Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

289results about How to "Solve the bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

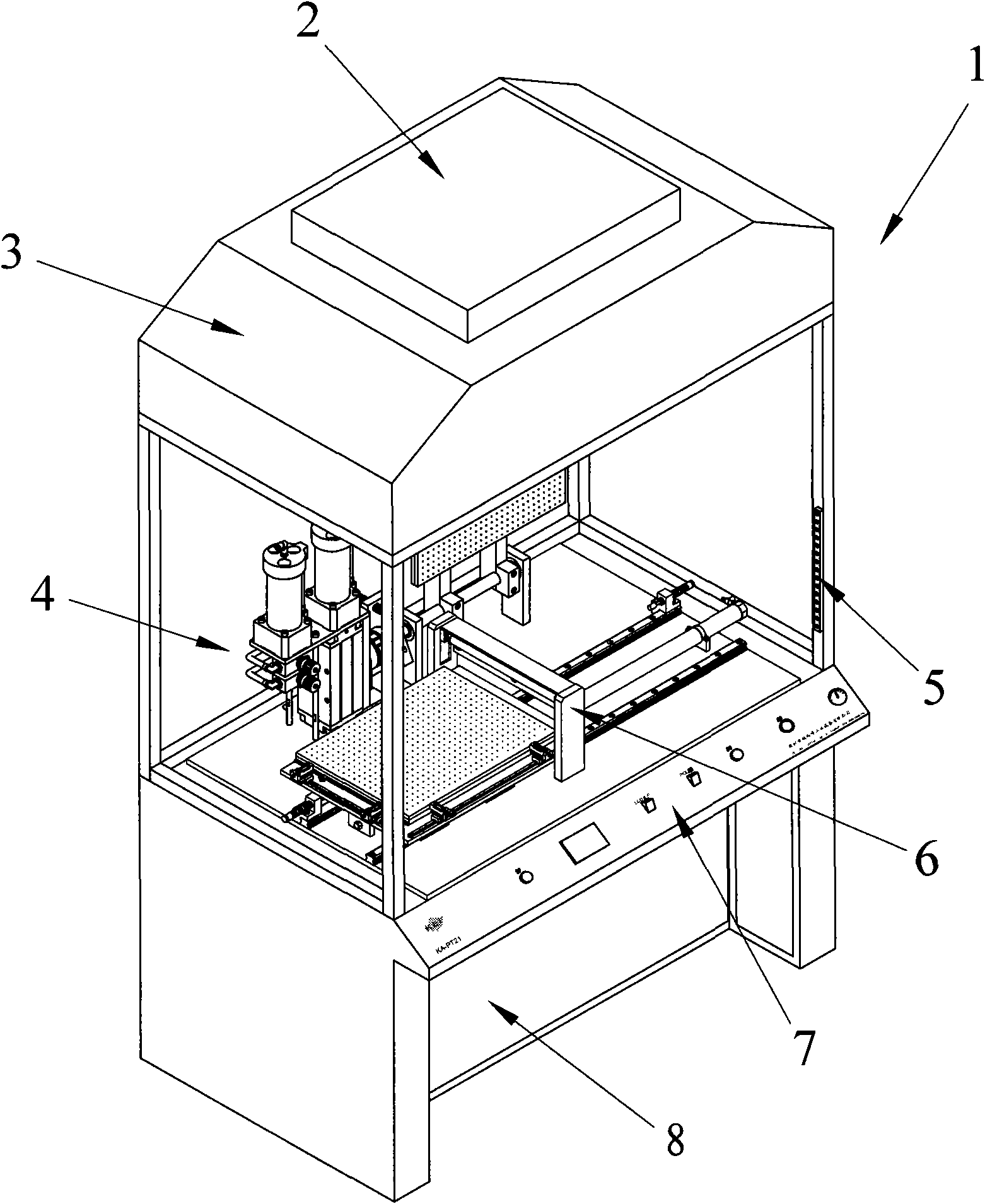

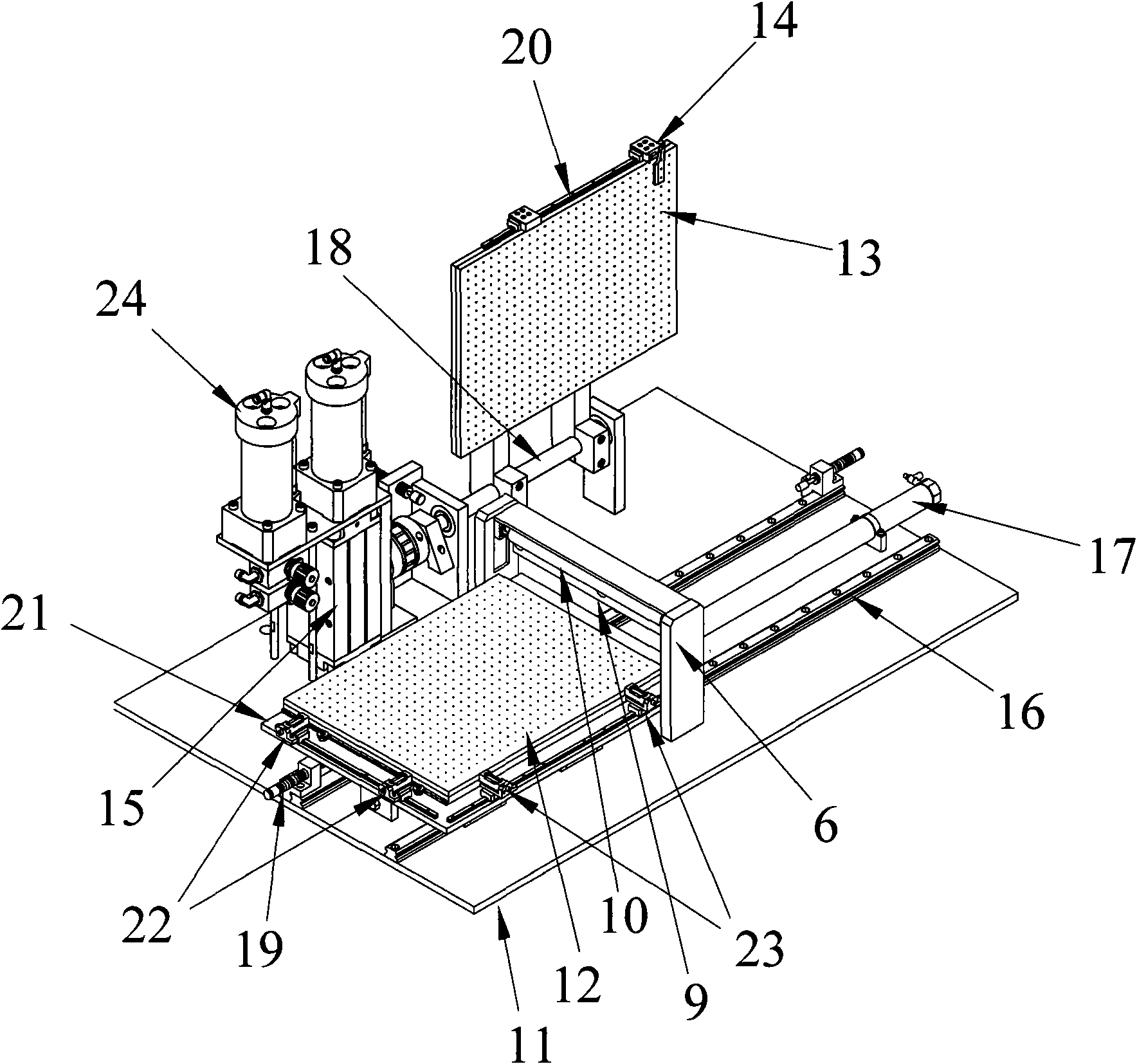

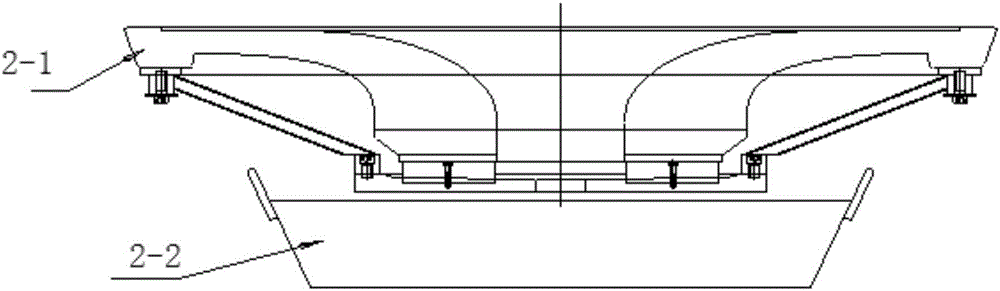

Semi-automatic laminating machine and laminating method thereof

InactiveCN101581850AGuaranteed cleanlinessEasy to operateLaminationLamination apparatusSemi automaticAtmospheric pressure

The invention discloses a semi-automatic laminating machine and a laminating method thereof. The semi-automatic laminating machine is provided with a stand, wherein an operating space for accommodating a laminating device is arranged in the middle part of the stand, an electric component box is placed in the stand and positioned below the laminating device, an air inlet opening is arranged at the top of the stand, an air purifier is placed at the top of the stand and an operating panel is installed on the stand and used for controlling the laminating machine. The material laminating is carried out by material placing, aligning, laminating by pressure roller, laminating completion and returning for standby. The semi-automatic laminating machine adopts various ways of vacuum adsorption, mechanical positioning and pneumatic motion to be provided with a precision fine adjustment device, a limitator, an oil-gas convertor, a linear slide rail and other precision components, thereby ensuring the laminating accuracy, reducing the dependence on the operators, overcoming the phenomenon of inaccurate positioning, low yield, air bubble, gauffer and defects existing in the laminating process of the diaphragm and the base material, reducing the running time due to the overlapped type motion and improving the production efficiency.

Owner:郑春晓

Thermal-melt optical clear adhesive (TOCA) and bonding method

InactiveCN103820042AGood adhesionGood light transmissionFilm/foil adhesivesLaminationNatural rubberPlasticizer

The invention discloses a thermal-melt optical clear adhesive (TOCA) and a method. The thermal-melt optical clear adhesive is composed of natural rubber or a thermoplastic elastomer, a plasticizer, an active diluent, an anti-oxidant, a radical initiator and a coupling agent. The thermal-melt optical clear adhesive has better bonding stress and good transmittance, and is easy to eliminate the bubbles, glue-spilling is difficultly generated while heating to melt, and the thermal-melt optical clear adhesive is especially suitable for bonding with a large-size touch screen. The thermal-melt optical clear adhesive is a great breakthrough based on a first generation optical clear adhesive (OCA) and a second generation optical clear adhesive (LOCA), a novel technology and equipment are cooperated, so that the bubble problem generated during a bonding process can be greatly solved, the method has the advantages of high yield, simple process, convenient repair and high production efficiency, so that the thermal-melt optical clear adhesive belongs to the third generation optical clear adhesive.

Owner:SHENZHEN EVER GLORY PHOTOELECTRICITY

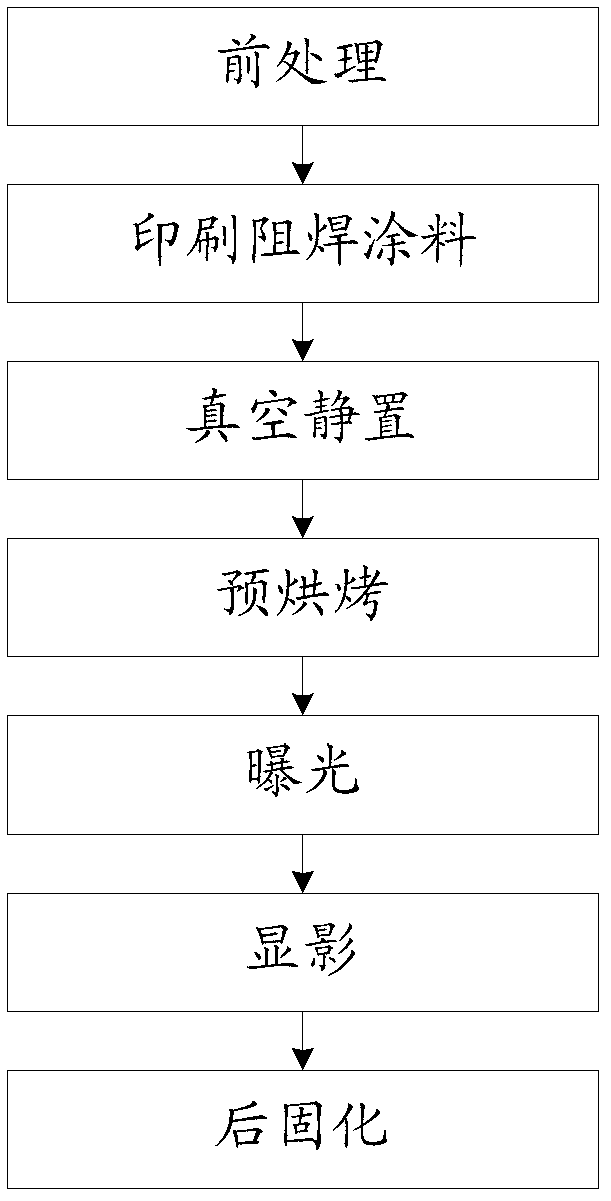

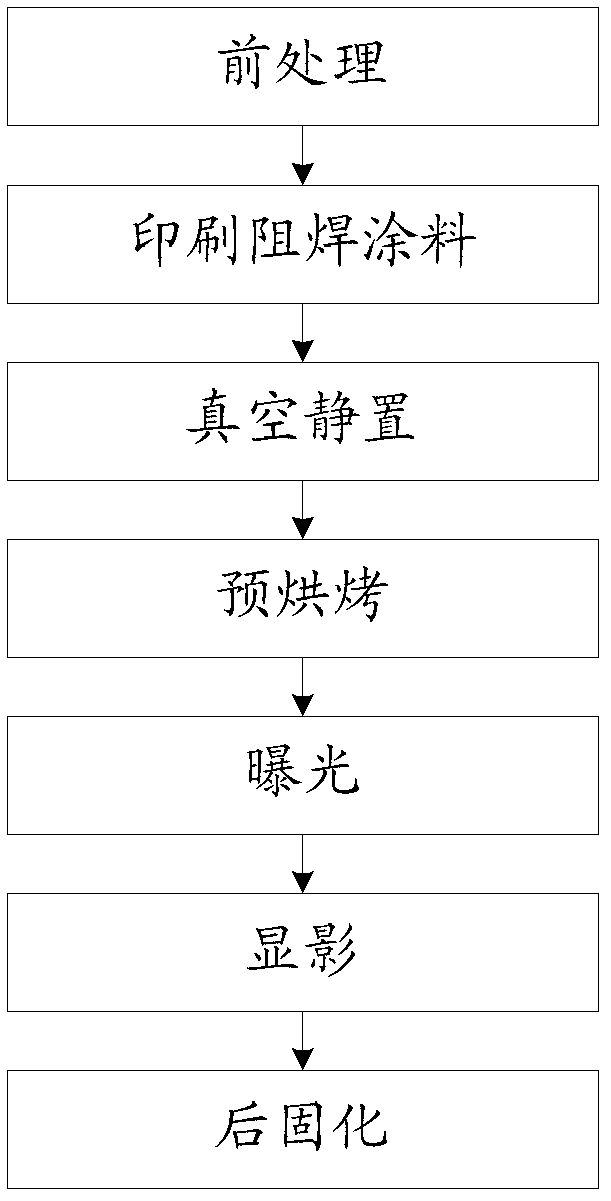

Circuit board resistance welding processing method

InactiveCN102361543AImprove exclusion effectSolve Thickness ProblemsNon-metallic protective coating applicationEngineeringCopper

The embodiment of the invention discloses a circuit board resistance welding processing method. The method comprises the steps of pretreatment, resistance welding coating printing, standing, pre-baking, exposure, development and post-curing, wherein the standing step is carried out in vacuum. The method has the following beneficial effects: the bubble elimination capability is improved by adopting vacuum standing; and the problems of insufficient resistance welding thickness and bubble generation during thick copper circuit board resistance welding processing can be solved, the process flow is shortened and the processing time is reduced.

