Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

399 results about "Isophorone di-isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-capsule self-repairing epoxy coating and preparation method thereof

InactiveCN105833811ASimple preparation processIncrease productivityMicroballoon preparationMicrocapsule preparationChemistrySilicon dioxide

The invention discloses a double-capsule self-repairing epoxy coating and a preparation method thereof. The preparation method mainly uses Pickering emulsion droplet template method and conducts an interface polymerization of interface isophorone diisocyanate and tetraethylenepentamine in water-oil of epoxy interface to prepare epoxy microcapsule and tetraethylenepentamine microcapsule; and the two microcapsules are added to epoxy resin microcapsules for the formation of double-capsule self-repairing epoxy coating. The Pickering emulsion droplet template method ensures the stability of the emulsion, prevents emulsion droplet blending, improves package amount and efficiency of the microcapsule core material; Pickering emulsion improves the repair efficiency of the double-capsule self-repairing epoxy coating; the introduction of nano silica particles and nano clay in the capsule walls of the epoxy microcapsule and tetraethylenepentamine microcapsule improves the mechanical strength and thermal stability of the microcapsule wall, but also improves the brittleness of the microcapsule and the releasing efficiency of the microcapsule core material, so as to ensure the repair performance of the double-capsule self-repair coating.

Owner:SOUTH CHINA UNIV OF TECH

Acrylate grafted aqueous polyurethane emulsion and preparation method thereof

ActiveCN102558460AImprove stabilitySmall particle sizeFibre treatmentCoatingsHydrophilic monomerPolymer science

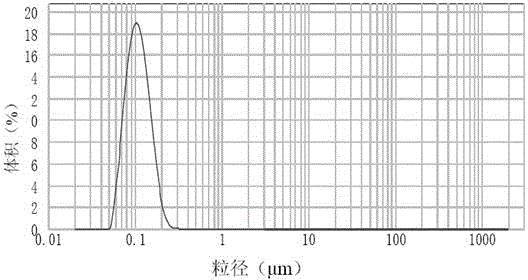

The invention discloses acrylate grafted aqueous polyurethane emulsion and a preparation method thereof. The emulsion is characterized is prepared from polyether polyol, dimethylol propionic acid, isophorone diisocyanate, ethylenediamine, hydroxyethyl acrylate and the like. The preparation method comprises the following steps: carrying out prepolymerization on polyether polyol, dimethylol propionic acid and isophorone diisocyanate so as to introduce a hydrophilic monomer; adding ethylenediamine and hydroxyethyl acrylate to carry out chain extension so as to introduce a functional monomer; adding an acrylate mixed monomer so as to reduce system viscosity; adding triethylamine for neutralization; adding deionized water for emulsification and dispersion under the condition of high-speed shearing to obtain emulsion; then dropwise adding the acrylate mixed monomer and an initiator, raising the temperature and carrying out reaction; and cooling to obtain the PUA (polyurethane-acrylate) emulsion. The emulsion prepared by the method has small grain size and excellent performances such as mechanical performance, is narrowly distributed and can be widely applied to industry fields such as leather finish, coatings, adhesives and fabric coatings.

Owner:顶立新材料科技股份有限公司

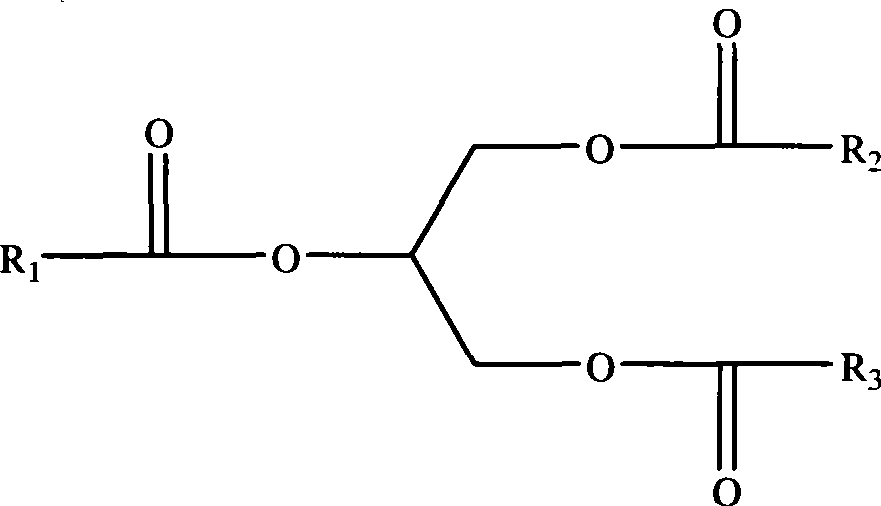

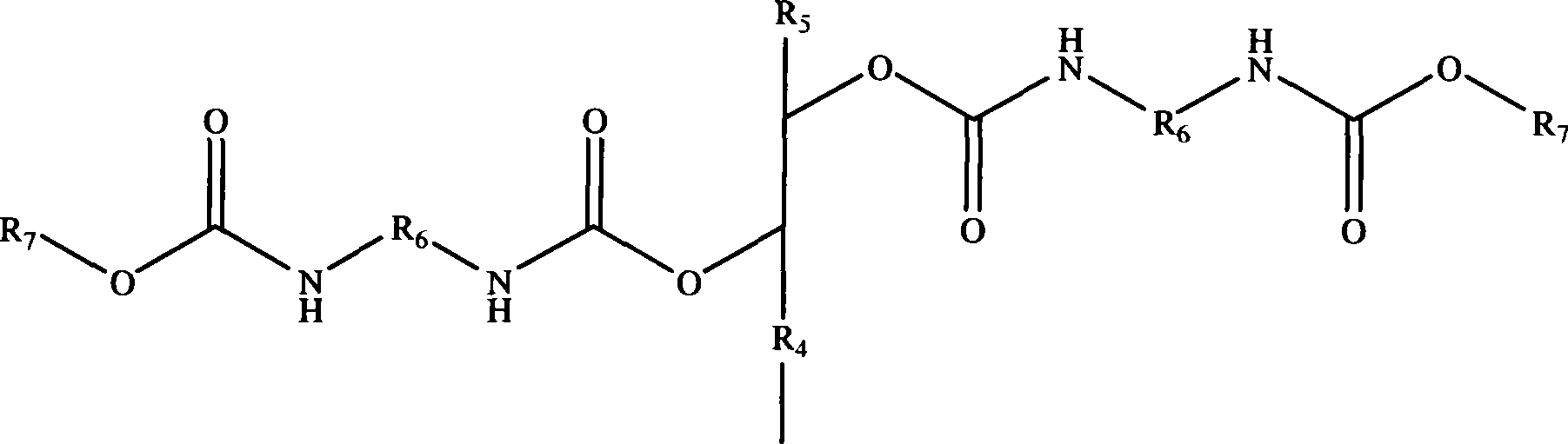

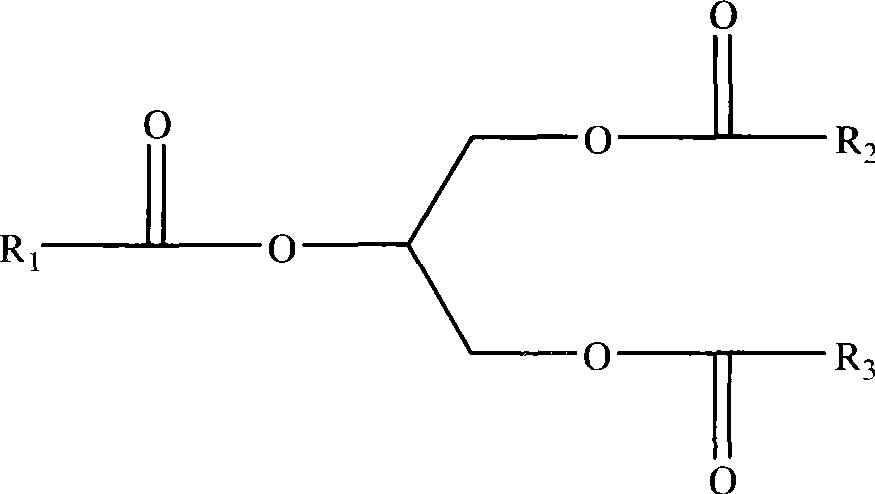

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

Polyurethane memory foam with superior anti-yellowing performance

The invention discloses polyurethane memory foam with superior anti-yellowing performance, and belongs to the field of polyurethane foam. The polyurethane memory foam is prepared from the following raw materials in parts by weight through reactive foaming: 10-90 parts of normal polyether glycol, 90-10 parts of slow recovery polyether glycol, 30-80 parts of isophorone diisocyanate, 1-5 parts of water, 1-3 parts of silicone oil, 0.4-2 parts of catalyst, 0.3-2 parts of stabilizer, 0.5-15 parts of physical foaming agent and 0.4-2 parts of crosslinking agent. The preparation method comprises the following steps of: adding corresponding parts by weight of polyether glycol (including normal polyether glycol and slow recovery polyether glycol) and isophorone diisocyanate into a mixer to stir uniformly; heating to 30-70 DEG C; adding corresponding parts of other raw materials into the mixer; and stirring at a high speed for 3-10 seconds and then pouring in a mould to foam and cure to obtain the corresponding polyurethane memory foam. Since the isophorone diisocyanate not containing benzene ring is adopted as a raw material, the produced polyurethane memory foam has superior anti-yellowing performance such as antioxidation, irradiation resistance, aging resistance and the like.

