Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Dibutyltin diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyltin diacetate was tested at doses of 0, 33, 100, 333, 1000, and 3333 ug/plate in four Salmonella typhimurium strains (TA98, TA100, TA1535, and TA1537) in the presence and absence of Aroclor-induced rat or hamster liver S9.

Single-component silicone seal gum for solar component and method for manufacturing same

InactiveCN101654609AMeet the needs of rapid productionMeet the use requirementsAdhesivesSemiconductor devicesDrying timeVinylsilane

The invention relates to a macromolecular bonding seal material, in particular to a single-component silicone seal gum for a solar component used in a solar optoelectronic conversion device and a method for manufacturing the same. The single-component silicone seal gum for the solar component comprises the following raw materials in portion by weight: 50 to 60 portions of hydroxyl terminated polydimethyl siloxane, 55 to 60 portions of calcium carbonate reinforcing agent, 0.5 to 1 portion of dibutyltin diacetate catalyst, 55 to 60 portions of methyl silane coupling agent, and 1 to 2 portions ofvinyl silane coupling agent. Tests show that when the single-component silicone seal gum, produced by adopting the components and the method, is used for producing seal materials of the solar components, the seal materials have good weather resistance, a the surface drying time kept within 6 to 8 minutes in general, meet needs for quick scale production of the large-scale solar components, and meet the use requirements of the solar components on other items such as electrical property and the like.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Attapulgite-based polymer material additive as well as preparation method thereof and application thereof in preparation of flame-retardant polymer materials

The invention discloses an attapulgite-based polymer material additive. The attapulgite-based polymer material additive is attapulgite which is chemically grafted with dibutyltin diacetate on the surface. The attapulgite-based polymer material additive can be obtained by enabling attapulgite to react with the dibutyltin diacetate in an organic solvent at 60-100 DEG C. The attapulgite-based polymermaterial additive can significantly improve the crusting property of polymer materials, has the macro performance of flame retardancy, reduces flue gas emission, reduces toxicity during combustion, increases carbon residual rate after combustion, and can be used for preparing flame-retardant polymer materials such as a halogen-free low-smoke flame-retardant cable material.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC +1

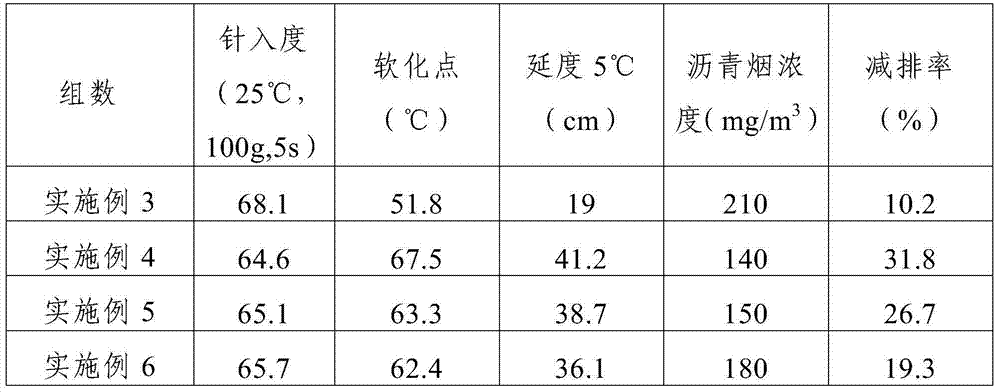

Composite modified asphalt

The invention discloses a composite modified asphalt. The composite modified asphalt is prepared from, by weight, 95 to 105 parts of asphalt, 2 to 9 parts of spodumene powder, 1 to 10 parts of boron carbide powder, 0.5 to 1.5 parts of 3-(isobutylene acyloxy)propyltrimethoxysilane, 0.1 to 1 part of dibutyltin diacetate, 1 to 5 parts of a fire retardant, and 0.2 to 0.9 part of a dispersant. The composite modified asphalt is capable of satisfying requirements on asphalt road using performance, possesses excellent heat mixing emission reduction effect, the release amount of glance coal in blendingprocess can be reduced effectively, construction environment can be improved, and excellent economical and social benefit is achieved.

