High-performance wear-resistant glaze and preparation method thereof

A high-performance, glazed technology, applied in the field of architectural ceramics, can solve the problems of glazed tiles that are easy to be scratched, the surface is dull, and the wear resistance is difficult to meet, so as to achieve less pores on the glazed surface, efficiently match the production system, and improve The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0040] A kind of wear-resisting glazed tile, prepared according to the following steps:

[0041] (1) According to the weight percentage, the frit powder is prepared according to the mineral composition of the frit powder in Table 2. After the melting temperature is 1520° C. for 30 minutes, the discharge water is cooled to form a frit, and the prepared frit is powdered and sieved, Dry and get the 100 mesh sieve for subsequent use;

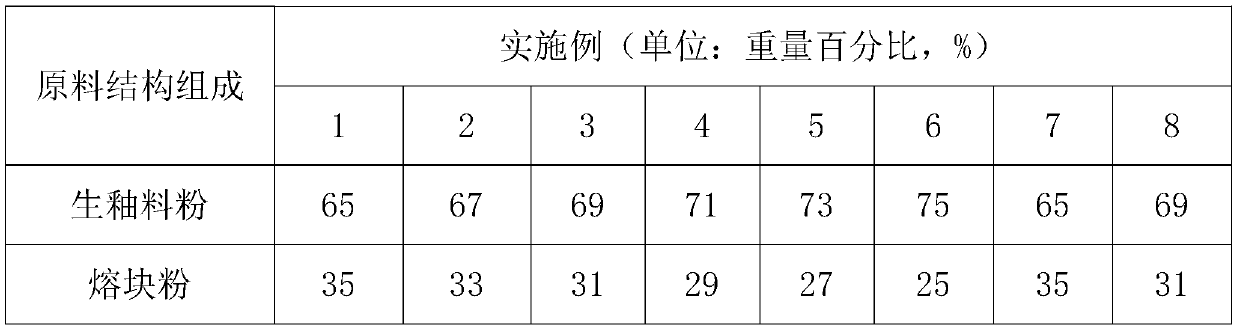

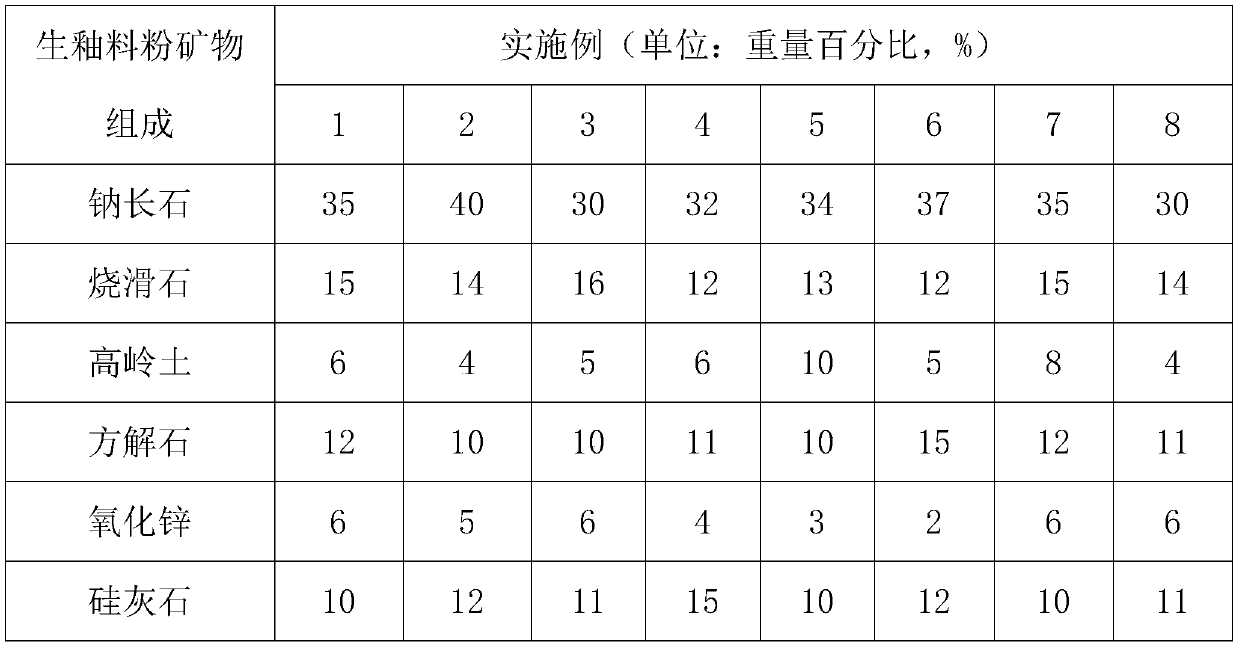

[0042] (2) According to the percentage by weight, according to the raw material composition of the high-performance wear-resistant glaze in Table 1, and the mineral composition of the raw glaze powder in Table 2, take by weighing for subsequent use;

[0043] (3) Add the above raw materials to water ball mill for 9 hours to obtain a glaze slurry, control the fineness of 325 mesh to 1.2% mass fraction, and then stale for 49 hours to obtain a high-performance wear-resistant glaze.

[0044] (4) Replace the surface glaze in the existing production proce...

Embodiment 9

[0069] (1) Preparation of frit powder: by weight percentage, get kaolin 48%, calcined talc 28%, quartz powder 11%, zinc oxide 2%, wollastonite 7%, albite feldspar 2% and corundum 2% to prepare The frit powder is kept at a melting temperature of 1520°C for 30 minutes, and then the material is cooled by water to form a frit, and the prepared frit is powdered, sieved, dried, and the 100-mesh sieve is taken for use;

[0070] (2) Preparation of raw glaze powder: by weight percentage, get albite 35%, burnt talc 15%, kaolin 6%, calcite 12%, zinc oxide 6%, wollastonite 10%, corundum 10% and carbonic acid Barium 6%, mix well and set aside;

[0071] (3) By weight percentage, take 65% of raw glaze powder and 35% of frit powder prepared in the above steps, add water and ball mill for 8 hours to obtain glaze slurry, control the fineness of 325 mesh sieve to be 1% by mass fraction, then stale for 49 hours, and prepare Obtain high-performance wear-resistant glaze;

[0072] (4) Replace the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com