Perfluoropolyether-modified polysilazane and surface treatment agent using same

A technology of perfluoropolyether and polysilazane, used in the field of cured film articles and surface treatment agents, can solve problems such as disadvantages, and achieve the effects of excellent water and oil resistance and excellent chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] [Example 1] (synthesis of polysilazane)

[0069] In the 300ml three-neck bottle that is provided with thermometer, reflux condenser, stirrer, add the trichlorosilane 50.6g that following formula (3) represents through perfluoropolyether modification and meta-bis(trifluoromethyl)benzene 100g Afterwards, dry ammonia gas was introduced into the solution under stirring, and while the ammonia gas was blown in, the temperature of the liquid rose, and ammonium chloride was generated and turned into a cloudy state. According to the above method, the ammonia gas was blown in until the reflux state was reached, then the introduction of the ammonia gas was stopped, and the stirring was continued for 2 hours under the reflux state. Then, heat and stir for 4 hours while introducing nitrogen to remove excess ammonia, then filter the precipitated ammonium chloride, and remove m-bis(trifluoromethyl)benzene by distillation under reduced pressure from the filtrate, thereby obtaining 46.6...

Embodiment 2

[0081] [Example 2] (synthesis of polysilazane)

[0082] In addition to using 62.4 g of perfluoropolyether-modified trichlorosilane represented by the following formula (4) instead of perfluoropolyether-modified trichlorosilane represented by formula (3) in the compound used in Example 1 , using the same method as in Example 1 to obtain 53.7 g of a colorless transparent liquid. of the compound obtained 1 H-NMR and IR spectrum data are shown below.

[0083]

