Thirdly, the adjustment of the

motion range of the heald frame must be done manually through the mechanical operation of adjusting the length of the rocker, and the operating part is located under the heald frame. The operation is very inconvenient, but it is unavoidable to adjust the movement range of the heald frame during the process of changing the fabric type and debugging of the loom

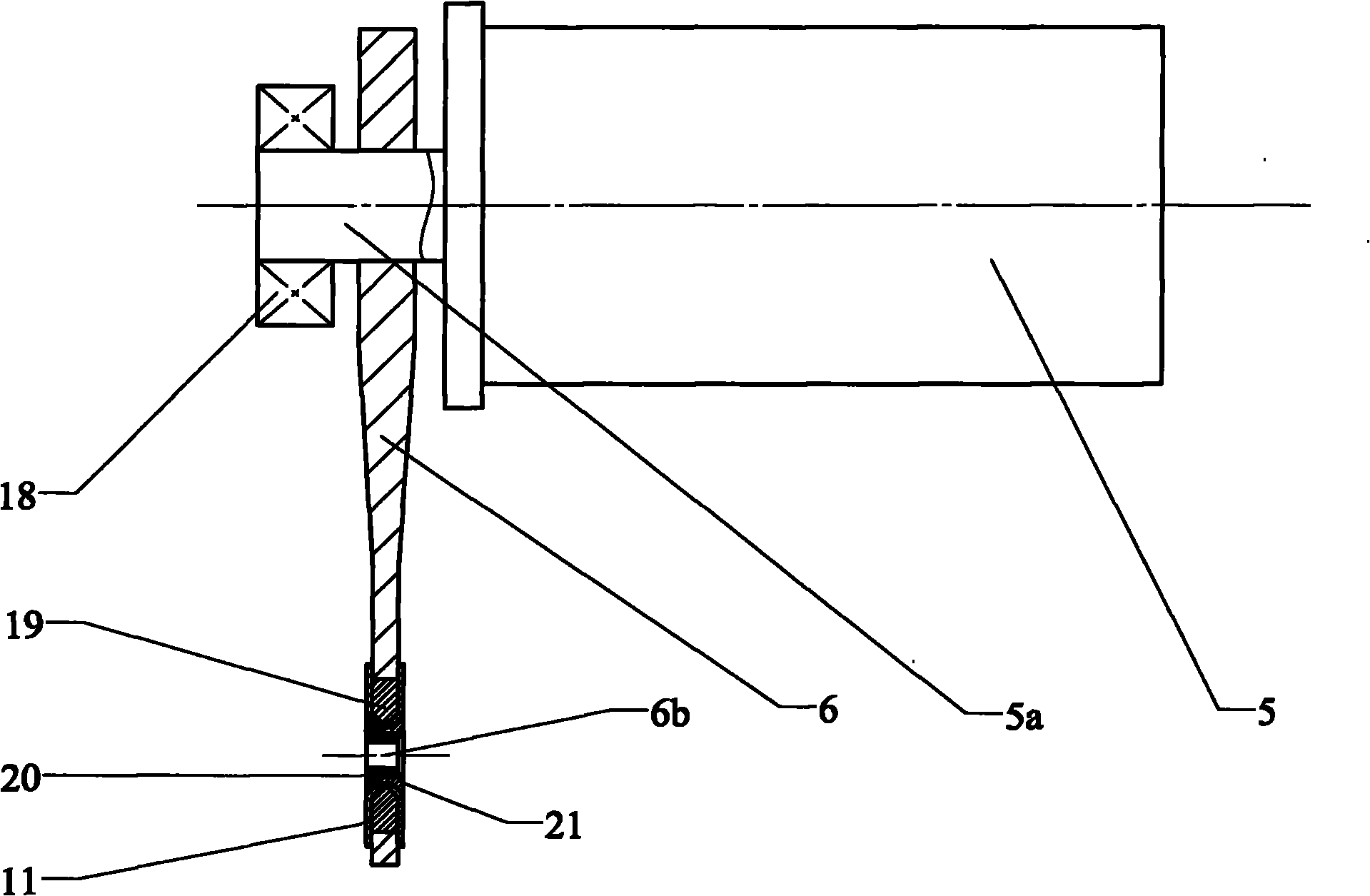

[0009] The above-mentioned JP 11-350285A proposes a scheme of driving a heald frame with two motors, but there are three defects in this scheme: first, there is a motor synchronization problem in the method of driving a heald frame by two motors, even if the synchronization problem is solved , but when any part of the

