Preparation method of graphene-based composite solid base catalyst with 3D structure

A solid base catalyst, graphene-based technology, used in the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of complex product separation process, achieve green process energy saving, improve electron transfer rate, The effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

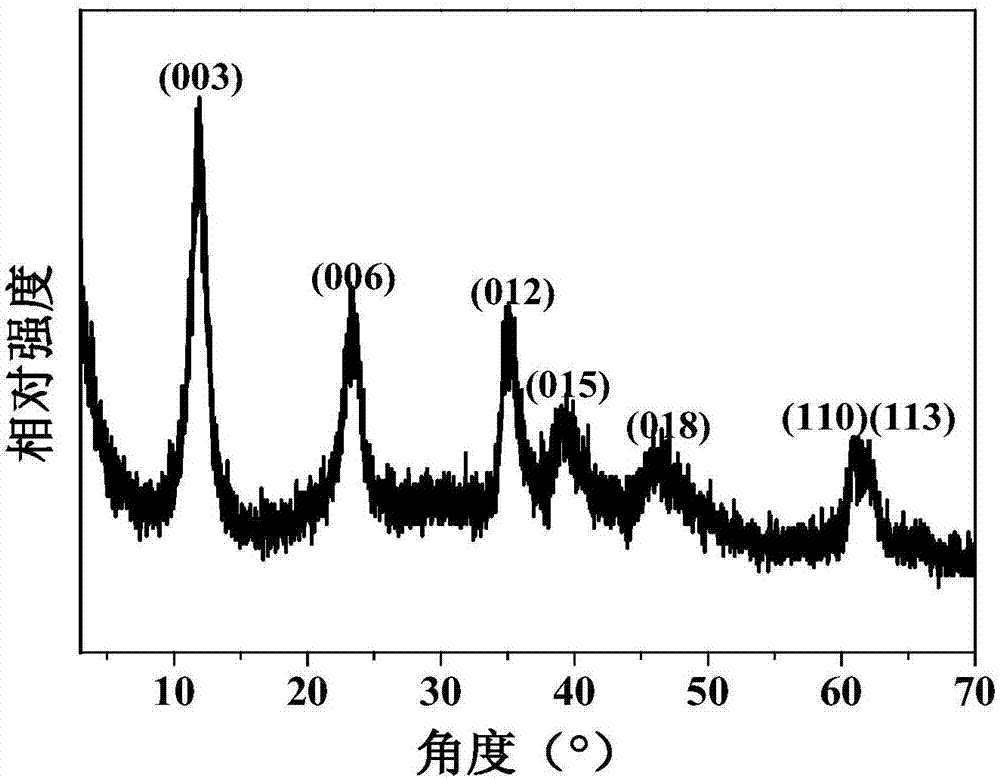

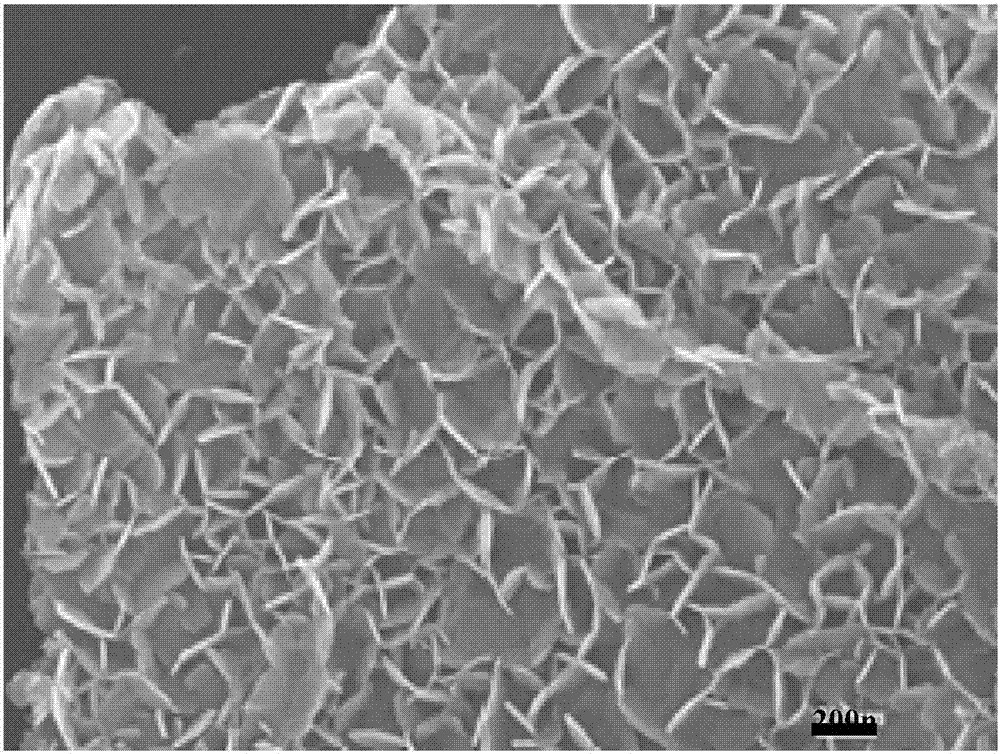

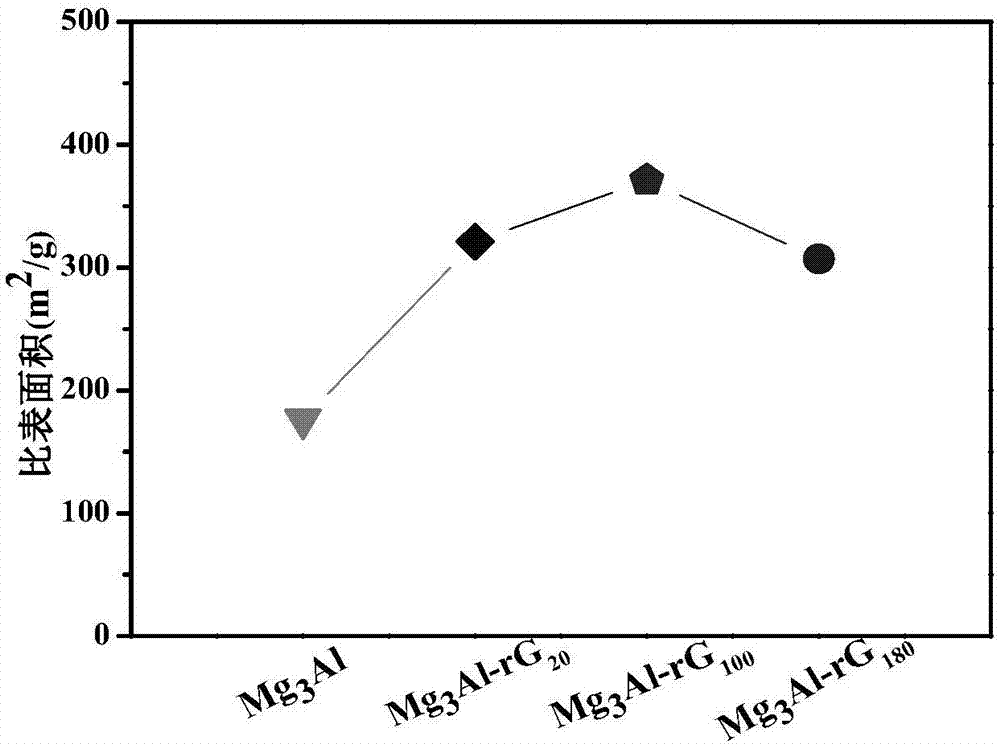

Embodiment 1

[0027] Weigh 3.077g Mg(NO 3 ) 2 ·6H 2 O, 0.852g Al(NO 3 ) 3 9H 2 O and 0.40 g of citric acid were dissolved in 100 mL of deionized water, the above salt solution was mixed with 100 mL of graphene oxide solution with a concentration of 2 mg / mL, and stirred ultrasonically for 30 min to obtain a graphene oxide mixed solution. Weigh 1.60g NaOH and 1.27g NaOH 2 CO 3 Dissolve in 100mL deionized water to obtain a mixed alkali solution. The above two solutions were dropped into a 500ml four-necked flask at the same time, keeping the pH value at 10, and the temperature at 15°C. After the titration was completed, the crystallization was continued at 65°C for 16h. The magnesium aluminum hydrotalcite / reduced graphene oxide composite was prepared by centrifuging and washing to neutrality, and freeze-drying.

[0028] Under nitrogen condition, the temperature was raised to 500°C at 5°C / min and kept for 6h. After cooling, stir in deionized water at 25°C for 6h, wash with ethanol, and...

Embodiment 2

