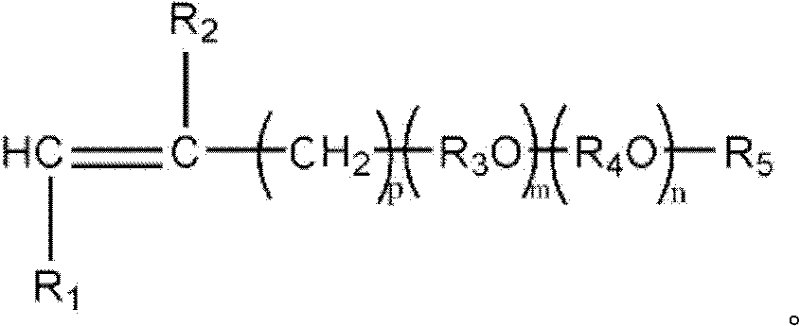

Low-dosage high-water-reduction type polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylate and water reducing agent, which is applied in the field of concrete admixture, can solve the problems of unsuitable development, high esterification reaction temperature, adverse environmental impact, etc., and achieve high slump retention, cement adaptability, and reaction cycle Short, low-equipment-required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Monomer A is methyl alkenyl polyoxyethylene polyoxypropylene ether, molecular weight is 2400; Monomer B is maleic anhydride; Monomer C is sodium methacrylate; Initiator D is sodium persulfate .

[0030] Add 24.46kg of monomer A, 4.1kg of monomer B, 0.42kg of monomer C and 70kg of distilled water into the reactor, heat up to 40°C while stirring, and add 1.01kg of sodium persulfate into the reactor after the monomers are dissolved , stir until dissolved. Then the monomer was reacted at 80°C for 4h, 90°C for 0.5h, and finally cooled to room temperature, and adjusted to pH 7 with 30% sodium hydroxide solution to obtain a polycarboxylic acid-based water reducer PC with a solid content of 30%. 1.

Embodiment 2

[0031] Example 2: Monomer A is methyl alkenyl polyoxyethylene polyoxypropylene ether with a molecular weight of 2800; Monomer B is itaconic acid; Monomer C is sodium propylene sulfonate; Initiator D is ammonium persulfate.

[0032]Add 21.87kg of monomer A, 5.76kg of monomer B, 0.80kg of monomer C and 30kg of distilled water into the reactor, heat up to 40°C while stirring, and add 1.56kg of ammonium persulfate into the reactor after the monomers are dissolved , stir until dissolved. Then the monomer was reacted at 75°C for 3.0h, and finally cooled to room temperature, and the pH was adjusted to 7 with 30% sodium hydroxide solution to obtain a polycarboxylate water reducer PC-2 with a solid content of 50%.

Embodiment 3

[0033] Example 3: Monomer A is methyl alkenyl polyoxyethylene ether with a molecular weight of 2400; Monomer B is fumaric acid; Monomer C is sodium methacrylate; initiator D is sodium persulfate.

[0034] Add 25.16kg of monomer A, 2.77kg of monomer B, 0.51kg of monomer C and 45kg of distilled water into the reactor, heat up to 40°C while stirring, and add 1.56kg of sodium persulfate into the reactor after the monomers are dissolved , stir until dissolved. Then the monomer was reacted at 75°C for 3.0 hours, and finally cooled to room temperature, and the pH was adjusted to 7 with 30% sodium hydroxide solution to obtain a polycarboxylate water reducer PC-3 with a solid content of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com