Owner:胡志刚

Preparation and application of water-borne polyurethane polyacrylate compound emulsion

InactiveCN102675798AOvercome the disadvantage of high energy consumptionInhibit sheddingPolyurea/polyurethane coatingsPolymer scienceMeth-

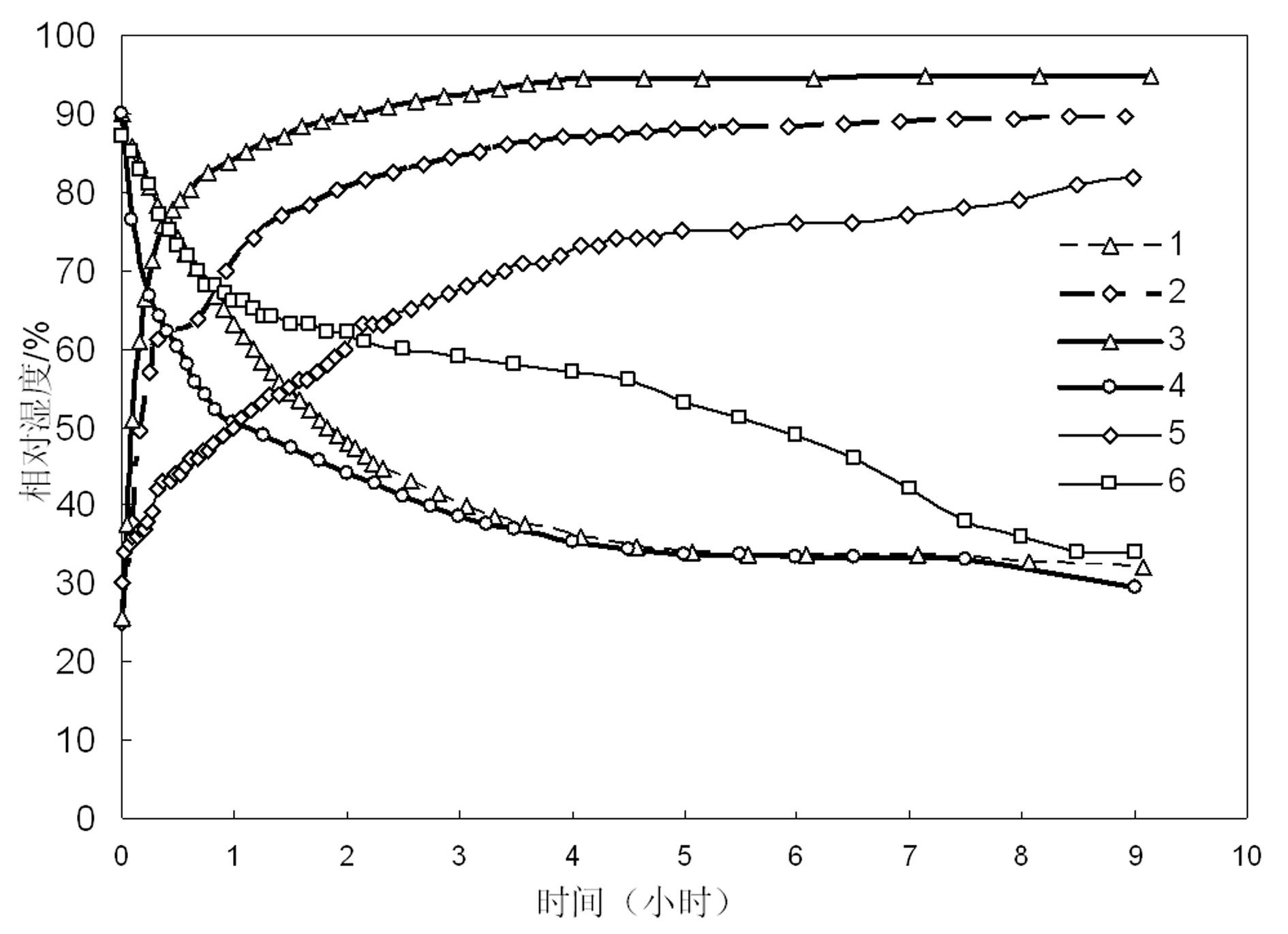

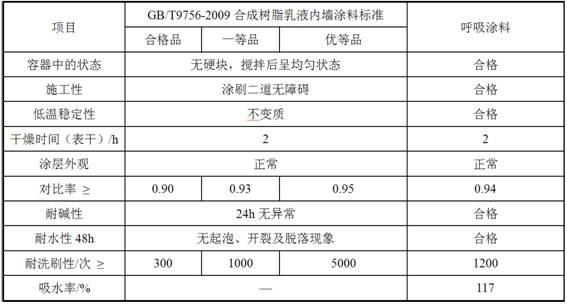

The invention provides a method for preparing water-borne polyurethane polyacrylate compound emulsion. The method comprises the following steps of: preparing water-borne polyurethane emulsion by using polypropylene glycol, 2,2-dihydromethyl propionic acid and isophorone diisocyanate as main materials; preparing polyacrylate emulsion by polymerizing methyl methacrylate, acrylic acid, butyl acrylate and diacetone acrylamide serving as main materials; and finally, mixing the water-borne polyurethane emulsion and the polyacrylate emulsion to obtain the water-borne polyurethane polyacrylate compound emulsion. The breathable coating produced by using the water-borne polyurethane polyacrylate compound emulsion as a main film-forming material of coatings integrates functions of decoration, humidity regulation, permeability, heat preservation and condensation prevention, water resistance, alkali resistance and the like, overcomes the defect of high energy consumption of conventional air conditioners, simultaneously prevents the falling of films caused by leakage and water condensation of walls, makes the films more durable and has a better application prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

UV (ultraviolet) photocured water-based fluorine-containing polyurethane latex film and preparation method thereof

InactiveCN102977758AStrong mechanical propertiesHigh hardnessPolyurea/polyurethane coatingsTetrafluoroethylenePolymer science

The invention discloses a UV (ultraviolet) photocured water-based fluorine-containing polyurethane latex film and a preparation method thereof. The UV photocured water-based fluorine-containing polyurethane latex film is prepared by the following specific steps: adding photoinitiator IRGACURE184 or IRGACURE907 into a UV-cured water-based fluorine-containing polyurethane emulsion, evenly stirring, coating on a tetrafluoroethylene board, and drying at 60 DEG C to a constant weight, wherein the photoinitiator IRGACURE184 or IRGACURE907 accounts for 3.73-4% of the UV-cured water-based fluorine-containing polyurethane emulsion in percentage by weight; and then, performing UV irradiation curing on a UV curing machine to obtain the UV photocured water-based fluorine-containing polyurethane latex film. The preparation method comprises the preparation of an isophorone diisocyanate tripolymer-fluorine alcohol addition compound, the preparation of the UV-cured water-based fluorine-containing polyurethane emulsion and the preparation of the UV photocured water-based fluorine-containing polyurethane latex film. The finally obtained UV photocured water-based fluorine-containing polyurethane latex film transparent, can not be yellowed, and has favorable acid resistance, alkali resistance, water resistance and high hardness.

Owner:SHANGHAI INST OF TECH

Polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and preparation method thereof

InactiveCN102086348AStrong anti-fogHigh transparencyPolyurea/polyurethane coatingsAcrylic resinPolypropylene glycol

The invention discloses polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and a preparation method thereof. The paint is prepared from the following components in parts by weight: 130-190 parts of hydrophilic acrylic resin, 210-525 parts of blocked polyether-isocyanate used as curing agent and 2.00-5.00 parts of butyltin dilaurate used as catalyst, wherein the blocked polyether-isocyanate curing agent uses polypropylene glycol and isophorone diisocyanate as raw materials. The preparation method of the paint comprises the following steps: reacting to obtain polyether-isocyanate prepolymer and then reacting with methyl ethyl ketoxime used as sealing agent. The test result shows that the paint prepared by the method has high anti-fogging property, good transparency and abrasion resistance and low production cost; and under the premise of ensuring the good anti-fogging property of the paint, the surface wear resistance can be increased and the application prospectis wide.

Owner:上海旺俊化工有限公司

Preparation method of waterborne polyurethane adhesive for card matrix material

ActiveCN103173185AResistant to hydrolysisResistant to yellowingPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides a preparation method of waterborne polyurethane adhesive for a card matrix material, and belongs to the technical field of high polymer materials. The method comprises the following preparation steps of: carrying out polymerization reaction on mixed binary isocyanate formed by isophorone diisocyanate and dicyclohexyl methane-4,4-diisocyanate and polyhydric alcohol of taking polyester diol as a primary material and polyether glycol as an auxiliary material; adding proper hydroxyl acrylate to a reaction system, and preparing a polyurethane prepolymer by virtue of a chain extender; neutralizing by use of triethylamine, and adding water to emulsify in a high-speed disperser, so as to obtain a waterborne polyurethane dispersing body; adding ethanediamine to carry out chain extension again, and finally mixing with assistants such as a defoamer, a thickener, anti-adhesive and an ultraviolet light absorber to obtain the waterborne polyurethane adhesive for the card matrix material. The preparation method has the characteristics of being low in preparation cost, strong in adhesion and the like, is simple in production technology and can be used for easily coating products; the solid content can achieve 40%; and the coated film with glue is especially suitable for coating various color cards.

Owner:江苏华信高新材料有限公司

Preparation method of carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive

InactiveCN104327717ALow toxicityImprove thermal stabilityFireproof paintsNon-macromolecular adhesive additivesPolymer scienceSpinning

The invention relates to a preparation method of carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive. Specifically, the preparation method comprises the following steps: carrying out acidifying treatment on a carbon nano tube, modifying a carboxyl group on the surface in a certain proportion and condensing with acrylamide to prepare an amidated carbon nano tube intermediate; and finally condensing the amidated carbon nano tube with isophorone diisocyanate by virtue of in-situ polymerization, so as to improve the dispersibility of the carbon nano tube in aqueous polyurethane emulsion and enhance physical and chemical actions between polyurethane molecules, thus finally preparing as novel carbon nano tube-based electrically conductive and flame-retardant aqueous polyurethane coating and adhesive emulsion. The finished product can be widely used as a coating for a wall, furniture and metal appliances and also can be used as an adhesive for plastic, glass, rubber, papermaking, leather and spinning.

Owner:JINHUA VOCATIONAL TECH COLLEGE +1

Method For Preparing Carbon Nanotubes Graphene Modified Aqueous Polyurethane Coatings and Adhesives

ActiveUS20170114248A1Improve fire resistanceImprove light resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsBenzoic acidAdhesive

The present invention discloses a method for preparing carbon nanotubes graphene modified aqueous polyurethane coatings and adhesives: under the presence of dibutyltin dilaurate as catalysts, mixing polytetrahydrofuran ether glycol with isophorone diisocyanate, reacting at 60° C. to 80° C., adding 2-sulfobenzoic anhydride, carboxylated carbon nanotubes and graphene sheet into the mixture, reacting at 90° C. for 2 hours, and then polyurethane prepolymer A is obtained; adding chain extender and acetone into prepolymer A, reacting at 65° C. to 75° C., adding D-panthenol and 2,4,6-trihydroxy benzoic acid, reacting at 75° C. to 85° C. for 0.5 to 2 hours, adding triethylamine and benzamide for neutralization, reacting for 30-50 min, adding water for emulsification, and then carbon nanotubes graphene modified aqueous polyurethane coatings and adhesives are obtained. The prepared polyurethane is environment-friendly and low cost, can be wildly used as adhesives on plastic, glass, paper-making and textiles.

