Reduction and early strength polymer additive

A polymer and admixture technology, applied in the field of polycarboxylate high-performance water-reducing agent, shrinkage-reducing early-strength polymer admixture, can solve the problems of lack of availability and reducing concrete shrinkage, and achieve reduction of concrete shrinkage, shrinkage cracking, The effect of speeding up the hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

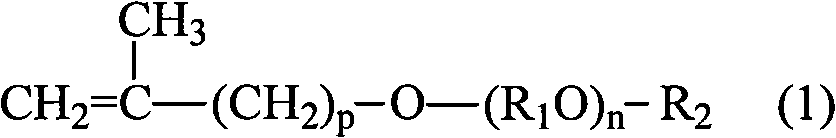

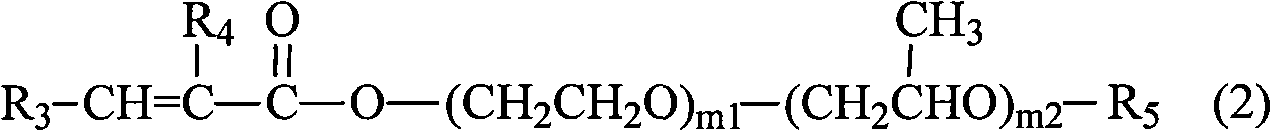

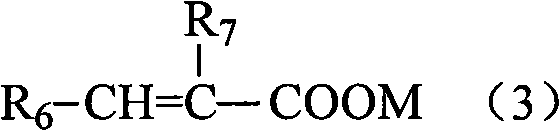

Method used

Image

Examples

Embodiment 1

[0045] Add 170.0 g of A-1, 143.9 g of water, and 5.0 g of 30% hydrogen peroxide into a 500 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 65°C. At the same time, 41.5g vitamin C aqueous solution (obtained by dissolving 0.5g vitamin C and 1.0g thioglycolic acid in 40.0g water) and 110.0g monomer aqueous solution (dissolving 14.0g B-1 and 16.0g C-1 in 80.0g water Obtained), the dropping time was controlled at 210 minutes and 180 minutes respectively, and the reaction temperature was controlled at 63~67°C. After the dropwise addition, keep the temperature at 63-67°C for 30 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50°C and add 29.6g of 30% NaOH aqueous solution to obtain the polymer additive PC-1 of the present invention with a solid content of 42.3% and a weight average molecular weight of 42,400.

Embodiment 2

[0047] Add 184.0 g of A-2 and 135.5 g of water into a 500 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 80°C. At the same time, 42.0g aqueous sodium persulfate solution (obtained by dissolving 2.0g sodium persulfate in 40.0g water), 21.5g aqueous solution of 3-mercaptopropionic acid (obtained by dissolving 1.5g 3-mercaptopropionic acid in 20.0g water) and 96.0 g monomer aqueous solution (obtained by dissolving 6.0g B-2, 8.0g C-1, and 2.0g C-2 in 80.0g water), the dropping time is controlled at 180 minutes, 150 minutes, and 150 minutes respectively, and the reaction temperature is controlled at 78~82℃. After the dropwise addition, keep the temperature at 78-82°C for about 60 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50° C. and add 21.0 g of 30% NaOH aqueous solution to obtain the polymer admixture PC-2 of the present inventi...

Embodiment 3

[0049] Add 176.0 g of A-3, 131.4 g of water, and 10.0 g of 30% hydrogen peroxide into a 500 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 65°C. At the same time, 41.6g vitamin C aqueous solution (obtained by dissolving 1.0g vitamin C, 0.6g 3-mercaptopropionic acid in 40.0g water) and 104.0g monomer aqueous solution (obtained by dissolving 6.0g B-1, 10.0g C-1, 4.0 g C-3 and 4.0 g D-1 were dissolved in 80.0 g water), the dropping time was controlled at 300 minutes and 270 minutes respectively, and the reaction temperature was controlled at 63-67°C. After the dropwise addition, keep the temperature at 63-67°C for 30 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50° C. and add 37.0 g of 30% KOH aqueous solution to obtain the polymer admixture PC-3 of the present invention, which has a solid content of 43.8% and a weight average mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com