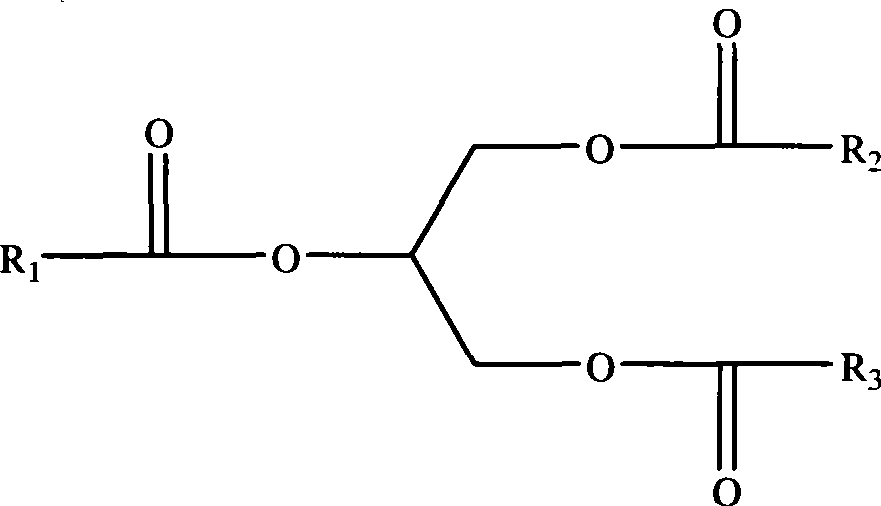

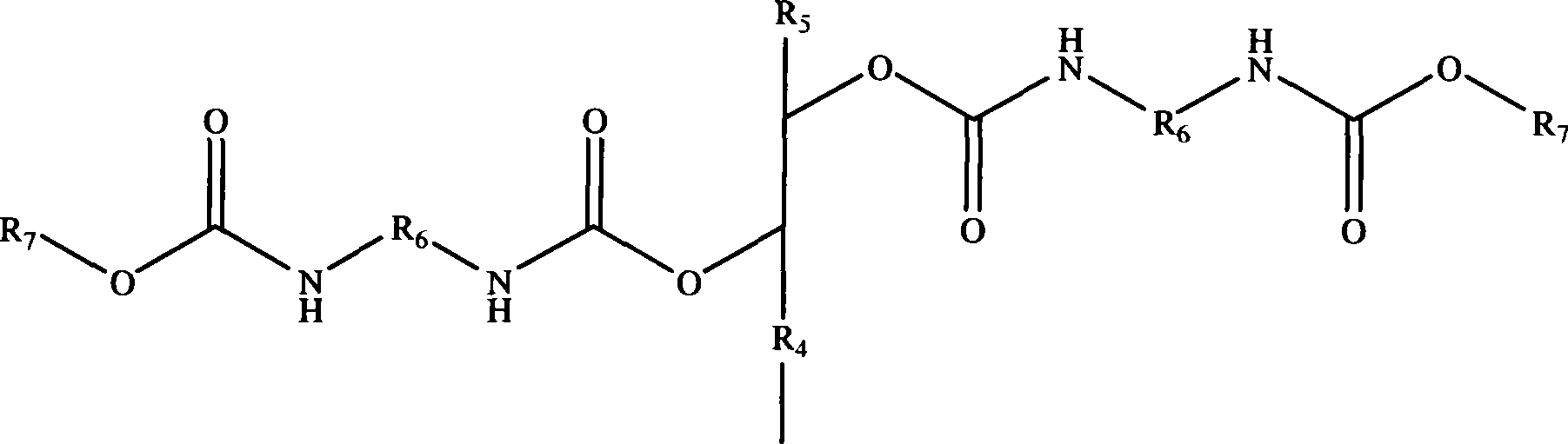

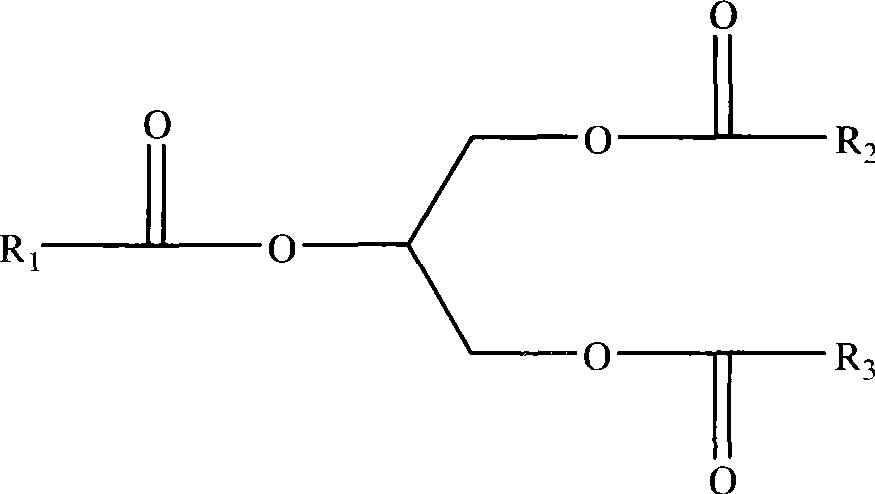

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

A polyurethane acrylate and vegetable oil-based technology, which is applied in polyurea/polyurethane coatings, chemical instruments and methods, surface etching compositions, etc., can solve the problems of high raw material costs and achieve low operating costs, wide sources, and simple preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 15mL of 30wt% hydrogen peroxide dropwise to 1.8g of tungsten powder and 7mL of water during stirring, then heat to 50°C and stir for 30 minutes. When the tungsten powder is completely dissolved, cool the solution and add 1.38g of 85% hydrogen peroxide of phosphoric acid and 14mL of water. Add 400 mL of soybean oil and 2.64 g of methyltrialkylammonium chloride into the reactor, and heat to 50° C. while stirring. Add the acidic tungsten powder solution into the above reactor with vegetable oil, then add 600mL of water, 120mL of phosphoric acid and 212mL of hydrogen peroxide. The mixture was also heated to 100°C and stirred rapidly for 6 hours. Then cool, add 250 mL of saturated sodium chloride solution and 500 mL of dichloromethane, separate the organic layer, and wash twice with 250 mL of saturated sodium chloride solution. The organic layer was dried with anhydrous magnesium chloride, filtered, and the solvent was distilled off under reduced pressure to obtain...

Embodiment 2

