A kind of hollow raising fabric and preparation method thereof

A hollow, fabric technology, applied in knitting, textiles and papermaking, weft knitting and other directions, can solve the problems of only composite silk on the fleece surface, restrict the selection of yarn types, and have large limitations, so as to improve the thermal insulation effect, Improve thermal insulation life and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

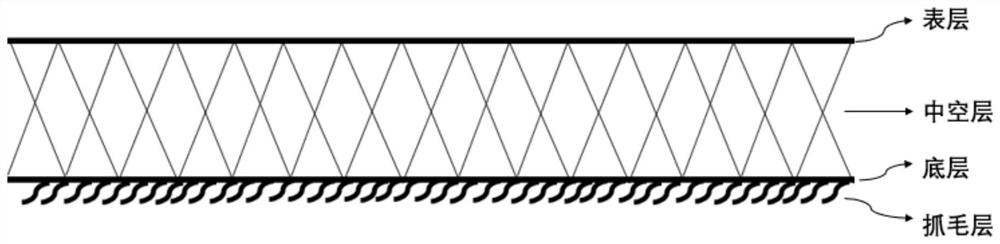

[0046] This embodiment provides a hollow raised fabric, the weaving diagram is as follows Figure 5 , the cross-section of the fabric is as Figure 9 , which includes a surface layer, a hollow layer and a bottom layer, wherein, the surface layer adopts 100% ring-spun cotton yarn of 30 British counts; the bottom layer adopts 20 British counts of polyester-cotton blended yarn (the first coil) and 50D / 36F polyester filament (the second coil ); the hollow layer is made of 50D / 36F polyester filament.

[0047] The manufacture method of present embodiment hollow raised fabric is:

[0048] Using 18G double-sided circular knitting machine, the distance between the needle cylinder and the dial is specially adjusted on the machine platform, that is, the distance between the cylinder opening is 2.2MM, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

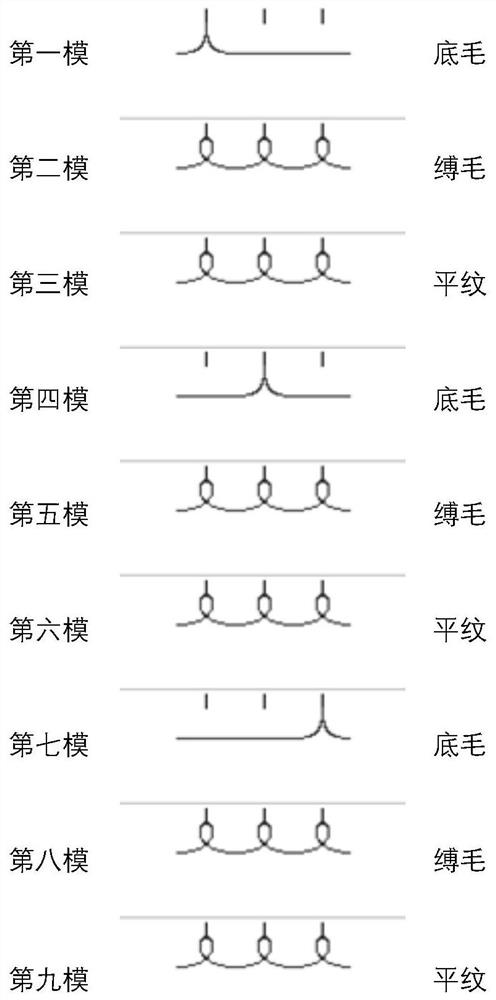

[0049] Using plain weave ten-mode weaving me...

Embodiment 2

[0068] The present embodiment provides a hollow raised fabric, comprising a surface layer, a hollow layer and a bottom layer, wherein, the surface layer adopts 100% ring-spun cotton yarn of 30 British counts; the bottom layer adopts 20 British counts of polyester-cotton blended yarn (the first coil) and 50D / 36F polyester filament (the second coil); the hollow layer adopts 50D / 36F polyester filament.

[0069] The manufacture method of present embodiment hollow raised fabric is:

[0070] Using 18G double-sided circular knitting machine, the distance between the needle cylinder and the dial is specially adjusted on the machine platform, that is, the distance between the cylinder opening is 2.2MM, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

[0071] It adopts plain weave eight-mode weaving method, including: 18G double-sided large circular knitting machine and upper and lower knittin...

Embodiment 3

[0083] The present embodiment provides a hollow raised fabric, comprising a surface layer, a hollow layer and a bottom layer, wherein, the surface layer adopts 100% ring-spun cotton yarn of 30 British counts; the bottom layer adopts 20 British counts of polyester-cotton blended yarn (the first coil) and 50D / 36F polyester filament (the second coil); the hollow layer adopts 50D / 36F polyester filament.

[0084] The manufacture method of present embodiment hollow raised fabric is:

[0085] Using 18G double-sided circular knitting machine, the distance between the needle cylinder and the dial is specially adjusted on the machine platform, that is, the distance between the cylinder opening is 2.2MM, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

[0086] The 12-mode bead pattern is adopted, including: 18G double-sided circular knitting machine upper and lower knitting needles are arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com