Owner:SHENNAN CIRCUITS

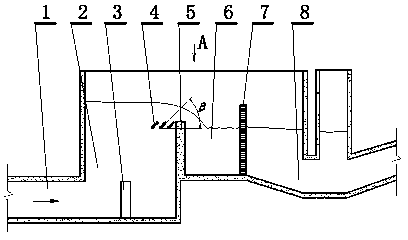

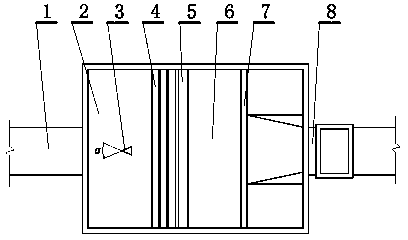

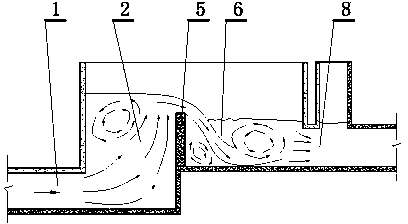

Combined defoaming and siphoning well and combined defoaming and siphoning method

The invention relates to a combined defoaming and siphoning well and a combined defoaming and siphoning method. The combined defoaming and siphoning well comprises at least one siphoning well combined body, wherein the siphoning well combined body comprises a vertical well with a water inlet square culvert, a spill pit, an overflow weir, a spill pit and a water conveying square culvert; a diversion pier is arranged between the water inlet square culvert and the overflow weir at the bottom of the vertical well and is opposite to the central axis of the water outlet direction of the water inlet square culvert; the overflow weir is arranged on one side of the vertical well, and the part, adjacent to the top, of the overflow weir is provided with front weir diversion grids arrayed horizontally; at least one vertically-arranged defoaming orifice plate used for dividing the spill pit into two parts is arranged between the overflow weir in the spill pit and the outlet of the water conveying square culvert; the bottom, connected with the water outlet square culvert, of the spill pit inclines downwards. The siphoning well is provided with the diversion pier and the front weir diversion grids, so that the nappe over weir is uniform and stable; the defoaming orifice plate is used for energy dissipation and flow equalization, so that the flowing speed of waterflow after jumping is reduced; the inlet elevation of the water conveying square culvert is reduced, so that bubbles are prevented from entering the water conveying square culvert. By virtue of the measures, the bubble problem of the drainage siphoning well is solved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

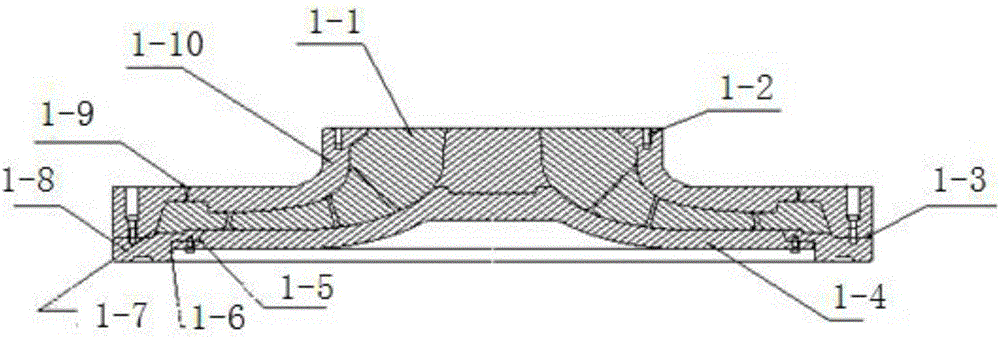

Solar panel and encapsulation process

ActiveCN101916788ASolve the flatnessSolve the bubblesFinal product manufacturePhotovoltaic energy generationWhole bodyHot melt

The invention relates to a solar panel and an encapsulation process. The solar panel comprises a silicon wafer, wherein the back of the silicon wafer is adhered to a printed circuit board (PCB) board; a polythylene terephthalate (PET) material light-transmitting layer is arranged on the upside of the silicon wafer; and the PCB board is provided with anode and cathode printed coils which are connected with the anode and cathode of the silicon wafer. The encapsulation process of the solar panel comprises the following steps of: firstly, clamping the silicon wafer and flake-like ethylene vinyl acetate (EVA) hot melt glue between the PCB board and the PET material light-transmitting layer and placing the whole body in a vacuum laminating machine; secondly, vacuumizing the vacuum laminating machine and then heating materials to be processed in the vacuum laminating machine; and finally charging air into air bags in the vacuum laminating machine for pressurization.

Owner:HANGZHOU SOLAR PHOTOELECTRICITY

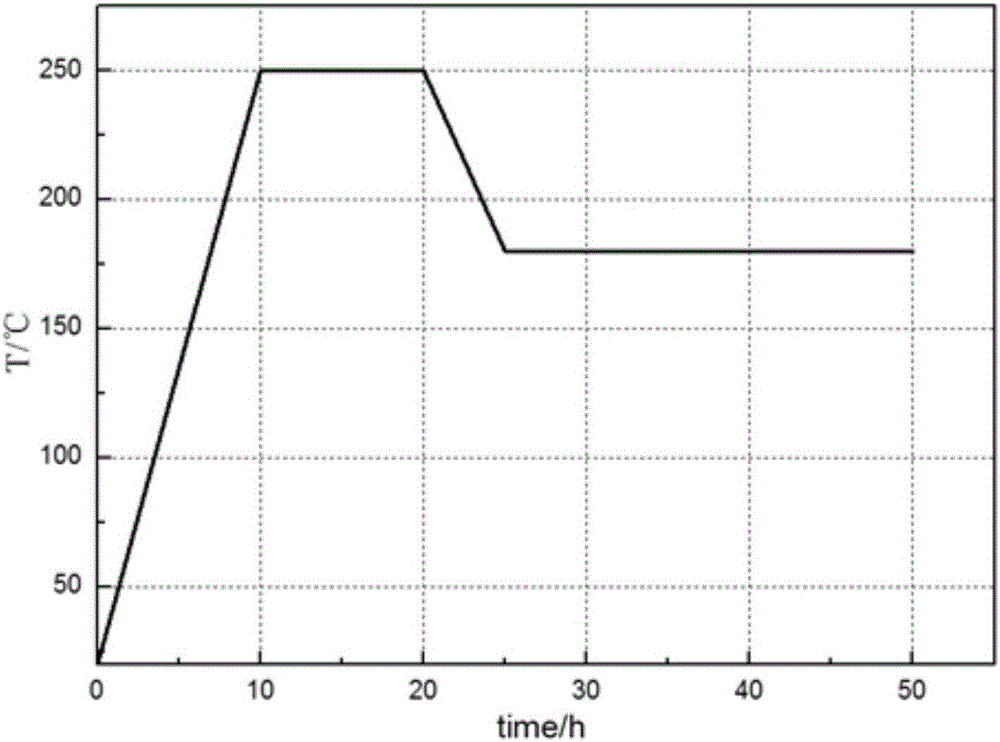

Production method for aramid fiber 1414 paper substrate material

InactiveCN103174053ASolve the bubblesAvoid recontaminationPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperMaleic anhydrideIon

The invention relates to a production method for aramid fiber 1414 paper substrate material, which comprises the following steps of uniformly mixing aramid fiber 1414 chopped fiber size, modified thermoplasticity fiber size and aramid fiber 1414 pulp fiber size and then defibering; adding maleic anhydride-acrylic copolymer for mixed pulp dispersing; then regulating the concentration of the pulp and forming and hot pressing the obtained pulp suspension through manufacture paper with pulp so as to obtain aramid fiber 1414 paper substrate body paper; dipping the aramid fiber 1414 paper substrate body paper in polyimide resin glue solution, and removing volatile solvent after drying so as to obtain the aramid fiber 1414 paper substrate material. The preparation method is environment-friendly, metal ion can be prevented from contaminating the fiber again, the problem of a conventional dispersing agent generating bubbles in manufacture paper with pulp process is solved, the defect of adding a third fiber and organic resin alone is overcome, the physical property, resistance to high temperature and insulating property of the produced end product paper are greatly improved, and the functional index of the high performance aramid fiber 1414 paper substrate material can be fully achieved.

