Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Solve the problem of easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

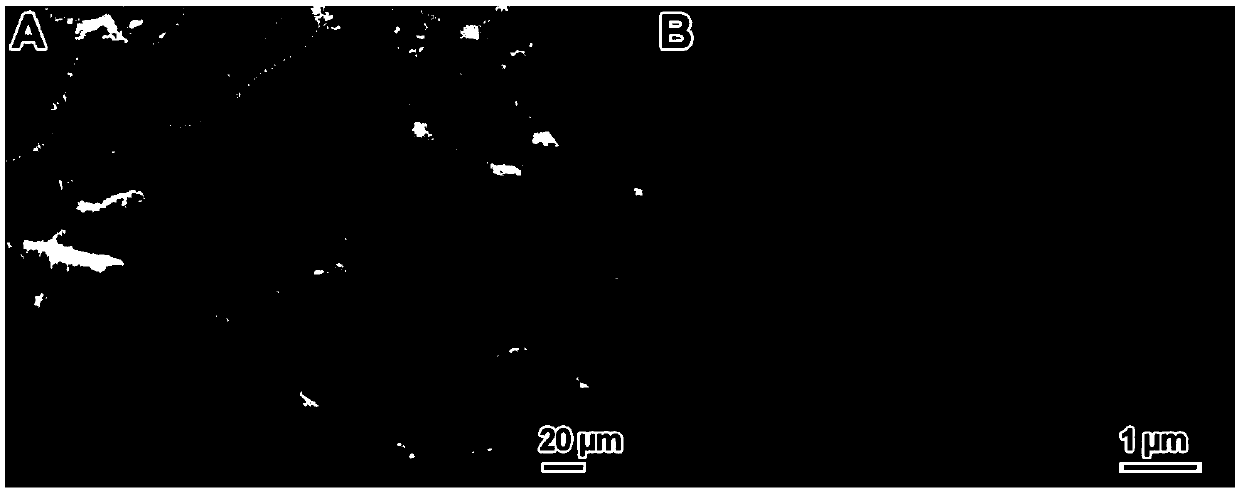

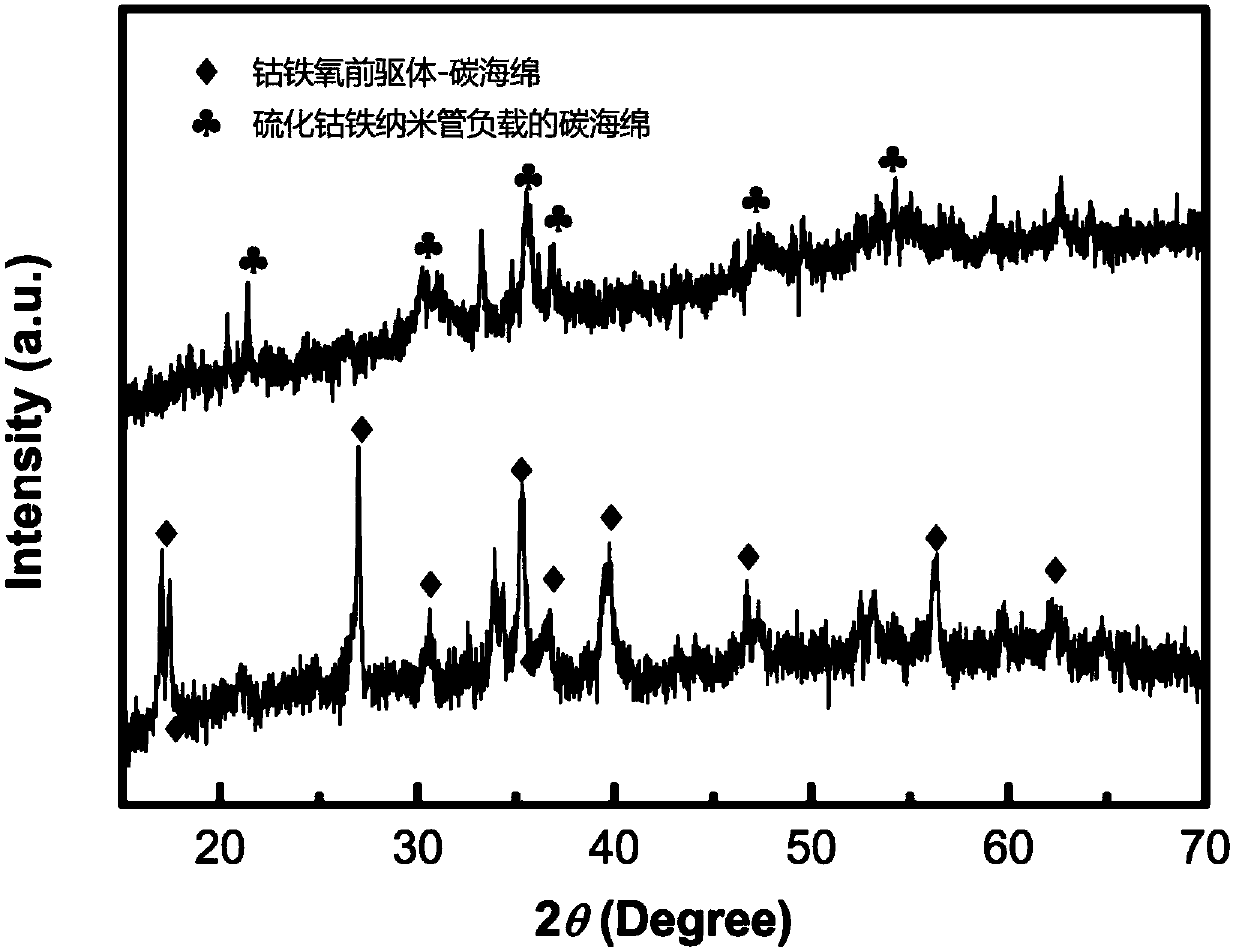

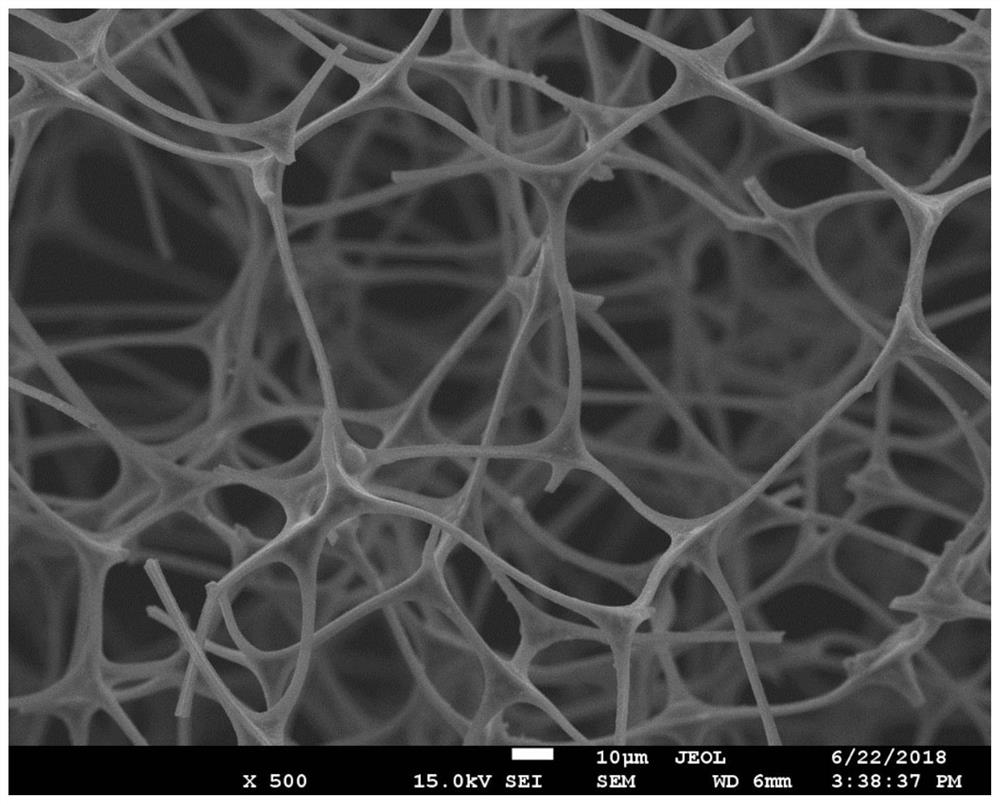

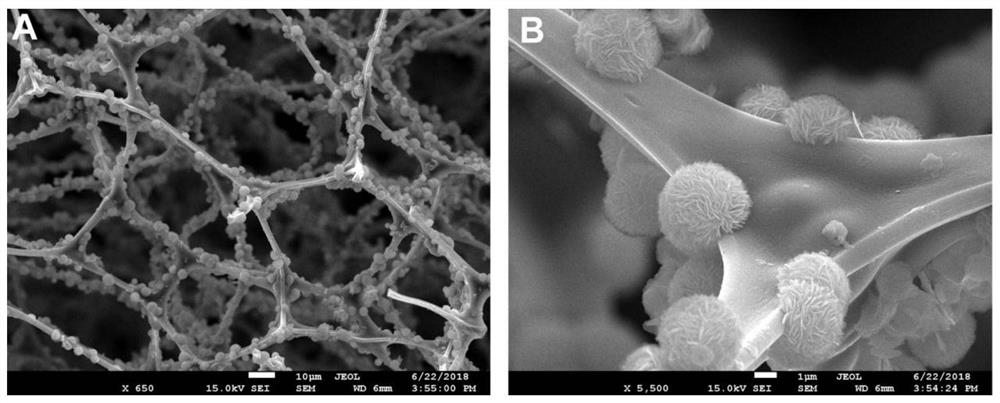

Preparation method of ferrocobalt sulfide nanotube loaded carbon sponge flexible composite material

