Environment-friendly fluorinated polyurethane-polyacrylate emulsion and preparation method thereof

A polyacrylate emulsion and acrylate technology, applied in the field of polymer chemistry, can solve problems such as poor stability, pollution, and unfavorable application performance of fluorine-containing emulsion products, and achieve the effects of improving water resistance, improving surface properties, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

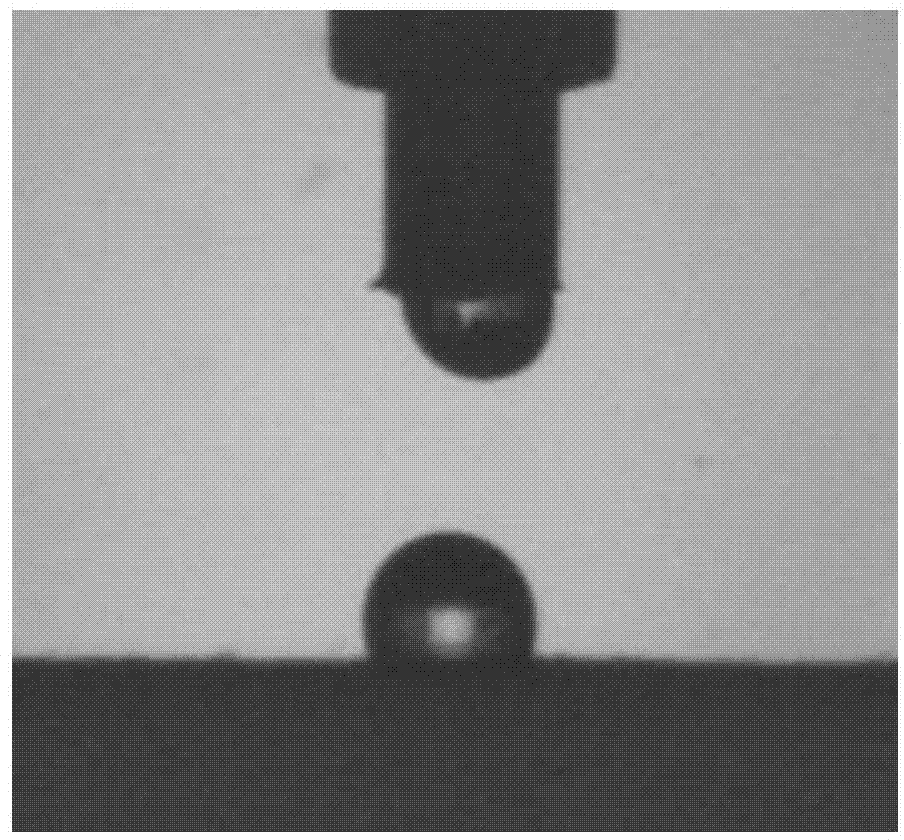

Image

Examples

preparation example Construction

[0031] A kind of preparation method of organic solvent-free fluorine-containing polyurethane-polyacrylate emulsion of the present invention comprises the following steps:

[0032] (1) Mix 5-10 parts of vinyl monomer, 0.5-2.5 parts of fluorine-containing methacrylate or fluorine-containing acrylate to prepare solution A;

[0033] (2) Add 1.5 to 2 parts of polyols, 7 to 9 parts of diisocyanate compounds, 1 to 2 parts of anionic hydrophilic chain extenders and 0 to 0.095 parts of catalysts in solution A, the reaction temperature is 70 to 85 °C, and the reaction time is Obtain polyurethane prepolymer solution B after 2~4 hours;

[0034] (3) Then, add 1 to 4 parts of hydrophilic vinyl monomer to solution B for capping, react for 0.5 to 2 hours, then cool the system temperature to 30 to 50°C, and then add 0.8 to 1.9 parts of organic Alkali, neutralize for 20 to 30 minutes, then add 60 to 100 parts of small molecule post-chain extender aqueous solution with a concentration of 0.5% t...

Embodiment 1

[0038] Mix 6 parts of methyl methacrylate, 4 parts of butyl acrylate, and 2.5 parts of perfluorooctyl ethyl acrylate to prepare solution A; add 1.5 parts of polycaprolactone diol, 7 parts of iso Phorne diisocyanate compound, 1.5 parts of anionic hydrophilic chain extender dimethylol butyric acid and 0.05 part of catalyst dibutyltin dilaurate, the reaction temperature is 70 ° C, and the reaction time is 4 hours to obtain polyurethane prepolymer solution B; Then, add 1 part of hydrophilic vinyl monomer hydroxyethyl acrylate to solution B for capping, react for 1 hour, then cool the system temperature to 30°C, then add 1.4 parts of organic base triethylamine to neutralize React for 30 minutes, then add 60 parts of sodium ethylenediaminoethanesulfonate aqueous solution with a concentration of 1%, and disperse with high-speed stirring for 30 minutes to obtain polyurethane dispersion C; add water-soluble initiator ammonium persulfate to dispersion C, and disperse The mass ratio of b...

Embodiment 2

[0040]Mix 5 parts of methyl acrylate, 4.5 parts of ethyl methacrylate, and 2 parts of dodecafluoroheptyl acrylate to prepare solution A; add 2 parts of polyhexamethylene adipate, 9 parts of toluene di Isocyanate, 2 parts of anionic hydrophilic chain extender dimethylol propionic acid and 0.095 parts of catalyst dibutyltin diacetate, the reaction temperature is 75 ° C, and the reaction time is 3 hours to obtain polyurethane prepolymer solution B; then, in solution B Add 4 parts of hydrophilic vinyl monomer hydroxyethyl methacrylate for capping, react for 0.5 hours, then cool the system temperature to 35°C, then add 1.9 parts of organic base trimethylamine, neutralize for 30 minutes, and then Adding 100 parts of sodium ethylenediamine di-o-phenyl acetate aqueous solution with a concentration of 1.5%, stirring and dispersing at a high speed for 40 minutes, obtained polyurethane dispersion C; adding water-soluble initiator potassium persulfate to dispersion C, dispersion C and pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com