Owner:YANTAI UNIV

Preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials

The invention discloses a preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials. Under the condition that a dibutyltin dilaurate catalyst exists, PTMG and IPDI (isophorone diisocyanate) are mixed for reaction at the temperature of 75-95 DEG C for 1.5-3.5 hours, so that polyurethane prepolymer can be obtained; a hydrophilic chain extender, of which the weight of carboxyl groups is 1.2-3.2 % of that of the polyurethane prepolymer, and an acetone solvent, of which the weight is 12-25% of that of the polyurethane prepolymer, are added into the polyurethane prepolymer for reaction at 65-85 DEG C for 1.5-3.5 hours, then, triethylamine is added for neutralization reaction for 30-50 minutes, and water is added for emulsification, so that polyurethane emulsion A can be formed; nano material emulsion, with the weight being 5-10% of that of the polyurethane emulsion A, is added into the polyurethane emulsion A, and the mixture of the nano material emulsion and the polyurethane emulsion A is subject to shear agitation for 20-50 minutes under the condition that the pH value is 7, as a result, the fire resistance waterborne polyurethane can be obtained. The prepared fire resistance polyurethane is environment-friendly and low is price, and can meet the low cost requirement on fire resistance leather products by the market.

Owner:STATE GRID CORP OF CHINA +3

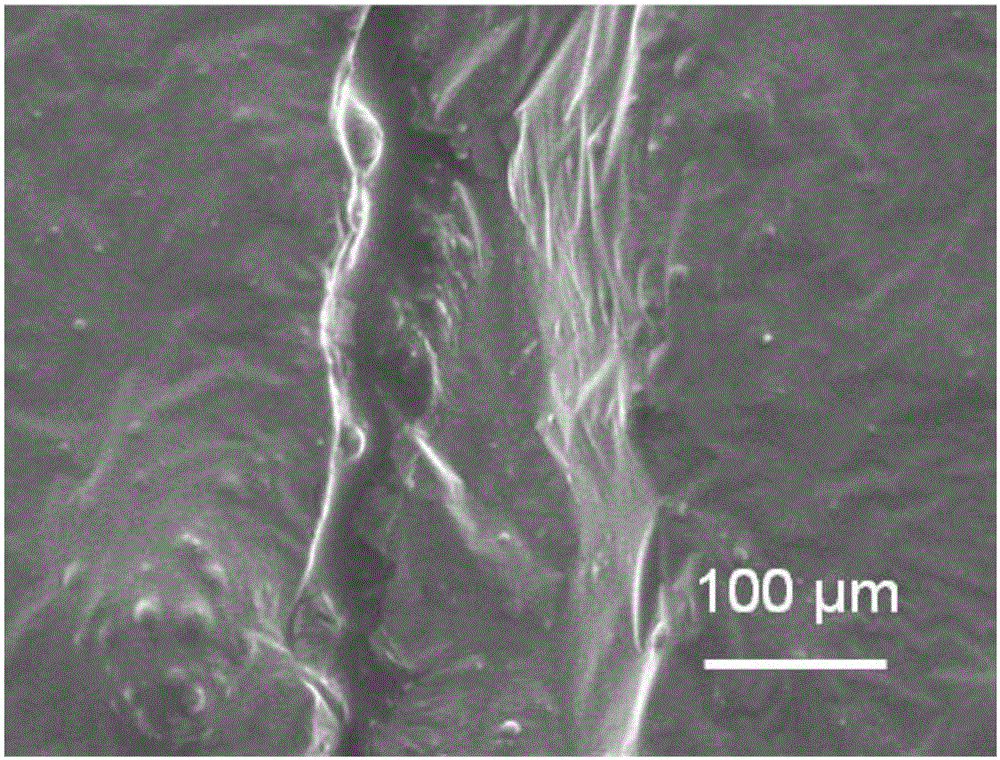

Preparation method and application method of solvent-free moisture-curable resin for synthetic leather

The invention provides a preparation method and an application method of a solvent-free moisture-curable resin for synthetic leather. The preparation method is as below: adding polytetrahydrofuran glycol, isophorone diisocyanate and bismuth octoate to the reactor, heating to 75-80 DEG C, polymerizing for 1-1.5 h to obtain the solvent-free moisture-curable resin for synthetic leather. The application method is as below: mixing and stirring the solvent-free moisture-curable resin for synthetic leather and bis-N,N'-(methyl-butyl methylene)-diethylenetriamine, coating the mixed material on the synthetic leather surface by a roller coating method, curing at the temperature of 85-95 DEG C, then drying at 120-135 DEG C, and finally cooling and rolling. The solvent-free moisture-curable resin for synthetic leather obtained by the invention is used for surface moisture solidification process for synthetic leather, so as to obtain brightening surface with high brightness, water resistance and wear resistance. The application process does not produce contamination, and can solve the solvent pollution problem in synthetic leather moisture curing process.

Owner:SHAANXI UNIV OF SCI & TECH

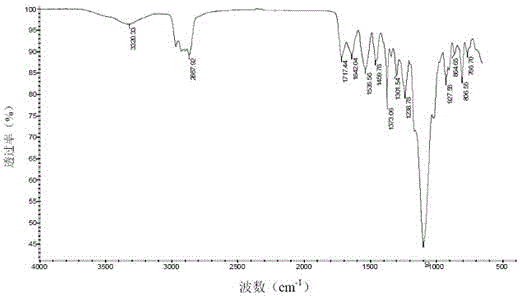

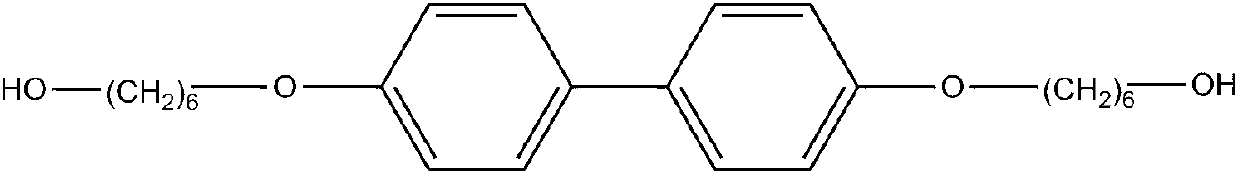

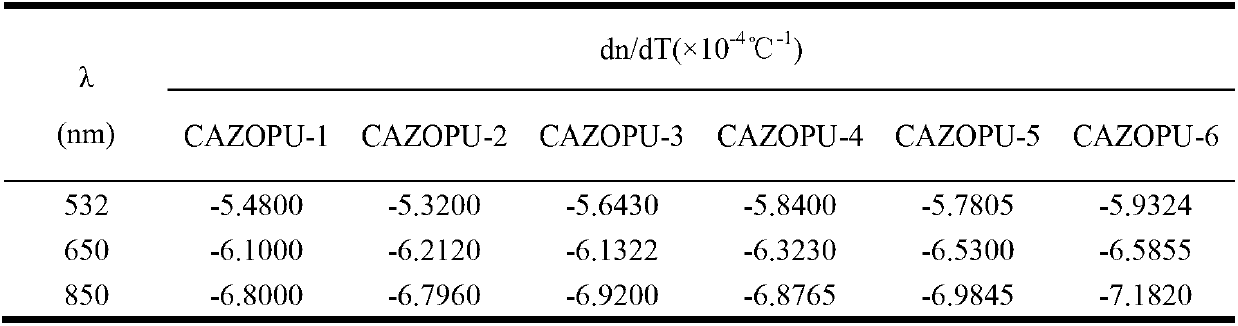

Preparation method and application of chirality azo polyurethane thermal-optic material

The invention belongs to the field of organic synthesis, relates to a preparation of chirality azo benzene compounds, and in particular to a preparation method and an application of a chirality azo polyurethane thermal-optic material. Diatomic alcohol 4, 4'-di (6-hydroxyhexyloxy) biphenyl (shown as 6BP) which contains a biphenyl structure and isophorone diisocyanate (IPDI) are utilized to be reacted with a catalyst of dibutyltin dilaurate, polyurethane preformed polymer of isocyanic acid root end capping is prepared; and preformed polymer is reacted with hydroxy azo benzoic acid borneol ester (shown as AZO) to prepare the chirality azo polyurethane thermal-optic material. The preparation process is simple, chromophore molecule containing chirality carbon atom is induced into polyurethane, so that central asymmetry of a polyurethane material is realized, and non-linearity property of the polyurethane material is improved; and meanwhile, when polyurethane is prepared, the alcohol biphenyl-typed glycol is selected, thermal stability of the material is improved by the induction of rigidity groups, and the possibility of researching on a novel digital thermal-optic switch which is provided with low driving power is provided.