[0032] Weigh 2.051g Mg(NO 3 ) 2 ·6H 2 O, 0.852g Al(NO 3 ) 3 9H 2 O, and 0.40 g of citric acid were dissolved in 100 mL of deionized water, and the above-mentioned salt solution was mixed with 100 mL of graphene oxide solution having a concentration of 2 mg / mL, and stirred ultrasonically for 30 min to obtain a graphene oxide mixed solution. Weigh 1.20g NaOH and 0.63g NaOH 2 CO 3 Dissolve in 100mL deionized water to obtain a mixed alkali solution. The above two solutions were dropped into a 500ml four-necked flask at the same time, keeping the pH at 9 and the temperature at 25°C. After the titration was completed, continue to stir and crystallize at 75°C for 18h. The magnesium aluminum hydrotalcite / reduced graphene oxide composite was prepared by centrifuging and washing to neutrality, and freeze-drying.

[0033] Under nitrogen condition, the temperature was raised to 600°C at 2°C / min and kept for 8h. After cooling, stir in deionized water at 35°C for 7h, wash with etha...

Embodiment 3

[0036] Weigh 2.051g Mg(NO 3 ) 2 ·6H 2 O, 0.426g Al(NO 3 ) 3 9H 2 O and 0.40 g of citric acid were dissolved in 100 mL of deionized water, and the above salt solution was mixed with 100 mL of graphene oxide solution with a concentration of 2 mg / mL, and stirred ultrasonically for 30 min to obtain a mixed solution of graphene oxide; weigh 0.8 g of NaOH and 0.64 g Na 2 CO 3 Dissolve in 100mL deionized water to obtain a mixed alkali solution. The above two solutions were dropped into a 500ml four-neck flask at the same time, keeping the pH at 11 and the temperature at 35°C. After the titration was completed, the crystallization was continued at 85°C for 20h. The magnesium aluminum hydrotalcite / reduced graphene oxide composite was prepared by centrifuging and washing to neutrality, and freeze-drying.

[0037] Under nitrogen condition, the temperature was raised to 700°C at 10°C / min and kept for 10h. After cooling, stir in deionized water at 45°C for 8h, wash with ethanol, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com