Owner:杭州睿琦化工科技有限公司

High-refractive-index organic silicon material for LED encapsulation

InactiveCN104130585AHigh refractive indexHigh strengthSemiconductor devicesAntioxidantRefractive index

The invention discloses a high-refractive-index organic silicon material for LED encapsulation. The organic silicon material is prepared from the following components in parts by weight: 20-30 parts of methyltrimethoxysilane, 20-30 parts of triethylchlorosilane, 3-6 parts of hexahydrophthalic anhydride, 5-10 parts of aluminium acetylacetonate, 0.5-5 parts of triphenyl phosphine, 1-3 parts of dibutyltin diacetate, 0.5-2.5 parts of cobalt caprylate, 1.5-3 parts of acryloyl siloxane, 1.5-3 parts of methacryloyl siloxane, 5-15 parts of vinyl-terminated poly-methyl-vinyl silicon oil, 0.5-2.5 parts of an antioxidant, 0.5-2.5 parts of ultraviolet absorber and 5-10 parts of nano-silicon dioxide, wherein the antioxidant is tris-(2,4-di-tert-butyl-pheny)-phosphite, and the ultraviolet absorber is a benzotriazole absorbent. According to the high-refractive-index organic silicon material, the refractive index, the ultraviolet resistance and other performances of the organic silicon LED encapsulation materials can be effectively optimized and reinforced by adding the nano-silicon dioxide, the antioxidant and the ultraviolet absorber, and the strength and cohesiveness of the organic silicon materials can be effectively strengthened while high refractive index and excellent high temperature resistance of the organic silicon materials can be maintained.

Owner:TONGLING GUOXIN LIGHT SOURCE TECH DEV

Composite modified asphalt

InactiveCN104262978AGood storage stabilityEvenly dispersedBuilding insulationsSocial benefitsEpidote

The invention provides composite modified asphalt which is prepared from the following raw materials in parts by weight: 100 parts of asphalt, 3-12 parts of epidote powder, 3-12 parts of rhyolite powder, 0.1-3 parts of stannite powder, 0.1-2 parts of gamma-aminopropyl triethoxysilane, 0.1-0.8 part of dibutyltin diacetate and 0-0.8 part of dispersing agent. According to the benefits of the composite modified asphalt, the composite modified asphalt has the efficacies of hot mixing and emission reduction while the asphalt pavement performance can be met, the release quantity of asphalt fume in the mixing process can be effectively reduced, the construction surrounding environment is improved, and the economic benefit and the social benefit are good.

Owner:CHANGAN UNIV

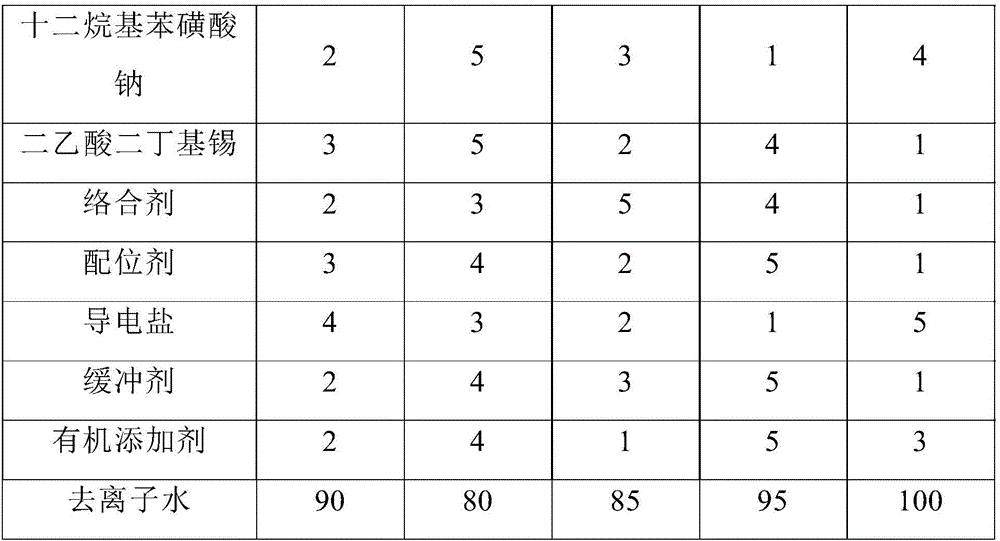

Electrochromism solution for gridiron and electrochromism method thereof

The invention provides an electrochromism solution for a gridiron and an electrochromism method thereof. The solution comprises, by weight parts, 40-50 parts of chromic salt, 20-30 parts of cobalt sulfate, 10-20 parts of sodium sulphate, 15-25 parts of potassium sulfate, 15-30 parts of magnesium sulfate, 5-10 parts of sodium dodecyl sulfate, 5-10 parts of nano-sized aluminum nitride, 1-5 parts of sodium dodecylbenzene sulfonate, 1-5 parts of dibutyltin diacetate, 1-5 parts of complex agent, 1-5 parts of coordination agent, 1-5 parts of conducting salt, 1-5 parts of buffering agent, 1-5 parts of organic additives and 80-100 parts of deionized water. The chromic salt is adopted for the electrochromism solution, and the electrochromism solution is environmentally friendly and favorable for production workers' health, does not contain harmful metals such as lead, cadmium and mercury and is high in plating thickness, hardness and corrosion resistance.