Owner:JIANGSU UNIV

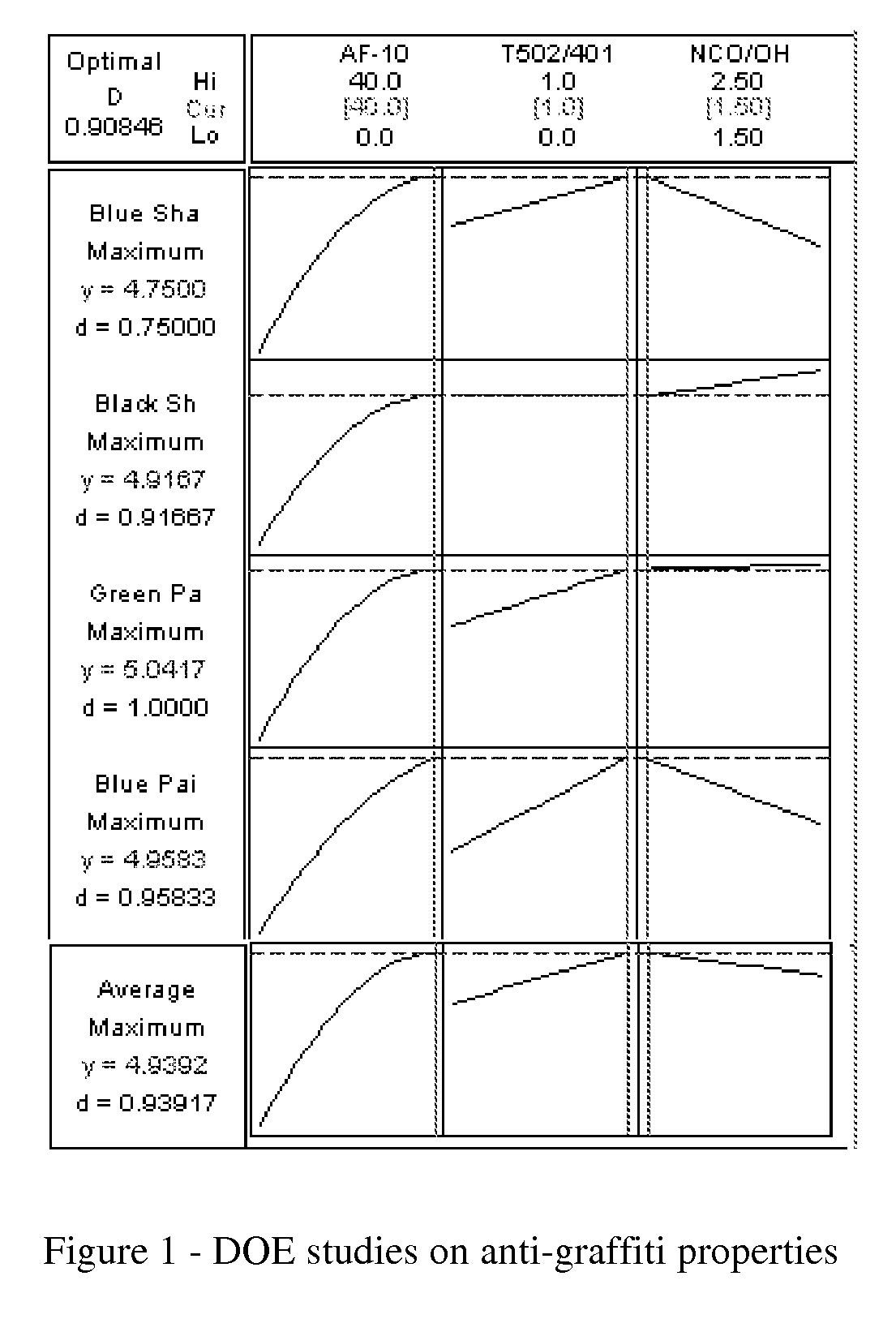

Two component waterborne polyurethane coatings for Anti-graffiti application

ActiveUS20090054570A1Impart propertyGood recoatabilityPolyurea/polyurethane coatingsPolymer sciencePolyol

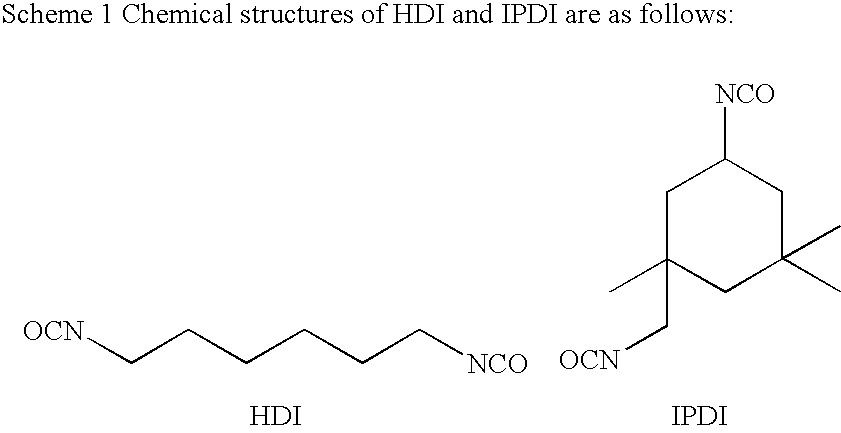

Two component (2K) waterborne polyurethane coating compositions which when cured achieve excellent anti-graffiti properties at low VOC level (below 100 g / L) are disclosed. The composition comprises (A) a fluorinated polyol and optionally a non-fluorinated polyol; and (B), a blend of polyisocyanates comprising a hydrophilically modified trimer of hexamethylene diisocyanate (HDT) and a hydrophilic ally modified trimer of isophorone diisocyanate (IPDT). The glass transition temperature of the ambient cured coatings, crosslinked network structure, and fluorine content at the surface enable excellent anti-graffiti properties. The waterborn coatings of the invention have excellent recoatability and exceptional chemical resistance.

Owner:RHODIA OPERATIONS SAS +1

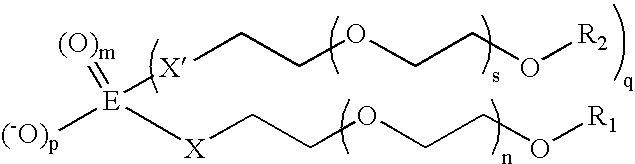

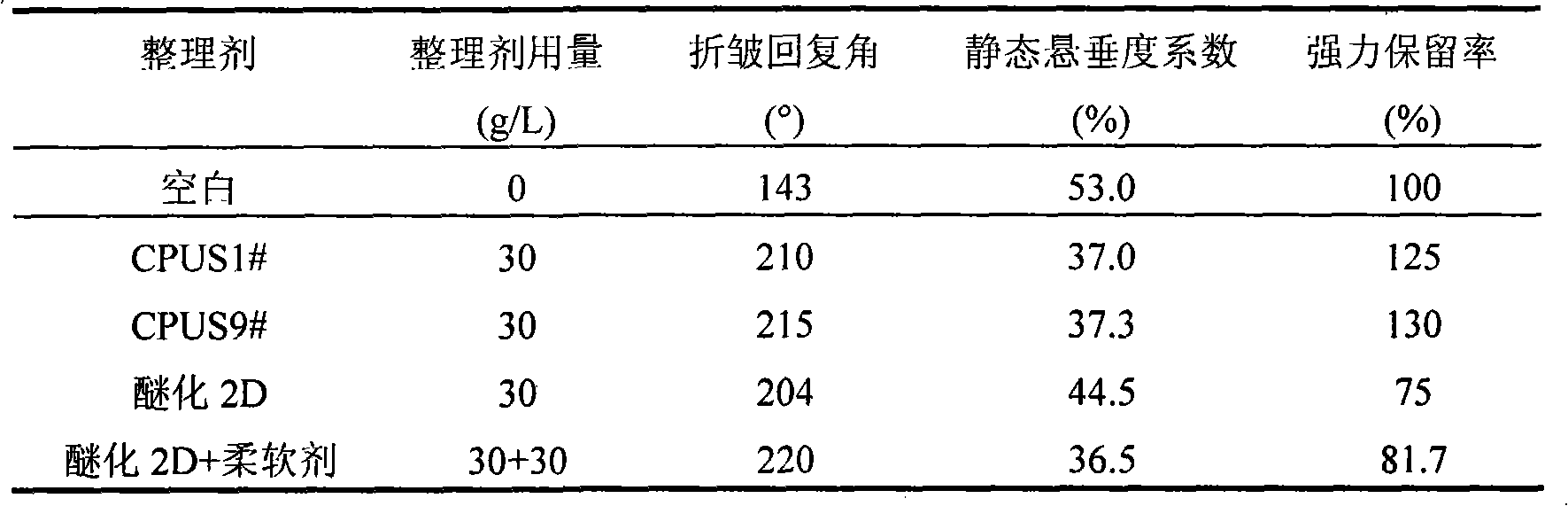

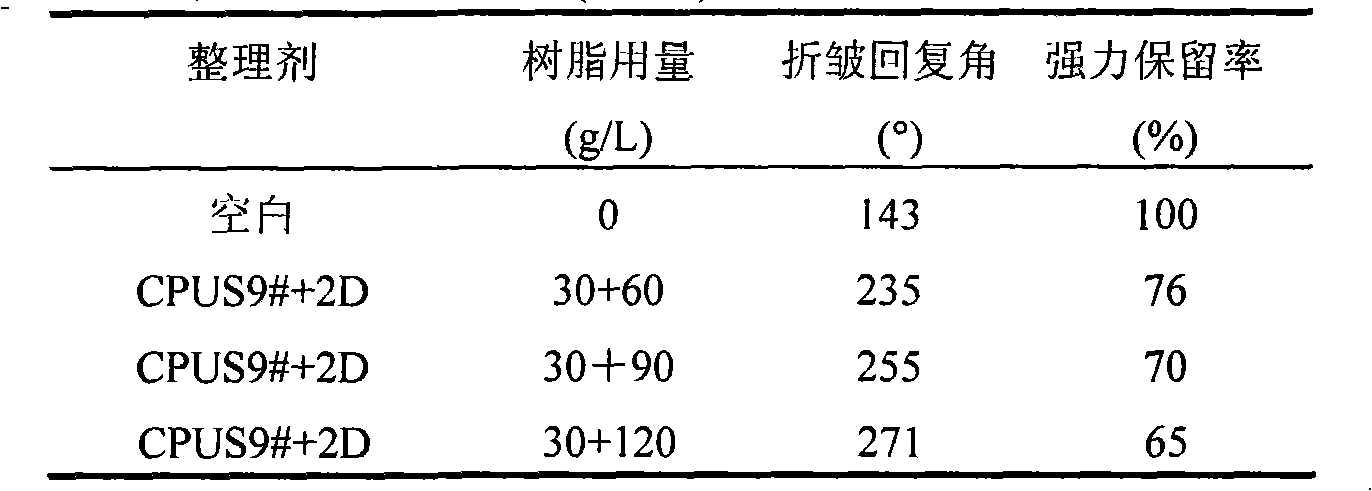

Cationoid polyurethane and modified silicon oil composite water dispersion, preparation and applications

The invention relates to a cationic polyurethane and modified silicone oil composite nano aqueous dispersion and a preparation method and an application thereof. The dispersion particles of the dispersion are compounded with cationic polyurethane and modified silicone oil, the diameters of the dispersion particles are less than 100nm. The mass composition of the modified silicone oil in the dispersion particles is 10 to 50 percent. High molecular weight polyether glycol and cationic diol chain extender react with isophorone diisocyanate(IPDI) to form ionic polyurethane after end capping and neutralization. The ionic polyurethane and the modified silicone oil are compounded and added with water to conduct self-emulsification at the room temperature to form the polyurethane and modified silicone oil composite nano aqueous dispersion. The nano aqueous dispersion can be used as a multifunction finishing material cotton cloth and can effectively improve the crease resistant, draping property and strength conservation rate and improve the hand feeling of fabrics and hydrophilcity and hydrophobicity of the surfaces of the fabrics.