Owner:SHAANXI UNIV OF SCI & TECH

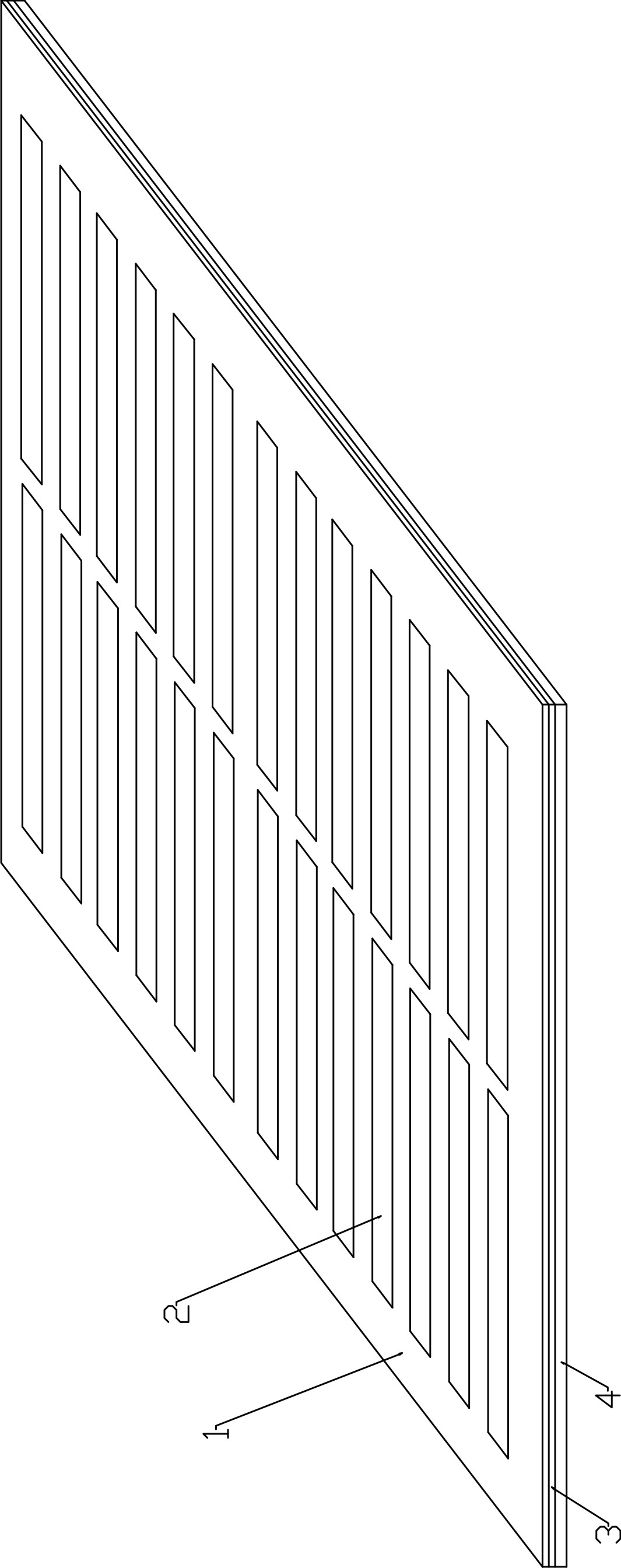

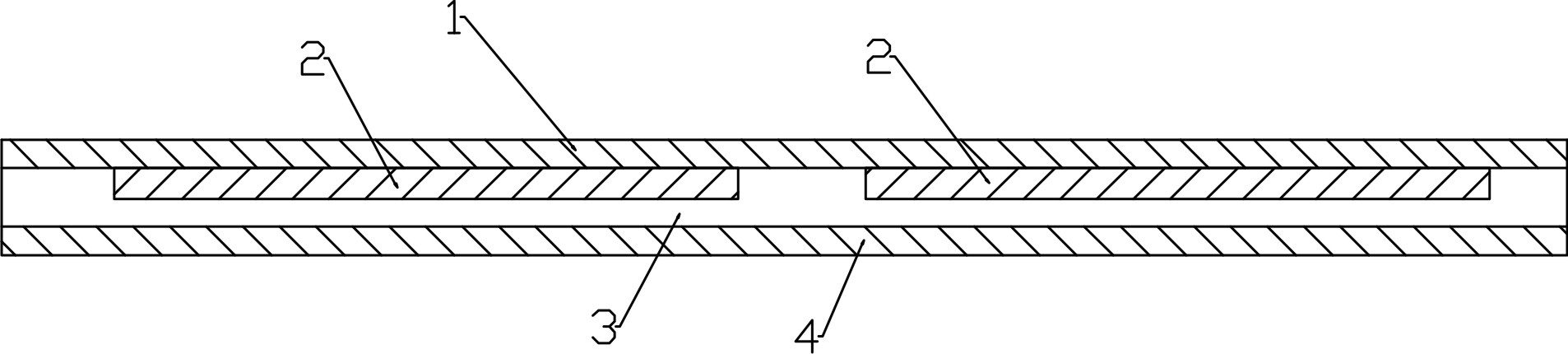

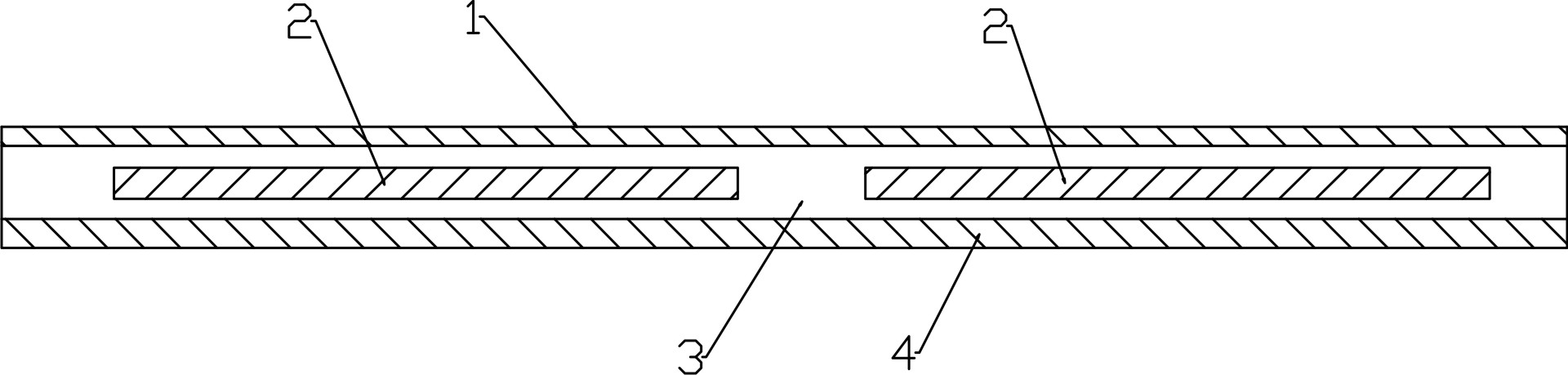

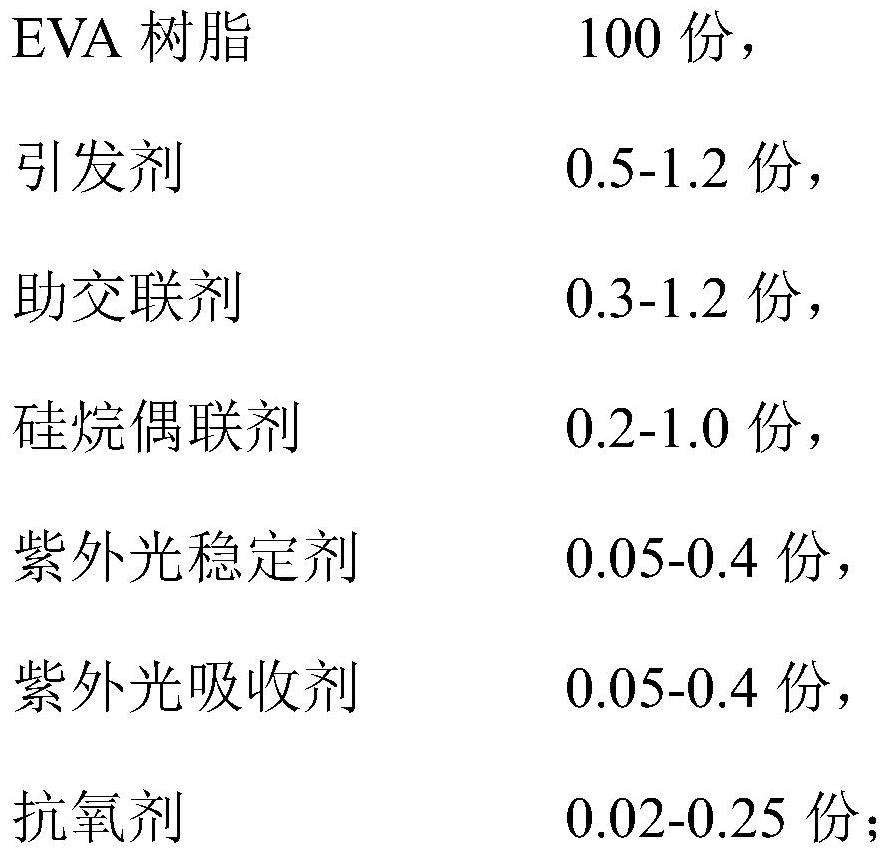

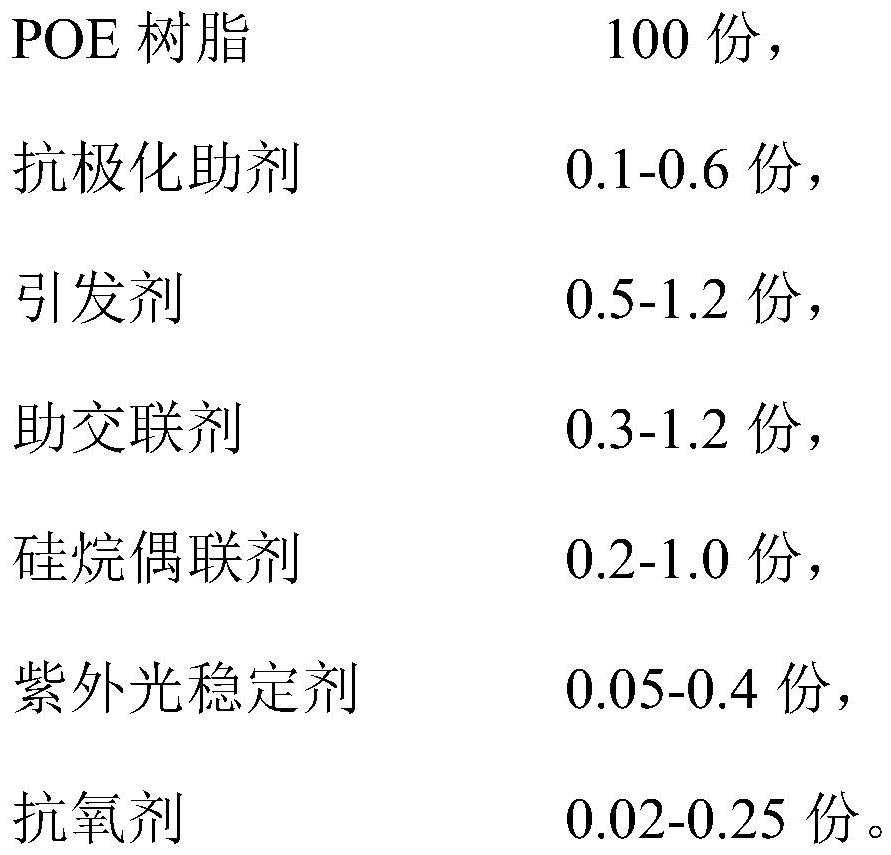

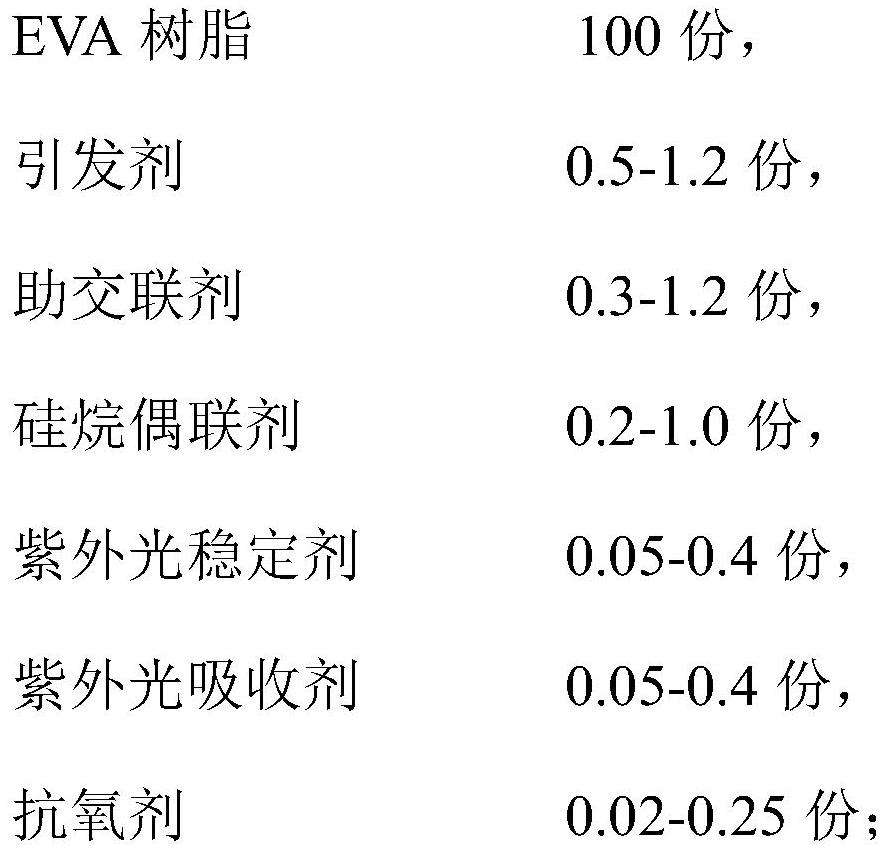

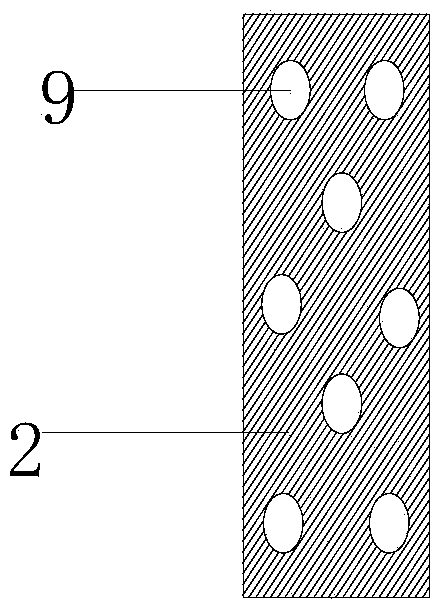

Three-layer co-extrusion composite adhesive film for packaging photovoltaic module and preparation method thereof

PendingCN111793442AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceTransmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a three-layer co-extrusion composite adhesive film for packaging a photovoltaic module and a preparation method thereof. The composite adhesive film comprises EVA layers, a POE anti-polarization layer and an EVA layer which are sequentially arranged from top to bottom, wherein EVA resin has a melt flow rate of 5 g / 10 min-30 g / 10 min, light transmittance of larger than 85%, volume resistivity of larger than or equal to 1.0 * 10<14>, melting temperature of 30-80 DEG C, and VA content of5-30%; POE resin has a melt flow rate of 3 g / 10 min-20 g / 10 min, light transmittance of greater than 86%, volume resistivity of greater than or equal to 1.0 * 10<15> and melting temperature of 30-80DEG C. The EVA layers are adopted on the two sides of the composite adhesive film, the compatibility of the EVA layers and polar auxiliaries is good, and the problems of bubbles, slippage and piece combining during assembly laminating can be solved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

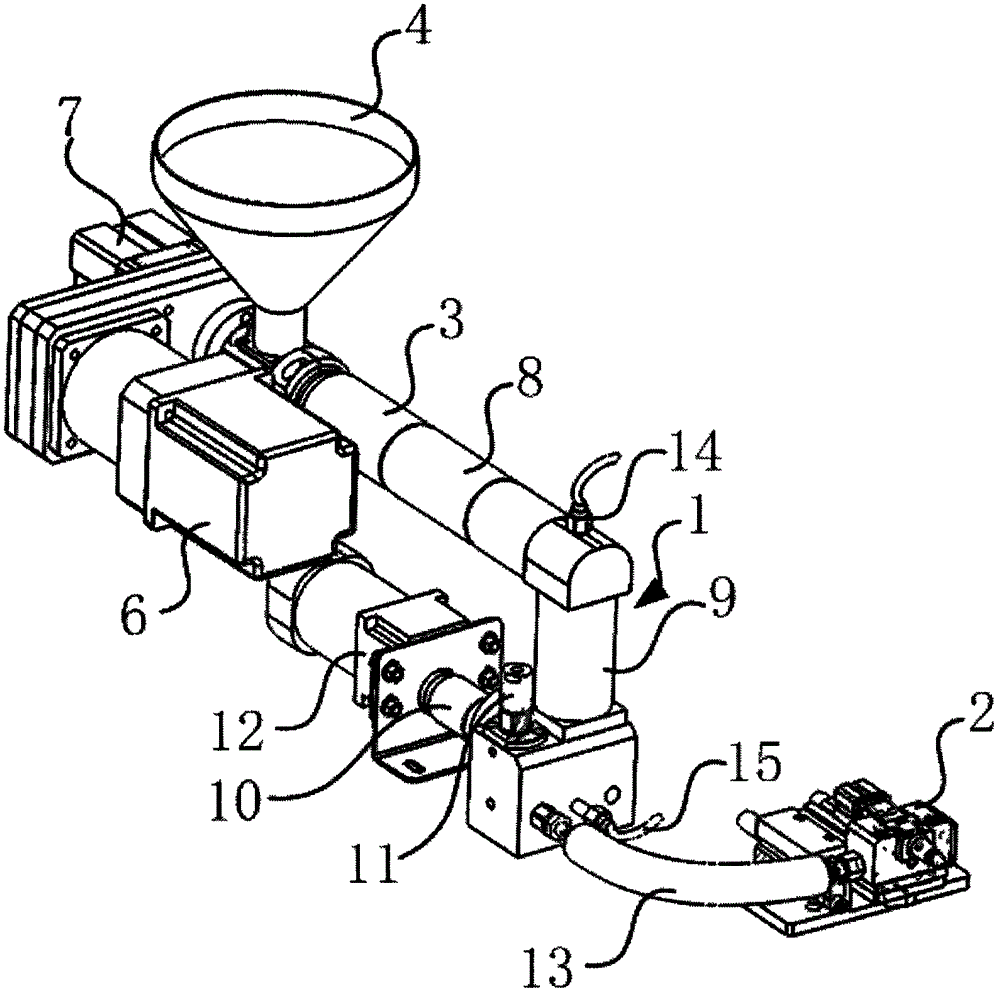

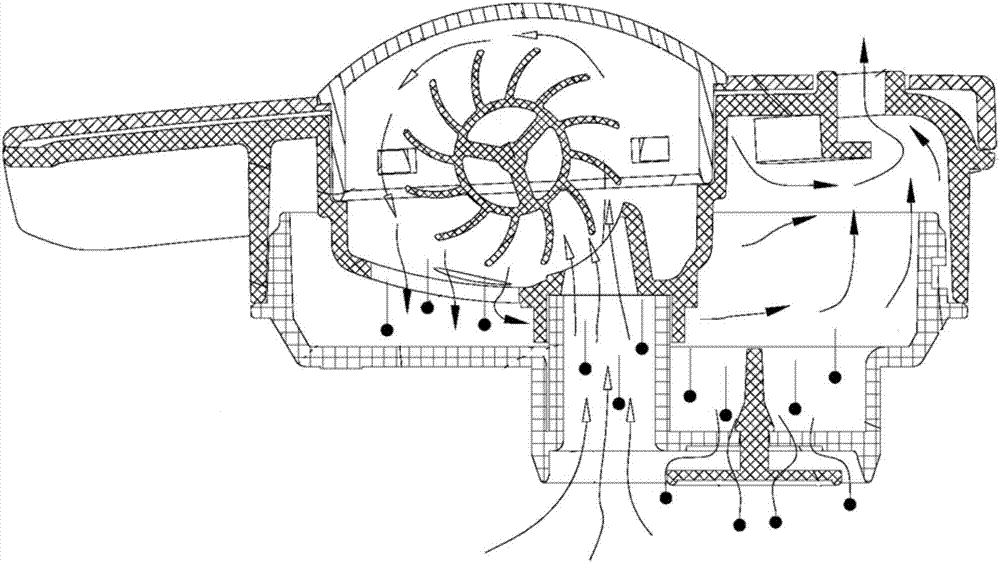

Melt-and-play glue melting device

The invention provides a melt-and-play glue melting device which comprises a glue cylinder, a glue injection gun nozzle, wherein the glue cylinder is used for storing a liquid glue stock; the glue injection gun nozzle is used for jetting the liquid glue stock; the conveying pipe is connected with the glue cylinder; and a screw rod is arranged in the conveying pipe, and rotates to melt a solid glue stock into the liquid glue stock. The melt-and-play glue melting device has the advantages that the boot waiting time can be shortened; the carbonization of the glue stock is removed; and the obtained glue is free of a bubble.

Owner:SUZHOU KONIG ELECTRONICS TECH CO LTD

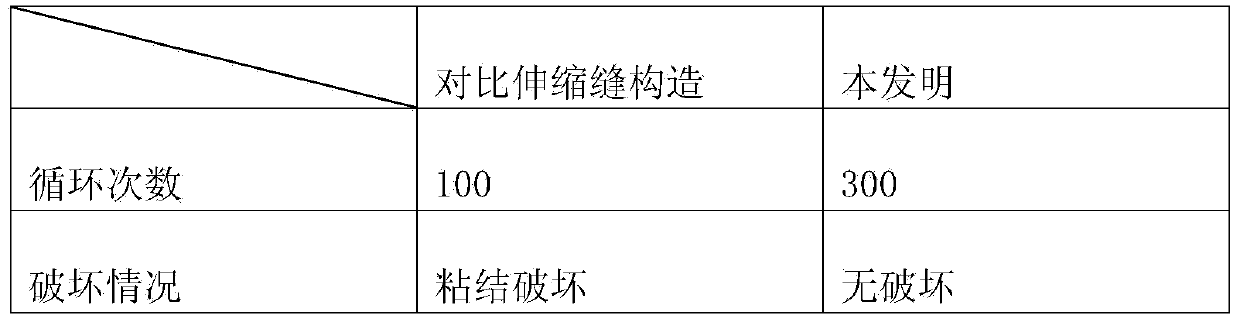

Road and bridge expansion joint structure

InactiveCN103669202AEasy constructionReasonable designBridge structural detailsStress conditionsIn vehicle

The invention discloses a road and bridge expansion joint structure. The road and bridge expansion joint structure comprises an inverted-T-shaped plate component with the bridge longitudinal cross section being in an inverted T shape. Two wing plates of the inverted-T-shaped plate component transversely extend into a base body of a bridge pavement layer. A web extends upwards to be flush with the upper surface of the bridge pavement layer. Each wing plate is sequentially provided with a cushion layer and a protection wear-resisting layer from bottom to top in a laying mode and is longitudinally connected with the bridge pavement layer. An expansion joint notch and the two sides of the expansion joint notch are filled with elastic layers to be sealed. The road and bridge expansion joint structure has the advantages of being convenient to construct, reasonable in design, high in efficiency, good in vehicle load bearing performance, good in elasticity, smooth and attractive in surface, and good in waterproofing, anti-aging, anti-fatigue, shock resistance and corrosion resistance. In accordance with the characteristics of an expansion joint, three materials of different components and matching ratios are adopted, layered pavement is conducted according to different stress conditions and states, good durability is achieved, construction is rapid and simple, and the expansion joint performance requirement can be well met.