InactiveCN109559898AEasy to prepareEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsNitrogen gasFerrocobalt

The invention belongs to the field of functionalized porous nanometer materials, and relates to a preparation method of a ferrocobalt sulfide nanotube loaded carbon sponge flexible composite material.The preparation method comprises the following specific steps: cutting commercial tripolycyanamide sponge, then washing with distilled water and absolute ethyl alcohol, after drying, in a nitrogen orargon atmosphere, burning the tripolycyanamide sponge through temperature programming, carrying out carbonization treatment, and cooling to obtain carbon sponge; preparing a mixed solution containinga ferric salt and a cobalt salt, immerging the carbon sponge into the mixed solution, adding a pH accessory ingredient, carrying out a hydrothermal reaction to obtain a ferrocobalt precursor-carbon sponge composite material, then immerging the ferrocobalt precursor-carbon sponge composite material into a vulcanizing agent solution, and carrying out a secondary hydrothermal reaction to obtain theferrocobalt sulfide nanotube loaded carbon sponge flexible composite material. According to the preparation method, the flexible, porous and self-supporting carbon sponge is taken as a growth template, and the difficulty that a nanometer material is easy to cluster is solved successfully; and the obtained composite material has a great number of exposed active sites, abundant holes and good conductivity.

Owner:JIANGSU UNIV

Wear-resistant polyurethane elastomeric fiber and preparation method thereof

InactiveCN105155017AImprove wear phenomenonWith wear resistanceMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberWear resistant

The invention relates to a wear-resistant polyurethane elastomeric fiber and a preparation method thereof, specifically to a polyurethane resin composition containing a wear-resistant aid and the polyurethane fiber with excellent wear resistance prepared from the polyurethane resin composition. The method comprises the following steps: 1) subjecting oligomer dihydric alcohol and excess organic diisocyanate to primary polymerization so as to obtain prepolymer; 2) dissolving the prepolymer in an organic solvent, then reacting the dissolved prepolymer with diamine and monoamine and carrying out secondary polymerization so as to prepare a polyurethane solution; and 3) adding the wear-resistant aid accounting for 0.5 to 10 wt% of the weight of the polyurethane polymer into the polyurethane solution so as to obtain a mixture and carrying out spinning on the mixture so as to obtain the wear-esistant polyurethane elastomeric fiber. The preparation method is simple to implement and can be widely used for polyurethane elastomeric fibers of different kinds; and the prepared polyurethane elastomeric fiber has excellent wear resistance.

Owner:ZHEJIANG HUAFENG SPANDEX

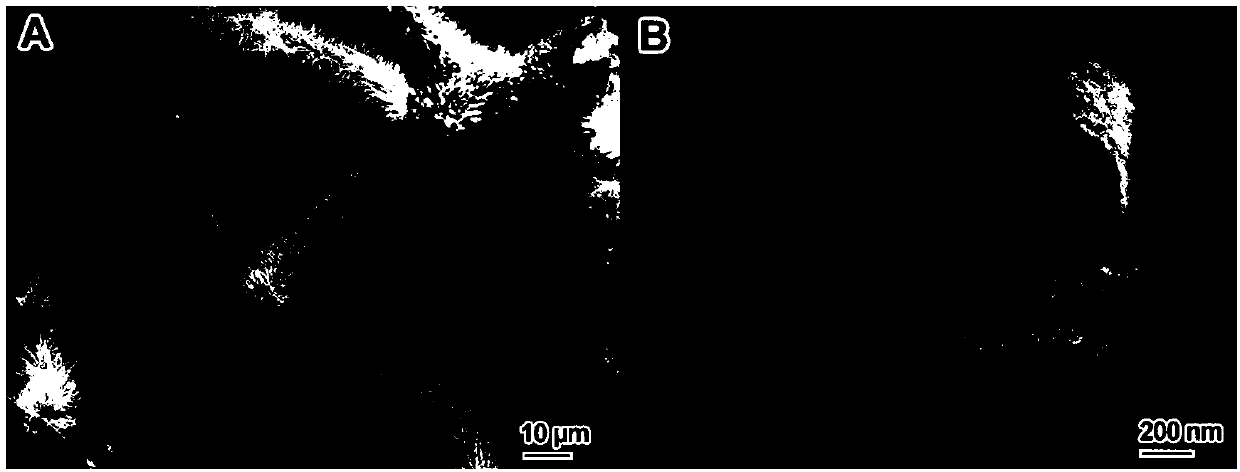

Method for preparing cobaltous oxide manganese nano flower/carbon sponge flexible composite material

ActiveCN109671575AEasy to makeEasy to operateHybrid capacitor electrodesCell electrodesArgon atmosphereManganese

The invention belongs to the field of functionalized porous nano materials, and particularly relates to a method for preparing a cobaltous oxide manganese nano flower / carbon sponge flexible compositematerial. The method comprises the steps of: taking a commercial melamine sponge, then performing washing with distilled water and absolute ethanol, performing drying, and then performing process temperature rise calcining of the melamine sponge under the nitrogen or argon atmosphere to obtain a carbon sponge after cooling; preparing a mixed solution containing a manganese salt and a cobalt salt,immersing the carbon sponge into the mixed solution for the hydrothermal reaction, taking out the carbon sponge after the reaction is finished, washing the carbon sponge with distilled water and performing drying to obtain a manganese-cobalt hydroxide precursor-carbon sponge composite material; and further, performing annealing reaction in the argon atmosphere to obtain a cobaltous oxide manganesenano flower / carbon sponge flexible composite material. The flexible, porous and self-support carbon sponge is taken as a growth template to successfully solve the problem that the nano material is easily gathered, and the obtained composite material has a lot of exposure active sites, abundant pores and good electrical conductivity.

Owner:JIANGSU UNIV

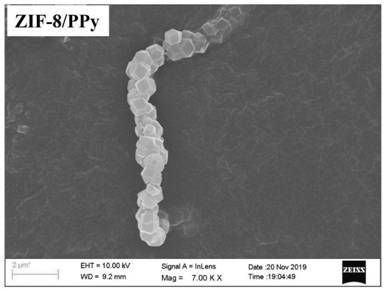

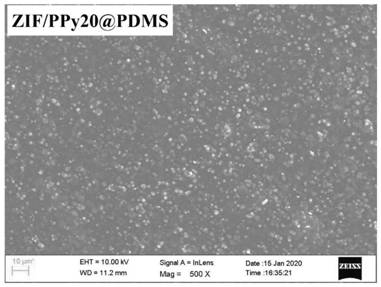

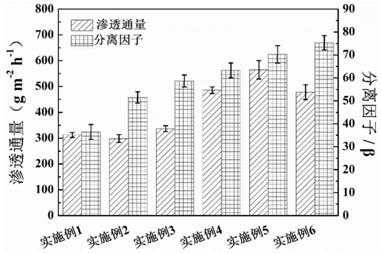

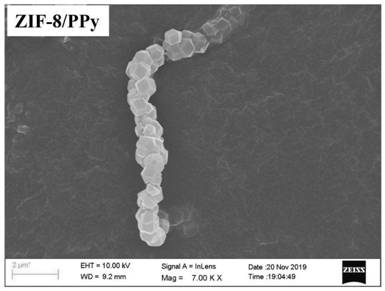

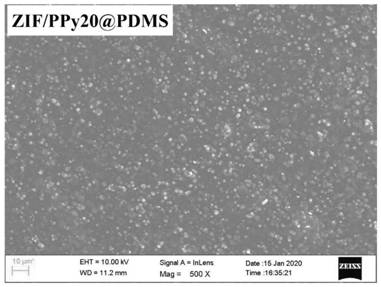

Mixed matrix membrane of bead-like MOF filled silicone rubber

ActiveCN112316741ASolve the problem of easy reunionGood dispersionMembranesDistillationPolymer sciencePtru catalyst