Owner:TIANJIN UNIV

Polyurethane modified organic silicone water-repellency and antibiotic finishing agent, preparation method and application

InactiveCN107059405AImprove water repellencyIncrease self-emulsifying abilityBiochemical fibre treatmentLiquid repellent fibresPrepolymerCarbon chain

The invention discloses a polyurethane modified organic silicone water-repellency and antibiotic finishing agent, a preparation method and an application. The method comprises the following steps: adding isophorone diisocyanate into polypropylene glycol and glycerin monostearate dissolved in tetrahydrofuran and then reacting; adding N-methyl-N-benzyl-N,N-dihydroxyethyl chloride and hexahydro-1,3,5-tris-s-triazine and performing chain extension cross-linking reaction, thereby acquiring isocyanate group closed polyurethane prepolymer; reacting with double-ended hydroxypropyl polysiloxane; and removing solvents and emulsifying, thereby acquiring the polyurethane modified organic silicone water-repellency and antibiotic finishing agent used for finishing cotton and dacron / cotton textile. According to the invention, the process is simple; the introduction of long carbon chains in glycerin monostearate molecules can effectively promote the water-repellency property of the finished textile; and meanwhile, the antibacterial quaternary ammonium salt and triazine group introduced into finishing agent macromolecules can endow the finished textile with a long-lasting antimicrobial property.

