Preparation method of (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion

A technology of fluorinated polyacrylate and acrylate, which is applied in the field of preparation of modified fluorinated polyacrylate emulsion, can solve the problems of unsatisfactory fabric stiffness and poor storage stability of emulsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

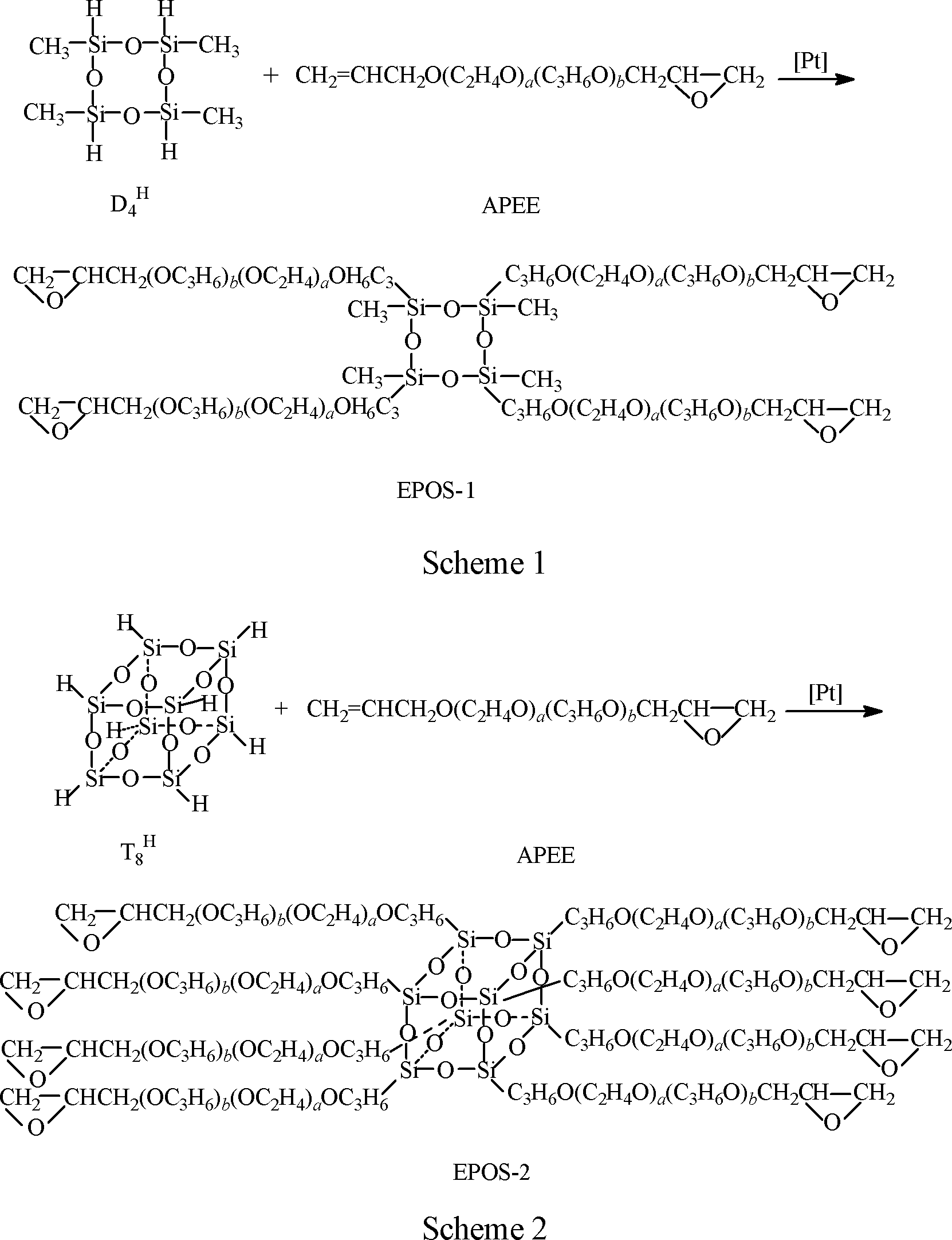

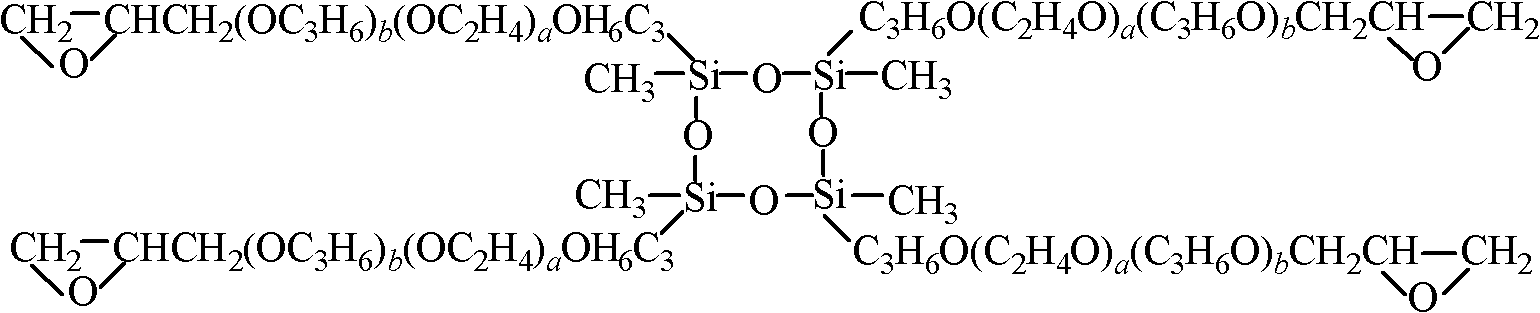

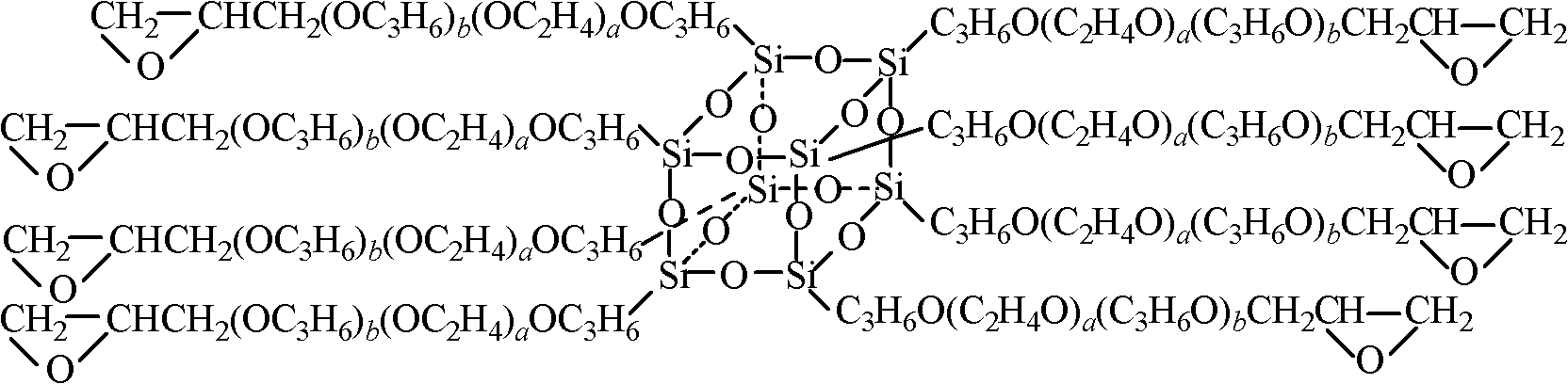

[0033] Preparation of epoxy polyether based (silsesquioxane) crosslinking agent

[0034] see figure 1 , take EPOS-1A as an example. In a three-necked flask equipped with a thermometer and a reflux condenser, add 24.1g of tetramethylcyclotetrasiloxane (D 4 H ) and 168.0g a / b=7:1, M n = 400 allyl polyoxyethylene polyoxypropylene epoxy ether (APEE), stirring and heating to 80 ° C, then adding 50 ppm platinum catalyst, after the system turns transparent, continue to stir and react for 10 minutes to obtain a transparent liquid, namely epoxy poly Ether-based siloxane crosslinking agent EPOS-1A.

[0035] The preparation method of other epoxy polyether-based (silsesquioxane) siloxane crosslinking agents is the same as that of EPOS-1A, and its raw material consumption is shown in Table 1.

[0036] Table 1 prepares the used raw material and consumption thereof of epoxy polyether base (silsesqui) siloxane EPOS

[0037]

[0038] APEE (1) : a / b=7:1, M n = 400; APEE (2) : a=10, ...

Embodiment 1

[0039] Example 1: Weighing 37.5g of the structure as CH in turn 2 =CHCOOCH 2 CH 2 (CF 2 ) 4~12 CF 3 Perfluoroalkane ethyl acrylate, 10.0g lauryl methacrylate, 1.5g hydroxypropyl acrylate and 0.5g 4-chloromethylstyrene and 0.5g vinyltriethoxysilane were mixed to form Oil