The invention discloses a mixed matrix membrane of bead-like MOF filled silicone rubber. A preparation method of the mixed matrix membrane comprises the following steps of: firstly, respectively adding FeCl3 and pyrrole into an aqueous solution of MO, stirring for reaction, washing and drying to obtain PPy; then dispersing PPy in a methanol solution, and adding a ligand to obtain a dispersion liquid 1; dropwise adding a methanol solution of 2-MeIm into the dispersion liquid 1, stirring for reaction, washing and drying to obtain MOF / PPy; and dispersing MOF / PPy in a solvent, adding silicone rubber, a cross-linking agent and a catalyst, stirring for reaction, coating a flat sheet membrane with the obtained product, standing, and drying to obtain the target product. The mixed matrix membrane provided by the invention has excellent permeability and separation performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Graphene dispersion liquid for anticorrosive coatings for oil pipes and preparation method of graphene dispersion liquid

The invention provides a graphene dispersion liquid for anticorrosive coatings for oil pipes and a preparation method of the graphene dispersion liquid. The graphene dispersion liquid is composed of graphene, a mixed solvent, a solubilizing agent and a coupling agent; the mixed solvent comprises dimethylbenzene, N, N-dimethylformamide, N-methylpyrrolidone and 1, 4-butanediol diglycidyl ether; themixed solvent may also comprise one or more of ethyl acetate, ethylene glycol butyl ether, butyl acetate, cyclohexanone and isoamyl acetate. The graphene dispersion liquid prepared by the invention has good graphene peeling property and obvious laminated structure, improves dispersibility of graphene, and can be added into the anticorrosive coatings to give full play to excellent physicochemical properties of the graphene and improve overall performance of the anticorrosive coatings, especially high-temperature and high-pressure resistance.

Owner:天津北方石墨烯产业研究院

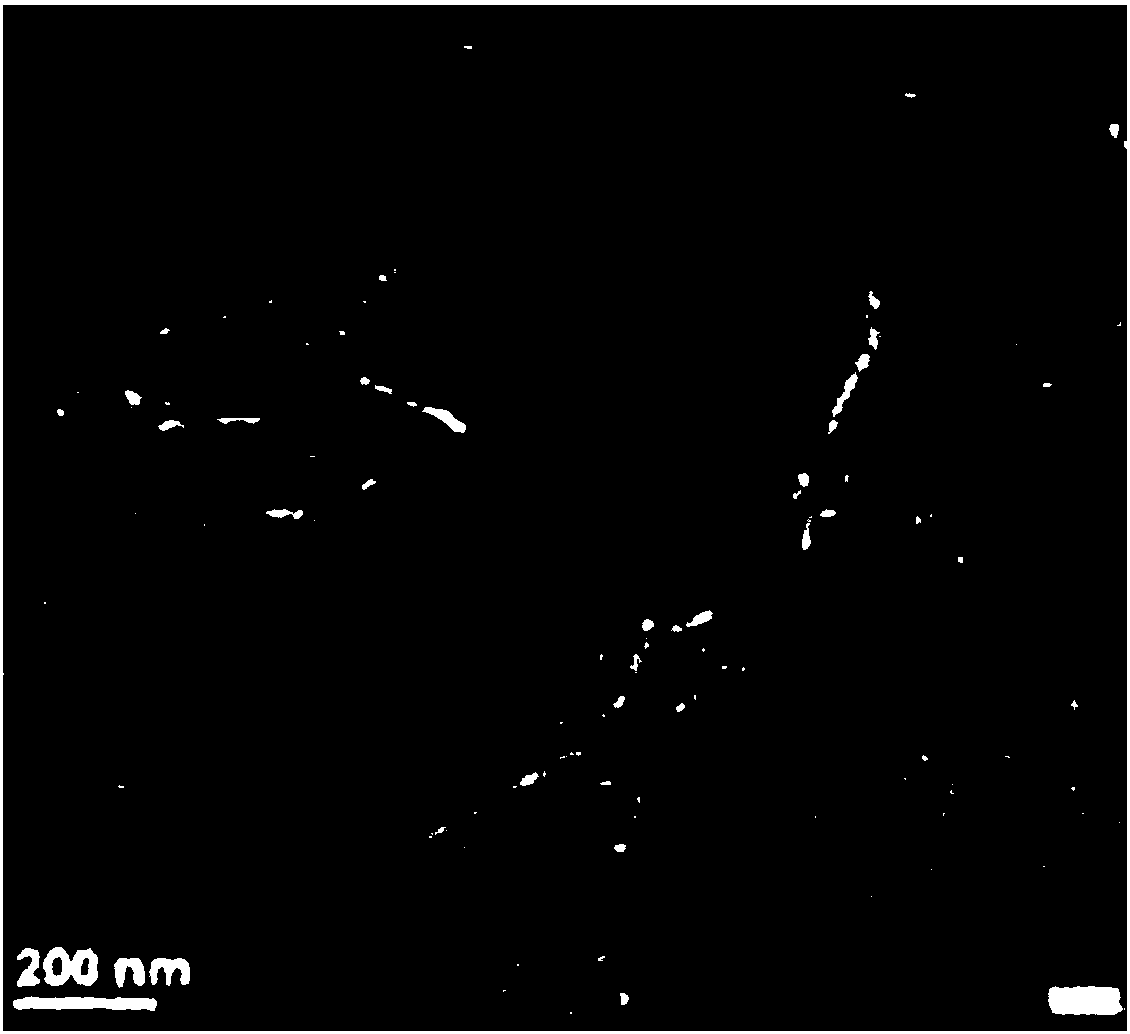

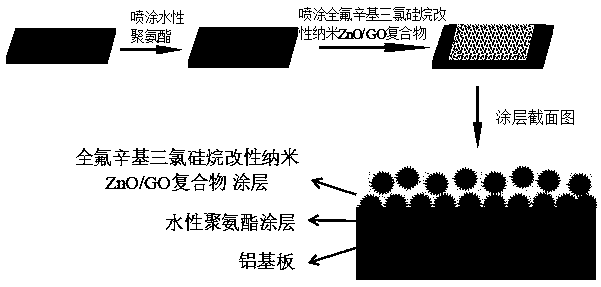

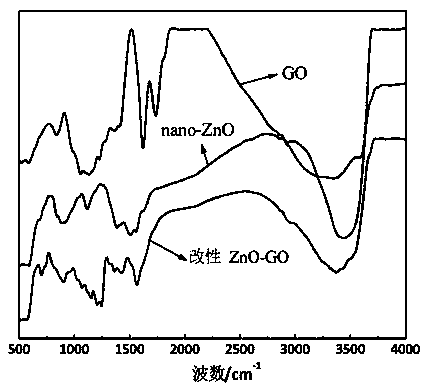

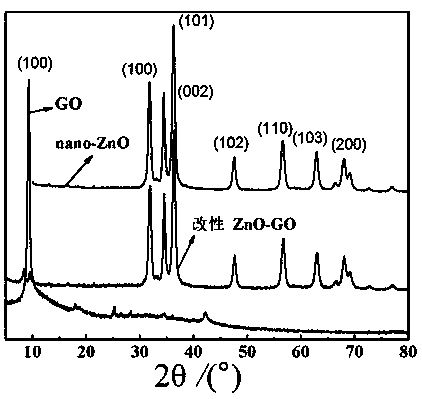

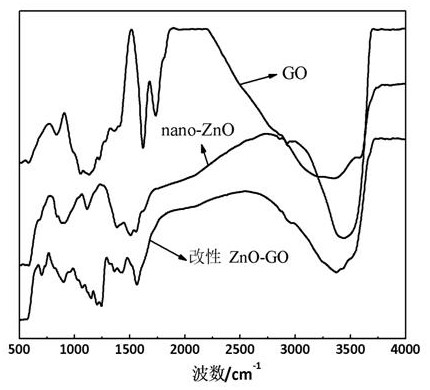

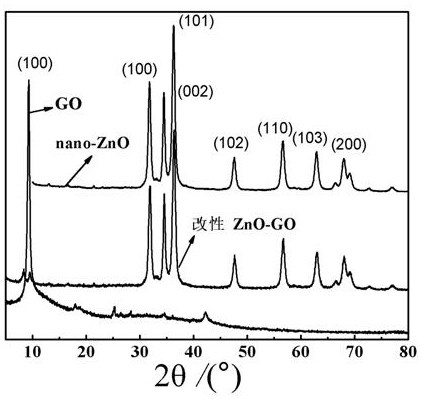

Method for preparing nano ZnO-GO/waterborne polyurethane super-amphiphobic coating through spraying method

ActiveCN109647680ASolve the problem of easy reunionEasy to prepareCoatingsSpecial surfacesZno nanoparticlesNano zinc oxide

The invention discloses a method for preparing a nano ZnO-GO / waterborne polyurethane super-amphiphobic coating through a spraying method. An ultrasonic hydrothermal composite method is adopted, nano zinc oxide is modified through perfluorooctyl trichlorosilane, then the modified nano ZnO carries GO, and nano ZnO-GO composite substance is obtained; a waterborne polyurethane layer is prepare on thesurface of a substrate; then a low-surfacce-energy nano ZnO-GO composite substance layer is established on the surface of the waterborne polyurethane layer; and after coating curing is finished, the surface topography and the static contact angle of a cured coating are tested. By means of the method, the surface energy of the nano zinc oxide is lowered, the surface hydrophobicity and lipophobicityof the nano ZnO-GO composite substance layer after fluoridation treatment are improved, the super-amphiphobic effect is achieved, and the stability of the coating is improved. The method is low in production cost, the preparation method is simple, the requirement for a reaction facility is low, the reaction conditions are mild, no environmental pollution occurs, and large-scale production can beachieved.