Owner:SUZHOU YISITE NEW MATERIAL TECH

Ultraviolet absorbent and preparation method thereof

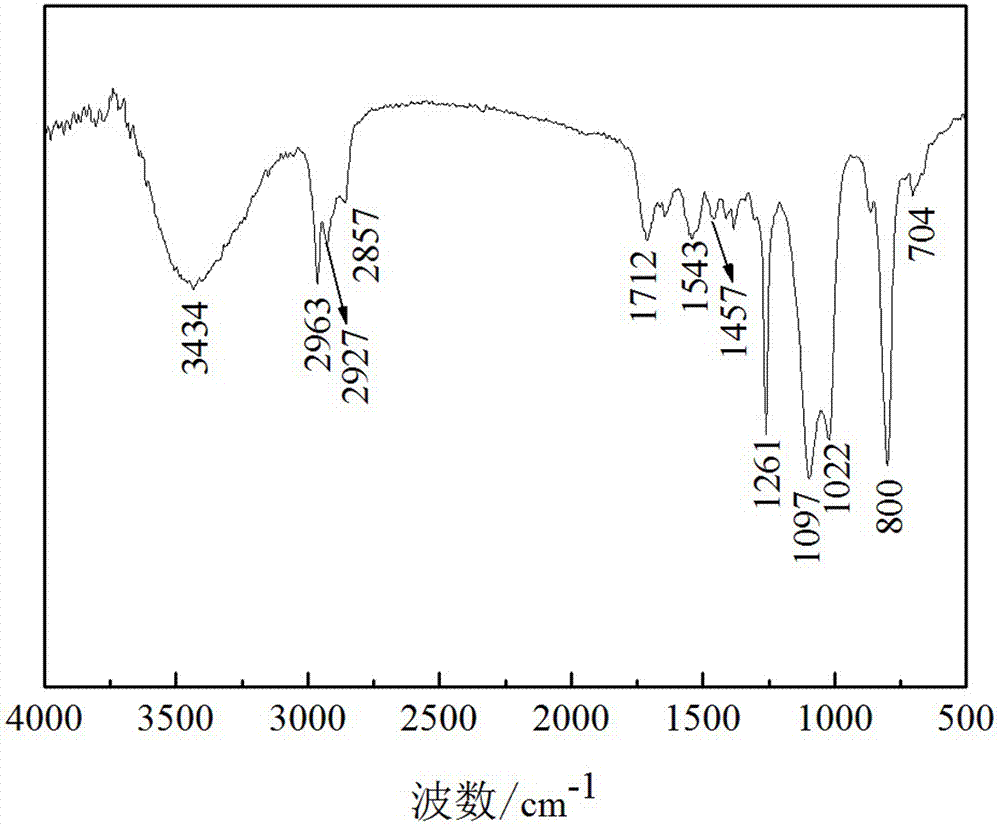

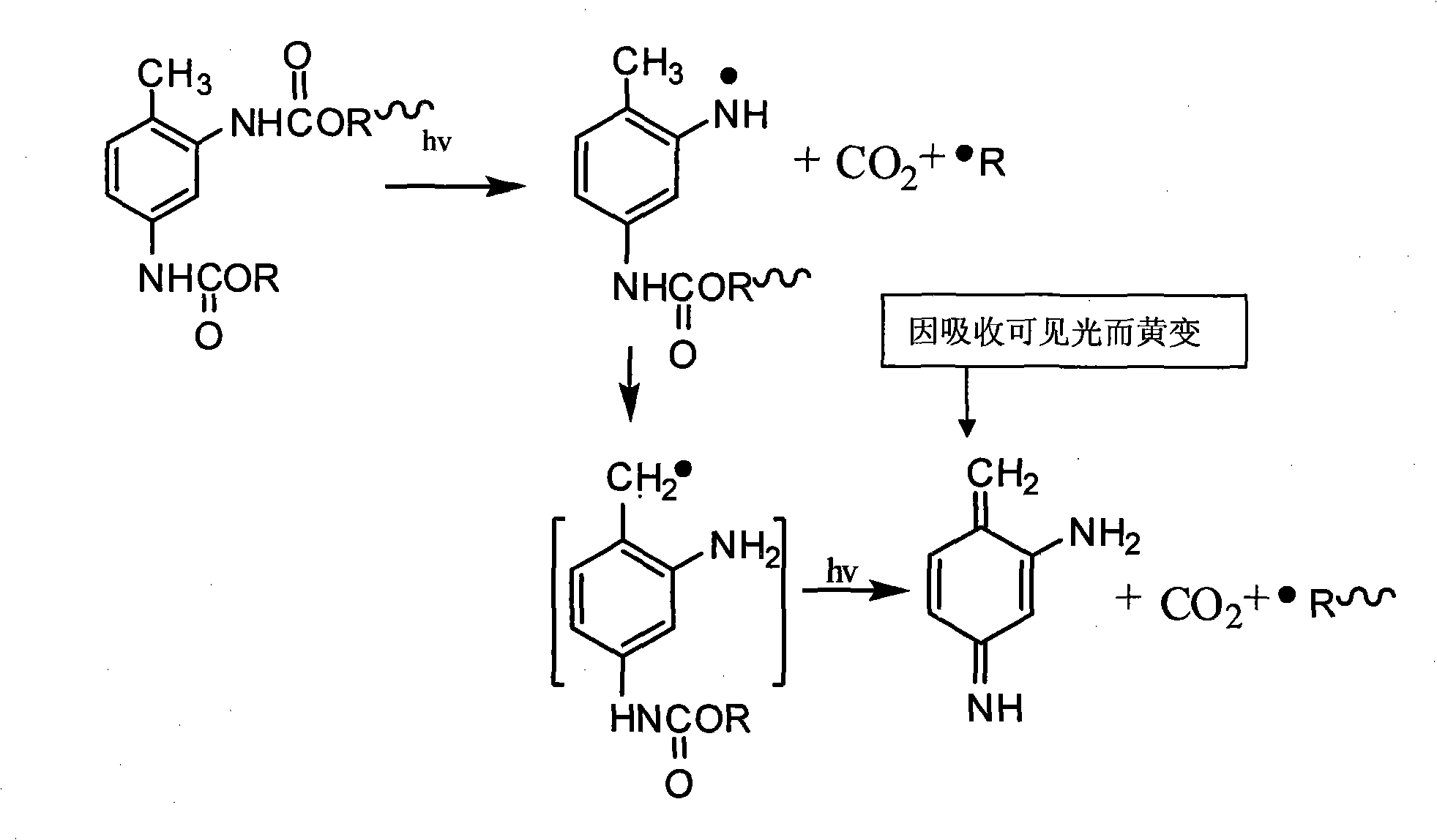

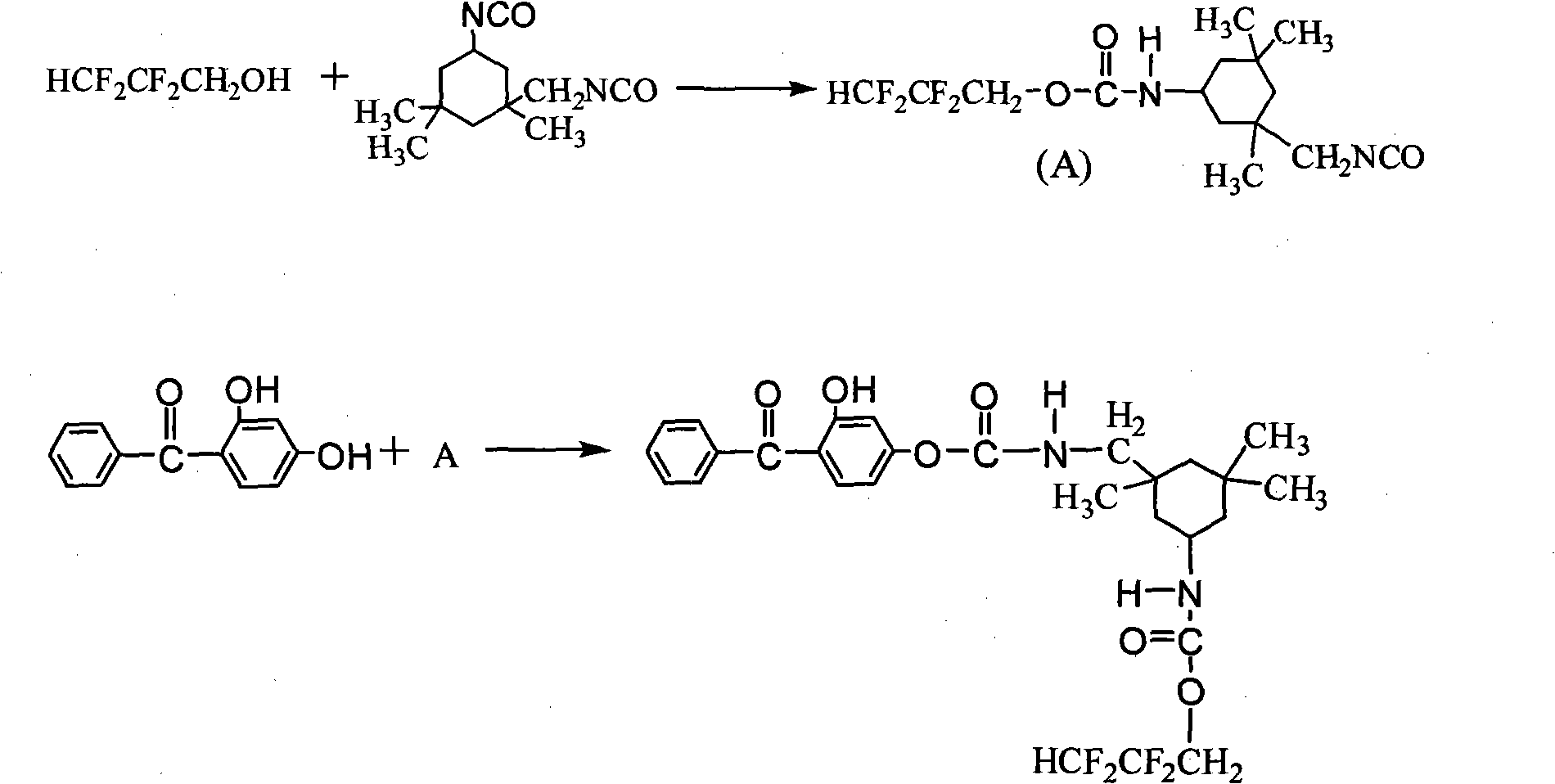

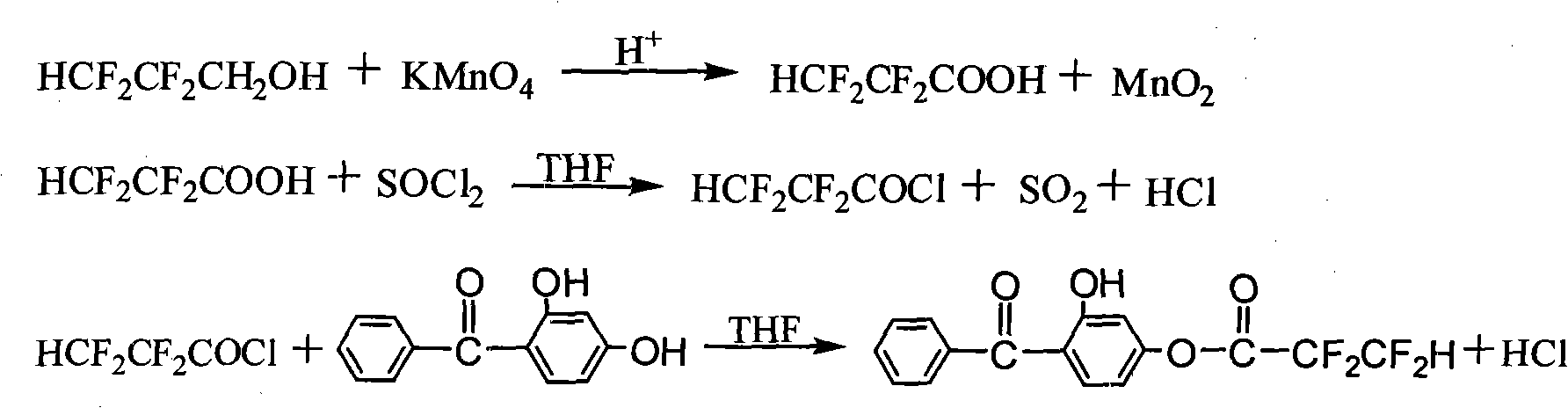

InactiveCN101629034APromote absorptionHigh strengthCarbamic acid derivatives preparationPreparation from carboxylic acid halidesIsophoroneSurface energy

The invention provides an ultraviolet absorbent. In the invention, a ptfe-propyl or a ptfe propionyl chain segment is connected on 2, 4-dihydroxy benzophenone (UV-0). The preparation method of the ultraviolet absorbent comprises the following steps: combining the 2,4-dihydroxy benzophenone (UV-0) and the ptfe-propanol together by isophorone vulcabond or thionyl chloride, wherein the mole ratio of the isophorone vulcabond or the thionyl chloride to the 2,4-dihydroxy benzophenone (UV-0) to the ptfe-propanol is 1-1.2:1:1-1.1; adding a catalyst under the condition of 50-80 DEG C, reacting for 4-10 hours and obtaining the ultraviolet absorbent. The molecules of the ultraviolet absorbent contain hydroxybenzophenone which can obviously absorb ultraviolet rays and the ptfe-propyl or the ptfe propionyl chain segment with low surface energy. In the invention, the prepared ultraviolet absorbent has the enrichment surface effect on the surface of a coating by introducing a chain segment containing a plurality of fluorine in the UV-0, the ultraviolet absorption area and the strength are greatly enhanced in comparison with the UV-0, the enrichment of the ultraviolet absorbent on the surface of the coating is realized, and the ultraviolet rays are preferentially absorbed with high efficiency, thereby achieving the purpose of protecting the coating.

Owner:CHONGQING UNIV

POSS (Polyhedral Oligomeric Silsesquioxane) fluorosilicone acrylate-polyurethane blood compatible coating and preparation method thereof

ActiveCN103468120AImprove hydrophobicityGood film formingPolyurea/polyurethane coatingsPolyvinyl chlorideEthyl acetate

The invention discloses a POSS (Polyhedral Oligomeric Silsesquioxane) fluorosilicone acrylate-polyurethane blood compatible coating and a preparation method thereof. The coating is formed on a medical polyvinyl chloride sheet by using a (methyl)acryloxy oligo-POSS fluorosilicone acrylate copolymer and one or two curing agents selected from hexamethylene diisocyanate and isophorone diisocyanate. The preparation method comprises the steps of preparing the POSS fluorosilicone acrylate copolymer into a mixed solution of dichloromethane or ethyl acetate and n-hexane; spraying the solution on the surface of medical polyvinyl chloride through a spray gun to form the coating with good blood compatibility. The POSS fluorosilicone acrylate-polyurethane blood compatible coating and the preparation method thereof have the advantages that the preparation method is simple in process, easy to obtain raw materials and easy to realize industrial and large-scale production; the prepared blood compatible coating has good film forming property and hydrophobicity, favorable blood compatibility and relatively high practical values.