Owner:孟献春

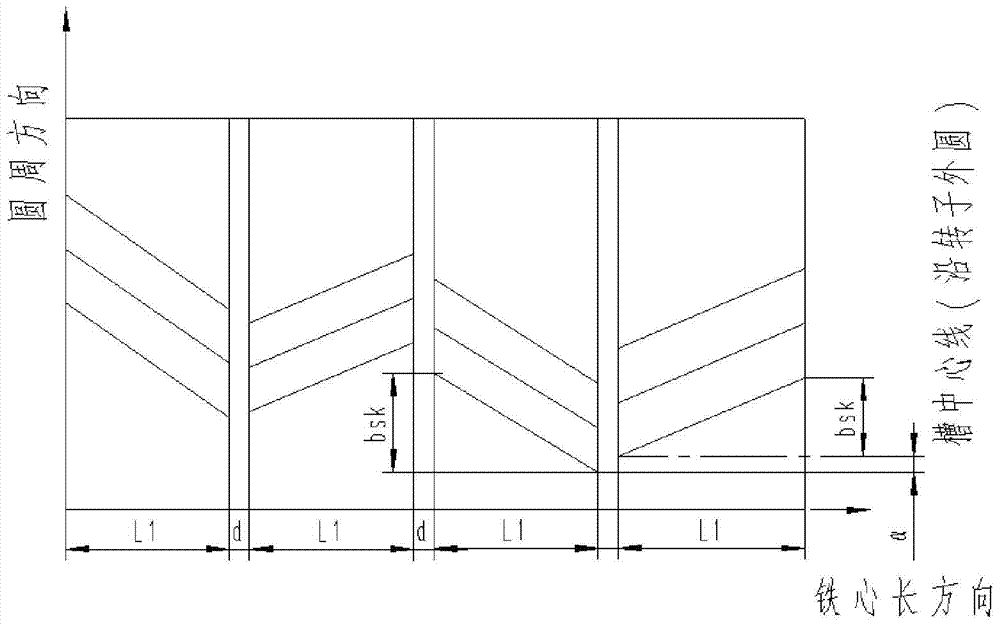

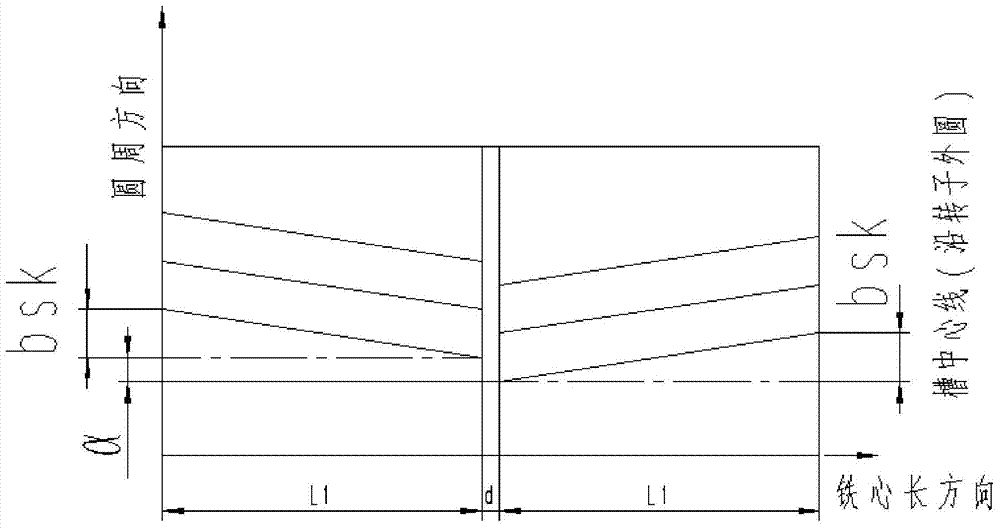

Chute low-noise motor

ActiveCN103501065AEliminate axialEliminate torsional vibrationMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which comprises a machine seat, a stator, a rotor and a rotating shaft, wherein the stator, the rotor and the rotating shaft are arranged on the machine seat, the rotor comprises at least two sections of rotor iron cores, the rotor iron cores are punched and laminated by a false axis inclination angle taper key method to form chute iron cores; chutes of the adjacent chute iron cores are in opposite directions and are in arrangement in a way of staggering for an angle alpha. Therefore, the chute low-noise motor has the following advantages that 1, great-degree optimization is respectively realized in aspects of vibration, noise, iron core laminating quality, cast aluminum quality and chute cast aluminum rotor structure adopted by a high-power motor, and the chute low-noise motor is suitable for small and medium-sized cast aluminum rotor structure alternating current motors with higher vibration and noise requirements; 2, the stress uniformity and the rigidity of iron core laminating punching are fundamentally ensured, the iron core laminating quality is improved, the influence of deformation on vibration noise is reduced, the aluminum overflowing and bubble problems are solved, and the quality of the cast aluminum rotor and the motor performance reliability are improved.

Owner:中国船舶重工集团公司第七一二研究所

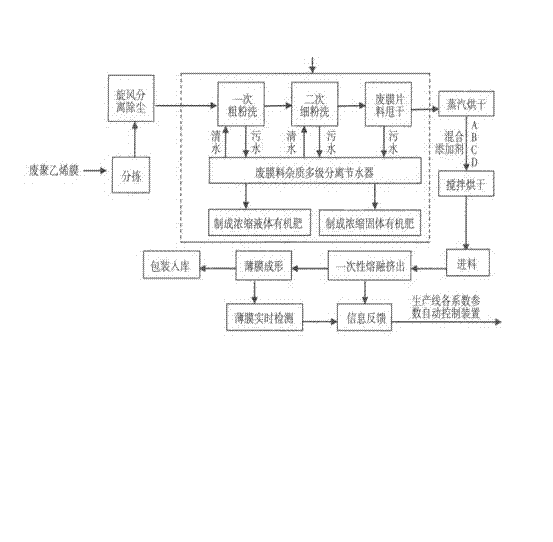

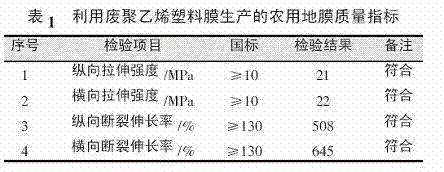

Preparation process of one-time fused and regenerated polyethylene agricultural plastic mulching film

InactiveCN103112184ASolve the bubblesSolve extrusion instabilityPlastic recyclingFlat articlesPlastic mulchPre treatment

The invention discloses a preparation process of an agricultural plastic mulching film, particularly relates to a preparation process of a one-time fused and regenerated polyethylene agricultural plastic mulching film, and belongs to the field of agricultural chemistry. The preparation process comprises the following steps of: firstly, pre-treating polyethylene agricultural plastic mulching film waste film materials; roughly crushing and washing by water; finely crushing and washing by water; centrifugally drying; and then, adding an addition agent; and carrying out agitation, drying, feeding and extrusion, fusion, blowing and molding to obtain a film-making product. Compared with the prior art, 100% of adopted raw materials are waste polyethylene film materials and the recycling utilization rate of the waste films is high; granulation is not needed and the film is formed by one-time fusion; the production process is unique and reasonable, has low investment and low cost and is easy to operate; and no 'three wastes' are generated in a production process and a new way for reutilizing the polyethylene agricultural plastic mulching film is provided.

Owner:HENAN YINFENG PLASTIC

Preparation method of PERC solar cell

ActiveCN105810779AShorten process timeReduce manufacturing costFinal product manufacturePhotovoltaic energy generationSilicon nitrideSolar cell

The invention discloses a preparation method of a PERC solar cell. The preparation method comprises the following steps of texturing, diffusing, back polishing, etching, impurity glass removal, passivation lamination film deposition on a back surface, a silicon nitride anti-reflection layer deposition on a front surface, local opening in the back surface, metal paste silk-screen printing on the front surface and the back surface and sintering, wherein the step of passivation lamination film deposition on the back surface comprises the following steps of (1) depositing an Al2O3 thin film on the back surface of a silicon wafer battery by an atomic layer deposition method; and (2) placing the battery in the step (1) in a tubular furnace for pre-annealing, depositing a SiO2 thin film on the battery, and depositing a SiNx thin film on the above SiO2 thin film. The steps of annealing and SiO2 / SiNx thin film deposition are integratedly carried out in the same tube, thus, the step of separate annealing of the Al2O3 passivation film and an annealing tube are omitted, the process time is saved, the production cost is reduced, and the preparation method is applicable to industrial production.

Owner:CSI CELLS CO LTD +1

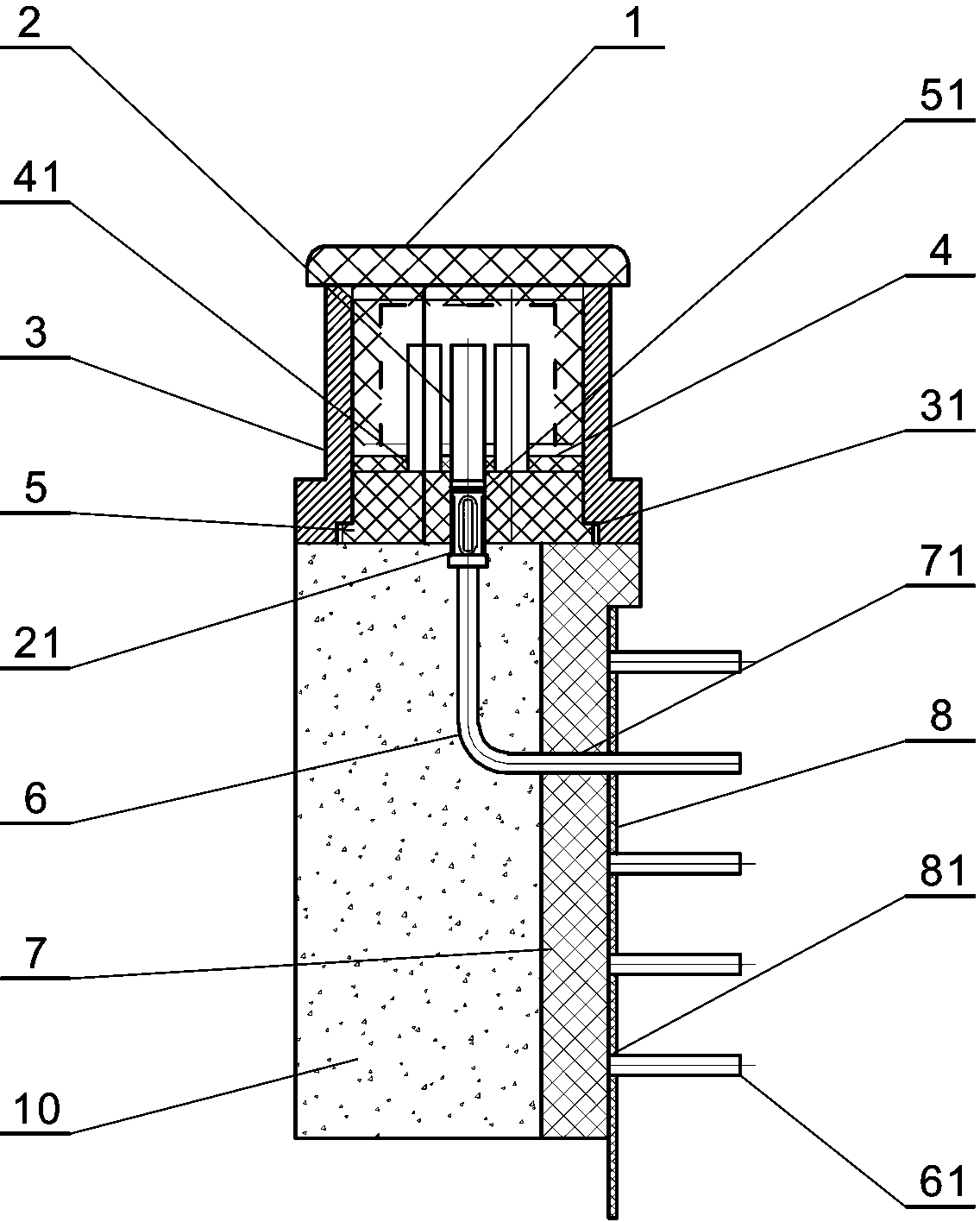

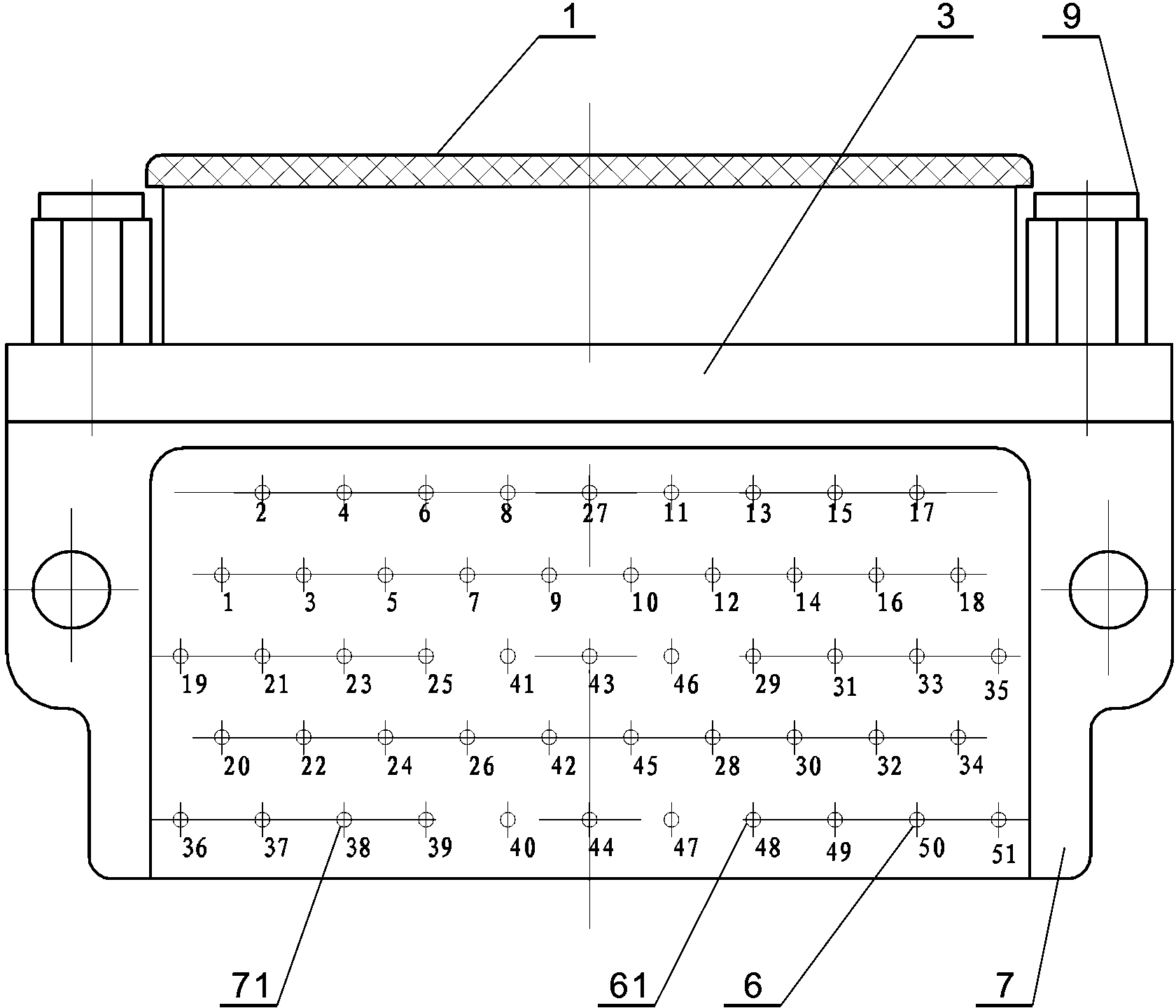

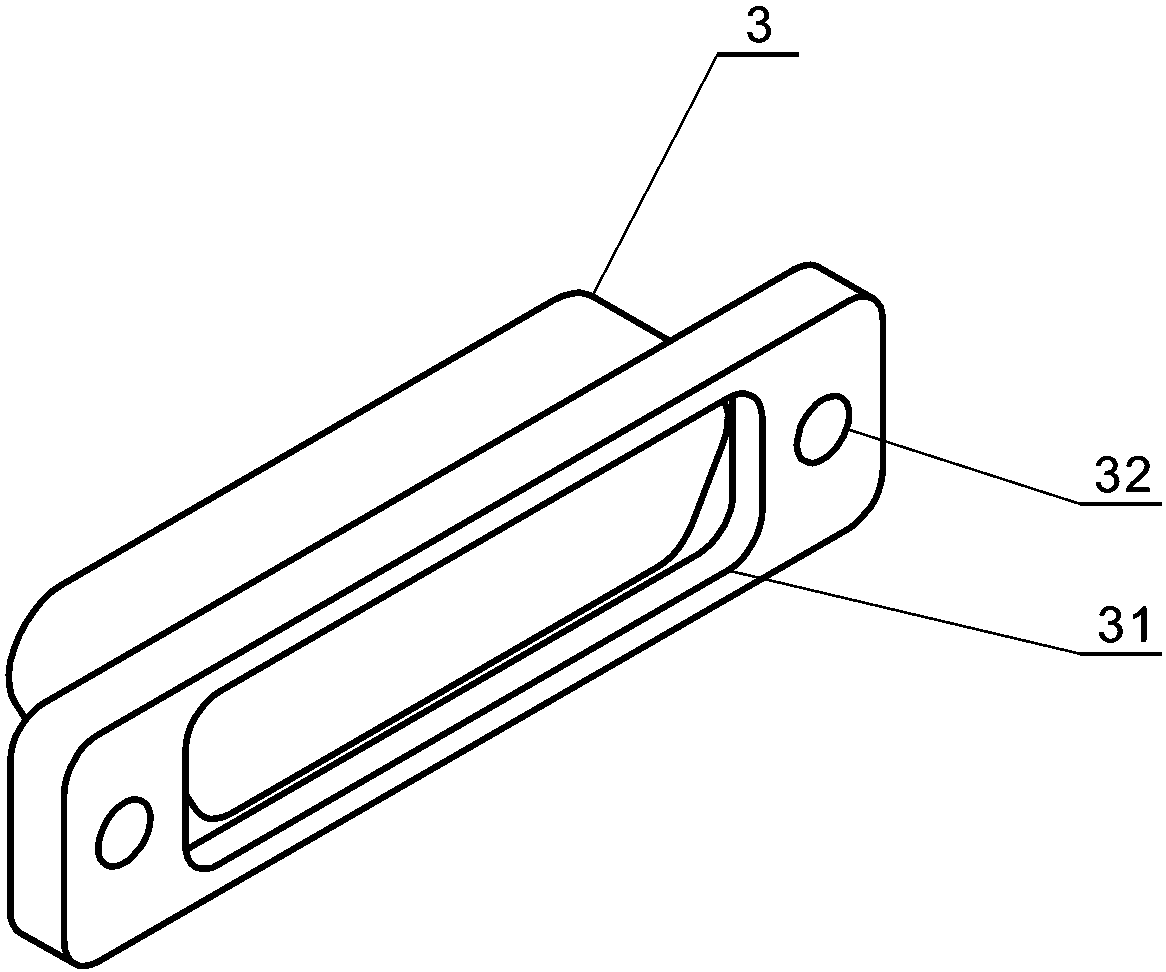

Embedment type 90-degree bent inserted PCB connector

ActiveCN103872492AEliminate loose filamentsIncrease stickinessCouplings bases/casesEmbedmentContact element