Owner:苏州市相城区星火粉沫涂料厂

Alkenyl succinic anhydride, and preparation method and application thereof

ActiveCN106316997AThe synthesis process is simpleShort reaction timeOrganic chemistryDibutyltin oxideChloride

The invention discloses a preparation method of alkenyl succinic anhydride. The preparation method comprises the following steps: carrying out a reaction on alpha-olefin, maleic anhydride and a catalyst at 140-240 DEG C under 0.3-0.5 Mpa for 5-10 h, and purifying the above obtained reaction product to obtain the alkenyl succinic anhydride, wherein the catalyst is selected from at least one of monobutyltin oxide, dibutyltin oxide, dibutyltin oxide chloride, dibutyltin dilaurate and dibutyltin diacetate, the particle size of the catalyst is 3-5 [mu]m, and the catalyst can be cyclically used. The alkenyl succinic anhydride is mainly used as a raw material for papermaking sizing agents. The preparation method has the advantages of simplicity, short reaction time and high efficiency.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Thermally conductive and insulating room temperature curing silicone rubber

InactiveCN109206915AImprove anti-settling effectImprove thermal conductivityHeat-exchange elementsCross-linkPolymer science

The invention discloses thermally conductive and insulating room temperature curing silicone rubber. According to the invention, alpha, omega-Hydroxyl terminated polydimethylsiloxane is used as a matrix, tetramethoxysilane is used as a cross-linking agent, Al2O3 is used as a main thermal conductive filler, AlN and SiC are used as auxiliary thermal conductive fillers, ZnO, nano-TiO2, nano-SiO2 andnano-Al2O3 are used as anti-settling additives, hydroxy silicone oil with viscosity of 1000mPa-s is suitable to be used as base silicone oil; tetramethoxysilane is used as a cross-linking agent, and the suitable use amount is 6 parts; dibutyltin diacetate and dibutyltin diacetylacetonate can be used as a catalyst, and the suitable use amount of dibutyltin diacetate is 0.3 wt%. When the filling amount of the thermally conductive and insulating room temperature curing silicone rubber is 8 wt%, 0.8 wt%, 0.8 wt% and 0.5 wt% respectively, the anti-settling performance of the silicone rubber is excellent, thermal conductivity of the silicon rubber can be raised to some extent, and the mechanical properties and insulating property are little influenced. The phenyl silicone oil and the hydroxy silicone oil are mixed according to a certain ratio as the base silicone oil to study the heat resistance of a pure silicone rubber matrix.

Owner:中绿新材料(江苏)有限公司

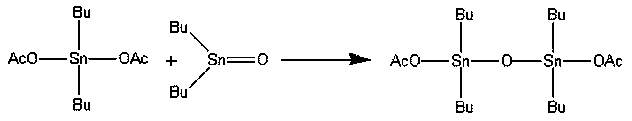

Preparation method of catalyst organotin acetate in sucralose production

InactiveCN111592564AImprove the on-site environmentReduce manufacturing costTin organic compoundsSugar derivativesPtru catalystDibutyltin oxide

The invention relates to a preparation method of a catalyst organotin acetate (DSDA) in sucralose production. The method comprises the following steps: directly reacting dibutyltin diacetate and dibutyltin oxide at a certain temperature to obtain organotin acetate (DSDA), and distilling the reacted material under reduced pressure to remove impurities, thereby obtaining the organotin acetate (DSDA)which can be used in sucralose esterification reaction. The method is simple and smooth in process, and can basically realize one-step implementation. And under the same equipment condition, the production efficiency is greatly improved. The problems of solvent volatilization and high energy consumption in the prior art are solved, and the solvent and steam consumption is reduced; and the environment is protected, the working intensity of field operators is greatly reduced, and the working environment is improved.

Owner:ANHUI JINGHE IND

Weather-proofing sealant used for bottom of lens and preparation method thereof

InactiveCN107674633AEasy to useExtensive adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesGas phaseTetra

The invention discloses a weather-proofing sealant used for bottom of lens and a preparation method thereof. The weather-proofing sealant comprises the following components by parts: 380-420 parts ofmodified 107 glue, 50-62 parts of phenolic-modified C9 resin, 20-30 parts of phenyl maleimide-based silicone resin, 15-24 parts of methyltrimethoxysilane, 32 parts of gas-phase silica, 0.1-0.4 parts of dibutyltin diacetate, 0.3-0.6 parts of tetra-n-butyl titanate, and 10-14 parts of hydroxyl silicone oil. The weather-proofing sealant has the advantages of excellent weatherability, little smell, and good construction performance, is suitable for assembling and sealing various glass, and has good bonding property.

