Melt-and-play glue melting device

A technology of melting glue and glue tank, which is applied in the field of instant melting glue device, which can solve the problems of affecting production efficiency, long melting time, and increased defect rate of glue injection products, and achieve the effect of saving glue and cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

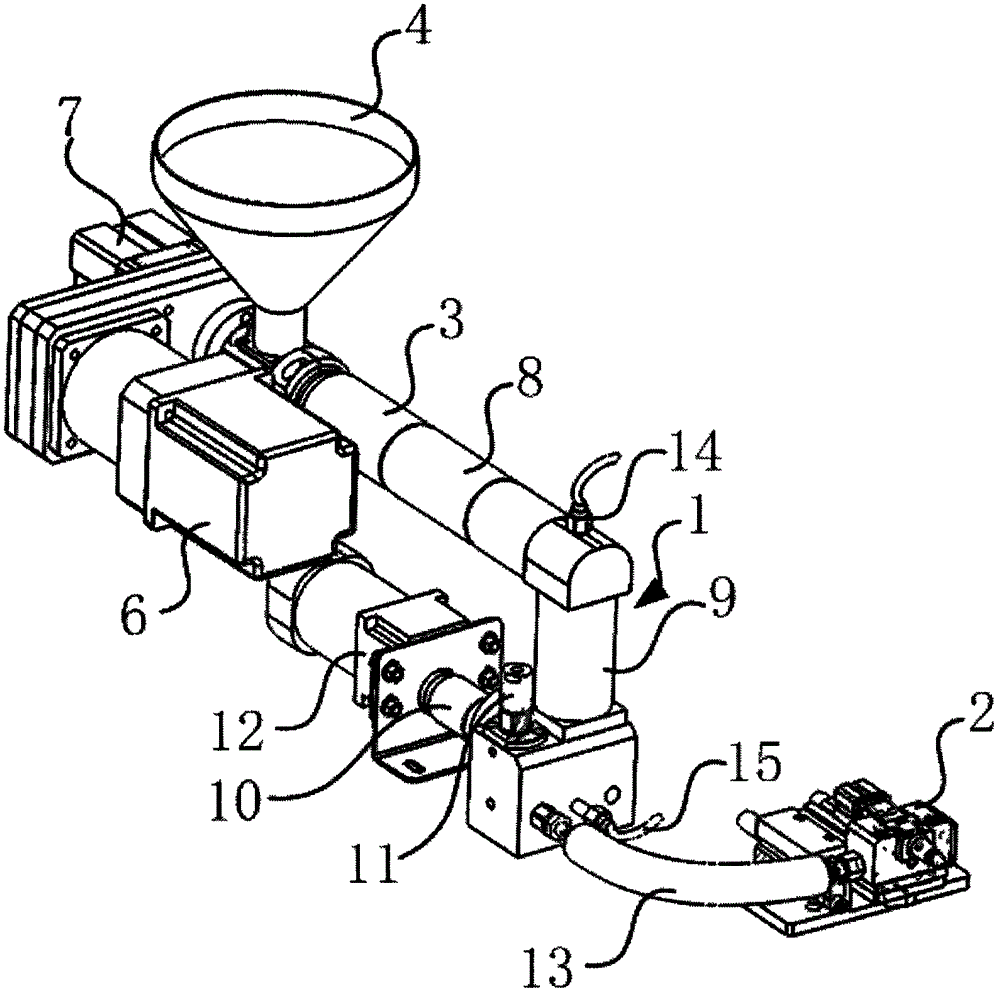

[0021] The specific implementation of the instant melt adhesive device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see figure 1 , figure 2 and image 3 As shown, the instant melt glue device of the present invention includes a glue tank 1 and a glue injection gun nozzle 2 . The glue tank 1 is used to store liquid glue, and the glue injection gun nozzle 2 is used to spray liquid glue.

[0023] The instant melt glue device also includes a delivery pipe 3 connected with the glue tank 1 . A hopper 4 is connected with the delivery pipe 3 . The solid glue is loaded through the hopper 4 and enters the delivery pipe 3, where the solid glue is transformed into a liquid glue.

[0024] A screw rod 5 is arranged in the delivery pipe 3, and the screw rod 5 rotates to melt the solid rubber material into a liquid rubber material. The screw rod 5 drives the solid rubber material to rotate, and the solid rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com