The invention discloses an embedment type 90-degree bent inserted PCB connector. The embedment type 90-degree bent inserted PCB connector is characterized by comprising an electrostatic dust prevention cover, a contact element, an outer shell, a rubber pad, a base, an enameled wire, a tail covering part, a gasket, an installation bolt and pouring sealant, wherein the contact element is arranged in the base adhering to the outer shell, the installation bolt is used for fixing the outer shell and the tail covering part, one end of the enameled wire is connected with the contact element in a pressed mode, the other end of the enameled wire penetrates out of the tail covering part, the pouring sealant is injected into a cavity between the tail covering part and the base, and the outer shell is covered with the electrostatic dust prevention cover. According to the embedment type 90-degree bent inserted PCB connector, a conductive wire and a pin which are integrated with the enameled wire are adopted, stickiness of the surface of the pouring sealant and the surface of the enameled wire is enhanced, the problem that the pouring sealant generates bubbles or holes is resolved, the phenomenon that the conductive wire scatters is eliminated, and the assembly technology of products is simplified. The embedment type 90-degree bent inserted PCB connector has the advantages of being simple in structure, low in cost, high in product percent of pass and reliable in quality.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Full-automatic quick measurement system and method for water quality hexavalent chromium

ActiveCN102980860ASolve the insurmountable bubble problemSolve the bubblesColor/spectral properties measurementsPeristaltic pumpWater quality

The invention relates to a full-automatic quick measurement system and method for water quality hexavalent chromium. A first electromagnetic valve is connected with a hexavalent chromium standard solution and a second electromagnetic valve and then is connected to a first joint of a six-way valve through a peristaltic pump; the second electromagnetic valve is connected with a standard sample; a second joint of the six-way valve is connected with a fifth joint through a quantifying ring; a sixth joint of the six-way valve is connected with waste liquid; a third joint of the six-way valve is connected to current carrying liquid through the peristaltic pump; a fourth joint of the six-way valve is connected with one end of a reaction pipe and a development agent passing through the peristaltic pump respectively through a three-way mixing machine; a third electromagnetic valve is connected to the other end of the reaction pipe and air respectively; and the third electromagnetic valve is also connected to the waste liquid through a photoelectric detection device. The full-automatic quick measurement system has the advantages of simple flow path design, pure digital photoelectric detection, bubble interference elimination and the like; and furthermore, a programmable logic controller (PLC) is used, so that the fault rate of an instrument control system is greatly reduced, and an instrument can really carry out unmanned full-automatic measurement.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Cellularization biological liver stent with anticoagulation property and preparation method of cellularization biological liver stent

ActiveCN104841017AEasy to manufactureLow costPharmaceutical containersMedical packagingMedicineAnti coagulation

The invention provides a cellularization biological liver stent with an anticoagulation property and a preparation method of the cellularization biological liver stent. The preparation method comprises the following steps: (a) pouring a solution containing heparin and / or heparinate into the cellularization biological liver stent, wherein the pouring speed is 80mL / min-150mL / min, and the pouring time is 5-12 hours; and (b) carrying out sterilization. The prepared cellularization biological liver stent is strong in anticoagulation property and good in cytocompatibility and plays a very important support role in the survival, differentiation and proliferation of cells planted on the cellularization biological liver stent, and a convenient and cheap source and the preparation method are provided for the construction of a heterologous tissue-engineered biological anti-coagulation stent with a clinical application value.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

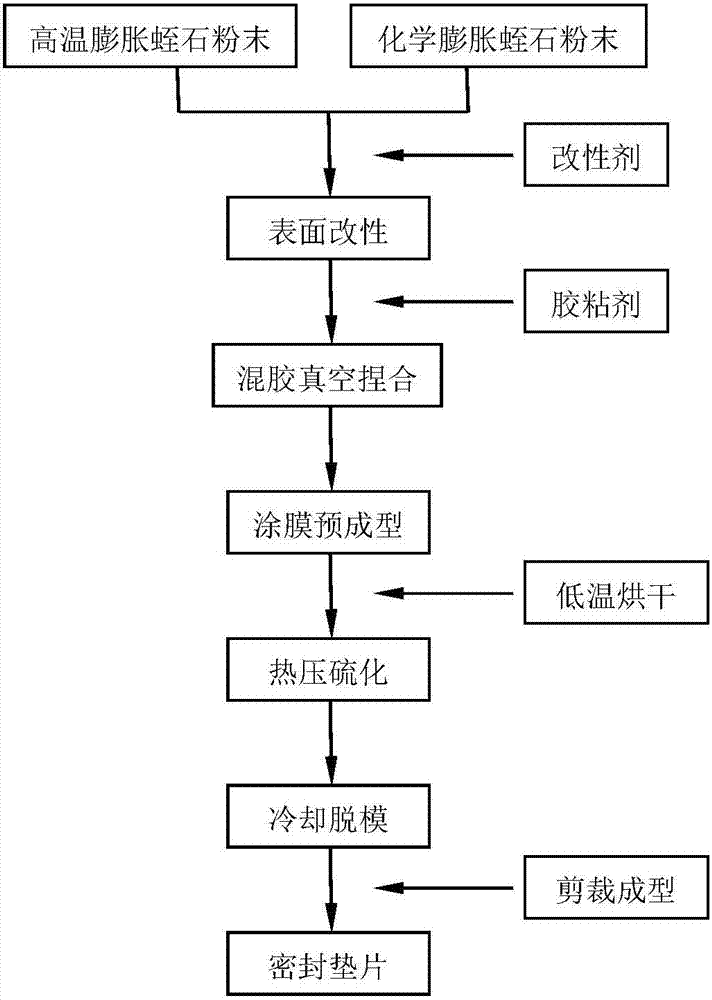

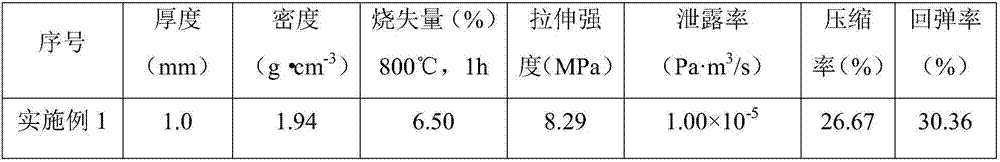

Preparation method of vermiculite-based high temperature-resistant sealing material

The invention relates to a preparation method of a vermiculite-based high temperature-resistant sealing material. The preparation method comprises the following steps: preparing materials: selecting high-temperature expanded vermiculite powder, chemical expanded vermiculite powder, a modifier and an adhesive; uniformly mixing two types of expanded vermiculite powder and water to obtain a mixed material with the mass concentration of 35-45%; sending the mixed material into a vacuum kneading machine, and adding the modifier for performing surface modification for 0.5-2h; adding the adhesive for performing vacuum kneading for 0.5-2.0h, together with the adhesive; performing coating premoulding on a kneaded slurry, and drying, wherein the moulding thickness is 2.0-4.0mm and the drying temperature is 60-75 DEG C; performing hot-pressing vulcanization moulding on a dried premoulded blank on a hot-pressing vulcanizing machine; cooling and demoulding the material, and cutting into shapes to obtain the vermiculite-based high temperature-resistant sealing materials with different thicknesses. According to a process method of performing coating premoulding first and then performing mould-pressing vulcanization molding, the vermiculite content can reach 95%, the contents of other auxiliary agents are low, and the high temperature resistance of the sealing material is effectively improved.

Owner:WUHAN UNIV OF TECH +1

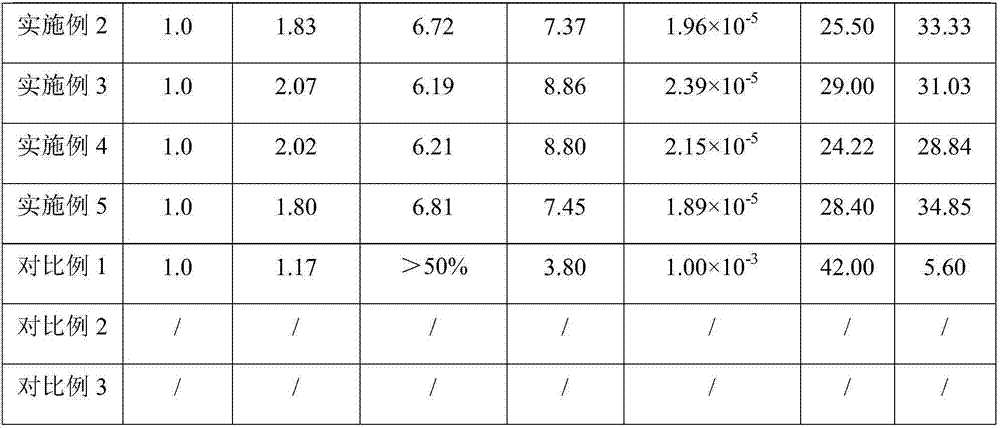

Waterborne epoxy composite cement mortar material as well as preparation and construction methods thereof

The invention discloses a waterborne epoxy composite cement mortar material. The material comprises a component A, a component B and a component C in the mass ratio being (0.5-1.5): (1-3): (12-18), wherein the component A is a waterborne epoxy emulsion, the component B is prepared from, in parts by weight, 3-10 parts of water, 3-10 parts of a curing agent and 0.01-0.1 parts of a defoaming agent, and the component C is prepared from 30-60 parts of quartz sand, 20-40 parts of cement, 0.1-0.5 parts of a water reducer, 0.2-1.0 part of an additive and 0.1-1.0 part of a defoaming agent. The material is green, environment-friendly and low in cost, has good matching performance in concrete, can be cured in humid interfaces and has reinforcement and permeation resistance functions, the problem that traditional floor coatings peel or have bubbles is solved, the one-time forming thickness can reach 2 mm or above, basic planes are easy to level, and construction is easy. The invention further discloses preparation and construction methods of the material. The preparation condition is mild, the method is simple and suitable for large-scale industrial production, the construction process is simple and feasible, and the construction cost is low.

Owner:深圳市威尔地坪材料有限公司

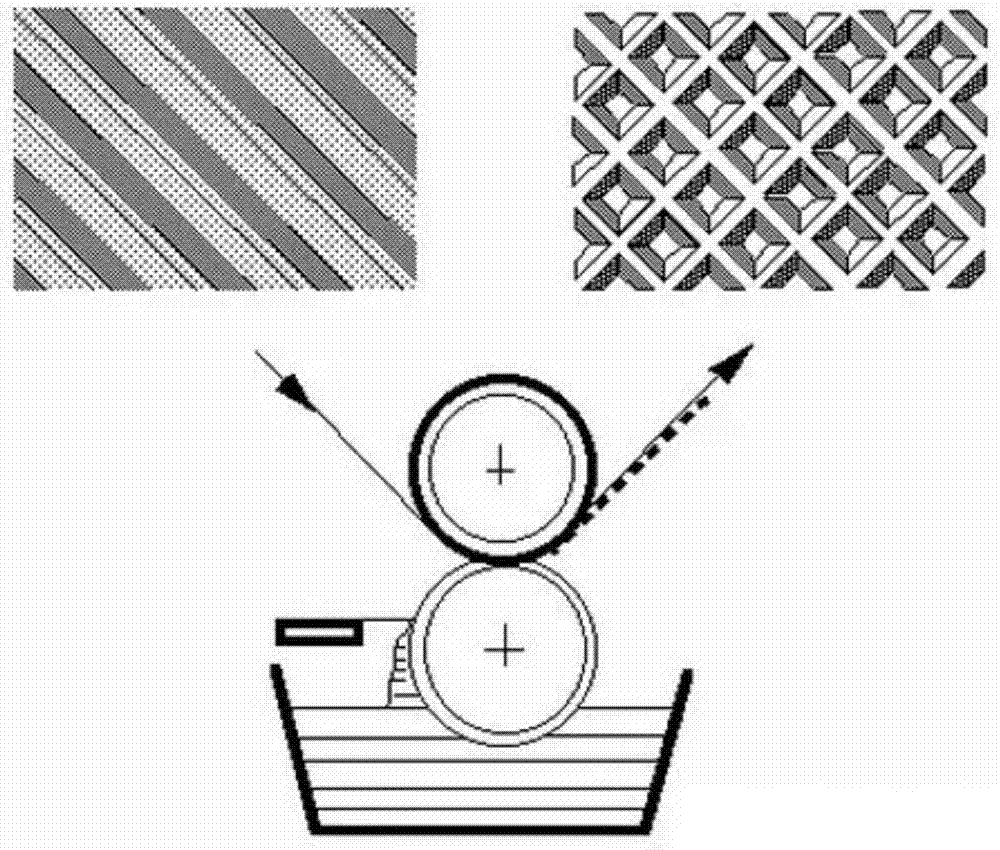

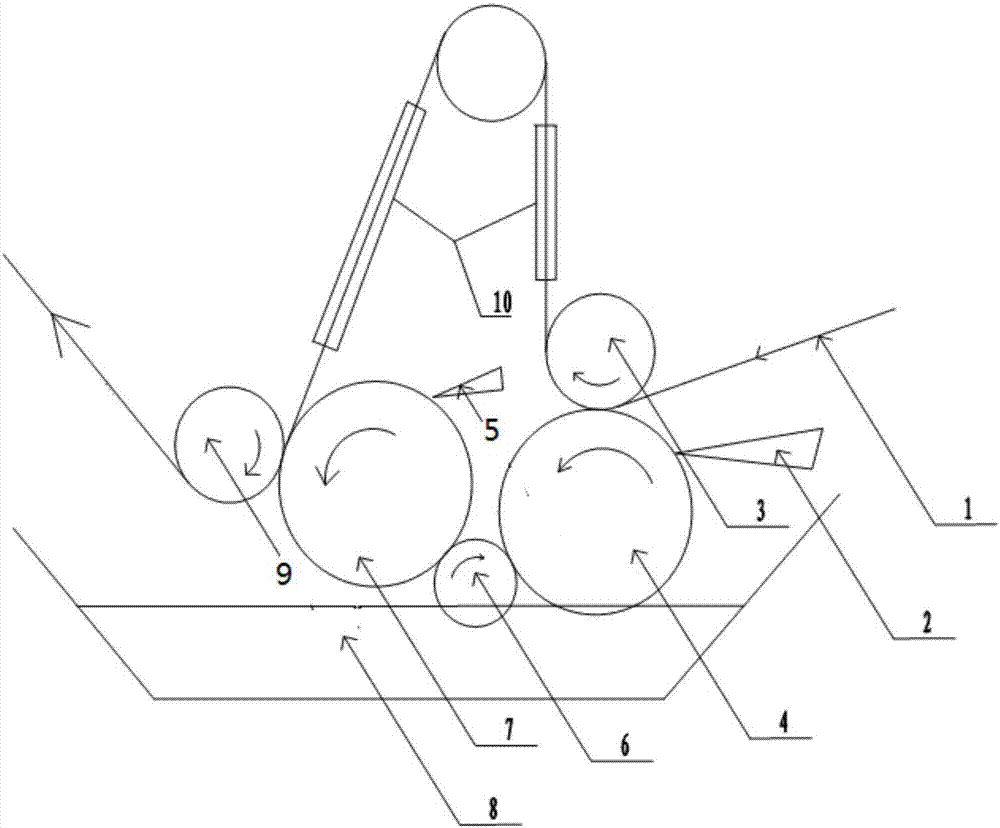

Single-trough and dual-roll secondary coating structure

ActiveCN107252760ASave electricityQuality assurancePretreated surfacesCoatingsEngineeringEnergy consumption