phase monomer mixture. Then, weigh 0.7g of mercaptoethanol, 2.5g of cetyltrimethylammonium chloride 1631, 1.5g of fatty alcohol polyoxyethylene ether and 163.2g of deionized water and mix them with the oil phase monomer mixture, and mix them evenly with mechanical stirring , and then ultrasonically emulsified at 30±2° C. for 30 minutes to make a stable pre-emulsion, which is recorded as component (I), placed in the dropping funnel (I), and set aside.

[0040] Another 1.5 g of ammonium persulfate was dissolved in 30.0 g of deionized water to make an aqueous initiator solution, which was recorded as component (II), and placed in the dropping funnel (II) for subsequent use.

[0041] In the four-neck flask e...

Embodiment 2

[0042] Example 2: Weigh 20.0g dodecafluoroheptyl methacrylate, 20.0g lauryl acrylate, 2.5g butyl acrylate, 3.0g N-methylolacrylamide, 2.0g 4-chloromethylbenzene Ethylene and 2.5g of γ-methacryloxypropyltrimethoxysilane were mixed to form the oil phase monomer mixture. Then, weigh 0.3g dodecyl mercaptan, 2.0g dodecyl dimethyl benzyl ammonium bromide and 3g fatty acid polyoxyethylene ether ester SG-10 and 211.2g deionized water and mix with oil phase monomer mixture , mechanically stirred and mixed, emulsified at 25° C. for 30 minutes with ultrasonic waves to make a stable pre-emulsion, recorded as component (I), placed in the dropping funnel (I), and set aside.

[0043] Take another 0.25g water-soluble azo initiator AV-40, dissolve it with 10.0g deionized water to make an aqueous solution of initiator, record it as component (II), place it in the dropping funnel (II), and set aside.

[0044] In the four-neck flask equipped with thermometer, reflux condenser, dropping funnel (I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com