Resin composition for urethane optical lens having excellent thermal resistance and reactivity

A resin composition and optical lens technology, applied in optics, optical components, instruments, etc., can solve the problems of reducing reactivity, lens whitening, liquid leakage, etc., to reduce the reaction temperature, solve the problem of bubbles at the edge, and solve the problem of whitening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Resin composition for optical lens

[0050]To 49.6 g of isophorone diisocyanate (isophorone diisocyanate) was added 3.9 g of 2,3-bis(2-mercaptoethylthio)propane-1-thiol (2,3-bis(2-mercaptoethylthio) propane -1-thiol) and 0.01g of dibutyltin chloride (dibutyltindichloride), and under nitrogen reflux conditions with 80 ° C for 8 hours to prepare the optical resin prepolymer of GSTIPDI0.1 and after cooling at room temperature, 4.2 g of 1,6-hexamethylene-1,6-diisocyanate, 33.2 g of 2,3-bis(2-mercaptoethylthio)propane-1-thiol ( 2,3-bis (2-mercaptoethylthio)propane-1-thiol) and 9.2g of pentaerythritol tetrakismercaptopropionate (pentaerythritoltetrakismercaptopropionate) to prepare a resin composition for optical lenses.

[0051] manufacture lens

[0052] (1) Put the resin composition for optical lens prepared as above into a mixing container capable of vacuum defoaming and stirring and maintain a temperature of 15° C., mix 0.1 g of ZELEC UN, 1.5 g of 2-( 2-hydroxy-5-t...