The invention discloses a single-trough and dual-roll secondary coating structure. The single-trough and dual-roll secondary coating structure comprises a first coating mechanism and a second coating mechanism; the first coating mechanism comprises a first net roll; the second coating mechanism comprises a second net roll; and defoaming rubber rolls are installed and matched with the first net roll and the second net roll, and part of the deforming rubber rolls are soaked into coating materials of a material trough. The single-trough and dual-roll secondary coating structure is simple in structure, convenient to use, and capable of reducing energy consumption, saving materials, reducing waste and avoiding the quality problems of coating bubbles, poor interlayer bonding, color flooding and the like.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Water-based amino baked varnish for agricultural machine and preparation method thereof

PendingCN106893423AHigh glossImprove the decorative effectCoatingsEnvironmental resistanceWater based

The invention discloses a water-based amino baked varnish for an agricultural machine and a preparation method thereof and belongs to the technical field of coatings. The water-based amino baked varnish is prepared from, by weight, water-based resins incuding 60-70 parts of water-based acrylic resin and 10-15 parts of water-based amino resin, additives including 1-2 parts of environmentally friendly solvent, 0.1-0.2 part of neutralizer, 0.2-0.5 part of antifoaming agent, 1-3 parts of surface isolation agent, 0.4-0.6 part of leveling agent, 0.3-0.5 part of base material wetting agent, 5-10 parts of deionized water and 0.5-1.0 part of thickening agent, and 0.1-0.3 part of adhesion promoter. The problems existing in the prior art can be solved, spraying of a next coating can be performed when a previous is not completely dried, multiple times of spraying can be performed, volatilization of organic solvents in the varnish does not occur in the last time of varnish baking, and pollution to the environment is reduced.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

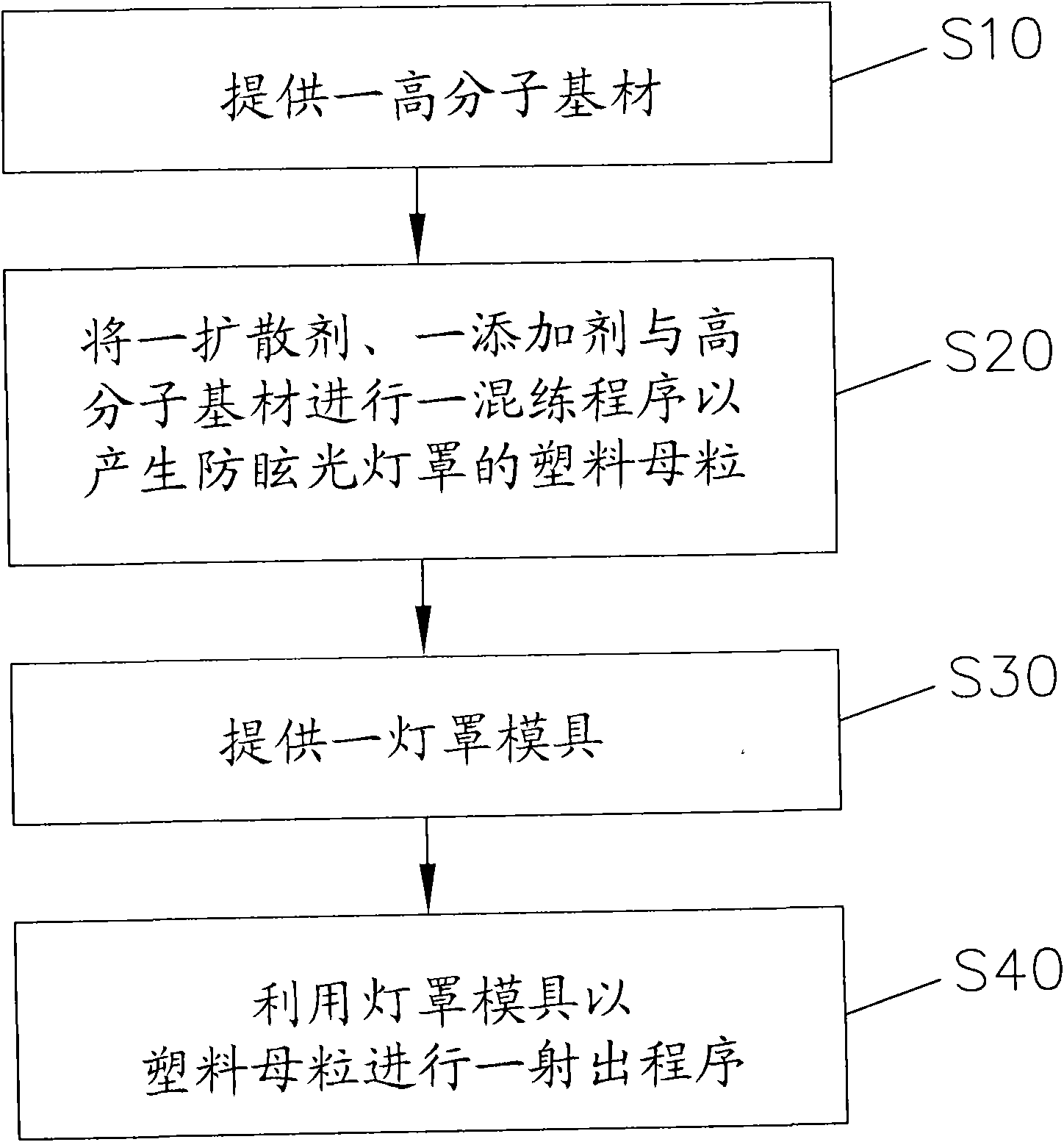

Manufacture method of anti-glare lampshade

InactiveCN101571258ASolve the disadvantage of having to pay an additional paste feeSolve the bubblesGlobesMaterials scienceAir bubble

The invention relates to a manufacture method of an anti-glare lampshade, comprising the following steps: providing a macromolecular substrate; carrying out a fixed refinement procedure to a diffusant, an additive and the macromolecular substrate so as to generate the plastic mother granules of the anti-glare lampshade; and providing a lampshade mould and utilizing the lampshade mould to carry out an ejection procedure by the plastic mother granules. The anti-glare lampshade can be a nonplanar circular arc light diffusion plate. The anti-glare lampshade comprises the macromolecular substrate, the diffusant and the additive, wherein the macromolecular substrate accounts for 90-99.8 of the anti-glare lampshade by weight percent, the diffusant accounts for 0.1-6 of the anti-glare lampshade by weight percent, the additive accounts for 0.1-4 of the anti-glare lampshade by weight percent, and the minimum thickness of the anti-glare lampshade is more than 0.5mm. The invention can solve the defects that the existing anti-glare film has to additionally expend a sticking expense, can generate air bubbles or crimples when being inadequately stuck and can generate air bubbles because of temperature or material aging after being used for a period of time.

Owner:LIGHTFUTURE PHOTOELECTRIC

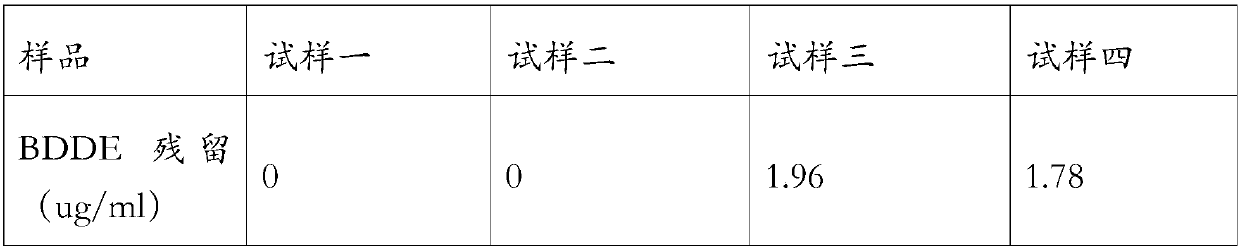

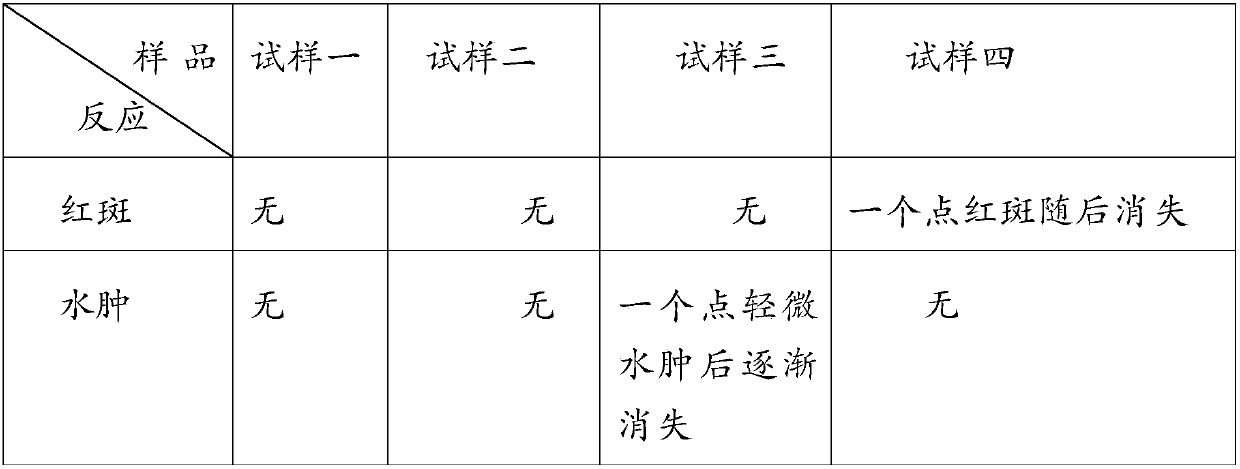

Preparation method of linear cross-linked hyaluronic acid

Belonging to the field of material preparation, the invention discloses a preparation method of a linear cross-linked hyaluronic acid. The method includes: firstly treating a hyaluronic acid raw material to reduce the molecular weight; then mixing an alkaline solution with a cross-linking agent into a mixed solution, adding the hyaluronic acid raw material into the mixed solution and performing stirring till complete dissolution, and then carrying out low temperature cross-linking reaction at 2DEG C-20DEG C for 12h-36h to form a hyaluronic acid gel; then carrying out hot alkali activation cross-linking reaction on the hyaluronic acid gel at 25DEG C-65DEG C for 1h-6.5h to form a gel; and then using PBS dialysate for dialysis treatment on the gel so as to obtain a gel paste.

Owner:HANGZHOU TECHDERM BIOLOGICAL PROD CO LTD

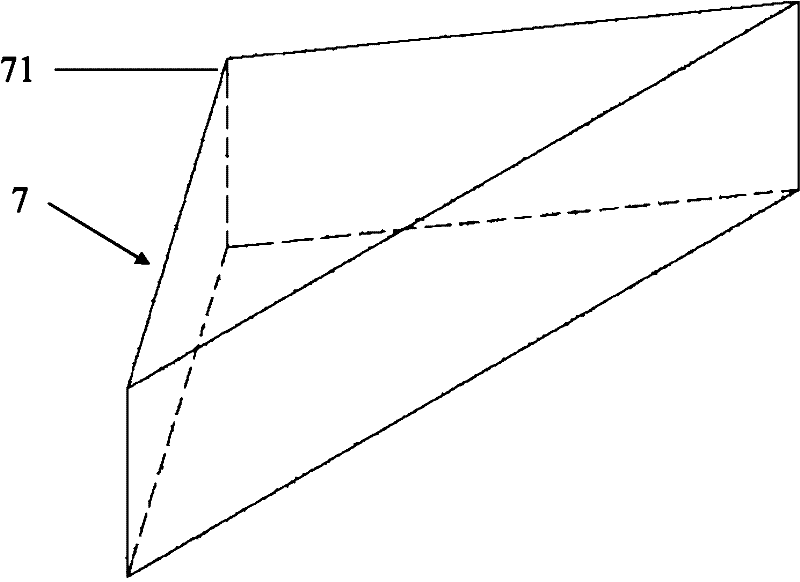

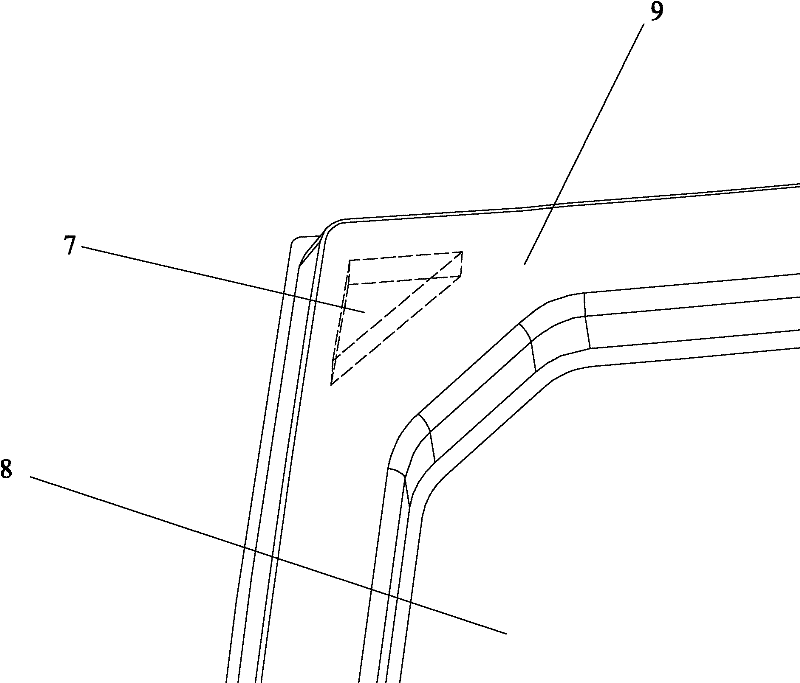

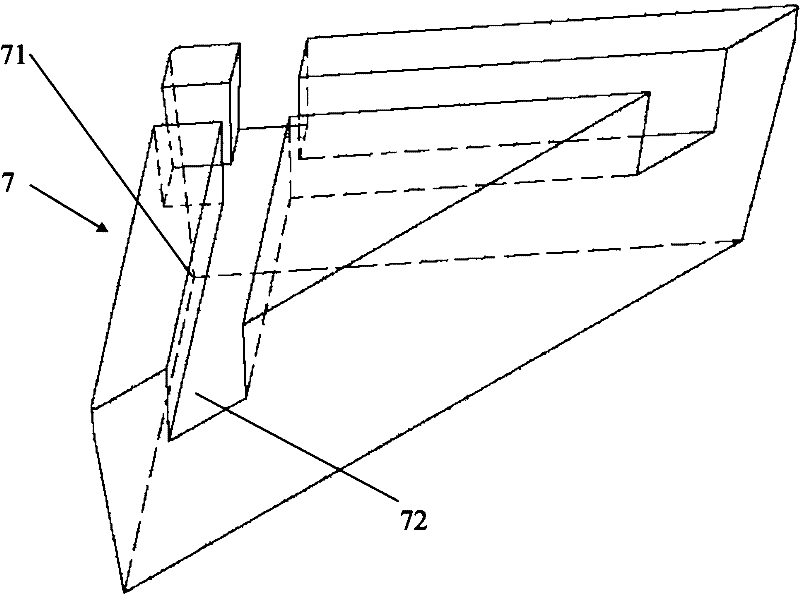

Method for eliminating bubbles of polyurethane (PU) injection moulding corner and obtained glass window

The invention relates to a method for eliminating bubbles of a polyurethane (PU) injection moulding corner and an obtained glass window and belongs to the field of injection moulding, in particular to the field of moulding of PU reaction injection moulding coated edges. The method comprises the steps of cleaning a glass plate and coating a prime coat and is characterized in that: prior to injection moulding, an insert is glued at a peripheral corner of the glass plate; the insert is a triangular block; when positioned in a mould, an edge part of the glass plate and the insert form a corner runner with a mould cavity of the mould; and the sectional area of the corner runner containing the insert is the same as the sectional area of the runner of adjacent spaces in front of or behind the corner, or different from the sectional area by 10 percent or less. The invention has the advantages that: the method is simple in operation, the problem of bubble generation during the injection moulding of PU resins can be effectively solved, and a neat and elegant PU edge-coated glass window can be obtained.