Owner:NANCHANG HANGKONG UNIVERSITY

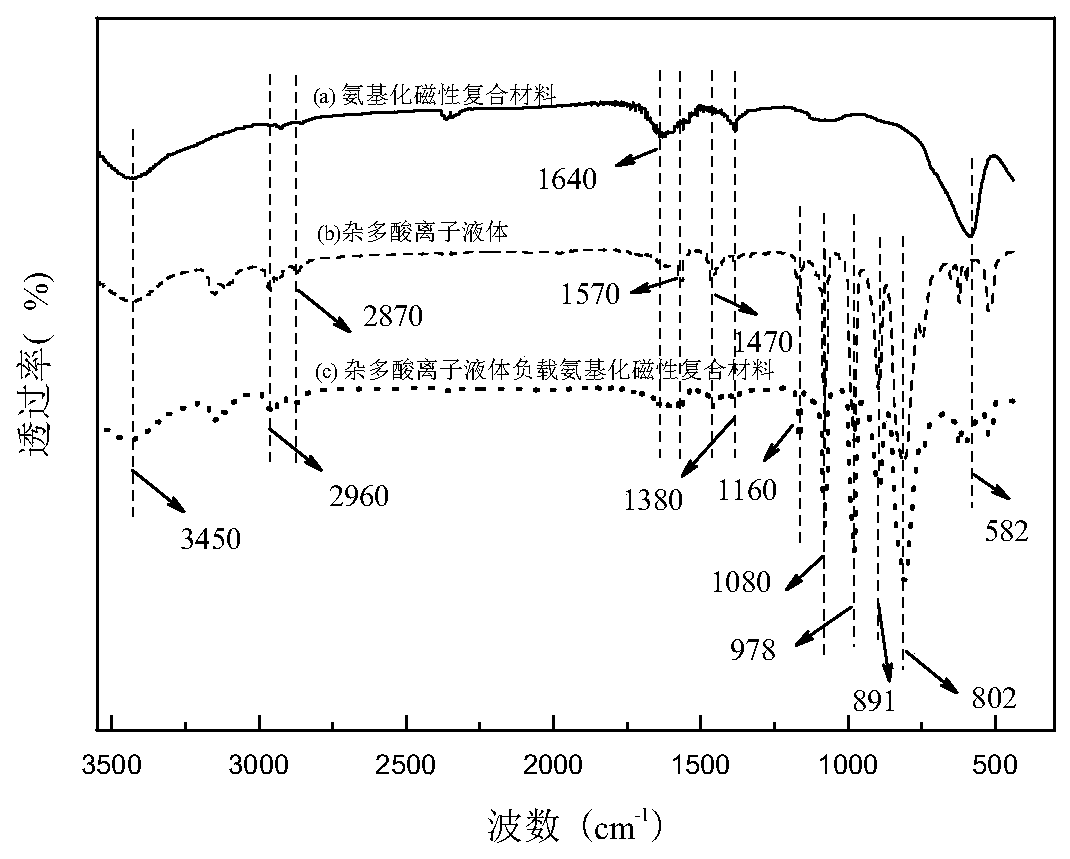

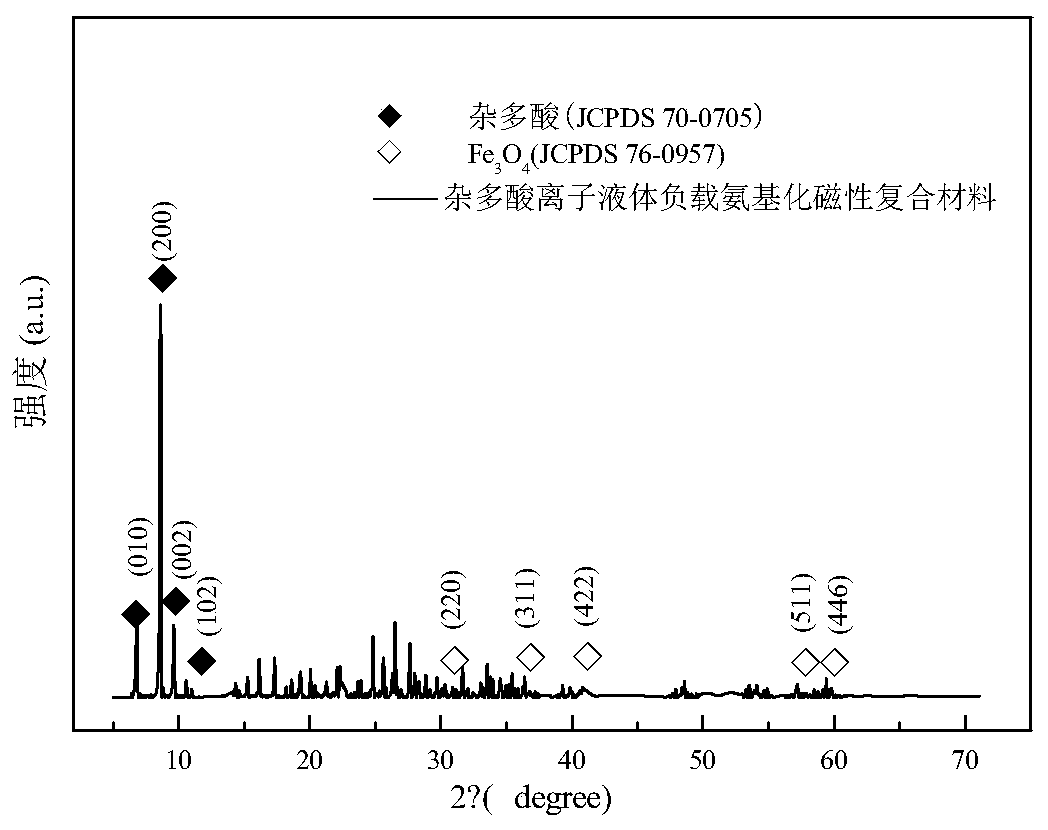

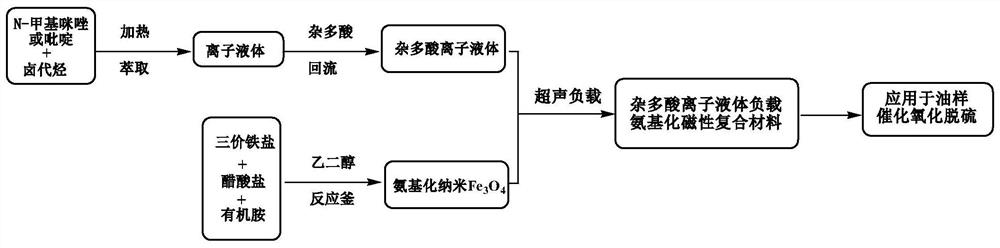

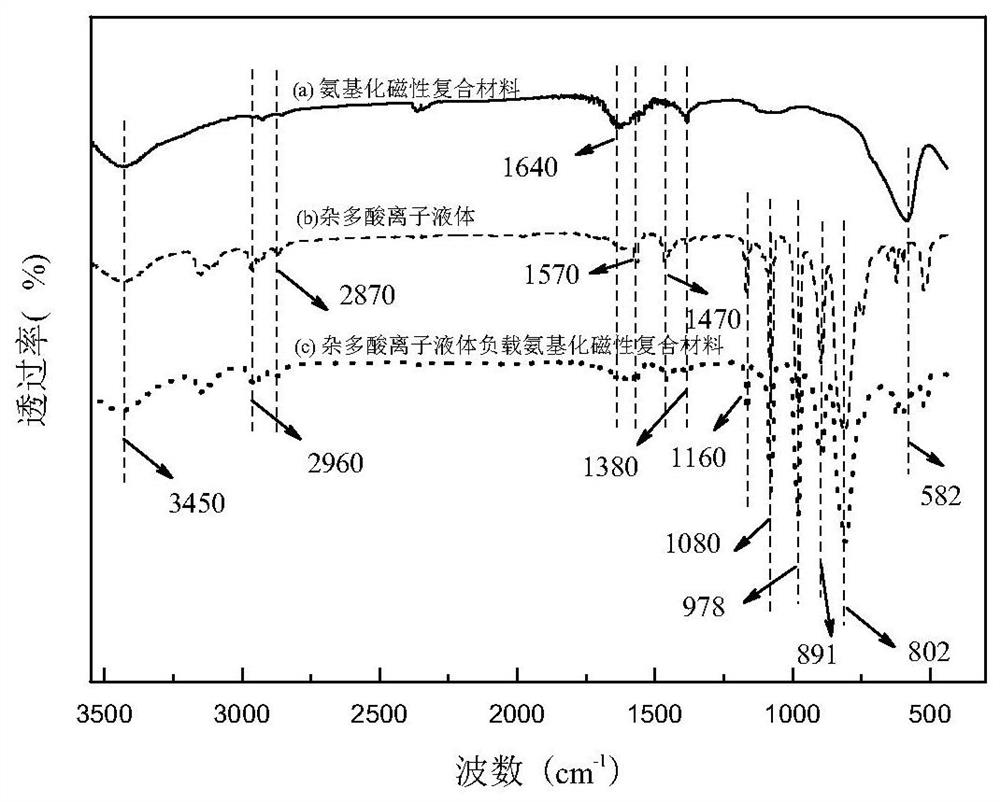

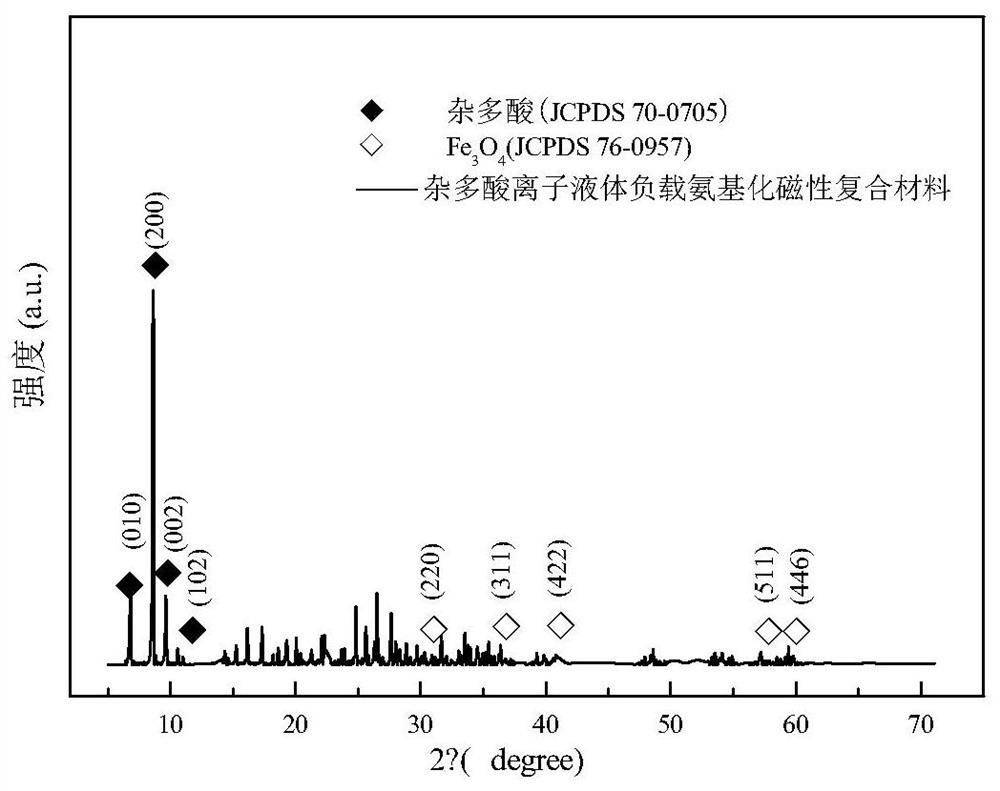

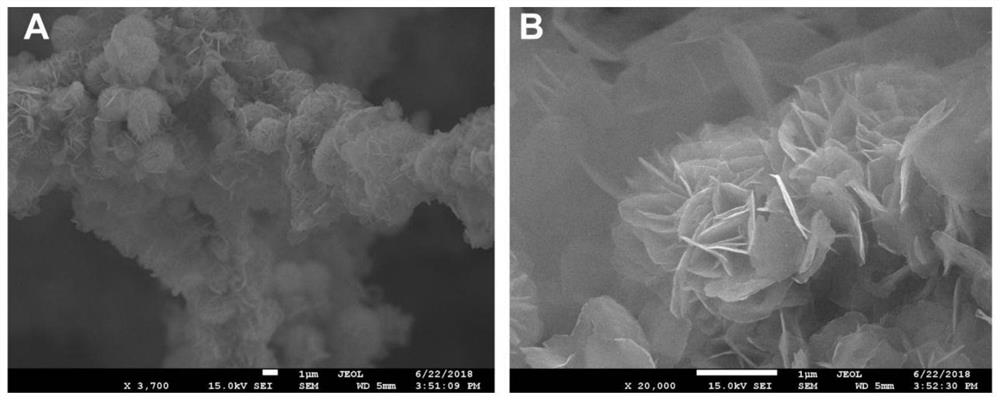

Heteropolyacid ionic liquid supported aminated magnetic composite of date cake structure, preparation method and application

ActiveCN109908962AEasy reunionSimplify operation stepsOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsChemistryPetroleum

The invention discloses a heteropolyacid ionic liquid supported aminated magnetic composite of a date cake structure, a preparation method and an application. The composite is prepared from raw materials including a heteropolyacid ionic liquid and an aminated magnetic composite by supporting the heteropolyacid ionic liquid on an aminated nano magnetic material with an ultrasonic immersing method.The preparation steps are shown as follows: firstly, the heteropolyacid ionic liquid is prepared through a substitution reaction, the aminated magnetic composite is prepared with a solvothermal method, and the heteropolyacid ionic liquid supported aminated magnetic composite is prepared with an ultrasonic supporting method. The product obtained with the method is powdery and brown, has uniform particle size distribution and has the date cake structure and stable properties. The defect of high probability of agglomeration of the magnetic materials is overcome, and the obtained material has gooddispersity, high magnetism and high yield, and raw materials are easy to obtain; the composite has magnetism and catalytic activity and can be effectively used for a catalyst for desulfuration of petroleum samples, and the catalyst can be separately recycled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