Owner:嘉兴天胶新材料股份有限公司

Sealant for hollow glass

ActiveCN104629630AInhibition of permeabilityImprove mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesZinc borateWater vapor

The invention discloses a sealant for hollow glass. The sealant is prepared from the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 10-12 parts of methyl methacrylate, 14-16 parts of polydimethylsiloxane, 24-26 parts of basic zinc carbonate, 16-18 parts of zinc borate, 9-11 parts of quartz powder, 10-12 parts of silica powder, 8-10 parts of kaolin, 16-18 parts of triethoxyvinylsilicon, 8-10 parts of gamma-methacryloxypropyltriethoxysilane and 0.3-0.5 part of dibutyltin diacetate; the transmittance of the water vapor of the sealant is 0.2-0.4; and the tensile strength is 0.6-0.8.

Owner:广州华士康环保粘胶科技有限公司

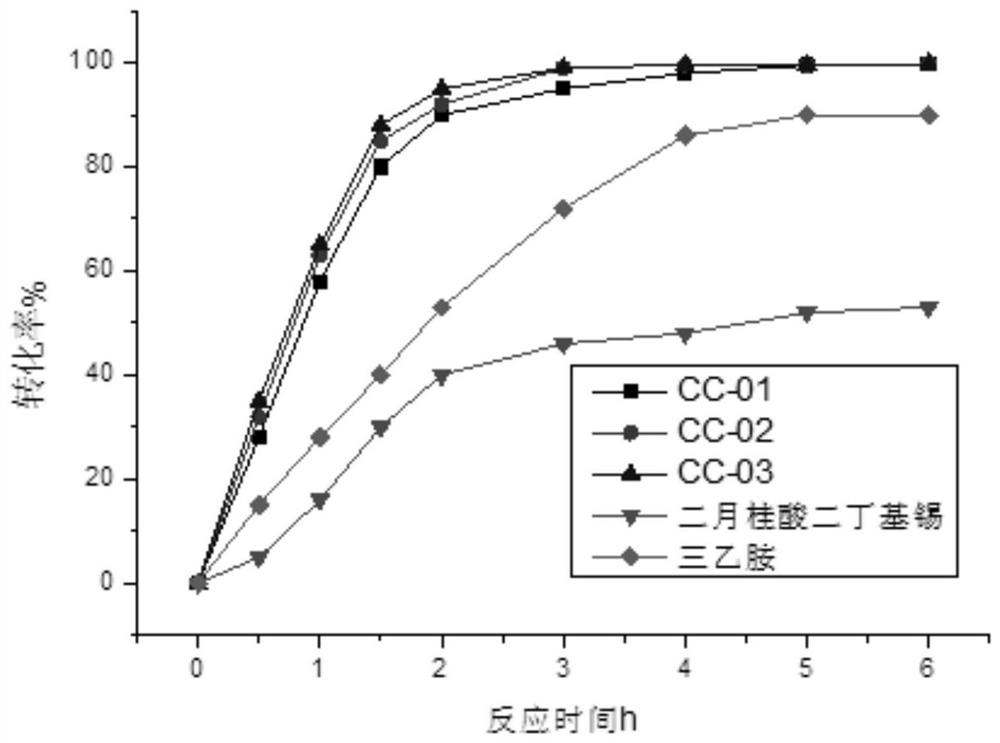

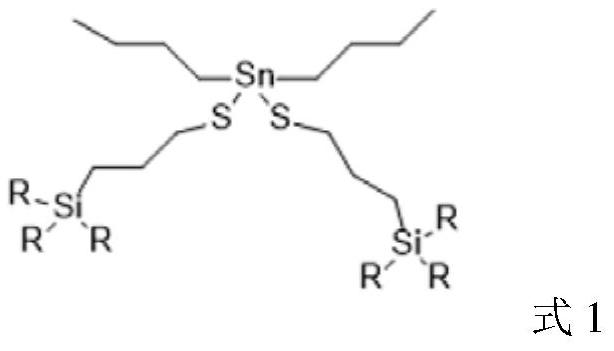

Catalyst for reaction of isocyanate and sulfydryl and preparation method of catalyst

ActiveCN111848666AEfficient responseTin organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention discloses a catalyst for reaction of isocyanate and sulfydryl. The catalyst is prepared by reaction of mercaptosilane and dibutyltin diacetate, has quite high reaction activity for reaction of isocyanate and sulfydryl, is quite high in final conversion rate, solves the problem of reaction of isocyanate and sulfydryl, and provides more technical methods for introduction of sulfydryl-containing materials into polyurethane materials.