Owner:天津渤化讯创科技有限公司

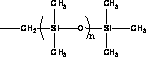

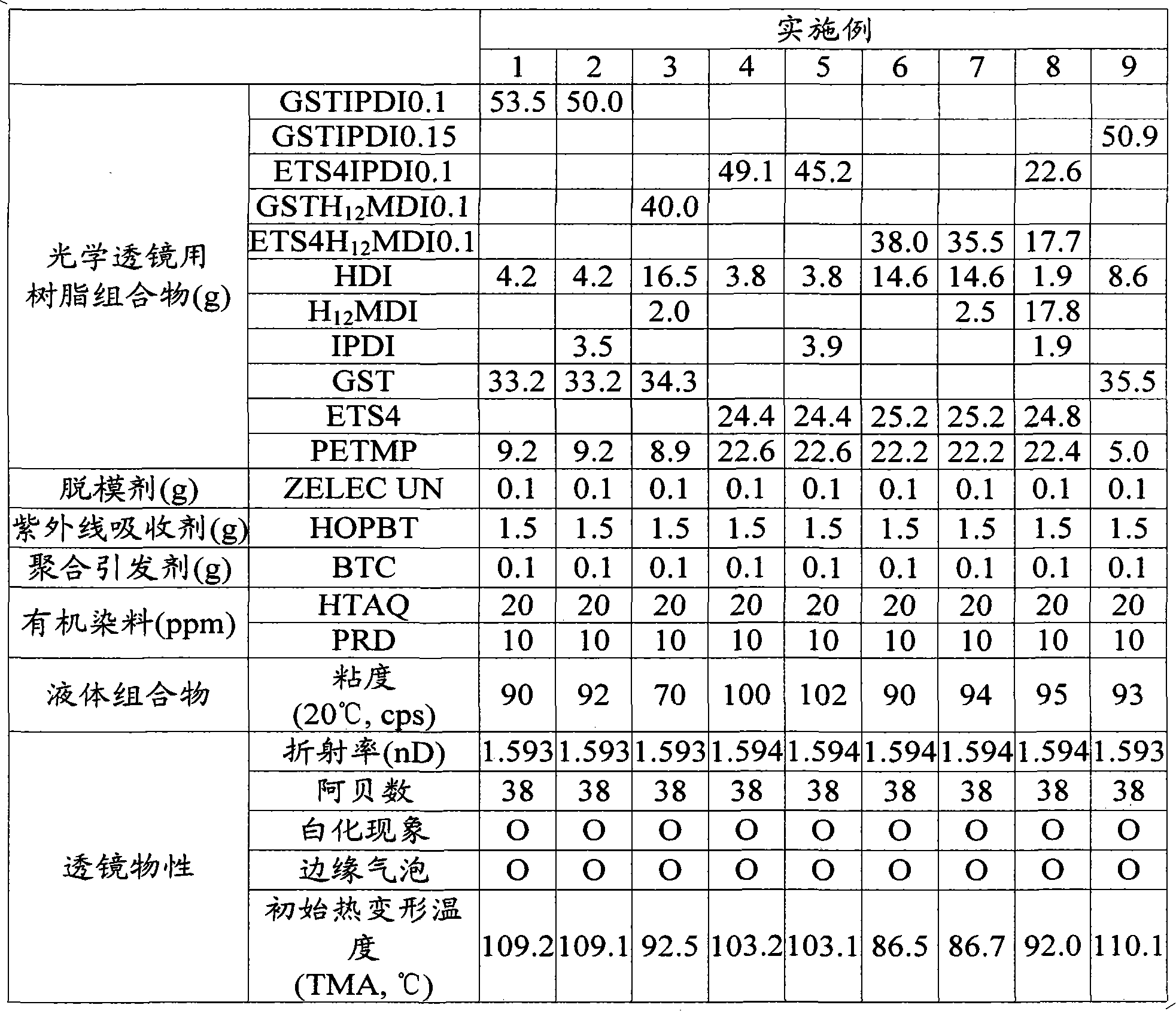

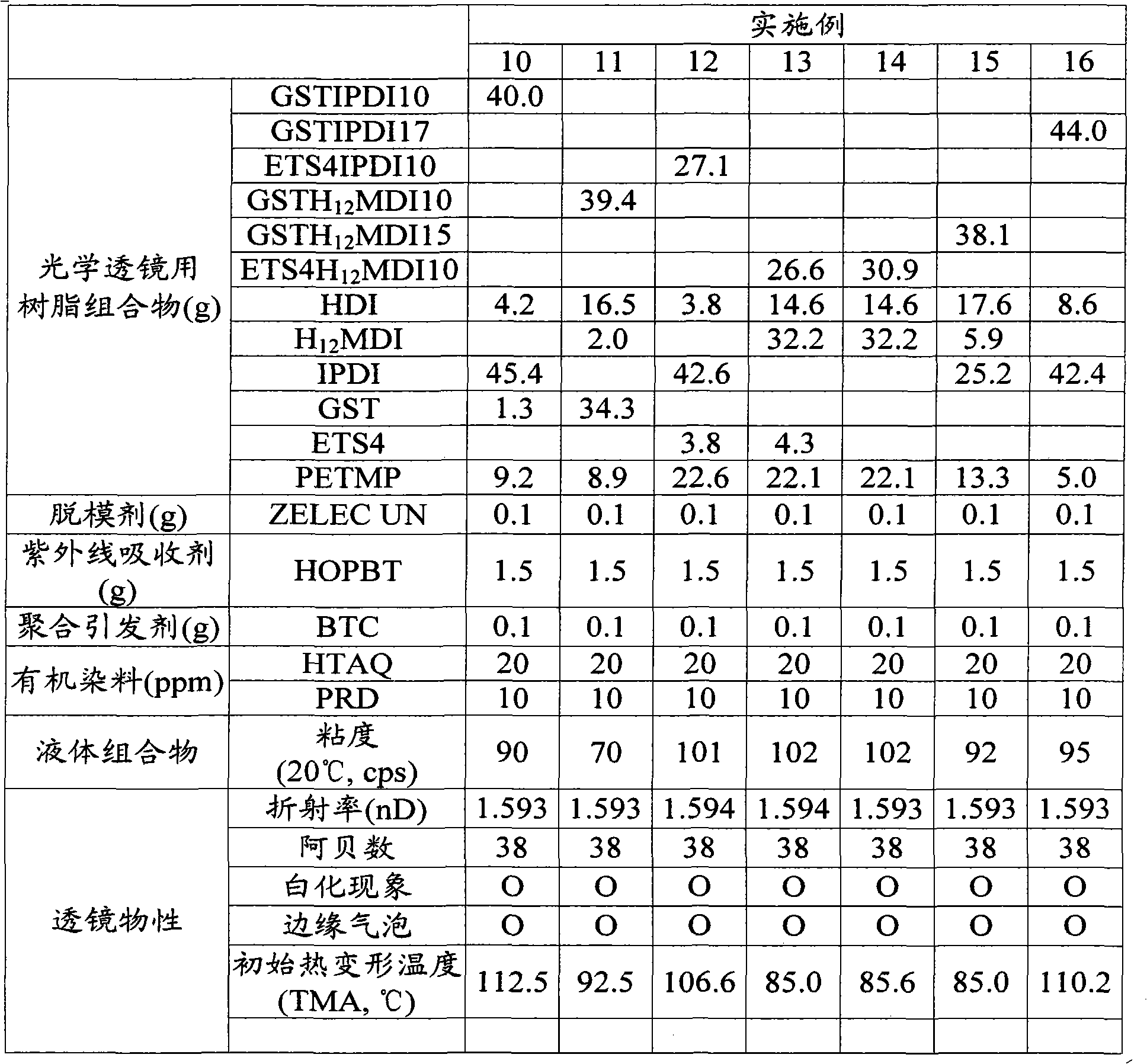

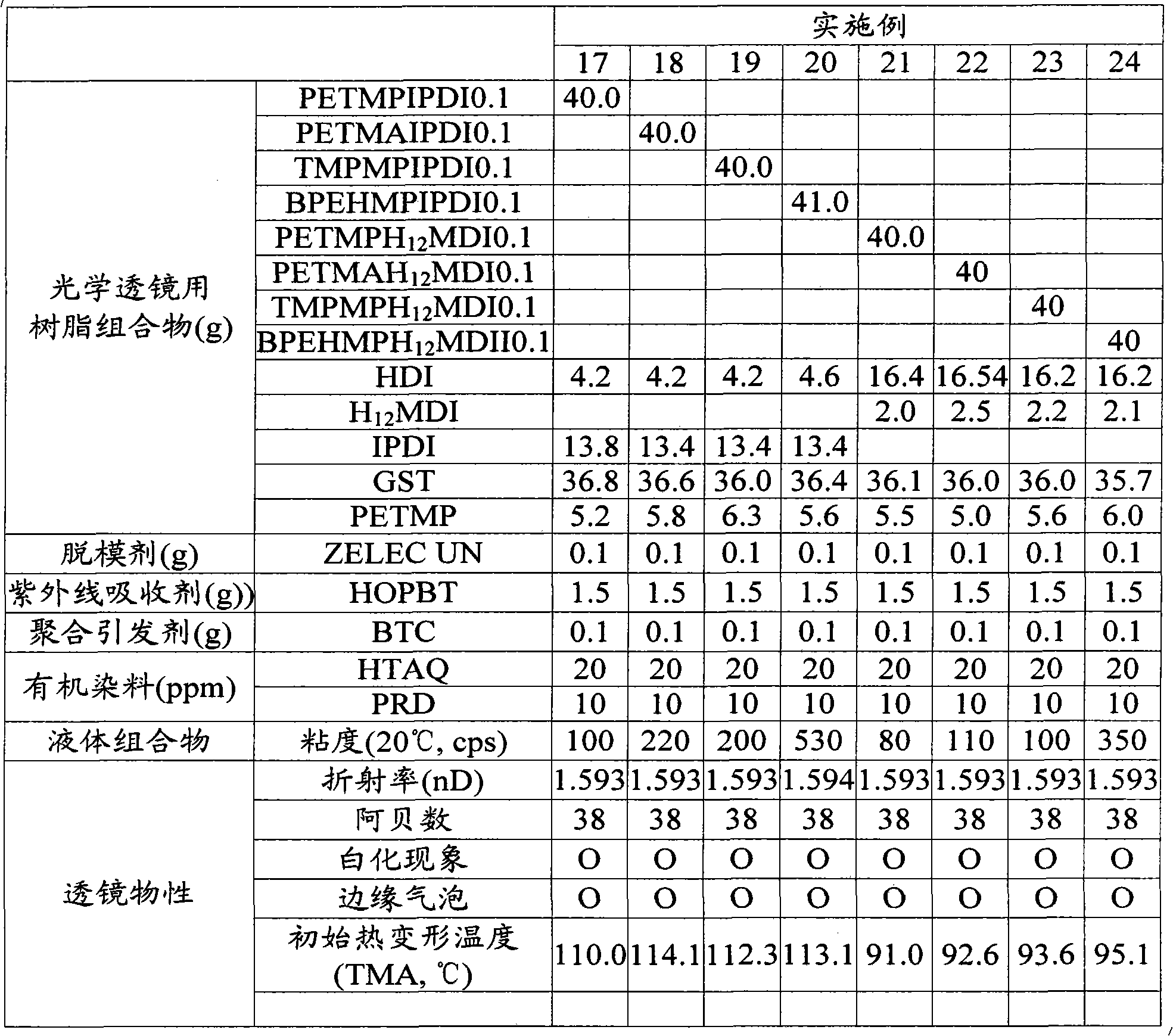

Resin composition for urethane optical lens having excellent thermal resistance and reactivity

The present invention relates to a resin composition for a plastic optical lens, and more specifically to a resin composition for a urethane optical lens having high thermal resistance and high reactivity. The resin composition for an optical lens of the present invention uses an optical resin prepolymer which is obtained from a preceding side reaction of a mercapto compound and a -SH / -NCO of isophorone diisocyanate or dicyclohexylmethanediisocyanate in appropriate mole ratios. The use of isophorone diisocyanate or dicyclohexylmethanediisocyanate results in enhancement of the thermal resistance of the optical lens, and the use of optical resin prepolymer at 20 to 70 weight % of the total weight of the resin composition for the optical lens, elutes the adhesive from adhesive tape due to lowered reactivity which results in a higher temperature reaction thereby resolving the problems of whitening phenomenon and foaming which occur on the edge of the lens due to a leak of the liquid composition when the reaction temperature increases.

Owner:KOC SOLUTION

Preparation method of flame-retardant and waterproof aqueous polyurethane coating and adhesive

ActiveCN104109457AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a preparation method of a flame-retardant and waterproof aqueous polyurethane coating and adhesive. The method comprises the following steps: mixing 1,4-di(dimethyl hydroxysilyl) benzene with isophorone diisocyanate in the presence of modified fullerene A, adding a synergist and 2-butoxyl-N-(2-diethylaminoethyl)-4-quinoline formamide hydrochloride and reacting for 1 to 5 hours at 70 DEG C to 80 DEG C so as to obtain a polyurethane prepolymer A; adding a chain extender and a solvent into the prepolymer A, reacting for 3 to 4 hours at 60 DEG C to 80 DEG C, then adding triethylamine and carrying out a neutral reaction for 30 to 60 minutes; then adding a modified manganese hypophosphate solution, coconut oil monoethanolamide and sulfaquinoxaline and reacting for 1 hour at 70 DEG C; and adding water and sodium dodecyl sulfate and emulsifying for 60 minutes, thereby obtaining the flame-retardant and waterproof aqueous polyurethane coating and adhesive. The prepared flame-retardant and waterproof aqueous polyurethane coating and adhesive is environment-friendly and low in cost, and can be widely applied to walls, furniture and metalware surfaces as well as can serve as an adhesive for plastics, glass, papermaking and textiles.