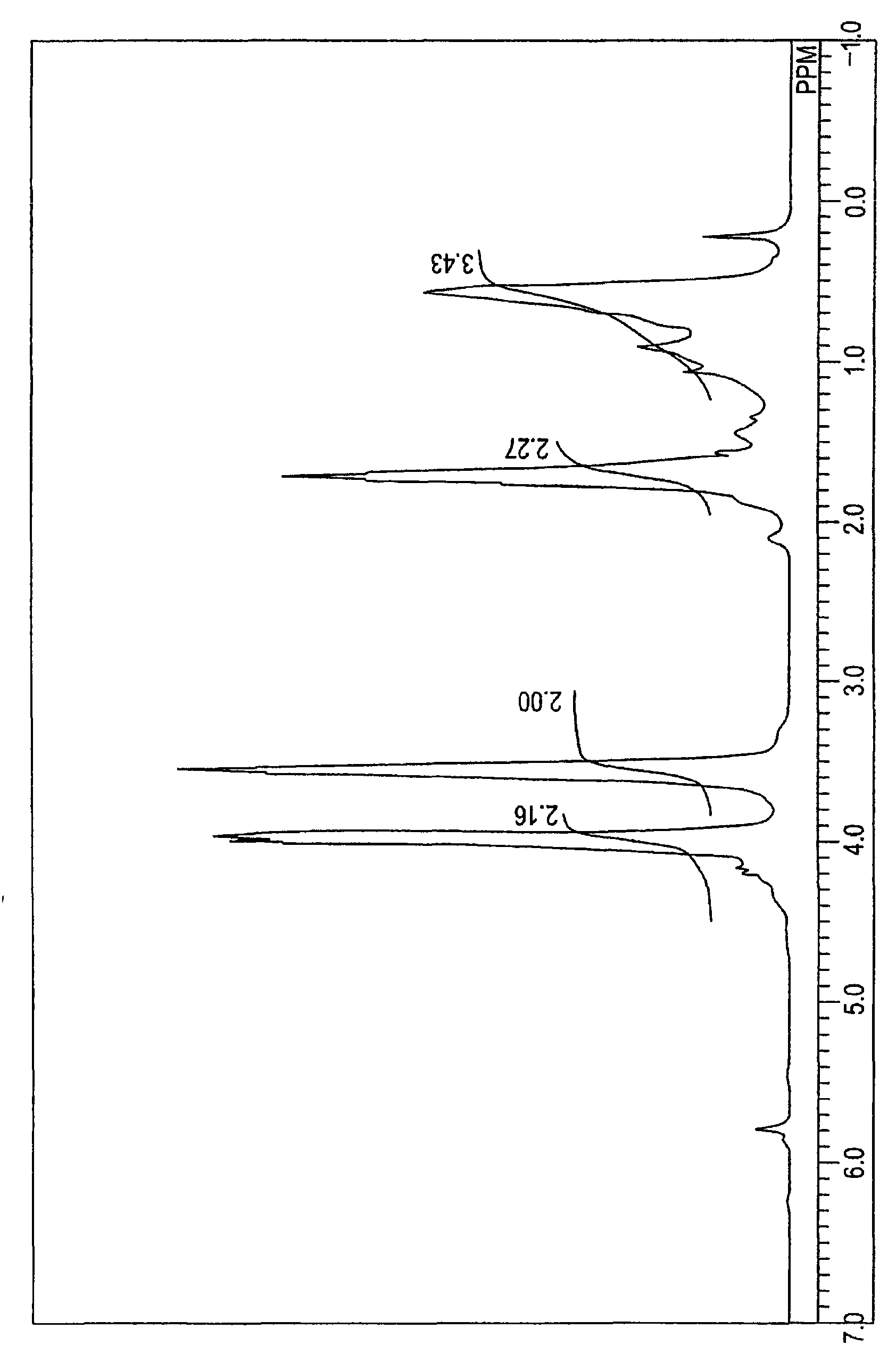

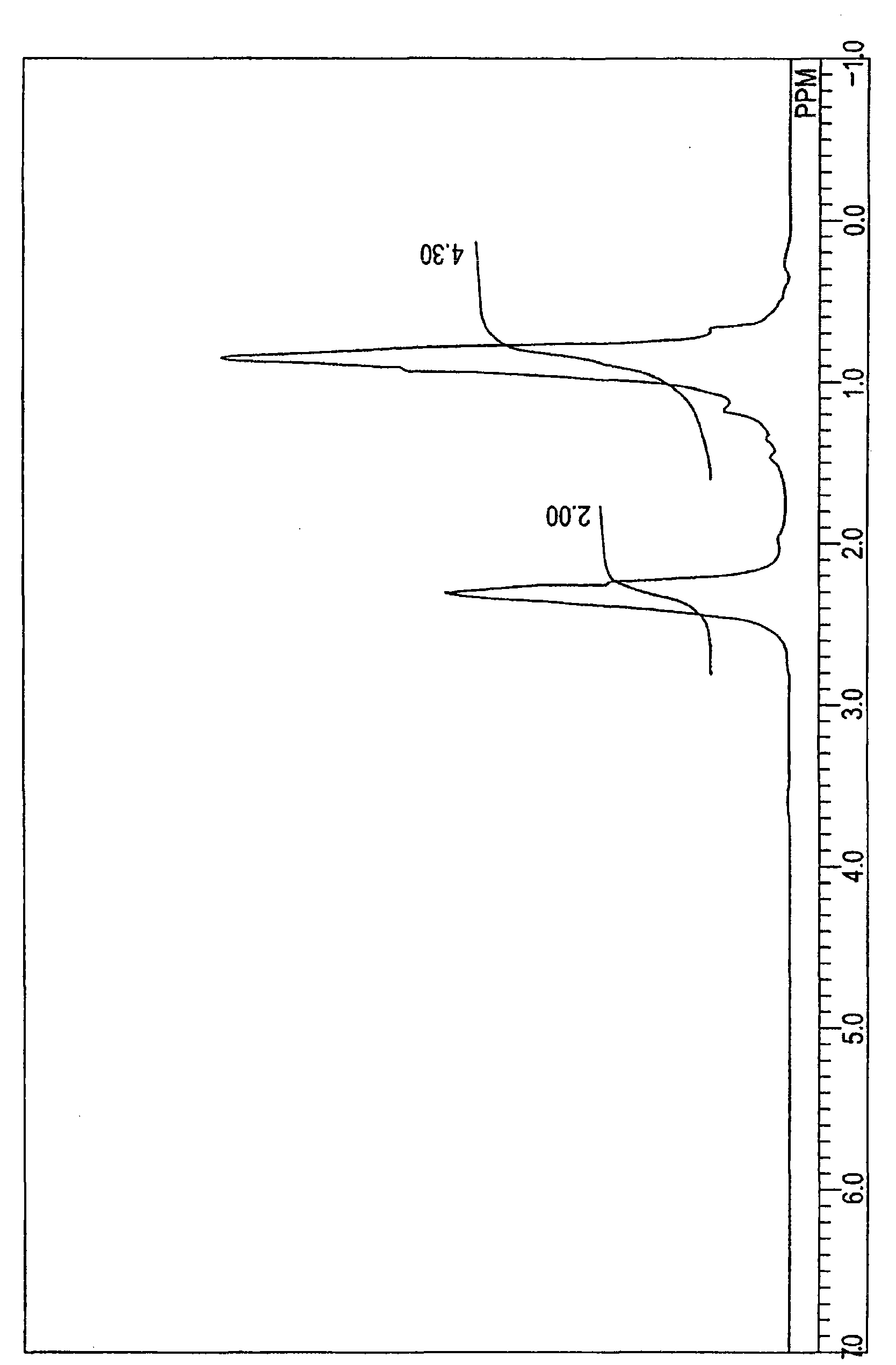

[0084] 1 H-NMR (with TMS as standard substance, ppm, see image 3 )