Owner:武汉长盈鑫科技有限公司

High-temperature resistant organosilicon adhesive

The invention discloses a high-temperature resistant organosilicon adhesive. The organosilicon adhesive is prepared through reacting the following substances in percentage by mass: 35-45% of organosilicon adhesive, 5-10% of hydroxyl polysiloxane, 2-3% of dibutyltin diacetate, 1-3% of aluminate, 0.5-2% of alkynol, 20-50% of tackifying resin and 12-25% of hydrazide compound foamer, wherein the alkynol is selected from methyl butynol, hexynol, ethyl octynol or 2,4,7,9-tetramethyl-5-decyn-4,7-diol, and the hydrazide compound foamer is selected from 4,4'-disulfonylhydrazide diphenyl ether, p-benzenesulfonyl hydrazide, 3,3'-disulfonylhydrazide diphenylsulfone, 4,4'-diphenyl disulfonylhydrazide, 1,3-phenyl disulfonylhydrazide or 1,4-phenyl disulfonylhydrazide. The organosilicon adhesive has the microporous organosilicon adhesive with a microporous structure, so that the organosilicon adhesive has exhausting property and adsorbability; meanwhile, micropores are hollow, so that the organosilicon adhesive has the function of adsorbing small molecules.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Easily-degradable anti-microbial nylon composite material and preparation method thereof

The invention discloses an easily-degradable anti-microbial nylon composite material and a preparation method thereof. The preparation method comprises the steps of with nylon resin, aluminum titanate fiber, ethyl acetate amide and hydroxystearic acid as the main components, adding N-ethylene amide distearate, resorcinol monobenzoate, octadecanoyl tributyl citrate, germanium powder, spinel powder, cetearyl alcohol, butylhydroxyanisole, zinc ricinoleate, dibutyltin diacetate, barium laurate soap, a silane coupling agent, an antioxidant and an antioxidant, and carrying out processes of stirring grinding, high-temperature calcination, ultrasonic dispersion, high-temperature smelting, extrusion molding and the like, so as to obtain the nylon composite material. The prepared nylon composite material has wide anti-microbial range, good sterilizing effect and excellent degrading performance, can meet the industrial requirements and further has a relatively good application prospect.

Owner:刘平

Preparation method of sealant for insulating glass

InactiveCN104629660AInhibition of permeabilityImprove mechanical propertiesNon-macromolecular adhesive additivesGraft polymer adhesivesZinc borateOmega

The invention discloses a preparation method of a sealant for insulating glass. The preparation method comprises the following steps: adding alpha, omega-dihydroxyl polydimethylsiloxane and methyl methacrylate into a vacuum kneading machine for kneading, wherein the vacuum degree is about 0.01-0.03 MPa, the kneading temperature is about 135-145 DEG C, and the kneading time is about 60-90 minutes, taking out the kneaded mixture at a sealed condition, putting the kneaded mixture in a vacuum reaction kettle with a stirring device, then adding basic zinc carbonate, zinc borate, quartz powder, silica powder, kaolin, triethoxyvinylsilane, gamma-methacryloxypropyltriethoxysilane and dibutyltin diacetate, controlling the vacuum degree to about 0.01-0.03 MPa, controlling the temperature to about 135-145 DEG C, controlling the stirring speed to 950-1050 r / min and controlling the stirring time to 90-120 minutes, and then packaging.

Owner:安泽县长亨中空玻璃加工有限公司

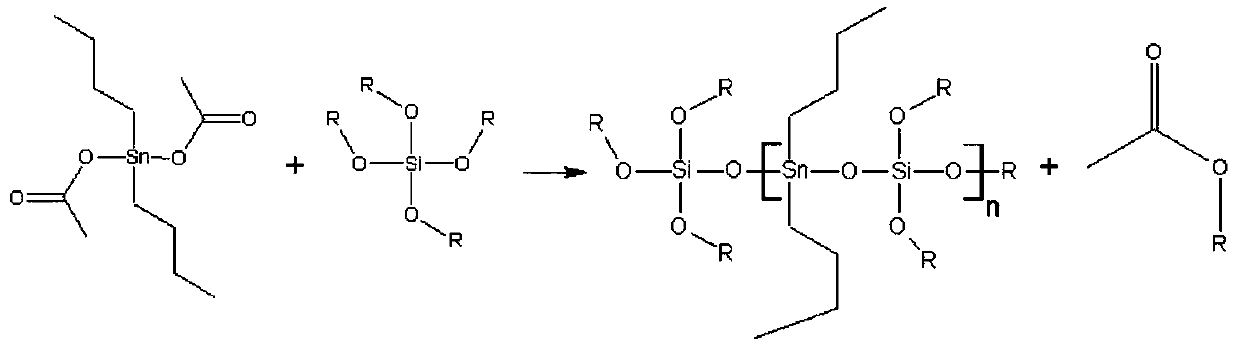

Preparation method of organotin catalyst, organotin catalyst and application thereof