Owner:FUYAO GLASS IND GROUP CO LTD +1

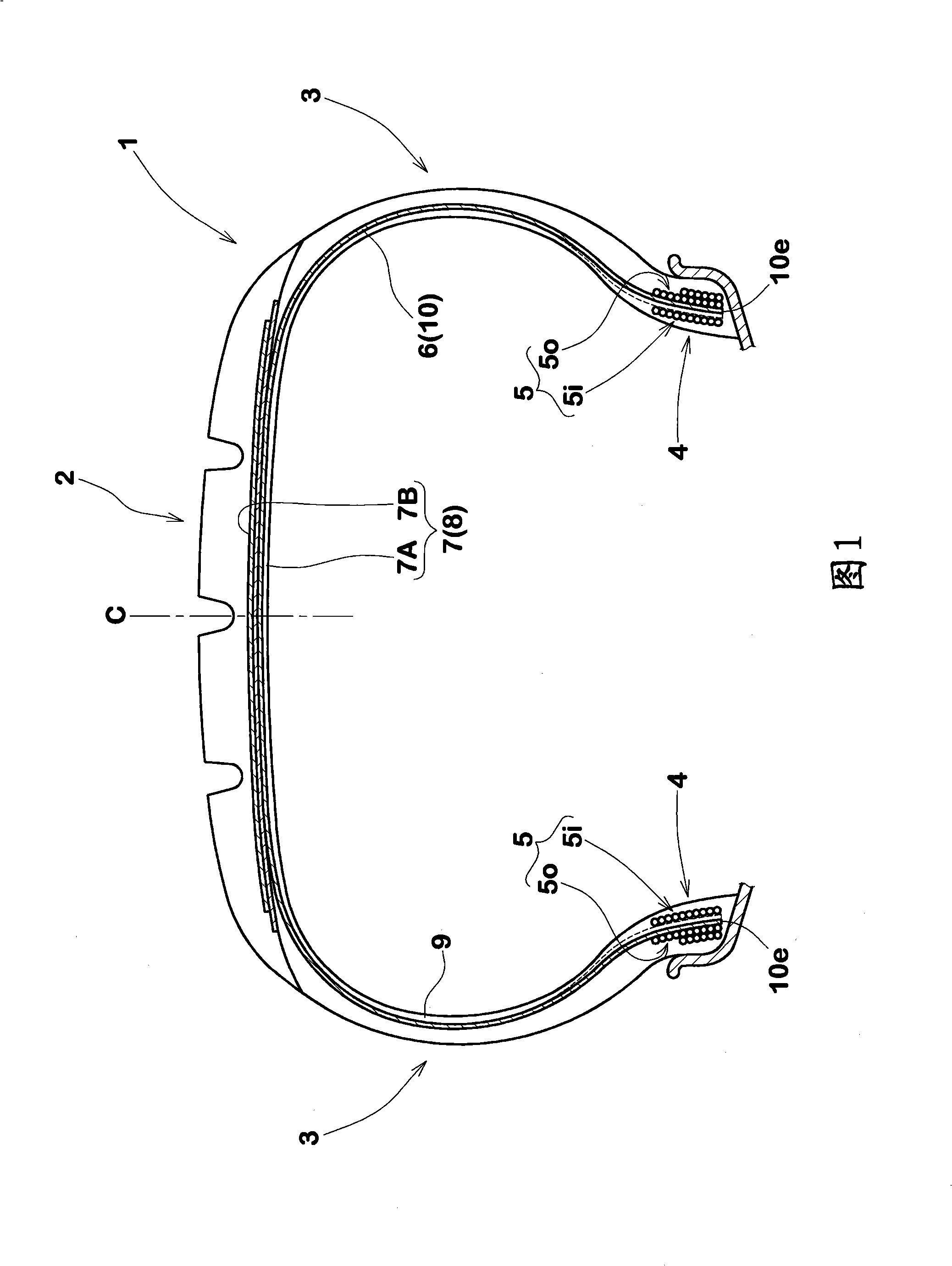

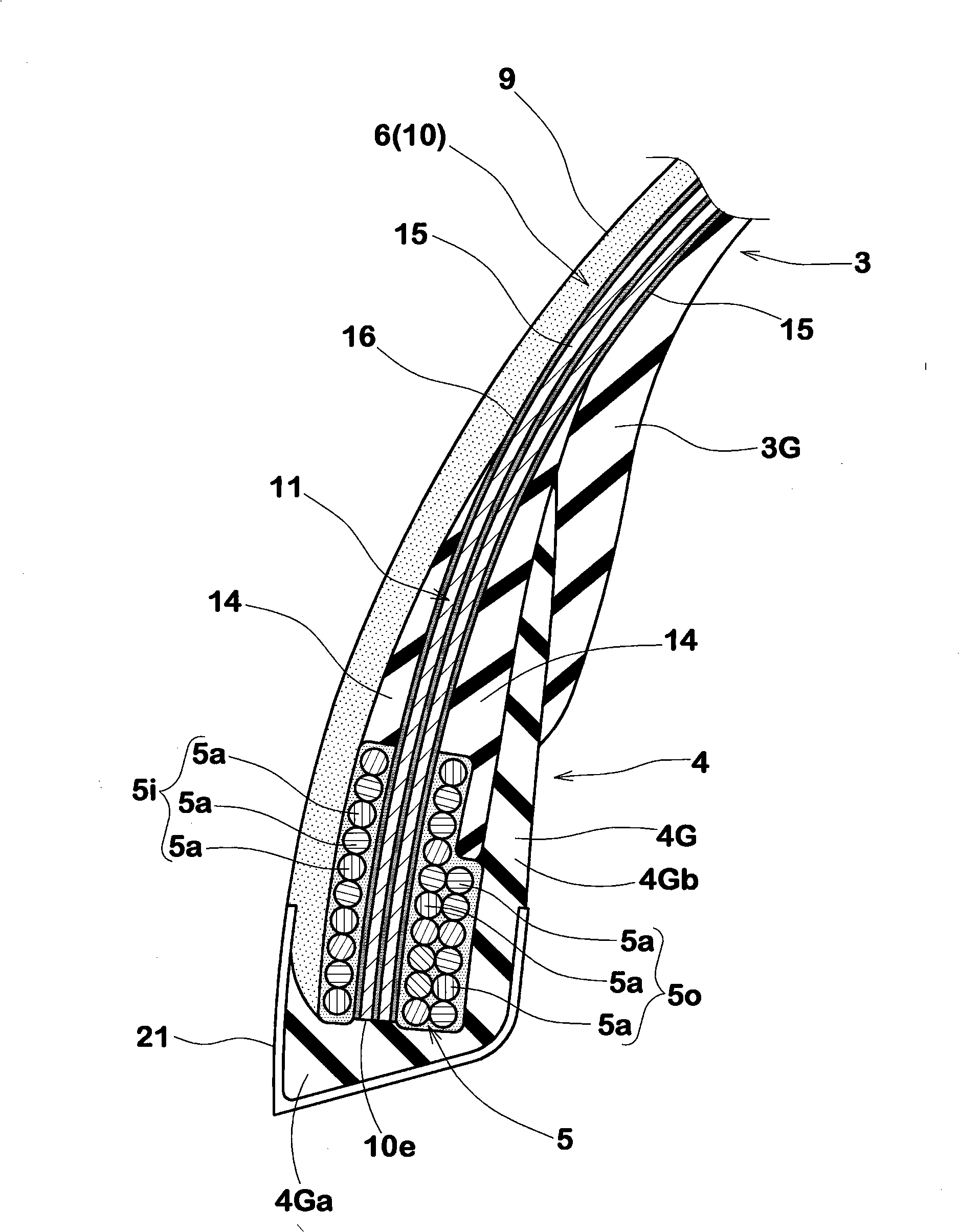

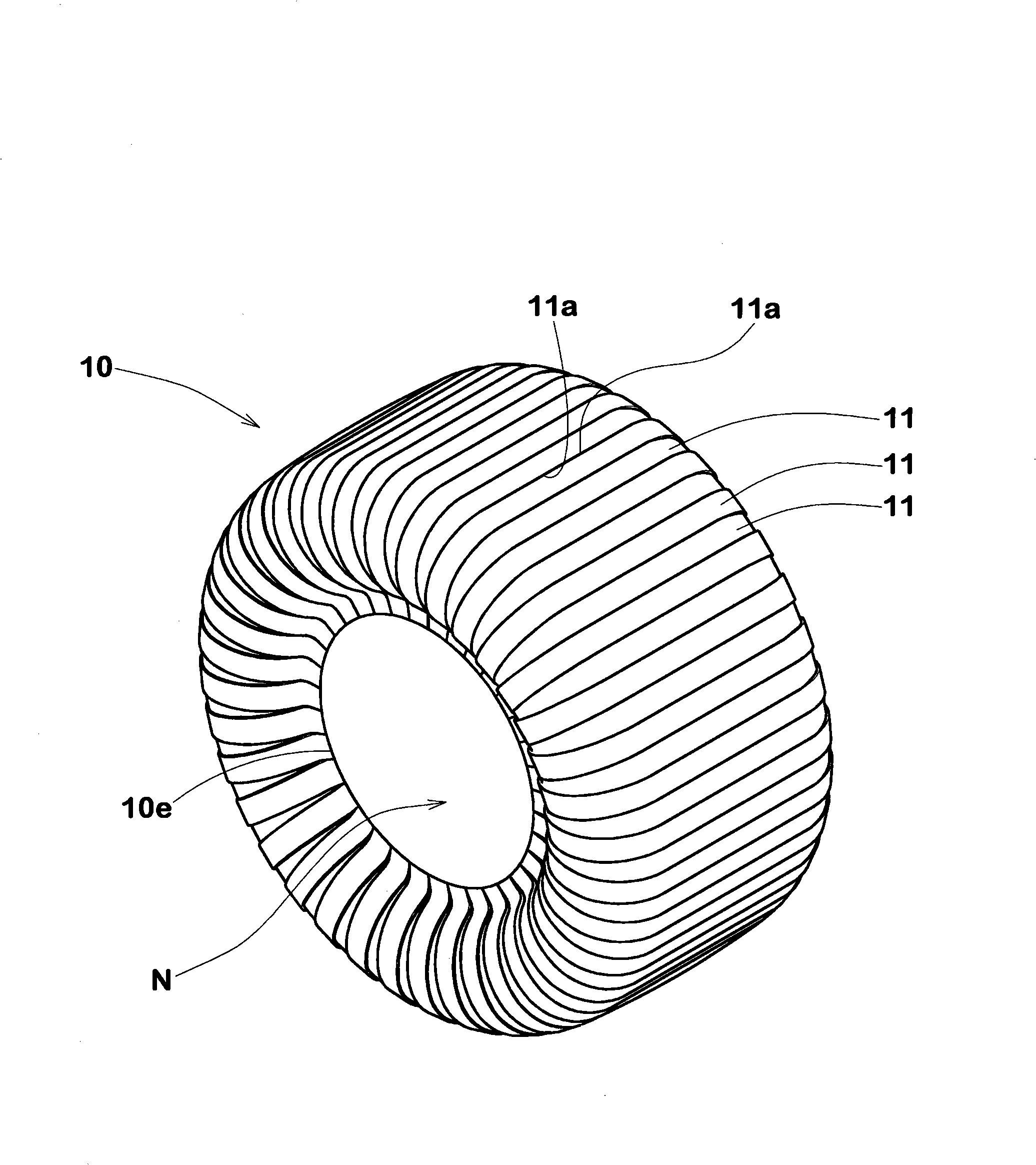

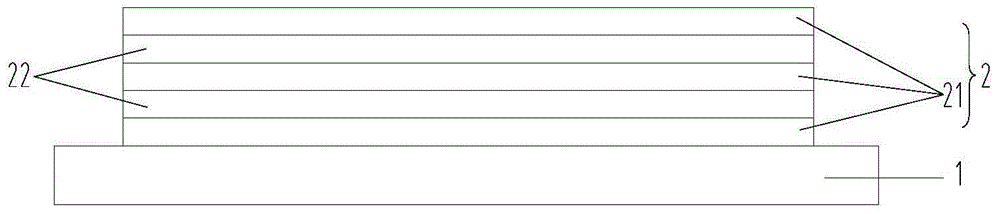

Pneumatic tire and method for manufacturing the same

InactiveCN101318451AEfficient dischargeSolve the bubblesTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

A pneumatic tire comprises a carcass ply extending between bead portions through a tread portion and sidewall portions. The carcass ply is formed by arranging unvulcanized strip pieces around a surface of a toroidal core which surface has a horseshoe-shaped profile, whereby the carcass ply is made up of a plurality of circumferentially arranged strip pieces. The strip pieces are each made of rubberized parallel cords extending between the bead portions through the tread portion and sidewall portions. In the green tire, the strip pieces are each provided on at least one side thereof with a plurality of vent grooves having a depth of 0.1 to 2.0 mm and a width of 0.1 to 3.0 mm.

Owner:SUMITOMO RUBBER IND LTD

Preparation method of carbon fiber solar panel and carbon fiber solar panel thereof

ActiveCN105810776AAvoid wrinklesResolve wrinklesFinal product manufactureLaminationFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber solar panel and the carbon fiber solar panel thereof. Carbon fiber cloth and a plastic package material layer are stacked on a horizontal carrier for many layers and are pressed to form a horizontal carbon fiber panel. A transparent plastic package material layer, a solar battery piece and a transparent plastic package material layer are sequentially and neatly stacked on another horizontal carrier, and are pressed to form a horizontal pre-pressed solar module. The horizontal carbon fiber panel, a plastic package material layer, the horizontal pre-pressed solar module and a transparent plastic package material layer are neatly stacked and pressed to form the horizontal carbon fiber solar panel. According to the invention, the carbon fiber cloth is heat-pressed and prepared into the horizontal carbon fiber panel; the solar battery piece and the transparent plastic package material layers are pre-pressed; the horizontal carbon fiber panel and the solar module are pressed into a whole body through a lamination machine; and the technical problems of carbon fiber cloth fold, bubble, delamination, shift and the like of the carbon fiber panel in a preparation process are solved.

Owner:紫石能源有限公司

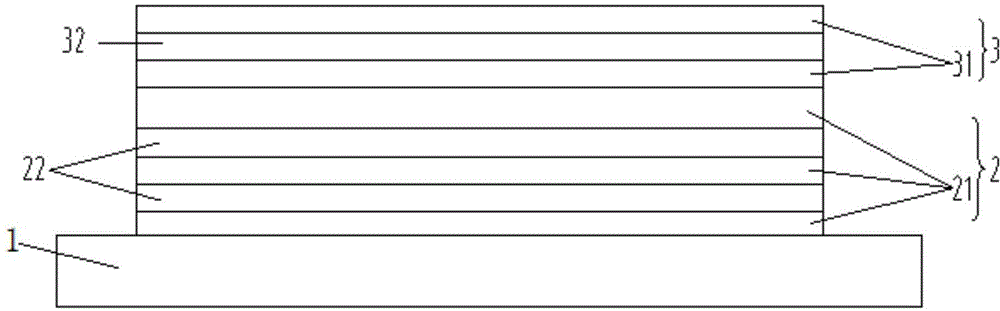

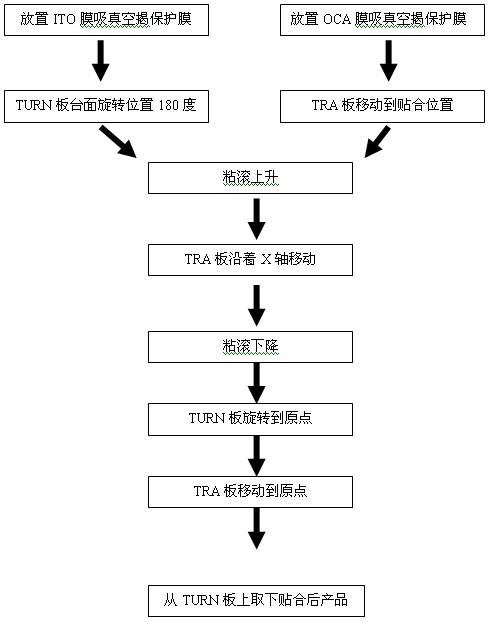

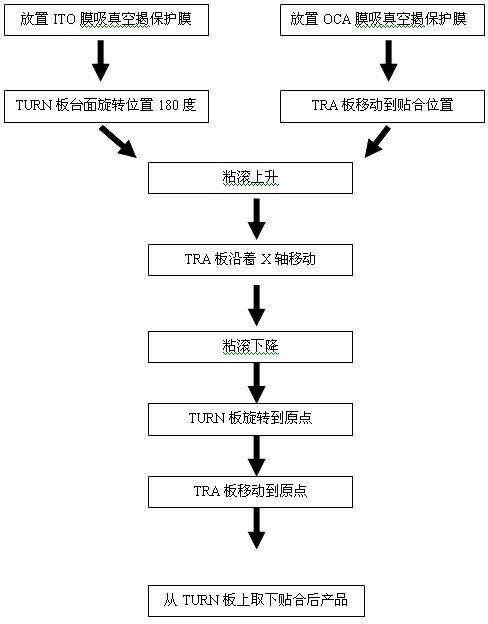

Capacitive touch screen laminating process

InactiveCN102303449ASolve misalignmentSolve the bubblesLaminationLamination apparatusForeign matterVacuum extraction

The invention relates to a capacitive touch screen laminating process. The process comprises the following steps: 1. selecting a lamination program according to the product model; 2. setting lamination parameters and vacuumizing the table board, wherein the pressure is -40 to -85 Kpa, the rolling shaft pressure is 400-600 g, and the shift-out speed is 30-50 cm / min; 3. clicking an original point and resetting a turning plate and a transfer plate; 4. clicking a locating needle button so that the locating needle pops up; 5. placing an optical clear adhesive (OCA) punched with locating holes on the transfer plate so as to carry out vacuum extraction; 6. placing a sheet needing to be laminated on the turning plate so as to carry out vacuum extraction; 7. removing the sheet needing to be laminated and a protective film on the OCA; 8. starting a start button so that equipment works; and 9. after the lamination, taking down the laminated sheet from the turning plate. Through the process, the problems of inaccurate alignment and bubble generation in the lamination process of the touch screen are solved, the lamination alignment precision is improved, the generation of foreign matters and bubbles is reduced, and the requirements on the product appearance are met. The lamination process is simple and fast and suitable for mass production.