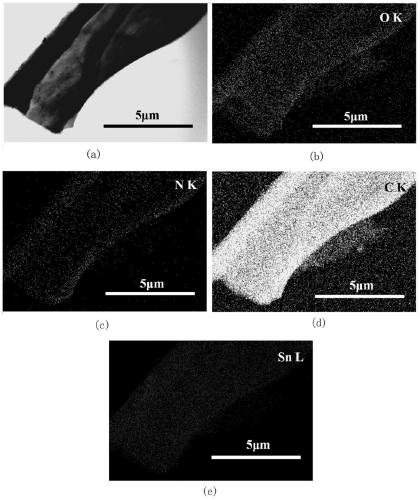

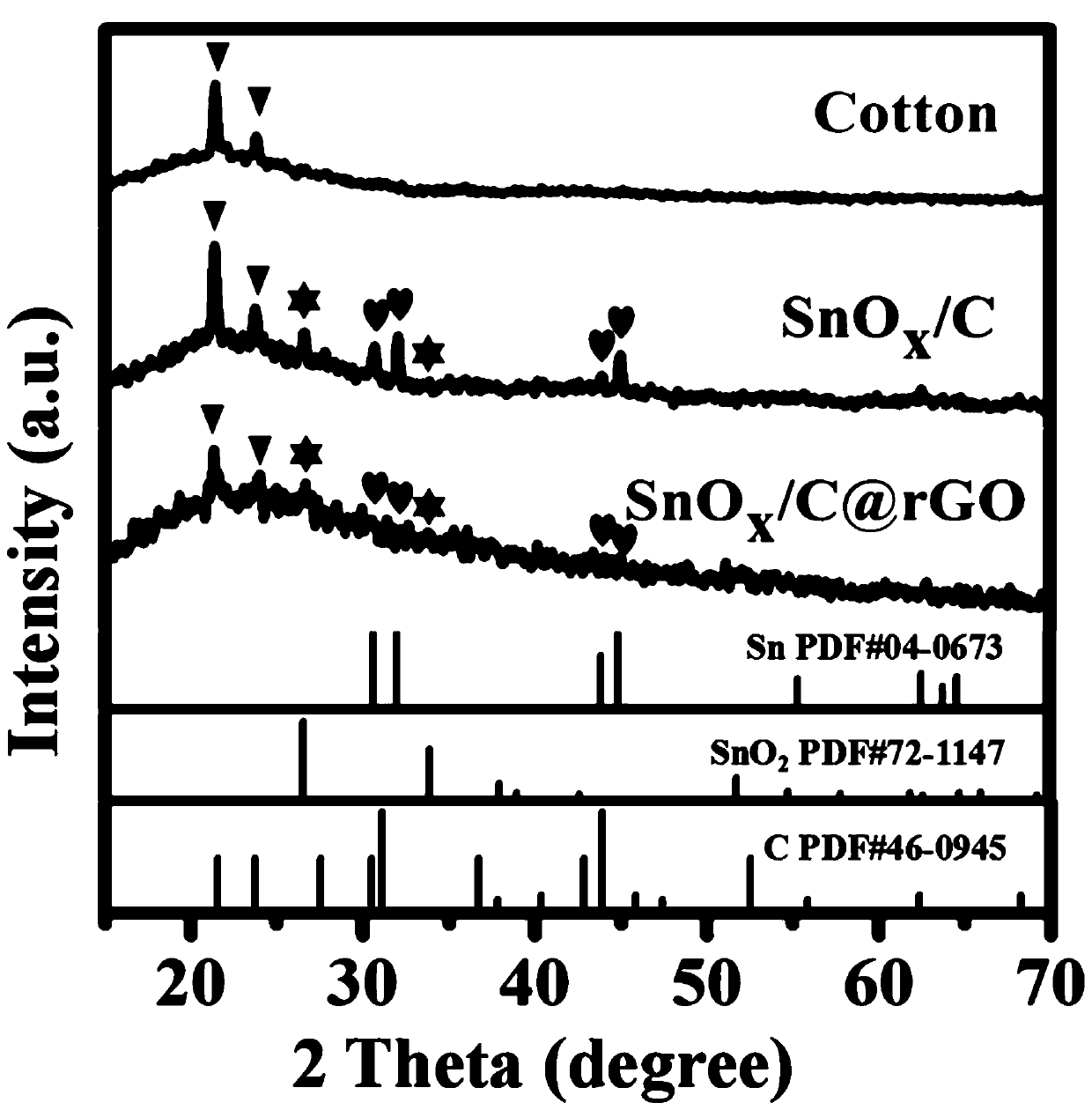

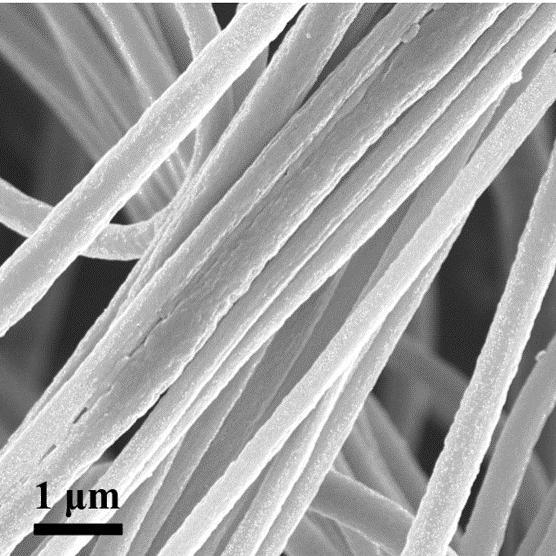

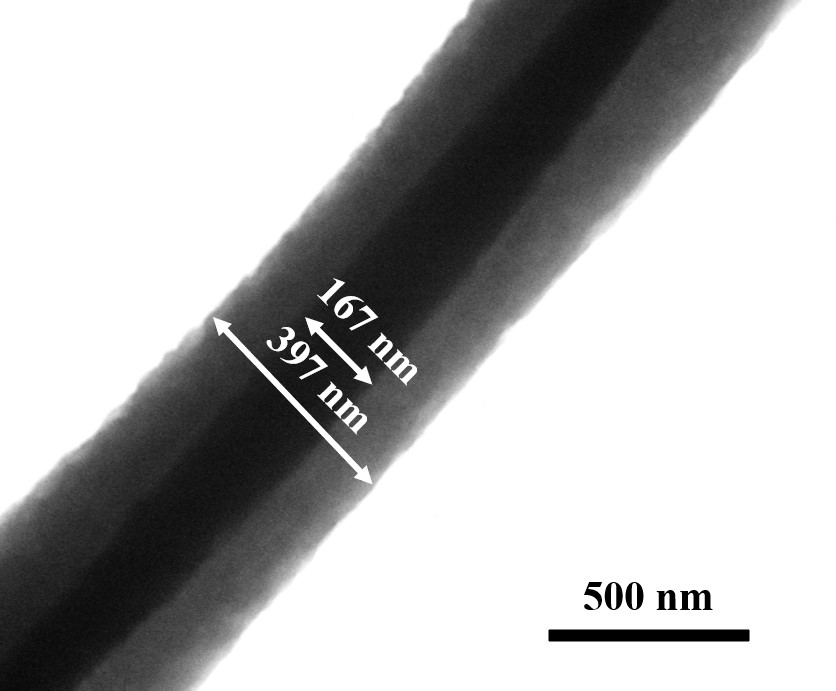

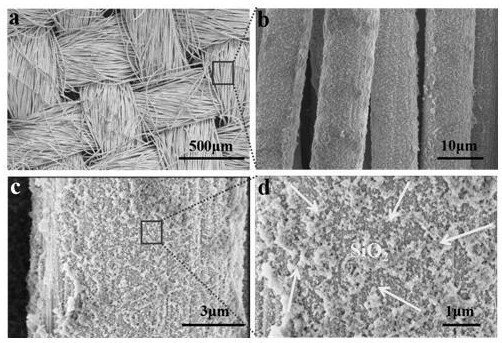

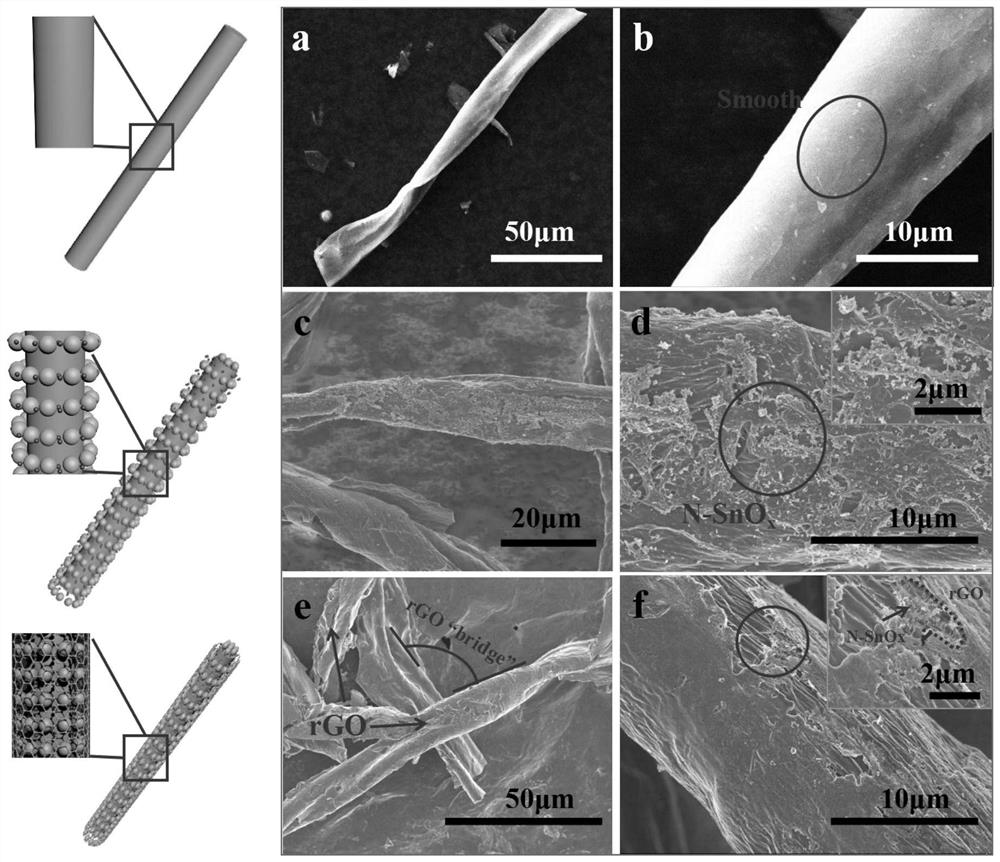

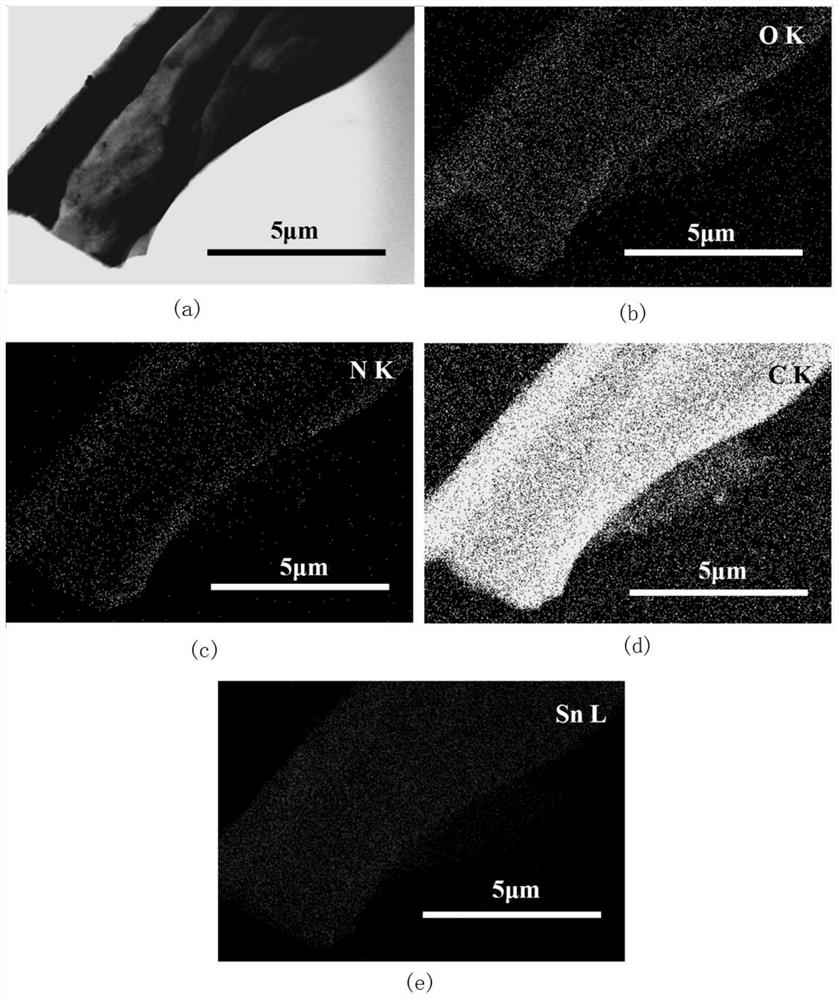

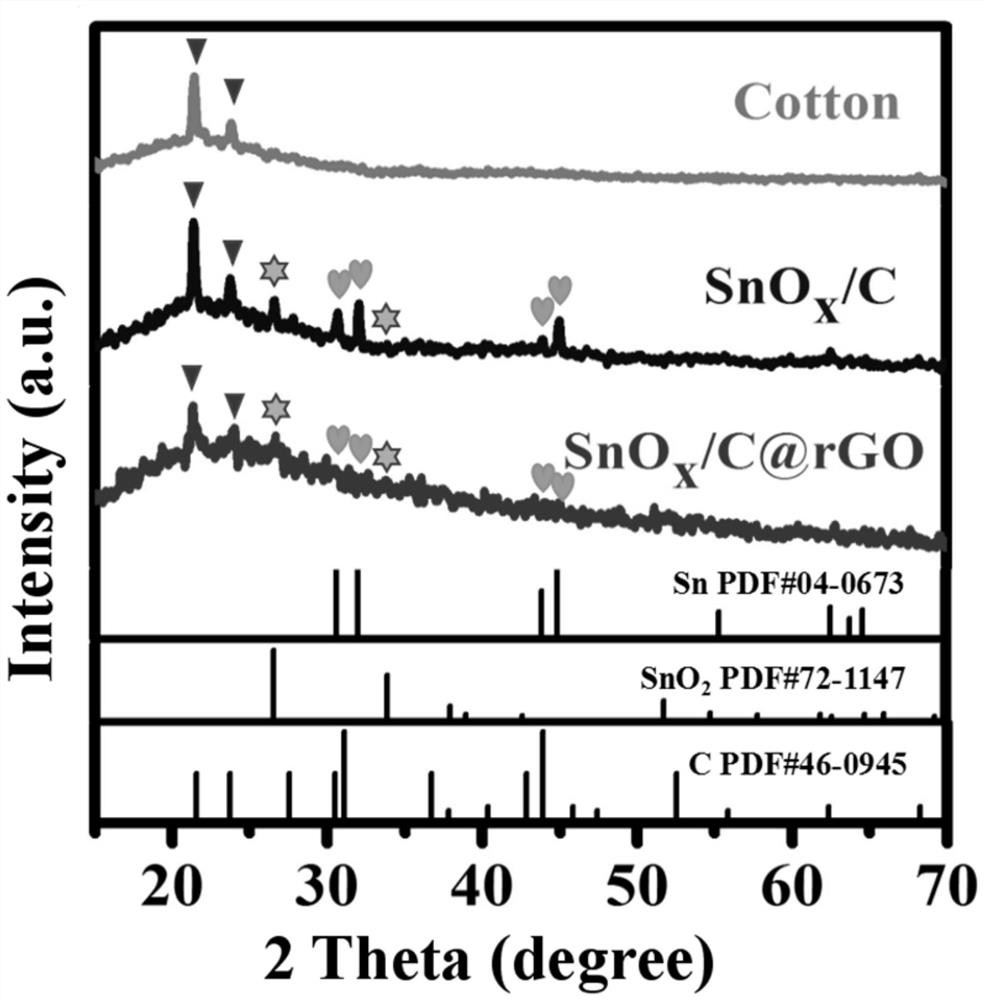

Flexible N/SnOx@ rGO composite material based on biological material substrate, preparation method and application thereof

ActiveCN111403746ASimple processEasy to operateFinal product manufactureCylindrical casing cells/batteryCarbon fibersFreeze-drying

The invention discloses a flexible N / SnOx@rGO composite material based on a biological material substrate, a preparation method and application thereof. The N / SnOx (at) rGO composite material is prepared by adopting a freeze drying method and a CVD (Chemical Vapor Deposition) method. A biological material degreasing cotton is selected as a carbon substrate, the material is cheap and easy to obtain, and the synthesis process is simple and easy to operate. The synthesized N / SnOx particles are small in size and high in crystallinity, in addition, the carbon substrate serves as a conductive carbonnetwork, electron transmission is facilitated, and rGO wrapping the carbon fibers can prevent the N / SnOx particles from falling off and can also serve as an electron transmission bridge to be connected with the carbon fiber network.

Owner:SHAANXI UNIV OF SCI & TECH

Self-early-warning coaxial electrostatic spinning fiber as well as preparation method and application thereof

PendingCN114574977AWith corrosion warning functionSolving Dispersion ProblemsConjugated cellulose/protein artificial filamentsElectro-spinningFiberPolymer science

The invention provides a preparation method and application of a self-early-warning coaxial electrostatic spinning fiber. Comprising the following steps: respectively adding chitosan and polyvinyl alcohol into a solvent, and dissolving to obtain two solutions; mixing the two solutions according to a certain proportion to obtain a shell solution, and preparing the film by taking the indicator solution as a core solution and adopting a coaxial electrostatic spinning method. And loading the self-early-warning fiber into the resin to obtain the self-repairing coating with the self-early-warning function. According to the invention, the loading stability and uniformity of the indicator in coaxial fibers can be effectively improved. The Q235 steel is used as a research substrate, when the coating is damaged, the indicator in the coaxial fiber is released and is combined with iron ions on the metal surface, obvious color change is generated, and a damage early warning function is achieved. Meanwhile, indicator molecules can form a dense film on the surface of steel to prevent corrosion of a base material. The composite coating based on the self-early-warning coaxial fiber has the functions of indicating and repairing damage, and has huge potential in practical application of material protection.

