SO42-/nano TiO2 catalyst and application thereof to preparing cyclohexenyl cyclohexanone

A catalyst, cyclohexanone technology, applied in physical/chemical process catalysts, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of low rush selectivity, polluting the environment, and many by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 16.0g with an average particle size of 10nm and a specific surface area of 82m 2 / g Nano-TiO 2 In a beaker, add 50ml, 2mol / L sulfuric acid while stirring, the molar ratio of nano-titanium dioxide to sulfuric acid is 2:1. Nano TiO 2 After complete impregnation, promote at 30°C for 3h, filter the impregnation solution, put the obtained filter cake in a drying oven at 100°C for 5h, and then bake in a muffle furnace at 300°C for 5h to prepare the catalyst.

[0020] The prepared catalyst is used for self-condensation of cyclohexanone to prepare cyclohexenyl cyclohexanone. The reaction is carried out in a tank reactor with stirring. Add 100g of cyclohexanone to the reactor, heat it to 140°C, add 3 grams of catalyst to the tank, and react for 2 hours under stirring. Then, take a sample and analyze the reaction in gas chromatography. The composition of the product, and the conversion rate of cyclohexanone calculated from this data is 51.5%, and the selectivity of cyc...

Embodiment 2-4

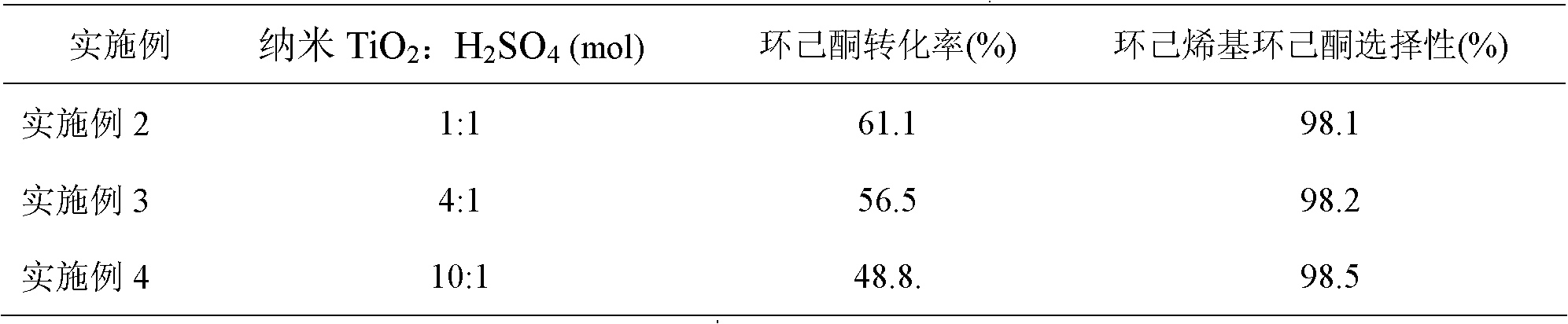

[0022] Catalyst preparation method is the same as embodiment 1, changes H 2 SO 4 with nano TiO 2 Molar ratio, the prepared catalyst was carried out under the same activity evaluation conditions as in Example 1, and the obtained cyclohexanone conversion rate and cyclohexenyl cyclohexanone selectivity were shown in Table 1.

[0023] Table 1 Nano TiO 2 with H 2 SO 4 Catalytic Activity of Catalysts Prepared by Different Molar Ratio

[0024]

Embodiment 5-7

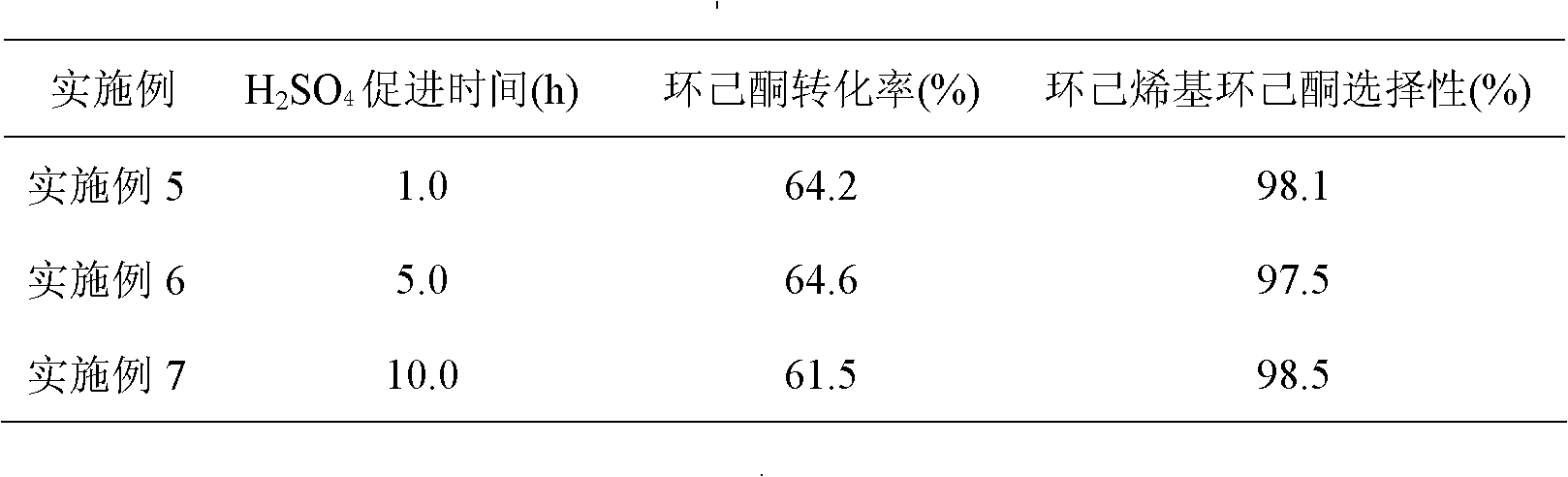

[0026] Catalyst preparation method is the same as embodiment 1, changes H 2 SO 4 Nano TiO 2 Acceleration time, the prepared catalyst was carried out under the same activity evaluation conditions as in Example 1, and the obtained cyclohexanone conversion rate and cyclohexenyl cyclohexanone selectivity are shown in Table 2.

[0027] Table 2H 2 SO 4 Catalytic Activity of Catalysts Prepared by Different Promoting Time

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com