Owner:TIANJIN ZHONGHUAN HI TECH

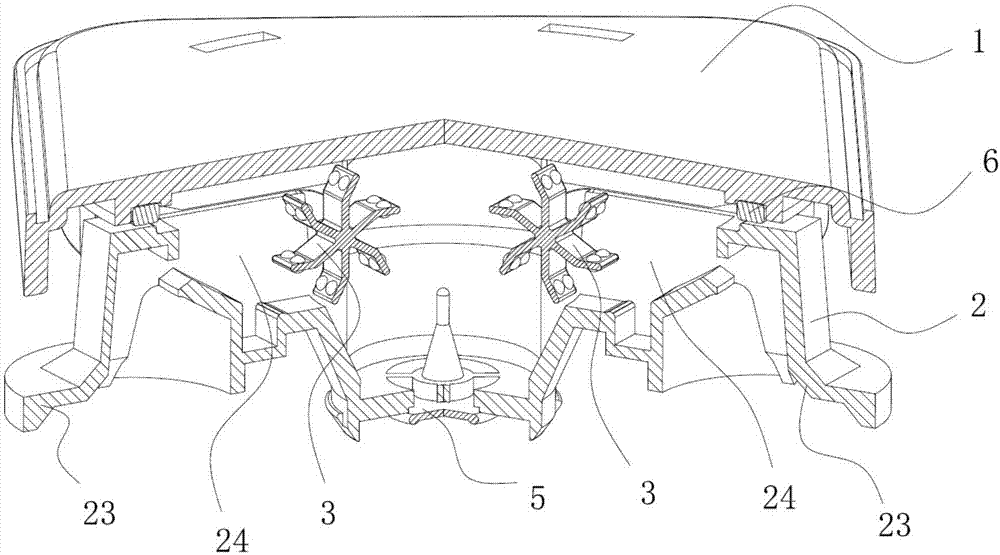

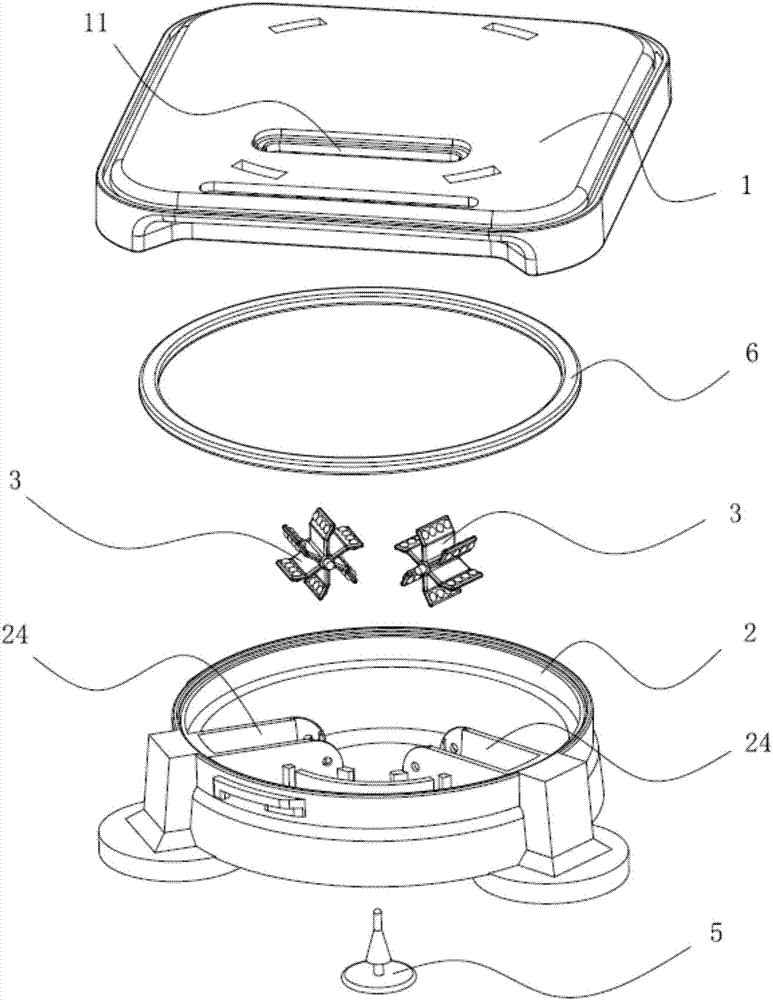

Steam valve assembly and steam heating device

ActiveCN107874600AFully contactedReduce the temperatureSteam cooking vesselsPressure-cookersDischarge efficiencyViscous liquid

The invention discloses a steam valve assembly and a steam heating device, belonging to the technical field of kitchen ware, and being designed aiming at solving the problem of the existing steam valve assembly that viscous liquid is hard to condense to reflow. The steam valve assembly comprises a valve cover, a valve seat and a bubble breaking fan blade, wherein an air outlet is formed in the valve cover, an air inlet communicated with the interior of the steam heating device is formed in the valve seat, the air outlet and the air inlet are respectively communicated with a steam chamber, a steam channel is arranged between the air inlet and the steam chamber, and the bubble breaking fan blade is arranged in the steam channel. The steam heating device comprises the steam valve assembly. According to the bubble breaking fan blade of the steam valve assembly and the steam heating device, formed bubbles in steam with liquid can be broken or crushed, the forming of new bubbles can be prevented, and the temperature of the steam with liquid can be reduced. Gas discharged from the air outlet is mostly common steam instead of steam with liquid, so that the problem that bubbles are formed at the air outlet is solved, the air exhaust temperature is low, the air discharge amount is great and the air discharge efficiency is high.

Owner:GREE ELECTRIC APPLIANCES INC

Manufacturing method and system for gypsum core used for casting of large impeller

The invention discloses a manufacturing method and apparatus for a gypsum core used for casting of a large impeller. The manufacturing method comprises the following steps: 1, inlaying cast mold low-melting-point alloy impeller blades in a gypsum core mold; 2, carrying out mixing to prepare gypsum slurry and adding the mixed gypsum slurry into a vacuum mixer; 3, carrying out vacuum-pumping and vibratory mixing on the gypsum slurry by using the vacuum mixer; 4, injecting the gypsum slurry having undergone bubble removal into the gypsum core under vacuum conditions and carrying out vibration and defoaming by using a vibration machine after completion of injection; 5, strickling the upper end of the gypsum core by using a tool after completion of injection; 6, placing the cured gypsum core on a special gypsum core drying bracket; 7, putting the bracket and the gypsum core into a drying machine; 8, taking the gypsum core and the bracket, separating the gypsum core from the bracket, collecting low-melting-point alloy for reuse, placing the gypsum core on a finishing rack, repairing flaws on the surface of the core and removing unwanted impurities; and 9, detecting the gypsum core before usage of the gypsum core.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

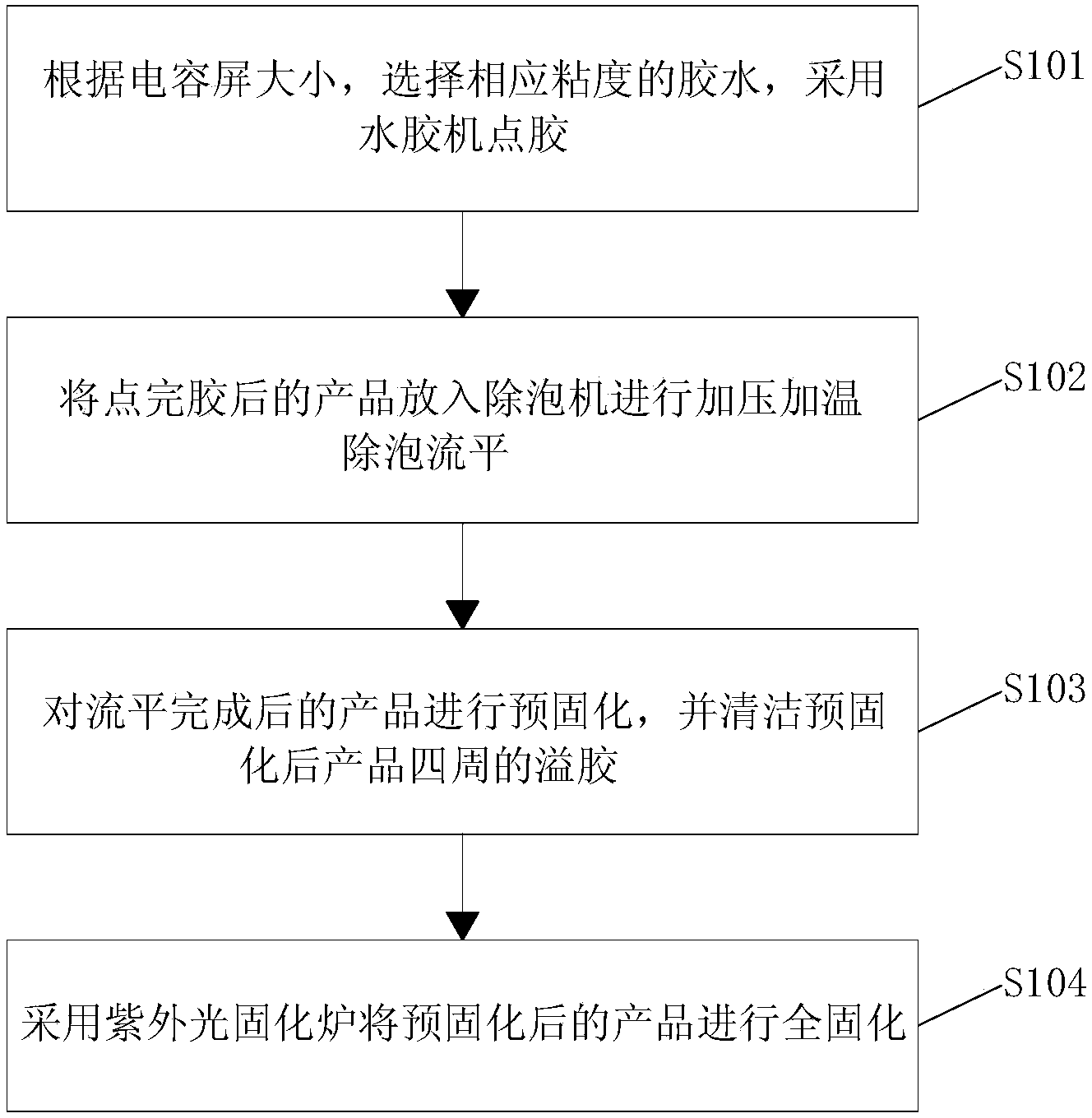

Rapid defoaming and leveling process for glue processing

InactiveCN103522727ASolve the problem of water glue bubblesImprove liquidityLaminationLamination apparatusViscosityPerformance requirement

The invention discloses a rapid defoaming and leveling process for glue processing. The rapid defoaming and leveling process comprises the following steps: A, choosing glue with corresponding viscosity according to the size of a capacitive screen and using a glue machine to dispense glue; B, putting a product with the glue dispensed into a defoaming machine for defoaming and leveling through pressurizing and warming; C, pre-curing the product which is leveled, and cleaning the overflown glue around the cured product; and D, fully curing the pre-cured product by using an ultraviolet light curing oven. According to the rapid defoaming and leveling process for the glue processing, defoaming and leveling are achieved through the pressurizing and warming modes, the yield of the glue processing process is increased, the performance requirements of the glue process on staffs, equipment and the glue are reduced, so that the production cost is lowered, and the rapid development of the glue laminating process is promoted.

Owner:广州市胶云新材料技术研究有限公司

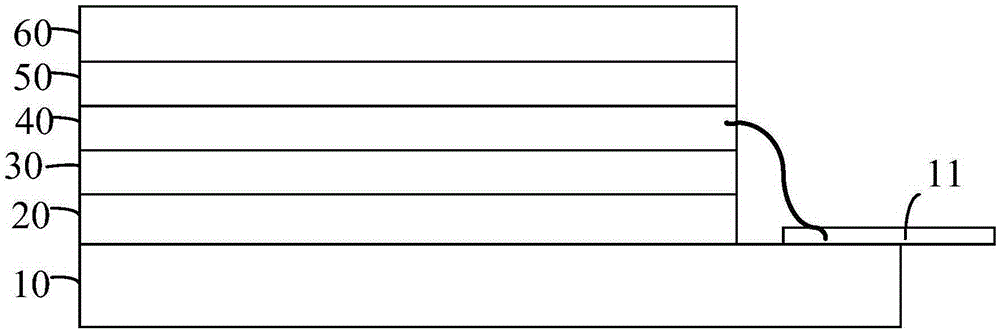

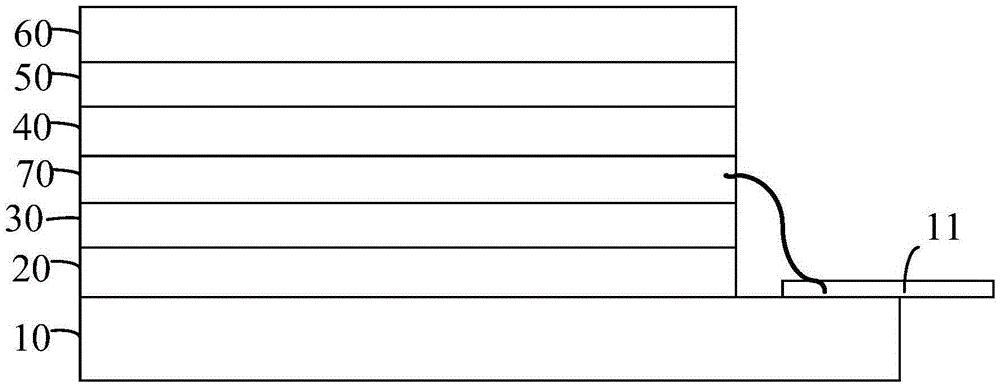

Embedded touch display panel and preparation technology thereof

InactiveCN105425455AReduce manufacturing costSolve the bubblesNon-linear opticsInput/output processes for data processingGlass coverColor gel

The invention discloses an embedded touch display panel and a preparation technology thereof. The embedded touch display panel sequentially comprises a TFT (thin film transistor) substrate, a liquid crystal layer, a color filter, a polarizer and a glass cover plate, wherein the polarizer is a non-conductive polarizer, a transparent conductive layer is arranged between the polarizer and the color filter, a ground pin is also arranged on the TFT substrate, and the transparent conductive layer is electrically connected with the ground pin on the TFT substrate. The transparent conductive layer and the non-conductive polarizer are adopted to replace a high-impedance-state polarizer in the embedded touch display panel, and the production cost is greatly reduced; the partial attachment method of the frame-attached non-conductive polarizer is adopted, so that the bubble problem caused by full-attached polarizers is effectively solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Shear type liquid core coupled surface plasma resonance imaging analyzer

ActiveCN103698304AGuaranteed to be verticalAvoid light distribution changesMaterial analysis by optical meansLiquid coreLight excitation

The invention discloses a shear type liquid core coupled surface plasma resonance imaging analyzer composed of a liquid core coupled surface plasma resonant unit, a surface plasma resonance imaging light excitation arm, a surface plasma resonance imaging light detection arm, a shear type two-arm linkage angle scanning mechanism, an electrical control system and an upper computer. When the shear type liquid core coupled surface plasma resonance imaging analyzer works, the position of a sensor chip is fixed, so that the light excitation angle can be scanned by only linking and rotating the surface plasma resonance imaging light excitation arm and the surface plasma resonance imaging light detection arm, an excited ray can be always vertical to an incident light window, and a reflected ray can be always vertical to an emitting light window, and furthermore, the defect of position offset of surface plasma resonance excitated light spots of the traditional instrument is overcome; and the shear type liquid core coupled surface plasma resonance imaging analyzer has the advantages such as no need of excited light angle correction, no need of binding oil, multi-interface reflection interference reduction and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com