Preparation method and application of chirality azo polyurethane thermal-optic material

A polyurethane and polyurethane prepolymer technology, which is applied in the field of chiral azo polyurethane thermo-optic materials and its preparation, can solve the problems of reduction and reduction of polymer thermal stability, and achieve simple preparation process, improved thermal stability, and improved Effects of Nonlinear Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

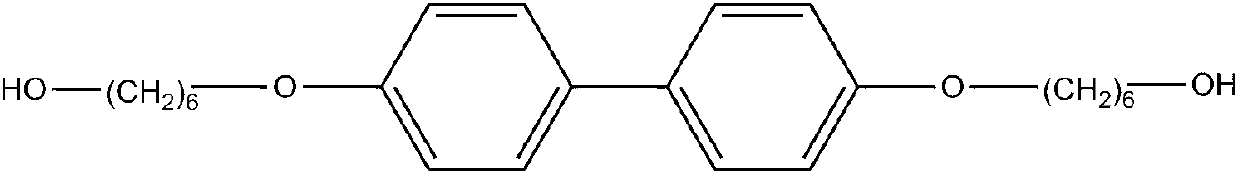

[0027] In a 250mL three-necked flask equipped with a stirring and reflux condenser, 0.66g of 4,4'-bis(6-hydroxyhexyloxy)biphenyl (6BP) was dissolved in 40g of N,N'-diphenyl Methylformamide (DMF), add 0.67g of isophorone diisocyanate (IPDI) and 2 drops of dibutyltin dilaurate (T-12) catalyst to it, react at 90°C for 4h, then add 0.71g of p- Bornyl hydroxyazobenzoate (AZO), continue to react at 90°C for 3h, add 15mL of methanol after the reaction, filter the separated precipitate, wash with 15mL of methanol three times, and vacuum dry at 60°C for 24h to obtain orange-red Chiral azo polyurethane material (CAZOPU-1).

Embodiment 2

[0029] In a 250mL three-necked flask equipped with a stirring and reflux condenser, 1.02g of 4,4'-bis(6-hydroxyhexyloxy)biphenyl (6BP) was dissolved in 65g of N,N'-diphenyl Methylformamide (DMF), add 1.13g of isophorone diisocyanate (IPDI) and 2 drops of dibutyltin dilaurate (T-12) catalyst, react at 90°C for 5h, then add 1.15g of p- Bornyl hydroxyazobenzoate (AZO), continue to react at 90°C for 4h, add 20mL of methanol after the reaction, filter the precipitated precipitate, wash with 20mL of methanol three times, and vacuum dry at 60°C for 30h to obtain orange-red Chiral azo polyurethane material (CAZOPU-2).

Embodiment 3

[0031] In a 250mL three-neck flask equipped with a stirring and reflux condenser, 0.51g of 4,4'-bis(6-hydroxyhexyloxy)biphenyl (6BP) was dissolved in 30g of N,N'-diphenyl Methylformamide (DMF), add 0.53g of isophorone diisocyanate (IPDI) and 2 drops of dibutyltin dilaurate (T-12) catalyst to it, react at 90°C for 4h, then add 0.60g of p- Bornyl hydroxyazobenzoate (AZO), continue to react at 90°C for 3 hours, add 15mL of methanol after the reaction, filter the precipitated precipitate, wash with 20mL of methanol three times, and vacuum dry at 60°C for 36h to obtain orange-red Chiral azo polyurethane material (CAZOPU-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com