Ultraviolet absorbent and preparation method thereof

An ultraviolet absorber and ultraviolet technology, which is applied in the preparation of carboxylic acid halide, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of limited ultraviolet absorption capacity, yellowing of coatings, and low content of ultraviolet absorbers, etc. To achieve the effect of UV absorption area and intensity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

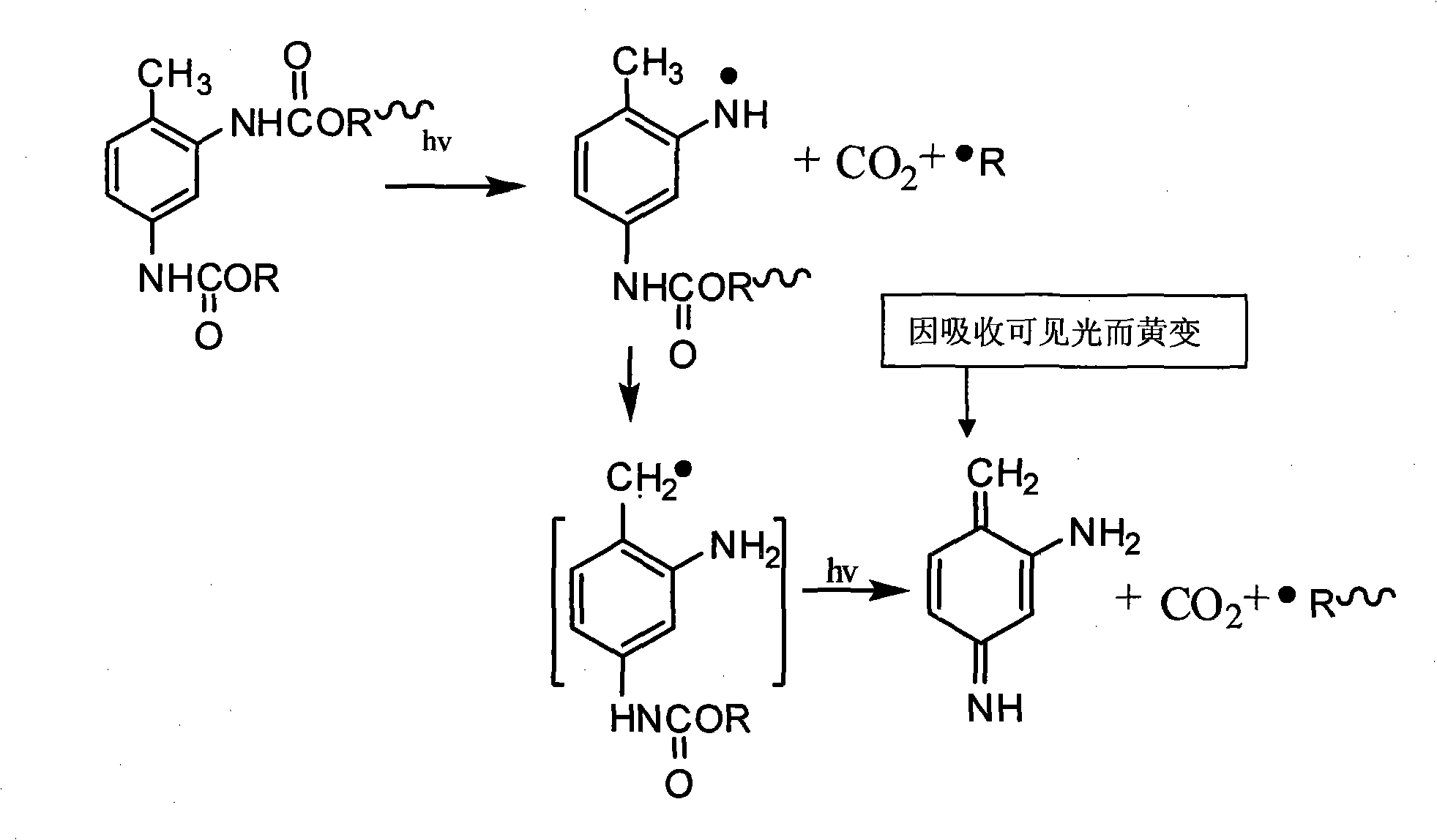

Problems solved by technology

Method used

Image

Examples

Embodiment 1

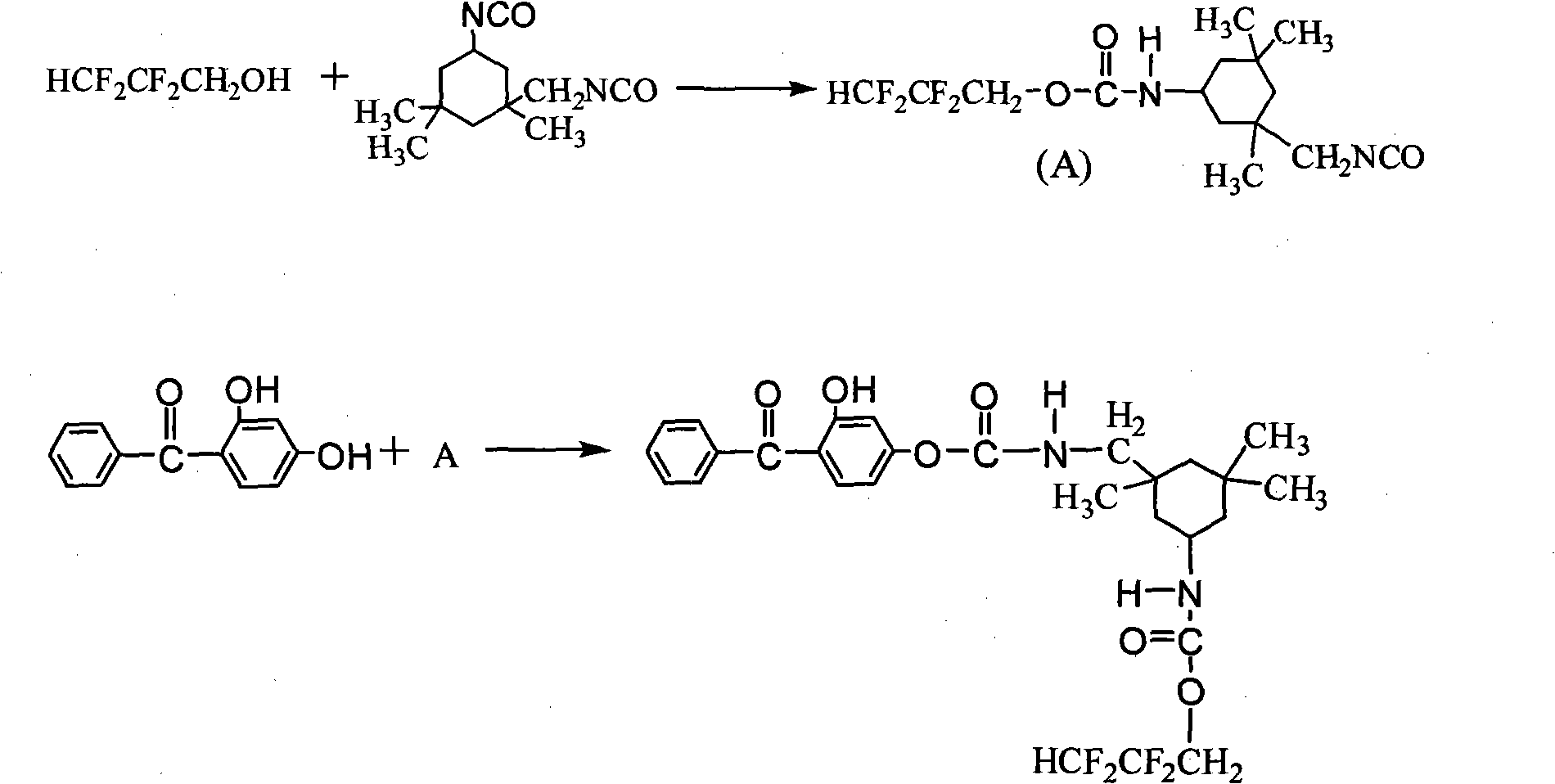

[0018] Add 10ml of isophorone diisocyanate (IPDI), 4.2ml of tetrafluoropropanol to the three-necked bottle, and dilute to 100ml with cyclohexanone, and install an electric stirrer, reflux condenser, and thermometer. Heated at 60°C in a water bath for 4 hours to obtain (A), then added 20.23g of 2,4-dihydroxybenzophenone (UV-0), 5ml of 5% dibutyltin dilaurate (DBTDL) xylene solution, The reaction was continued for 6 hours to obtain the reaction product, namely the ultraviolet absorber.

[0019]

[0020] The resulting ultraviolet absorber product is separated and purified and added 1% to polyurethane varnish, and the contact angle and ultraviolet absorption curve are measured after drying on a glass slide. The contact angles before and after addition are 70°10' and 77°20' respectively. Then there is a strong absorption band in the interval of 285-358nm, a strong absorption peak at 360nm, and a strong absorption band in the interval of 362-400nm.

