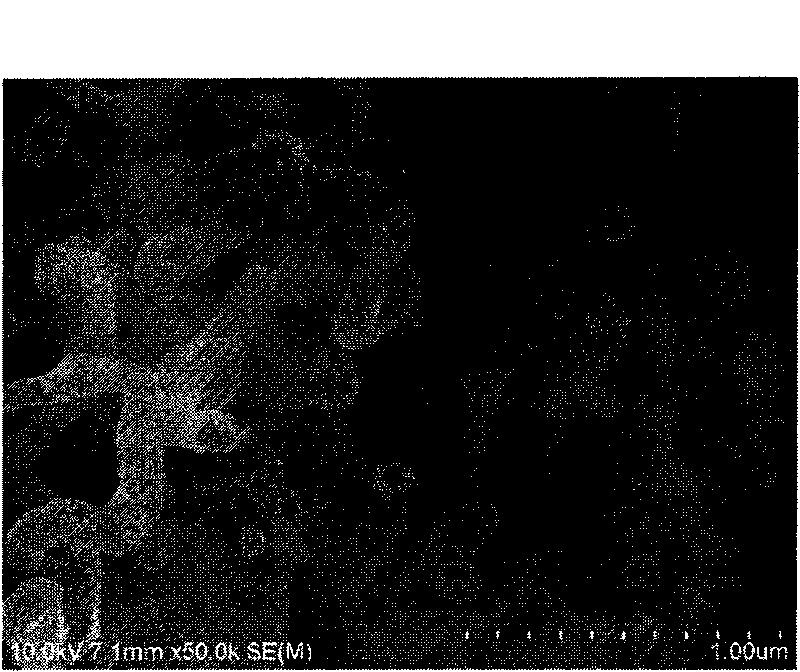

[0066] 75 wt% of SiO with a purity of 99.95% and an average particle size of 0.2 μm 2 The powder is mixed with 25wt% binder (as SiO 2 The total weight of powder and binder is 100%), pressed by mechanical pressure at 5MPa to about 10mm in diameter and 1.1mm in thickness, and heated in air at 1100°C for about 5 hours to sinter the formed SiO 2 The small piece is combined with a conductive cathode current collector as the cathode, and the graphite rod is used as the anode to melt the CaCl 2 As an electrolyte, in an argon environment, the temperature is 800°C, the voltage is controlled by a voltage regulator to perform constant voltage electrolysis, and the cell voltage is 3.0V. After 2 hours of electrolysis respectively, the electrolyzed product was rinsed with 1% by volume dilute hydrochloric acid, water, and absolute ethanol, and vacuum-dried to obtain a product such as figure 1 As shown, it is a curved silicon nanowire with a diameter of about 50 nm and a length of 2-5 micro...

