Manufacturing method and system for gypsum core used for casting of large impeller

A production method and technology of gypsum molding, which is applied to casting molding equipment, cores, casting molds, etc., can solve problems such as prone to air bubbles, complex impeller structure, and reduced contact area between the bottom and air, and achieve accurate molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

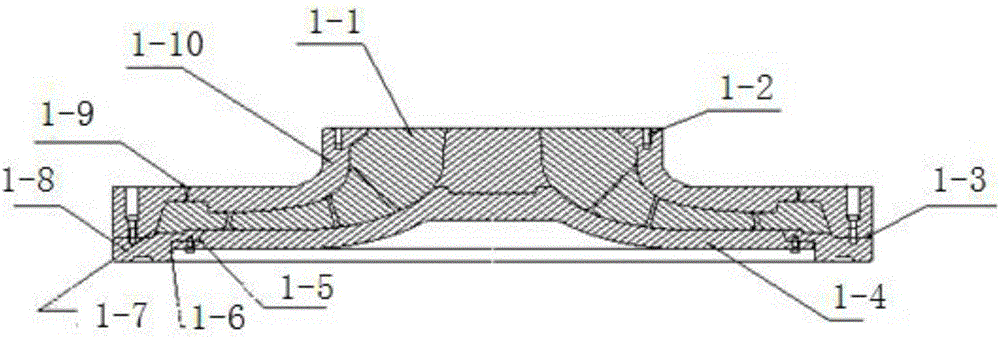

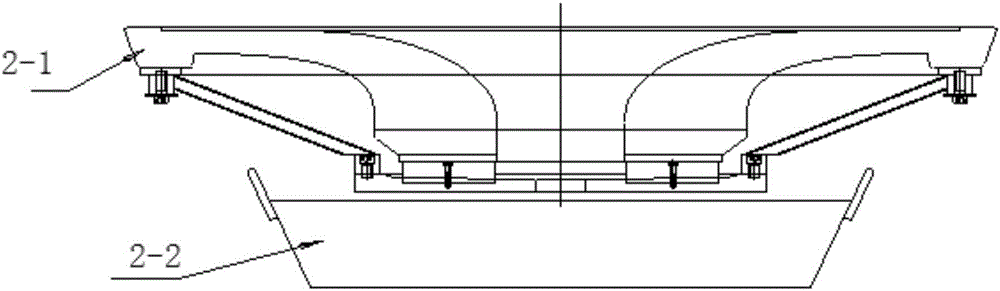

[0052] Below in conjunction with accompanying drawing, take the gypsum core of aluminum alloy impeller casting as example, the content among the present invention is described in detail:

[0053] The gypsum core manufacturing method that the large-scale impeller casting that the present invention uses comprises the following steps:

[0054] Step 1. Embed the cast low-melting point alloy blade in the plaster mold;

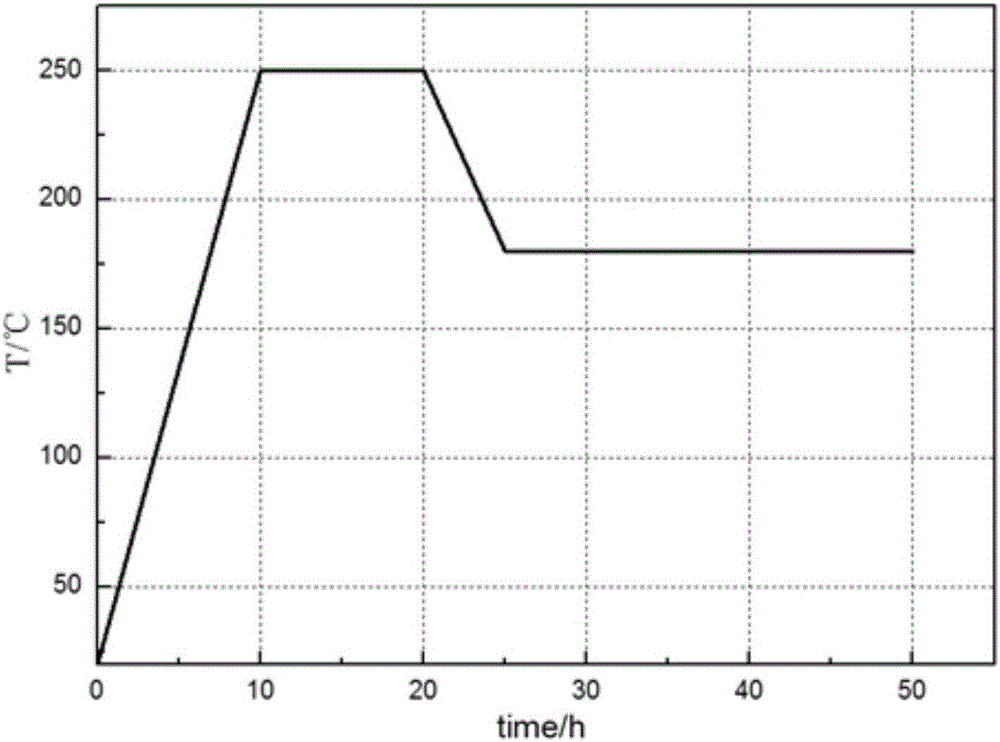

[0055] Step 2. Weigh 50-60Kg of gypsum powder, weigh 25-35Kg of pure water, mix them to make gypsum slurry, control the water temperature between 15-25°C, and put them into a vacuum mixer after mixing;

[0056] Step 3. When the vacuum degree of the vacuum mixer reaches 0.1Mpa, use the vacuum mixer to vacuumize and vibrate the mixed gypsum slurry. The rotation speed is 250-300rpm, the stirring time is 5±1min, and the vibration frequency is 1-5Hz, so that the gypsum is stirred evenly and the air bubbles in the gypsum are discharged;

[0057] Step 4. Pour the gypsum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com