Graded curing temperature-resistant epoxy adhesive and preparation method thereof

An epoxy adhesive and curing agent technology, applied in the field of construction structural adhesives, can solve the problems of structural adhesive performance changes, ambient temperature rise, difficult on-site use, etc., and achieve the effect of multi-time and opportunity and enhanced heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

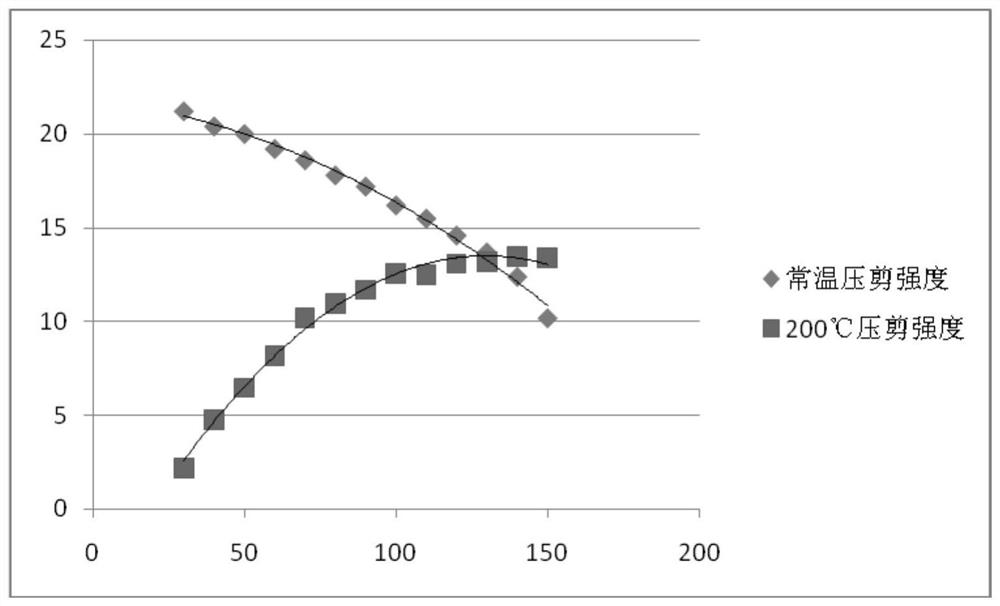

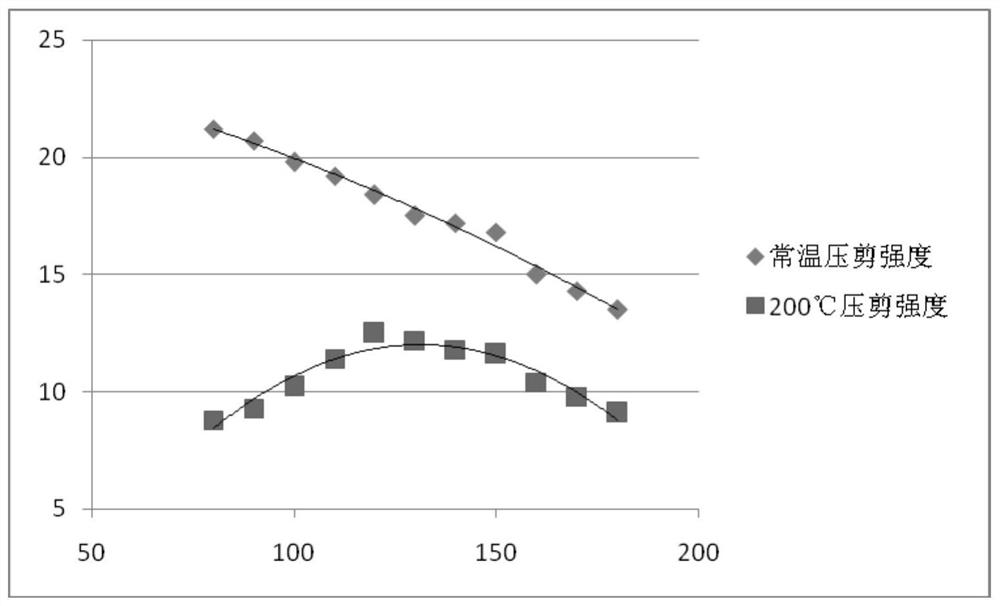

Image

Examples

preparation example Construction

[0032] The preparation method of described pretreatment powdery phenolic resin is as follows:

