Steam valve assembly and steam heating device

A steam heating device and steam valve technology, applied in the field of kitchen utensils, can solve the problems of reducing the reflux speed of viscous liquid and the difficulty of normal condensation of viscous liquid, and achieve the effects of fast reflux speed, large exhaust volume and high exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

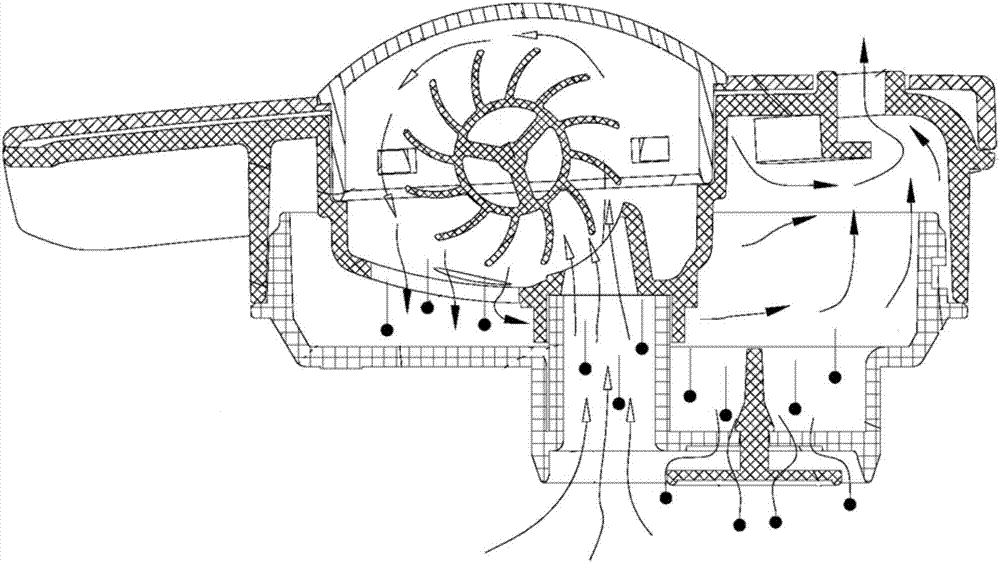

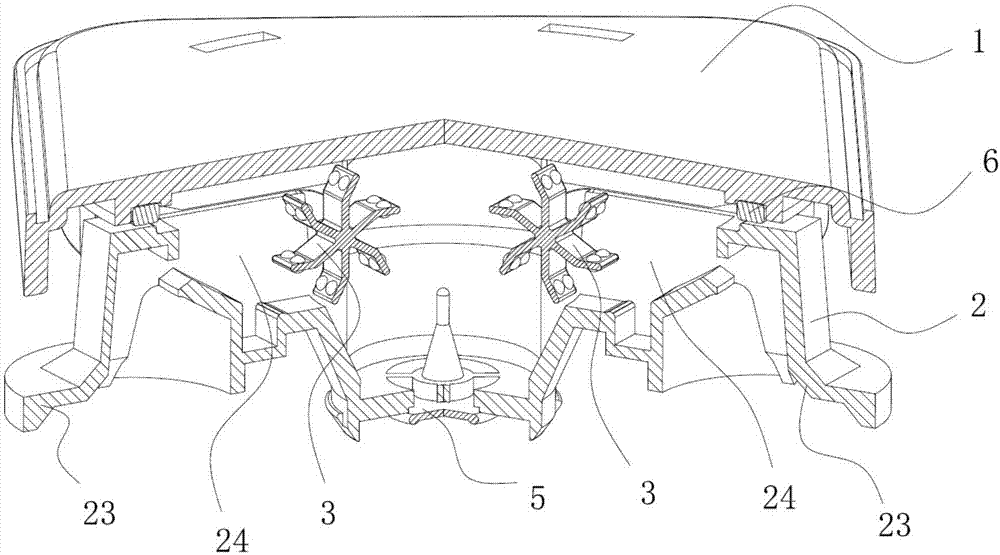

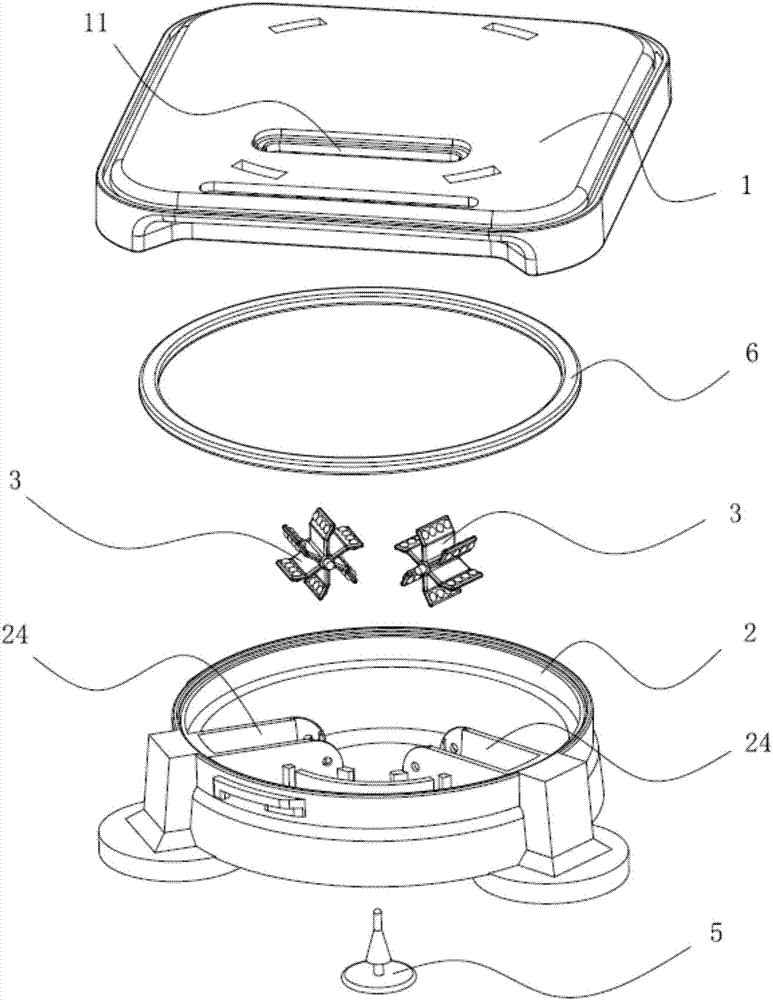

[0046] This embodiment discloses a steam valve assembly and a steam heating device including the steam valve assembly. Such as figure 2 and image 3 As shown, the steam valve assembly includes a valve cover 1, a valve seat 2 and a bubble-breaking fan blade 3. The valve cover 1 is provided with an air outlet 11, and the valve seat 2 is provided with an air inlet 23 communicating with the interior of the steam heating device. , the air outlet 11 and the air inlet 23 communicate with the steam chamber 4 respectively. A steam passage 24 is provided between the air inlet 23 and the steam chamber 4 , and the bubble-breaking fan blade 3 is arranged in the steam passage 24 . In order to prevent steam leakage from the periphery of the steam valve assembly, a sealing ring 6 is provided between the valve cover 1 and the valve seat 2 . After a certain amount of viscous liquid accumulates at the bottom of the steam chamber 4, it will press the return pad 5 to open it, and the viscous l...

Embodiment 2

[0064] This embodiment discloses a steam valve assembly and a steam heating device including the steam valve assembly, the structure of which is basically the same as that of Embodiment 1. The difference is that: if Figure 16 As shown, the bubble-breaking fan blade 3 is installed in the valve cover blade installation hole 13 on the valve cover 1. After the valve cover 1 and the valve seat 2 are installed, the bubble-breaking fan blade 3 is still located in the steam channel 24, and its function And the method of use is the same as in Example 1.

[0065] Such as Figure 17 and Figure 18 As shown, only one steam channel 24 is provided between the air inlet 23 and the steam chamber 4, the manufacturing cost is lower, and the flow of steam is easier to be effectively controlled.

[0066] The rotating shaft of the bubble-breaking fan blade 3 can also be vertically arranged between the valve cover 1 and the valve seat 2, so that the efficiency of crushing or squeezing the bubbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com