[0042] The preparation method of vegetable oil-based urethane acrylate is the same as in Example 1, only replace soybean oil with equimolar peanut oil in (1), the solvent is changed to toluene, the catalyst is changed to stannous octoate, and the polymerization inhibitor is changed to hydroquinone . The product is identified by infrared spectroscopy, when the isophorone diisocyanate (IPDI) isocyanate (NCO) infrared characteristic peak 2270cm -1 When it disappears, the reaction ends and peanut oil-based urethane acrylate is obtained. The yield was 82%.

Embodiment 3

[0044] (1) Add 10mL of 30wt% hydrogen peroxide dropwise to 1g of tungsten powder and 3mL of water during stirring, then heat to 30°C and stir for 30 minutes. When the tungsten powder is completely dissolved, cool the solution and add 1g of 85% phosphoric acid and 10 mL of water. Add 400 mL of soybean oil and 2 g of methyltrialkylammonium chloride into the reactor, and heat to 50° C. while stirring. Add the acidic tungsten powder solution into the above reactor with vegetable oil, then add 300mL of water, 100mL of phosphoric acid and 200mL of hydrogen peroxide. The mixture was heated to 100°C and stirred rapidly for 6 hours. After cooling, add 100 mL of saturated sodium chloride solution and 300 mL of dichloromethane, separate the organic layer, and wash twice with 100 mL of saturated sodium chloride solution. The organic layer was dried with anhydrous magnesium chloride, filtered, and the solvent was distilled off under reduced pressure to obtain the polyhydroxy soybean oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com