[0033] The thermoplastic modified phenolic resin is placed in a flask, heated to 130-150° C. to make it melt, and the thermoplastic modified phenolic resin contains a salicylic acid accelerator and a silane coupling agent (in the commercially available thermoplastic modified phenolic resin Already contains salicylic acid accelerator and silane coupling agent), while stirring, add 15% urotropine solution with a content of 33% as a curing agent, keep stirring for about 10-20 seconds, and then pour out the melt, After it is fully cooled, use grinding equipment to fully grind it to obtain powder, so that the particle size is 20-40 microns, that is, the pretreated powdered phenolic resin is obtained.

[0034] The preparation method of described phenolic resin coated quartz sand is as follows:

[0035] Use 100-150 mesh quartz sand, use a molding sand coating machine, heat the quartz sand...

specific Embodiment

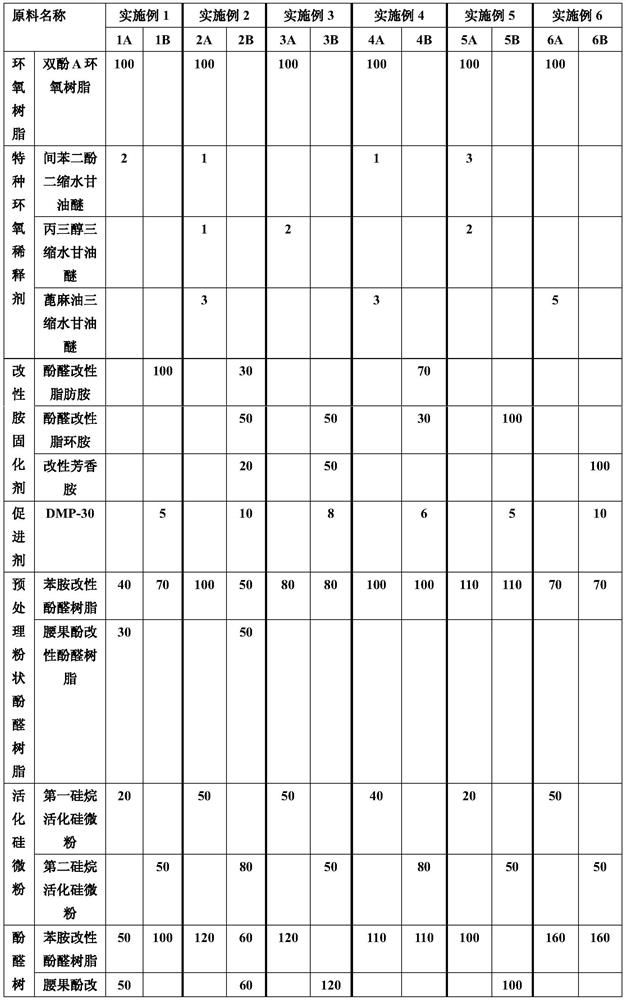

[0061] Table 1 is the component and proportioning table of embodiment 1-6

[0062]

[0063]

[0064] Table 2 is the component and proportioning table of embodiment 7-12

[0065]

[0066]

[0067] Table 3 is the component and proportioning table of embodiment 13-18

[0068]

[0069]

[0070] Table 4 is the detection data table of embodiment 1-18 of the present invention and comparative example:

[0071]

[0072] Among them, a certain brand of planting glue in the market was selected as the comparative example.

[0073] According to comprehensive performance, wherein embodiment 2, 8, 9, 17 are preferred embodiments, wherein embodiment 9 is the best embodiment.

[0074] Other parts not specified in detail are prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com