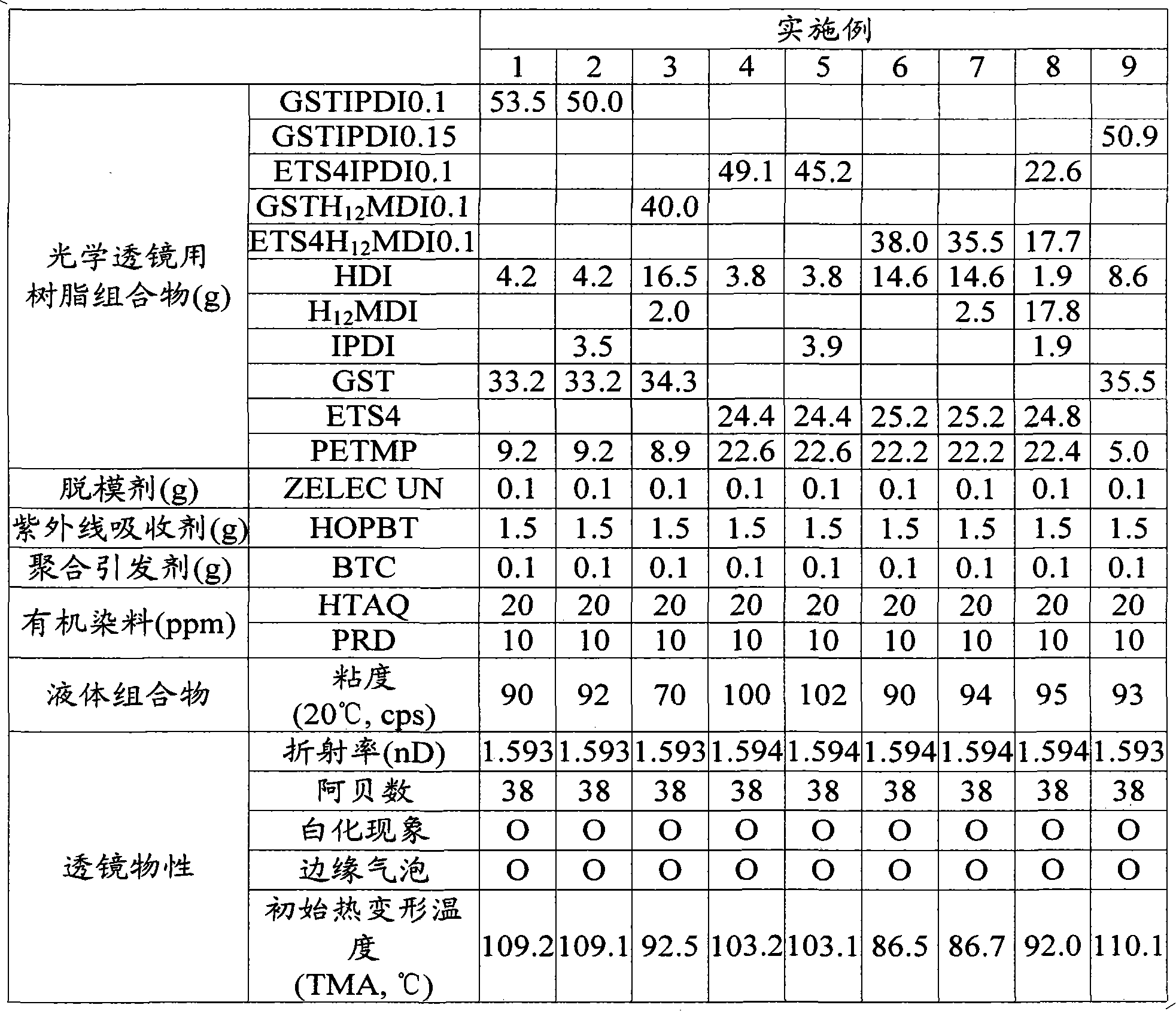

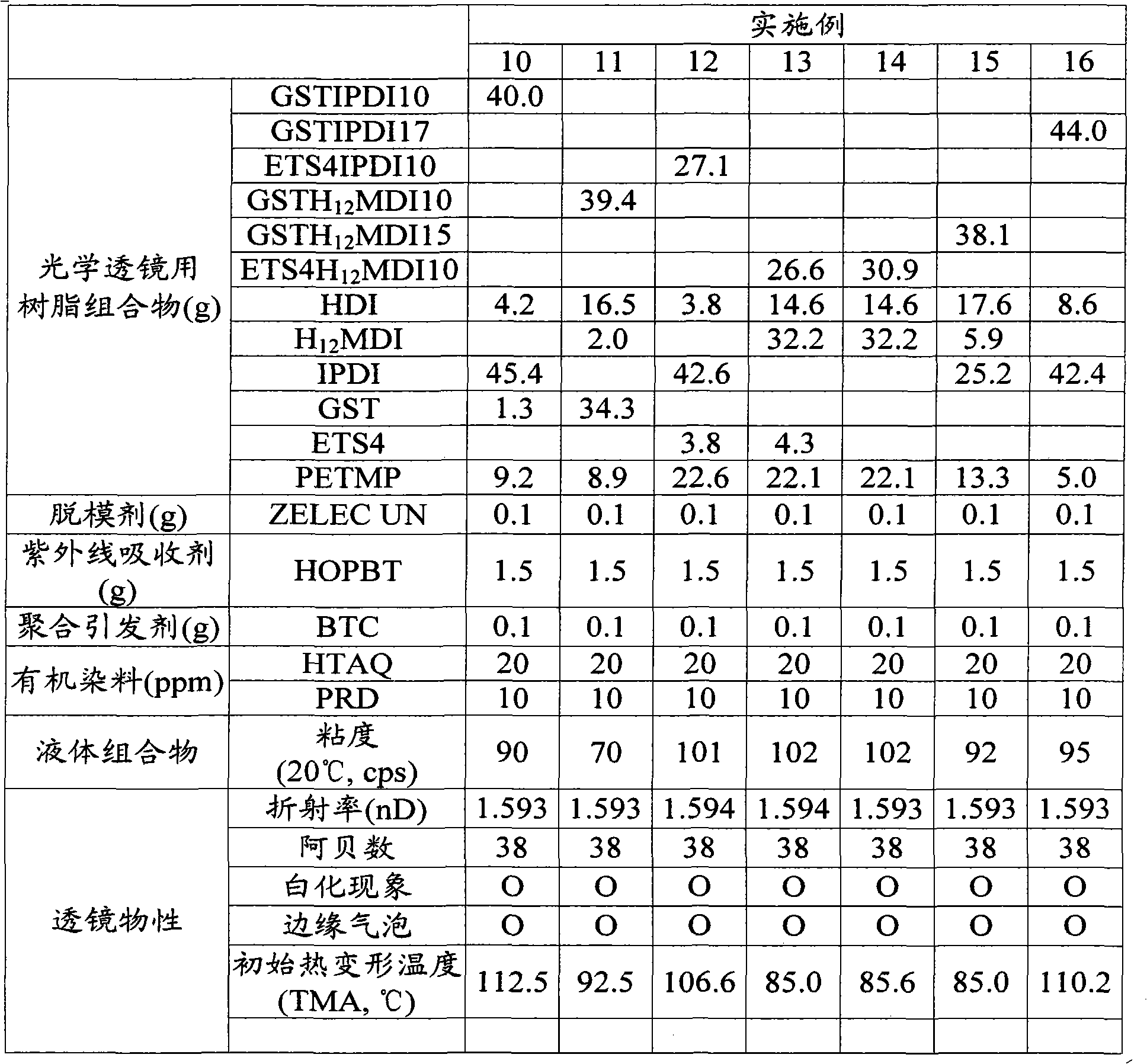

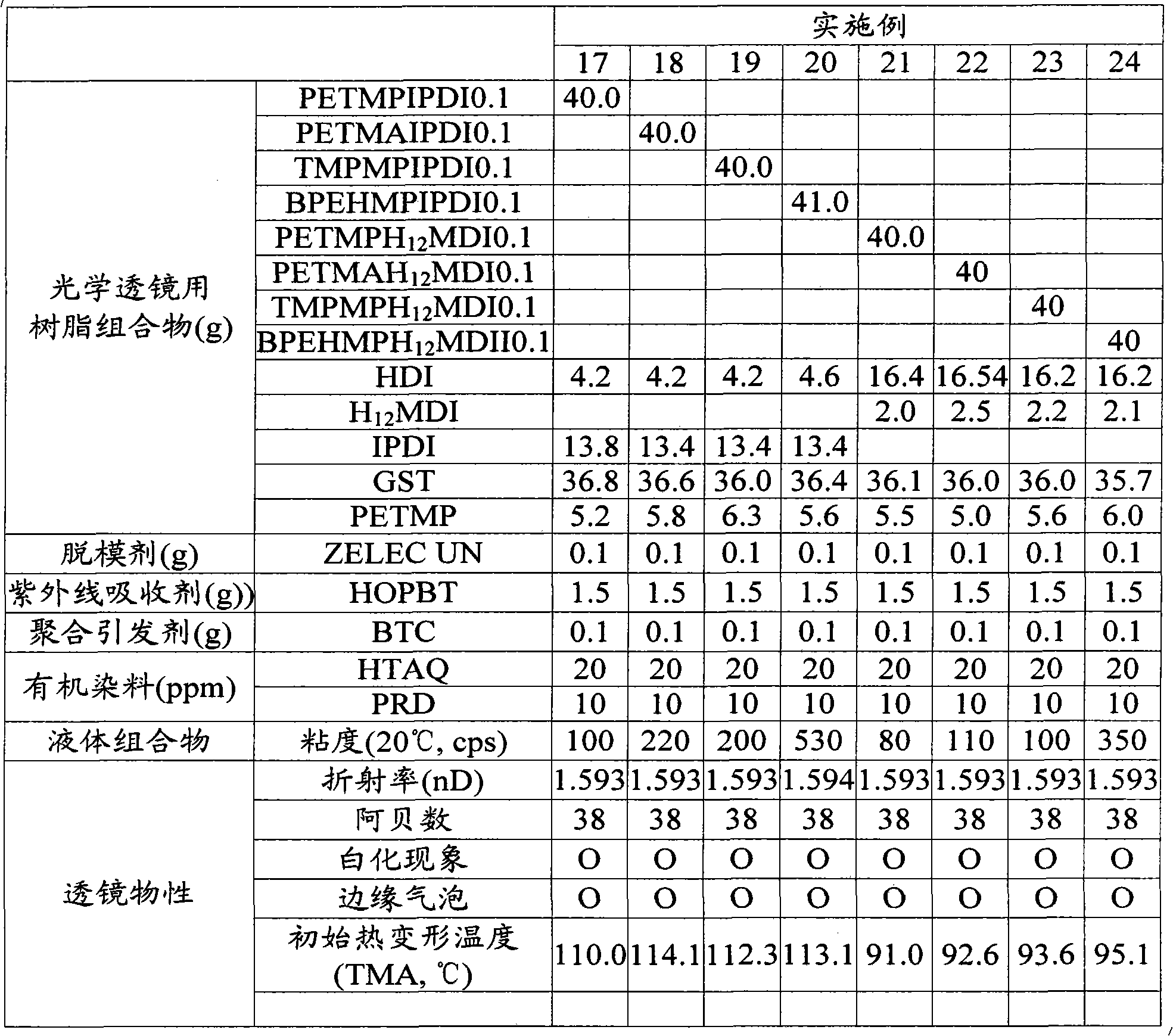

Embodiment 2~24

[0063] Using the same method as in Example 1, the respective compositions and lenses were prepared with the compositions shown in Tables 1-3, and physical property tests were performed, and the test results are recorded in Tables 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com