motor drive system breaks down, the synchronization will be destroyed, which will cause serious damage to the heald frame and other parts and the breakage of warp yarns, and there are hidden dangers in safety; The

pitch (the distance between the center planes of two adjacent heald frames) is generally controlled at 12mm. Due to the limitation of the

pitch of the heald frames, the motors can only be staggered up and down, and the height direction of the heald frames cannot accommodate the placement of the motors; the third , there is no deceleration device between the motor and the heald frame, which requires the motor to have both extremely high output torque and high-speed response performance to meet the high-speed

reciprocating motion requirements of the heald frame, which is quite difficult to achieve

The gravity of the permanent

magnet and the

centrifugal force generated by its

mass and arc motion will also generate an additional

bending moment on the connecting rod, increasing the rigidity of the connecting rod and reducing the quality of the connecting rod will become an unsolvable contradiction

In addition, the permanent

magnet can only move in a circular arc track, and cannot move in a complete straight line. The moving track is not completely consistent with the driving direction. Obviously, this will reduce the driving efficiency of the motor.

Fourth, since the permanent

magnet participates in the

lateral movement, while the exciting coil is stationary, there is always a non-overlapping part between the permanent magnet and the exciting coil, and the space position of the non-overlapping part is invalidly occupied, which makes the already extremely limited installation The spatial position of the motor cannot be fully utilized, or the

excitation coil of the motor can only exert about 70% of its driving capacity, and it also makes the drive control part of the

excitation coil more complicated, otherwise there will be a large loss of ineffective

electric energyFifth, the motor must become a specific special component. Due to the limitation of structure and size, the motor is no longer a separate product. The motor will be split in different parts of the loom, and each loom will drive different The motor components with the same function are not exactly the same, and cannot form a large-scale

mass production, and the cost of the motor will increase significantly

Sixth, the braking and positioning of the heald frame will be another major difficulty

Since the heald frame is required to be stationary at the upper and lower opening positions, that is, the heald frame is required to remain stationary at this position, so the shedding device must have a

brake or a position holder, unless the heald frame is controlled by the

linear motor itself. frame to maintain position, which is not advisable as it consumes a lot of energy in the

motor drive and overheats the motor

However, in the structure of this scheme, there is no suitable place for the

brake or position holder to be set, and even if it can be set, considerable braking energy will be consumed

Seventh, the resolution of the position detection during the movement of the heald frame is also affected, and it is impossible to accurately locate and control the movement of the heald frame

[0016] 1) The opening device occupies a large space outside the loom frame, which makes the loom occupy a large area, the female worker who stops the car has a long tour

route, and the construction cost of the factory building is high

[0017] 2) There are synchronization and safety problems in the existing technology that two motors drive the two ends of a heald frame to move

[0018] 3) The size of the motor is limited by the

pitch of the heald frame, which limits the ability of the motor to drive the heald frame, or the shedding device cannot meet the high-speed weaving requirements of the loom

[0019] 4) The adjustment of the

stroke of the heald frame must be done manually through mechanical operation, and it must be adjusted at the belly of the machine, which is very inconvenient to operate

[0020] 5) Due to the structural limitation of the mechanism design, the

layout of the motor position is difficult and messy, which increases the additional load of the motor

[0022] 7) The motor must become a variety of special-purpose components in the loom, which cannot be

mass-produced on a large scale, resulting in a substantial increase in the cost of the motor in the drive

system[0023] 8) In each group of driving mechanisms, the external dimensions of the components cannot be unified, and the

functional relationship between the motion law of the heald frame and the motion law of the motor rotation angle is inconsistent, which is not conducive to mass production, and there are many types of spare parts and high cost

[0024] 9) A variety of heald frames with different specifications must be used on the same loom, which brings many difficulties to the upper shaft and the previous heald drawing process

[0025] 10) The

pressure angle of the motion conversion mechanism is too large, the stress state of the heald frame and other parts is unreasonable, the

energy loss is large, and the damage rate of the parts is high

[0026] 11) The deceleration device cannot be used, resulting in a substantial increase in the cost of the motor and the volume of the motor

[0027] 12) It is difficult to

brake or maintain the position of the heald frame, and the control accuracy of the motion of the heald frame is low

Login to View More

Login to View More  Login to View More

Login to View More