InactiveCN109721736AHigh catalytic activityNo irritating smellTin organic compoundsNon-macromolecular adhesive additivesVulcanizationPolymer science

The invention discloses a preparation method of an organotin catalyst, an organotin catalyst and an application thereof. The preparation method comprises the following steps: S1,under the protection of nitrogen or an inert gas, dibutyltin diacetate and tetraalkoxysilane are added into a reaction kettle, and the molar ratio of dibutyltin diacetate to tetraalkoxysilane is 1:1.5-2; S2: reflux reaction is performed under stirring and heating conditions; S3: filtration is performed to obtain the organotin catalyst. The catalytic activity of the organotin catalyst prepared by the invention is higherthan that of dibutyltin dilaurate, and can meet the requirements of customers for preparing silicone room temperature vulcanization silicone rubber with different curing speeds.

Owner:湖北新蓝天新材料股份有限公司

Ultraviolet-resistant organosilicon adhesive

InactiveCN104893651ANot easy to migrateResolve color,Non-macromolecular adhesive additivesWeather resistanceAdhesive

The invention discloses an ultraviolet-resistant organosilicon adhesive which comprises an original silicon adhesive layer and a functional layer. The functional layer comprises the following components in parts by weight: 50-70 parts of organosilicon adhesive, 30-50 parts of hydroxy polysiloxane, 3-5 parts of dibutyltin diacetate, 1.2-2 parts of composite stabilizer, 1-2 parts of lubricant, 5-30 parts of reinforcer, 0.02-0.05 part of pigment, 5-8 parts of toughener and 30-40 parts of ultraviolet absorbent. The ultraviolet absorbent is a chlorobenzotriazole ultraviolet absorbent. By improving the formula, the ultraviolet absorbent and organosilicon adhesive functional layer master batch are mixed and molten by heating, and drawn to form the organosilicon adhesive, thereby solving the problem that color in the organosilicon adhesive in the prior art influences the visual effect. Meanwhile, by the aid of the weather resistance of the organosilicon adhesive, the ultraviolet absorbent can not easily migrate, thereby greatly prolonging the timeliness of the ultraviolet-resistant function.

Owner:WUXI ZHONGXING IND ADHESIVE TAPE

A kind of trivalent chromium electroplating method for cold rolled plate

Owner:泉州方寸新材料科技有限公司

Trivalent chromium electroplating method of cold-rolled sheet

The invention discloses a trivalent chromium electroplating method of a cold-rolled sheet. Plating liquid is prepared from chromium sulfate with the density being 135-145 g / L, sodium sulfate with the density being 210-230 g / L, potassium sulfate with the density being 30-40 g / L, magnesium sulfate with the density being 20-30 g / L, boric acid with the density being 65-75 g / L, formic acid with the density being 0.1-0.3 mol / L, oxalic acid with the density being 0.2-0.4 mol / L, sodium citrate with the density being 0.3-0.5 mol / L, sodium dodecyl sulfate with the density being 0.001-0.002 mol / L, benzene sulfinic acid sodium salt with the density being 0.0015-0.0025 mol / L, gamma-methacryloxypropyltriethoxysilane with the density being 0.2-0.4 mol / L and dibutyltin diacetate with the density being 0.5-0.7 g / L. The electroplating technology includes the steps that a graphite anode is adopted, the work temperature is about 50-55 DEG C, the pH is 3.5-4.5, the current density is 22-24 A / dm<2>, the electroplating time is 60-90 min, and the rotating speed of a stirrer is 100-120 r / min.

Owner:泉州方寸新材料科技有限公司

A kind of preparation method of sealant for insulating glass

InactiveCN104629660BInhibition of permeabilityImprove mechanical propertiesNon-macromolecular adhesive additivesGraft polymer adhesivesZinc borateSealant

Owner:安泽县长亨中空玻璃加工有限公司

A kind of sealant for insulating glass

ActiveCN104629630BInhibition of permeabilityImprove mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesWater vaporSealant

The invention discloses a sealant for hollow glass. The sealant is prepared from the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 10-12 parts of methyl methacrylate, 14-16 parts of polydimethylsiloxane, 24-26 parts of basic zinc carbonate, 16-18 parts of zinc borate, 9-11 parts of quartz powder, 10-12 parts of silica powder, 8-10 parts of kaolin, 16-18 parts of triethoxyvinylsilicon, 8-10 parts of gamma-methacryloxypropyltriethoxysilane and 0.3-0.5 part of dibutyltin diacetate; the transmittance of the water vapor of the sealant is 0.2-0.4; and the tensile strength is 0.6-0.8.