Embodiment 2

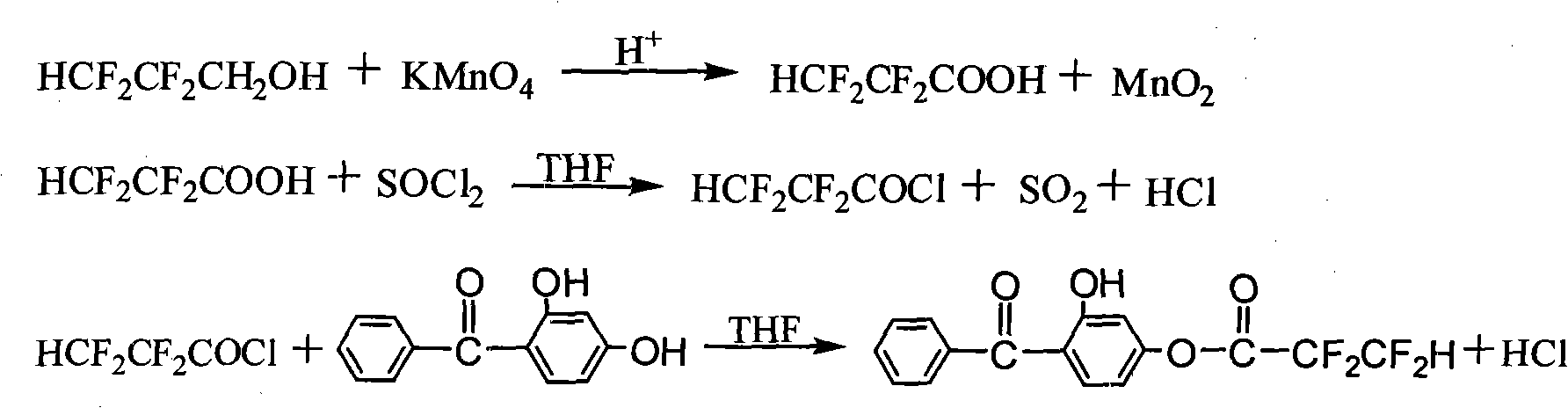

[0022] Under room temperature and weakly acidic conditions, oxidize tetrafluoropropanol with slightly excess potassium permanganate for 4-8 hours and then filter to obtain tetrafluoropropionic acid, then dissolve the reaction product tetrafluoropropionic acid in tetrahydrofuran (THF), and use Thionyl chloride (SOCl 2 ) at about 50°C to give tetrafluoropropionyl chloride. Tetrafluoropropionyl chloride was redissolved in tetrahydrofuran, and pyridine was used as a catalyst, and 2,4-dihydroxybenzophenone (UV-0) was added for esterification reaction for 6 hours to obtain the ultraviolet absorber 2,2,3,3-tetrafluoroethylene Fluoropropionic acid-3-hydroxy-4-benzoylphenyl ester (the reaction temperature can also be raised appropriately, such as reacting at about 60°C, 70°C or 80°C, the higher the temperature, the shorter the reaction time, such as 5 hours , 5.5 hours or 4 hours).

[0023]

[0024] The resulting product was separated and purified and added 0.2% to polyurethane va...

Embodiment 3

[0026] At about 50°C, tetrafluoropropanol was reacted with a slight excess of thionyl chloride for 3 hours, washed with water, left standing to separate layers, and the lower layer was 2,2,3,3-tetrafluoro-1-chloropropane. Put 2,2,3,3-tetrafluoro-1-chloropropane, sodium carbonate, PEG-400, potassium bromide, 2,4-dihydroxybenzophenone (UV-0) according to the mass ratio of 10: Add 1:0.2:1:10 to the four-necked flask in turn, and react for 8 hours at 110-140°C, for example, at 125-130°C, to obtain the ultraviolet absorber 2-hydroxyl-4-(2',2' , 3',3'-tetrafluoropropoxy)benzophenone.

[0027] HCF 2 CF 2 CH 2 OH+SOCl 2 →HCF 2 CF 2 CH 2 Cl+SO 2 +HCl

[0028]

[0029] The resulting product was separated and purified and added 0.2% to polyurethane varnish. The contact angle and UV absorption curve were measured after drying on a glass slide. The contact angles before and after addition were 70°10' and 81°35' respectively. The -365nm interval is a strong absorption band, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com