Embodiment 2

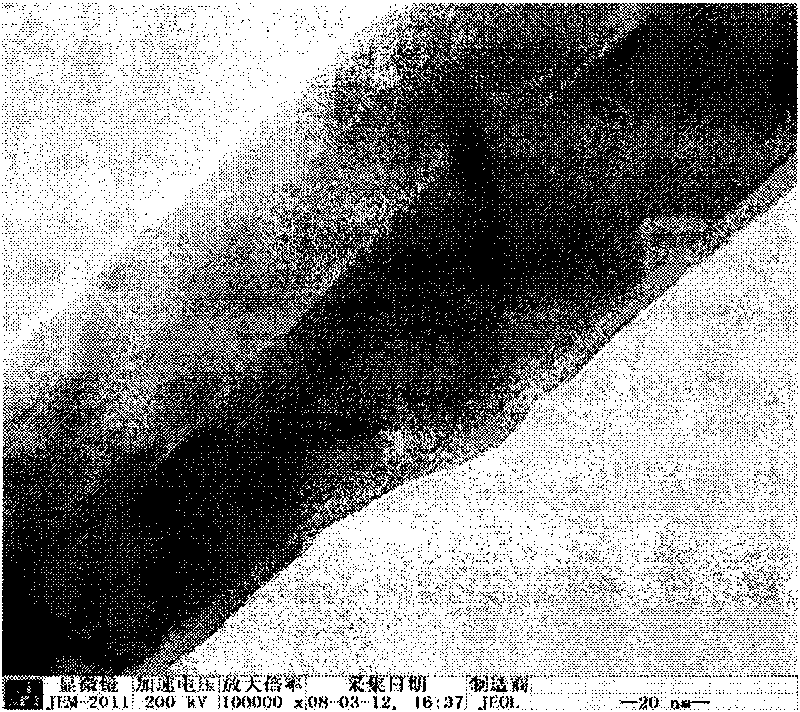

[0068] 75 wt% of SiO with a purity of 99.95% and an average particle size of 0.25 μm 2 The powder is mixed with 25wt% binder (as SiO 2 The total weight of the powder and the binder is 100%), pressed by mechanical pressure at 10MPa to a diameter of about 10mm, a thickness of 1.2mm, heated at 1200°C in air for about 4 hours, and the sintered SiO 2 The small piece is combined with a conductive cathode current collector as the cathode, and the graphite rod is used as the anode to melt the CaCl 2 As an electrolyte, in an argon environment, the temperature is 1000°C, and the voltage is controlled by a voltage regulator for constant voltage electrolysis, and the cell voltage is 2.0V. After 4 hours of electrolysis, the electrolyzed product was washed with 1% dilute hydrochloric acid, water and absolute ethanol successively by volume percentage, and vacuum-dried to obtain the product such as Figure 5 As shown, the product is mainly curved silicon nanowires / tubes with a diameter of 5...

Embodiment 3

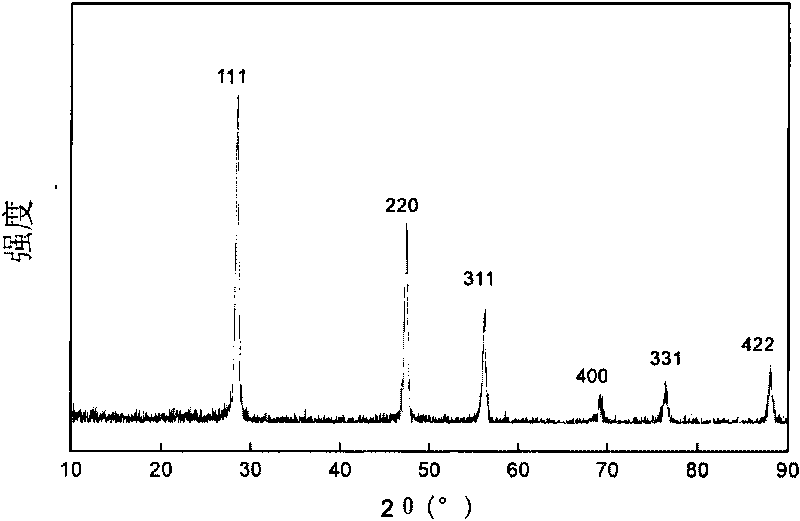

[0070] 75wt% of nano-SiO with a purity of 99.95% 2 The powder is mixed with 25wt% binder (as SiO 2 The total weight of the powder and the binder is 100%), pressed by mechanical pressure at 15MPa to a diameter of about 10mm and a thickness of 1.5mm, heated in air at 100°C for about 1.5 hours and then heated to 1100°C for 3 hours, and the sintered molded SiO 2 The small piece is combined with the conductive cathode current collector as the cathode, the graphite rod as the anode, and the CaCl 2 +NaCl mixed salt is the electrolyte (wherein CaCl 2 Accounting for 51% of the total weight of the mixed salt, NaCl accounts for 49%), in an argon atmosphere, the temperature is 600 ° C, the voltage is controlled by a voltage regulator to carry out constant voltage electrolysis, and the cell voltage is 2.5V. After 5 hours of electrolysis, the electrolyzed product was rinsed with 1% dilute hydrochloric acid, water and absolute ethanol successively by volume percentage, and vacuum-dried to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com