Owner:广州华士康环保粘胶科技有限公司

Preparation method of tin dioxide micron sheet with hexagonal profile

ActiveCN110759377ASimple preparation processReduce manufacturing costTin oxidesTin dioxidePhysical chemistry

The invention discloses a preparation method of a tin dioxide micron sheet with a hexagonal profile. A preparation process includes the steps: one of compounds of di-n-octyltin oxide and dibutyltin diacetate is selected to be mixed with graphene and sublimed sulfur, after tabletting, calcination is conducted for certain time at a certain temperature, and thus the tin dioxide micron sheet with thehexagonal profile is obtained. The method is simple, easy to operate and low in cost. The obtained tin dioxide micron sheet with the special profile has potential application prospects in micron devices.

Owner:HEBEI NORMAL UNIV

Preparation method of standard energy storage material

The invention belongs to the field of research and development of novel materials, and particularly relates to a standard energy storage material as well as preparation and application thereof. The standard energy storage material is prepared from the following components in parts by weight: 10-50 parts of sodium sulfite, 5-20 parts of a hardening agent, 40-70 parts of crystal wax, 10-25 parts ofwater, 1-4 parts of a curing agent, 0.5-1.0 part of dibenzoyl peroxide and 0.5-1.0 part of dibutyltin diacetate. The standard energy storage material has the advantages of being suitable for phase change temperature, relatively large in heat conductivity coefficient and high in energy storage density.

Owner:贾琳

Solvent-free polyurethane-acrylate floor material

InactiveCN109554097AImprove the decorative effectHigh tensile bond strengthPolyurea/polyurethane coatingsAcrylic resinSolvent free

The invention discloses a solvent-free polyurethane-acrylate floor material, comprising assemblys A and B, the raw material compositions of the assembly A comprise trimethylol propane, 2,2,4-trimethylhexamethylene diisocyanate, di(propylene glycol) methyl ether acetate, color paste, kaolin, talc powder, precipitated barium sulfate, N,N-dimethylcyclohexylamine, BYK-358N, BYK-066N and BYK-163; and the raw material compositions of the assembly B comprise acrylic resin, diethylene glycol and dibutyltin diacetate. The solvent-free polyurethane-acrylate floor material of the invention is green and friendly to environment, is applicable to various fields, is suitable for indoor and outdoor application, has high decorative property, good weather resistance, good wear resistance, good impact resistance, good hardness, good anti-slip property, good temperature-change resistance, and good adhesion even without a grounding primer, and can be combined with epoxy, cement, polyurethane and other foundations for use with high gloss.

Owner:FUZHOU ROYAL FLOOR

Nano polyurethane epoxy anticorrosive terrace coating

InactiveCN109554103AIncreased durabilityGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyWeather resistance

The invention discloses a nano polyurethane epoxy anticorrosive terrace coating. The nano polyurethane epoxy anticorrosive terrace coating comprises a component A and a component B, and is prepared from the component A and the component B according to a weight ratio of 6:1; the component A comprises the following raw materials in parts by weight: 30-40 parts of tolylene-2,4-diisocyanate, 30-40 parts of 1,6-hexamethylene diisocyanate, 40-45 parts of nano polyoxypropylene triol, 20-30 parts of ethylene glycol monoethyl ether acetate, 1-5 parts of methyldiethanolamine, 10-20 parts of epoxy resin,50-75 parts of filler, 1-8 parts of color paste, 0.1-0.3 part of BYK-320, 0.1-0.5 part of BYK-052N, 0.2-0.6 part of BYK-161 and 0.2-0.5 part of BYK-R605; and the component B comprises the following raw materials in parts by weight: 40-50 parts of hydroxyl-containing organic silicon resin, 10-20 parts of polyether and 1-5 parts of dibutyltin diacetate. A terrace prepared by the coating has more excellent corrosion resistance and higher salt fog resistance, wear resistance and skid resistance, and also has relatively good weather resistance.