Owner:上海汉司实业有限公司

Water-based bright gloss topcoat with high brightness, high tolerance and no dark bubbles or seeds, and preparation method and application thereof

The present invention provides a water-based gloss topcoat. The water-based gloss topcoat comprises a component A and a component B; the component A comprises, by weight, 50-110 parts of waterborne hydroxy acrylic resin, 3-6 parts of a cosolvent, 0.2-0.5 part of a wetting agent, 0.2-0.5 part of an antifoaming agent, 0.2-0.6 part of a thickener, 0.3-0.5 part of a mildew inhibitor, 0-25 parts of a color paste, and water; and the component B comprises, by weight, 60-110 parts of hydrophilic modified isophorone diisocyanate and hexamethylene diisocyanate, 15-30 parts of propylene glycol methyl ether acetate and 0.5-2 parts of a water scavenger. The water-based gloss topcoat provided by the invention has the advantages of high brightness, environmental protection, good yellowing resistance, high hardness, high water resistance and high chemical resistance; and the water-based gloss topcoat has high tolerance to the temperature, and can be cured at room temperature without seeds, and a filmformed by the gloss topcoat has high fullness, has almost no dark bubbles, thereby the gloss topcoat is very suitable for the coating production of toilet and bathroom cabinets.

Owner:深圳市雷巴环保材料有限公司

Weather-resistant leather finishing agent

InactiveCN102977764AImprove wear resistanceSolve the defect of easy yellowingPolyurea/polyurethane coatingsLeather surface finishingTripropylene glycolPolymer science

Owner:QINGDAO WINCHANCE TECH

Preparation method of polyurethane coating and adhesive with flame retardance and light resistance

ActiveCN105176368ALow toxicityReduce the amount of smoke releasedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a preparation method of a polyurethane coating and adhesive with flame retardance and light resistance. The preparation method comprises the following steps: in the presence of a catalyst dibutyltin dilaurate, mixing polytetrahydrofuran ether glycol with isophorone diisocyanate to react at 70-100 DEG C for 1-3 hours to obtain a polyurethane prepolymer A; and adding a chain extender and methyl ethyl ketone to the prepolymer A to react at 65-85 DEG C for 1.5-3.5 hours, adding modified manganese hypophosphite and 4-carboxyphenylboronic acid to react at 75-95 DEG C for 1-2 hours, adding triethylamine for neutralization, adding a substance B and adding water for emulsification, thus obtaining the polyurethane coating and adhesive with flame retardance and light resistance. The prepared polyurethane coating and adhesive with flame retardance and light resistance is environment-friendly in preparation method and is low in price, is widely applied to the surfaces of walls, furniture and metalware and serves as the adhesive of plastics, glass, paper and textiles.

Owner:广东合顺涂层材料有限公司

Preparation method of light-resistant and waterproof water-based flame retardant polyurethane coating and adhesive

InactiveCN104194607ANon-macromolecular adhesive additivesOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention discloses a preparation method of light-resistant and waterproof water-based flame retardant polyurethane coating and adhesive. The preparation method of the light-resistant and waterproof water-based flame retardant polyurethane coating and adhesive comprises the following steps: mixing polytetrahydrofuran glycol with isophorone diisocyanate in the presence of a fullerene catalyst, reacting at the temperature of 60-85 DEG C for 1-2 hours, adding coumaphos and propantheline bromide, and reacting at the temperature of 70 DEG C for 3 hours, so that polyurethane prepolymer A is obtained; adding a chain extender, butanone and riboflavin sodium phosphate into the polyurethane prepolymer A, reacting at the temperature of 60-85 DEG C for 2.5-3.5 hours, adding a flame retardant, reacting at the temperature of 75-85 DEG C for 1-2 hours, then adding 1,4-dihydroxy anthraquinone, polyacrylamide and a tackifying agent, reacting at the temperature of 75 DEG C for 1-2 hours, then adding triethylamine and carrying out neutralization reaction for 30-50 minutes, adding water and emulsifying for 30 minutes, so that the light-resistant and waterproof water-based flame retardant polyurethane coating and adhesive are obtained. The prepared light-resistant and waterproof water-based flame retardant polyurethane coating has triple performance of flame retardance, light resistance and water resistance; meanwhile, polyurethane is environment-friendly and low in cost, so that the prepared light-resistant and waterproof water-based flame retardant polyurethane coating can be widely applied to surfaces of a wall body, furniture and metalware; the prepared light-resistant and waterproof water-based flame retardant polyurethane adhesive can be taken as a binder for plastic, glass, paper, textiles and leather.

Owner:慧融高科新型材料科技有限公司

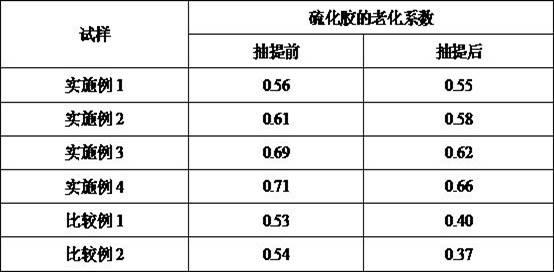

Polymer type anti-oxidant, preparation method thereof, and application thereof

ActiveCN102516488AImprove antioxidant capacityExcellent thermal and oxidative aging resistanceRubber materialPolymer science

The invention relates to the field of a polymer type anti-oxidant, and provides a polymer type anti-oxidant, a preparation method thereof, and an application thereof. According to the invention, under the effect of a catalyst dibutyltin dilaurate, hydroxyl-terminated polybutadiene and isophorone diisocyanate are subject to a reaction under a temperature of 30 to 50 DEG C, such that an adduct is synthesized; the adduct is subject to a reaction with a low-molecular bisphenol anti-oxidant under a temperature of 60 to 80 DEG C, such that the polymer type anti-oxidant is prepared. The thermal oxidative aging resistance of the polymer type anti-oxidant is better than that of the corresponding low-molecular bisphenol anti-oxidant. Also, the polymer type anti-oxidant has an excellent extraction resistance. The anti-oxidant can be widely applied in rubber materials.

Owner:SOUTH CHINA UNIV OF TECH

Degradable waterborne polyurethane, and preparation method and applications thereof

ActiveCN105693987AImprove stabilityImprove water resistancePolyurea/polyurethane coatingsElectrically-conductive paintsPolyesterPolymer science

The invention discloses a degradable waterborne polyurethane, and a preparation method and applications thereof, and belongs to the technical field of high-molecular material. The preparation method comprises following steps: lactic acid is reacted with 1, 4-butanediol so as to prepare hydroxyl-terminated polylactic acid butanediol ester; polymerization reaction of a binary isocyanate mixture of isophorone diisocyanate and hexamethylene diisocyanate, with a binary polyester diol mixture of polylactic acid butanediol ester and poly(butylene succinate) is carried out, a certain amount of a hydroxied acrylate is added into an obtained reaction system, triethylamine is used for neutralization, and ethylenediamine is used for a second time of chain extension; an appropriate amount of ultrafine silica is added; and an obtained product is mixed with accessory ingredients such as a defoaming agent, an anti-adhesive, and an antistatic agent so as to obtain the degradable waterborne polyurethane. The degradable waterborne polyurethane is low in preparation cost, and excellent in printing effect; and coating layers are capable of adapting PHA smart card material laser printing, and possess degradability.

Owner:江苏华信高新材料有限公司

Prepration method of nanometer material capable of improving fire resistance of waterborne polyurethane coating and adhesive

ActiveCN104449325AReduced maximum smoke densityDensity time extensionFireproof paintsNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a prepration method of a nanometer material capable of improving fire resistance of a waterborne polyurethane coating and an adhesive. The method comprises the following steps: mixing polytetrahydrofuran glycol with isophorone diisocyanate, reacting in the presence of a Pd / Fe3O4-CNT catalyst, so as to obtain a polyurethane prepolymer A; adding dimethylolpropionic acid to the polyurethane prepolymer A, and reacting; adding triethylamine and carrying out neutral reaction; adding water and emulsifying, so as to form polyurethane B; adding a nanometer material emulsion C to the polyurethane B; and shearing and stirring under the condition that pH is 7, so as to obtain the prepared waterborne polyurethane coating and adhesive. The polyurethane material is environment-friendly and low in price, and can meet the low-cost requirements of the market.

Owner:成都富安纳新材料科技有限公司

Highly-filled isophorone diisocyanate (IPDI) polyurethane-based composite material, and preparation method and use thereof

The invention discloses a highly-filled isophorone diisocyanate (IPDI) polyurethane-based composite material, and a preparation method and the use thereof. The components of the highly-filled IPDI polyurethane-based composite material comprises functional solid filler, a polyurethane substrate produced through a reaction of IPDI and oligomer polyol, and other performance adjusting additives. The functional solid filler, the additives and the oligomer polyol are evenly mixed, and then the IPDI is added to an obtained mixture; and the mixture is mechanically kneaded to react and then casted into a die to be cured and formed, so that a product is manufactured. The composite material can be used as a building structure material, a roof waterproof material, a gap repairing material, an energetic blasting material, an indoor decoration material and an insulation material. As the IPDI polyurethane is adopted as the substrate of the composite material, the composite material can be filled with high content of solid filler, which can reach up to 90 wt%, so that the functional effects of the solid filler in the composite material can be greatly played.

Owner:WANHUA CHEM GRP CO LTD +1

Preparation method and application of beta-cyclodextrin, graphene oxide and kieselguhr composite

InactiveCN105289523ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsCyclodextrinCross linker

The invention belongs to the field of macromolecule composite synthesis, and relates to preparation of a beta-cyclodextrin and kieselguhr composite, in particular to a preparation method and application of the beta-cyclodextrin, graphene oxide and kieselguhr composite. The method includes the steps of preparing graphene oxide through an improved Hummers method, preparing beta-cyclodextrin and graphene oxide powder from beta-cyclodextrin and graphene oxide under the effect of isophorone diisocyanate cross-linking agents, mixing beta-cyclodextrin and graphene oxide powder with preprocessed kieselguhr in an ultrasonic mode, and finally obtaining the beta-cyclodextrin, graphene oxide and kieselguhr composite. The material prepared through the method serves as adsorbent, a methylene blue solution serves as an adsorption object, and experimental results show that the composite has a good adsorption effect; when dyes in sewage are processed through the material, the material has the advantages of being easy and convenient to operate and high in adsorption rate and has certain practical value.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com