[0085] -CH 2 C H 2 Si≡0.7~0.9

[0086] -SiN H - 0.9~1.0

[0087] =CFC H 2 CH 2 - 2.2~2.4

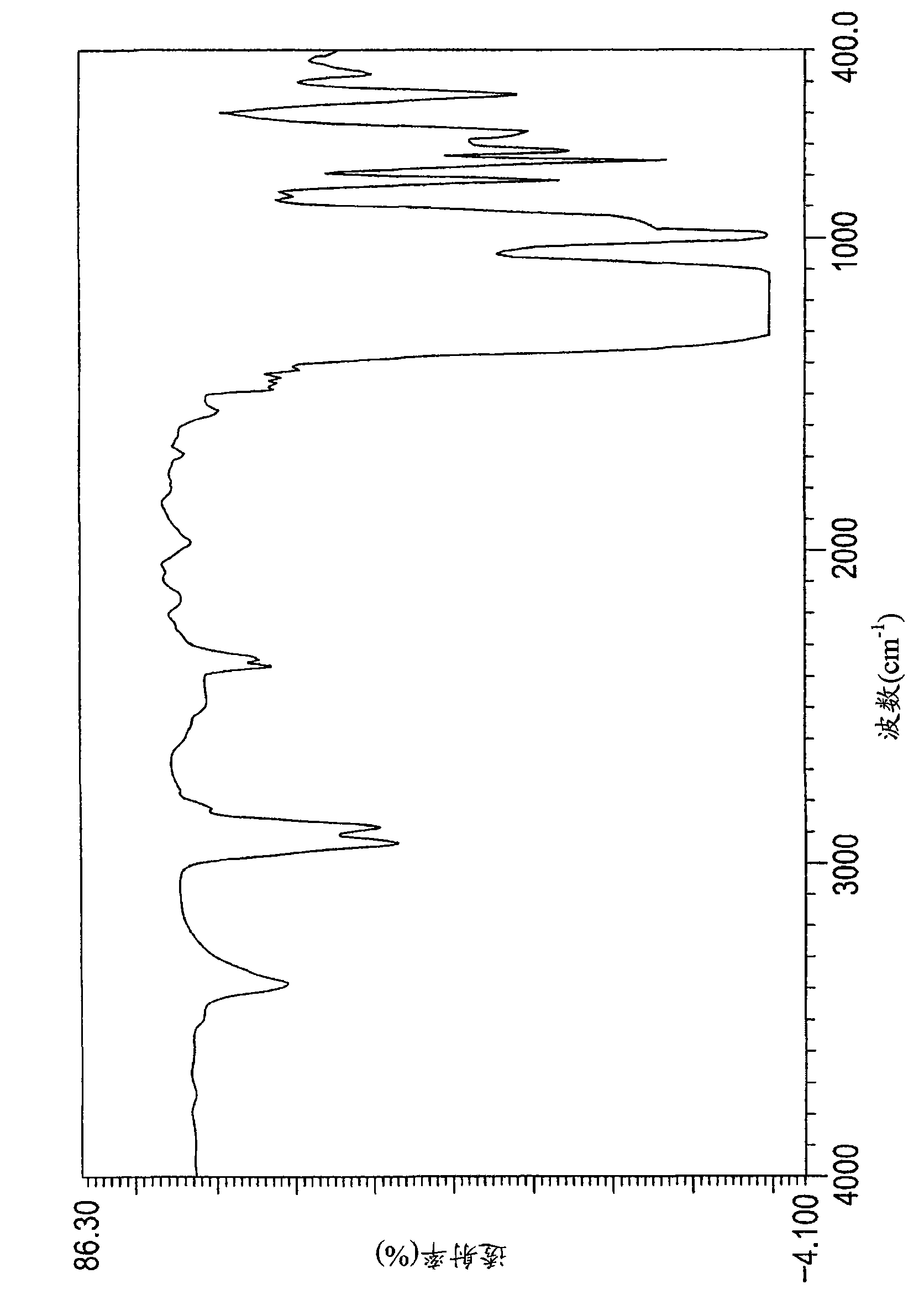

[0088] IR (KBr plate, liquid film method, cm -1 , see Figure 4 )

[0089] 3420(N-H), 2950-2850(C-H), 1315-1090(C-F)

[0090] From the above results, it was found that the obtained compound consisted of units represented by the following formula.

[0091]

Embodiment 3

[0092] [Example 3] (synthesis of polysilazane)

[0093] Except that the compound represented by the following formula (5) was used instead of the perfluoropolyether-modified trichlorosilane represented by the formula (3) among the compounds used in Example 1, the same method as in Example 1 was used to obtain compound.

[0094]

[0095] by it 1 According to H-NMR and IR spectrum data, the obtained compound is composed of units represented by the following formula.

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com