Owner:FUZHOU ROYAL FLOOR

Production method of acidic silicone structural adhesive dedicated to large-plate glass

InactiveCN108148540ANon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveBottle

The invention relates to a production method of acidic silicone structural adhesive dedicated to large-plate glass. The acidic silicone structural adhesive comprises room-temperature vulcanized methylsilicone rubber, dimethicone, vapor-phase method silicon dioxide, a propyl crosslinking agent and dibutyltin diacetate according to the weight proportion, wherein the room-temperature vulcanized methylsilicone rubber is a supporting raw material, the vapor-phase method silicon dioxide is a filling raw material, the dimethicone is a plasticizer, and methyltriacetoxysilane and the dibutyltin diacetate are functional aids. The invention provides acidic structural adhesive by mainly aiming at the quality problems that the existing silicone adhesive for large-plate glass structure adhesion is low in weight loading capacity, is liable to change color after construction, and short in storage period, the internal part of a bottle is liable to thicken, and adhesive at the bottom of the bottle within the guarantee period is solidified. The acidic structural adhesive is suitable for structure adhesion of large-plate glass with various sizes, and the adhesive does not turn yellow permanently and avoids whitening after adhesive application. The storage life can reach 15 months, the bottom of the bottle does not have dry adhesive, the colloid is not thickened, and the acidic silicone structuraladhesive is ideal acidic silicone structural adhesive dedicated to the large-plate glass.

Owner:WEIHAI CHENGJING SILICONE TECH

Efficient phase-change energy storage composite and preparation method thereof

The invention belongs to the field of novel material research and development, and particularly relates to an efficient phase-change energy storage composite, and preparation and application thereof.The phase-change energy storage composite is prepared from the following components in parts by weight: 10-50 parts of sodium sulfite, 5-20 parts of a hardening agent, 40-70 parts of crystalline wax,10-25 parts of water, 1-4 parts of a curing agent; 0.5-1.0 part of dibenzoyl peroxide, and 0.5-1.0 part of dibutyltin diacetate. The phase-change energy storage composite has the advantages of suitable phase-change temperature, large thermal conductivity and high energy storage density.

Owner:原东

Chromium plating method for metal base material

The invention discloses a chromium plating method for a metal base material, and belongs to the technical field of electroplating. The method comprises the steps a, the surface of the metal base material undergoes oil removal and rust removal , and then the surface of the metal base material is cleaned and polished; b, an electroplating solution is prepared, the electroplating solution comprises,by weight, 20-30 parts of chromium chloride, 10-20 parts of chromium sulfate, 5-10 parts of zinc nitrate, 20-30 parts of sodium phosphate, 1-5 parts of dibutyltin diacetate, 1-5 parts of a complexingagent, 1-3 parts of oxalic acid, 1-3 parts of methanol, 1-5 parts of a buffering agent, 1-5 parts of ethane and 80-100 parts of deionized water; and c, after the electroplating solution is stirred for1-2 hours, the metal base material obtained from the step a is immersed in the electroplating solution, and the temperature of the electroplating solution is 30-40 DEG C. The binding force between the plating and the metal base material is strong, the wear resistance and the corrosion resistance of the plating are enhanced, and the service life and performance are improved.

Owner:四川精通机械科技有限公司

A kind of alkenyl succinic anhydride and its preparation method and application

ActiveCN106316997BSpeed up the synthesis processShort reaction timeOrganic chemistryDibutyl tin dilaurateDibutyltin oxide

The invention discloses a preparation method of alkenyl succinic anhydride. The preparation method comprises the following steps: carrying out a reaction on alpha-olefin, maleic anhydride and a catalyst at 140-240 DEG C under 0.3-0.5 Mpa for 5-10 h, and purifying the above obtained reaction product to obtain the alkenyl succinic anhydride, wherein the catalyst is selected from at least one of monobutyltin oxide, dibutyltin oxide, dibutyltin oxide chloride, dibutyltin dilaurate and dibutyltin diacetate, the particle size of the catalyst is 3-5 [mu]m, and the catalyst can be cyclically used. The alkenyl succinic anhydride is mainly used as a raw material for papermaking sizing agents. The preparation method has the advantages of simplicity, short reaction time and high efficiency.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation of low-melting-point phase-change energy storage material

InactiveCN109694694AOvercome supercoolingOvercoming separationHeat-exchange elementsSulfite saltVolumetric Mass Density

Preparation of low-melting-point phase-change energy storage material. The invention belongs to the field of new material research and development, and particularly relates to a phase change energy storage material as well as preparation and application thereof. The phase change energy storage material is prepared from the following components in parts by weight: 10-50 parts of sodium sulfite; 5-20 parts of a hardening agent; 40-70 parts of crystalline wax; 10-25 parts of water; 1-4 parts of a curing agent; 0.5-1.0 part of dibenzoyl peroxide and 0.5-1.0 part of dibutyltin diacetate. The phasechange energy storage material has the advantages of being suitable for phase change temperature, relatively large in heat conductivity coefficient and high in energy storage density.

Owner:贾琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com