Owner:OCEAN UNIV OF CHINA

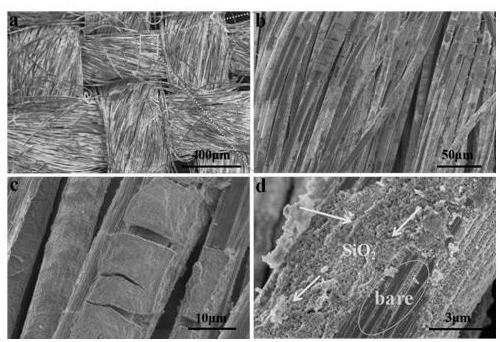

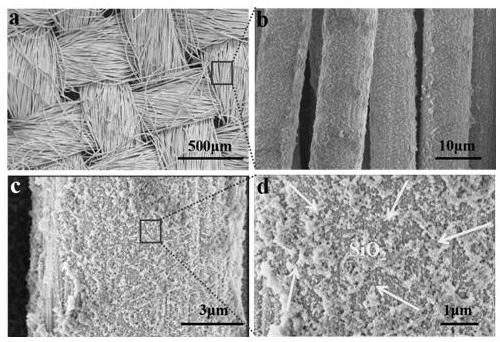

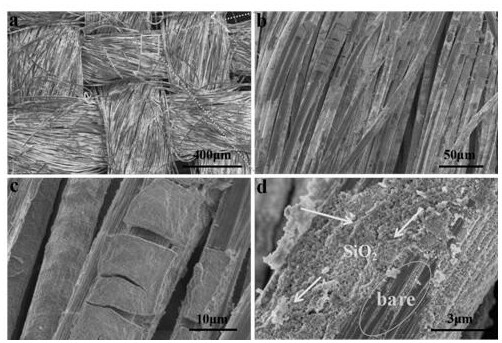

Preparation method and application of self-supporting binder-free flexible SiO2@C composite material

ActiveCN111463422AThe synthesis process is simpleEasy to operateNegative electrodesSecondary cellsCarbon fibersNanoparticle

The invention discloses a preparation method and application of a self-supporting binder-free flexible SiO2@C composite material. The self-supporting binder-free flexible SiO2@C composite material isprepared by adopting a one-step hydrothermal method, and the synthesis process is simple and easy to operate. Moreover, carbon cloth is selected as a carbon substrate, and the material is cheap and easily available. Besides, nanoscale SiO2 particles are provided with more lithium ion contact sites on the surfaces and can be sufficiently reacted with lithium, and the carbon cloth is used as a SiO2particle carrier, so that the nano particles are uniformly distributed on the surface of the carbon fiber, and the problem that the nano particles are easy to agglomerate is solved. In addition, carbon fibers can form a conductive carbon fiber network, electrons are easy to transmit, and the electrons are smooth and unobstructed on the whole flexible substrate.

Owner:SHAANXI UNIV OF SCI & TECH

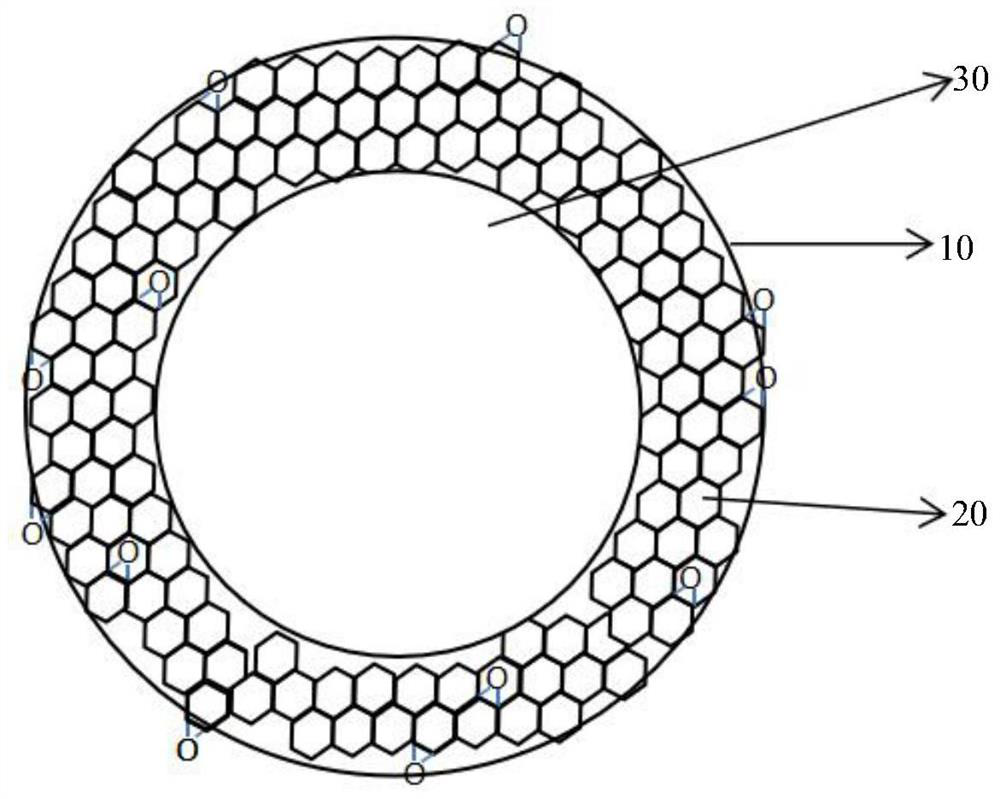

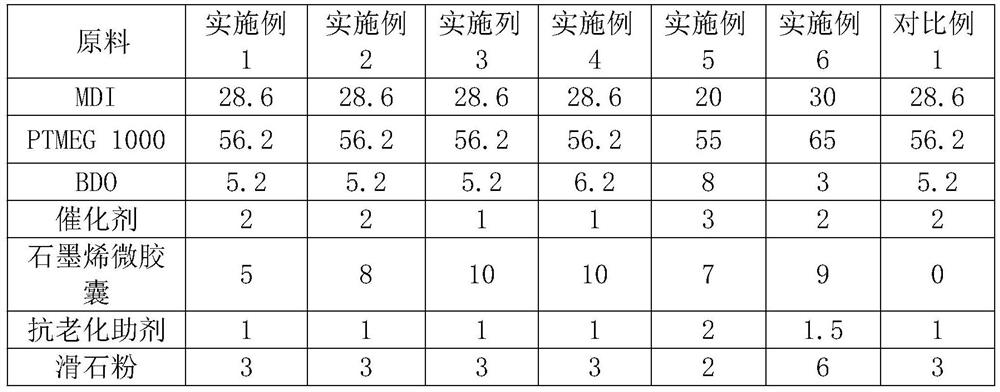

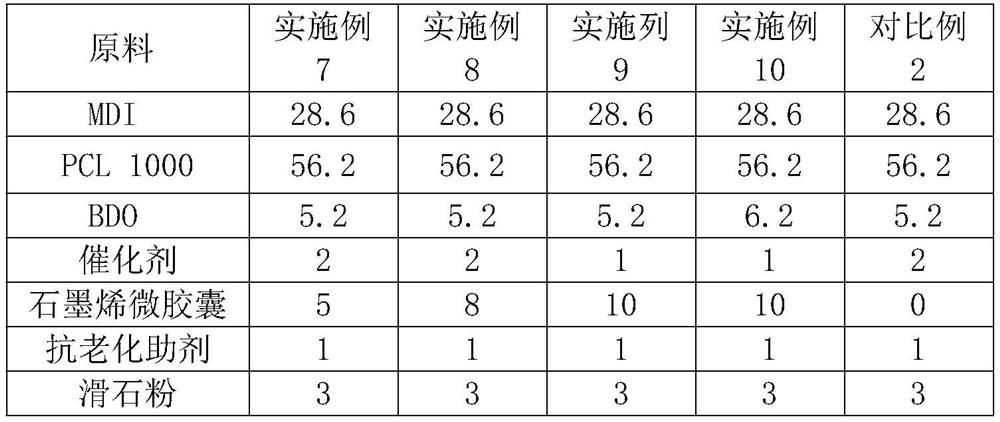

High-barrier polyurethane self-repairing composition and preparation method thereof

PendingCN113831830AImprove barrier propertiesImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsIsocyanatePolymer chemistry

The invention provides a high-barrier polyurethane self-repairing composition and a preparation method thereof. The high-barrier polyurethane self-repairing composition comprises the following components in mass ratio: 20-30 of polyisocyanate, 55-65 of polyhydric alcohol, 3-8 of a chain extender, 5-10 of graphene microcapsules, 1-2 of an anti-aging auxiliary agent, 2-6 of talcum powder and 1-3 of acatalyzer. The graphene microcapsule is of a double-wrapping structure, a wall material is methacrylonitrile, a central core material is silica sol, and a middle core material between the wall material and the central core material is graphene oxide. The prepared high-barrier polyurethane self-repairing composition has an excellent self-repairing function, micro-mark repairing can be rapidly achieved when the high-barrier polyurethane self-repairing composition is heated, meanwhile, excellent barrier performance is achieved, erosion of external water vapor and salt can be effectively blocked, and the protection effect is better.

Owner:江苏图研新材料科技有限公司

Pearlescent dye for papermaking and preparation method thereof

InactiveCN109098035AImprove stabilityImprove the decorative effectCoatings with pigmentsPaper/cardboardPapermakingCitric acid

The invention provides a pearlescent dye for papermaking and a preparation method thereof, and relates to the technical field of dyes for paper. The pearlescent dye for papermaking is prepared from modified kaolin, citric acid, neopentyl glycol, pearlescent pigment, thickener, dispersant and deionized water. The pearlescent dye for papermaking is used for paper surface printing, is good in paper decoration effect, has high glossiness and is bright and excellent in color fidelity, the dyed paper does not shade easily after being used for a period of time, the dye stability is good, the paper surface is smooth and fine, the paper is good in touch, natural and straight, and the addition of the pearlescent pigment makes the paper color expression layers rich, realistic and moving.

Owner:ANHUI ZHONGYA PAPER

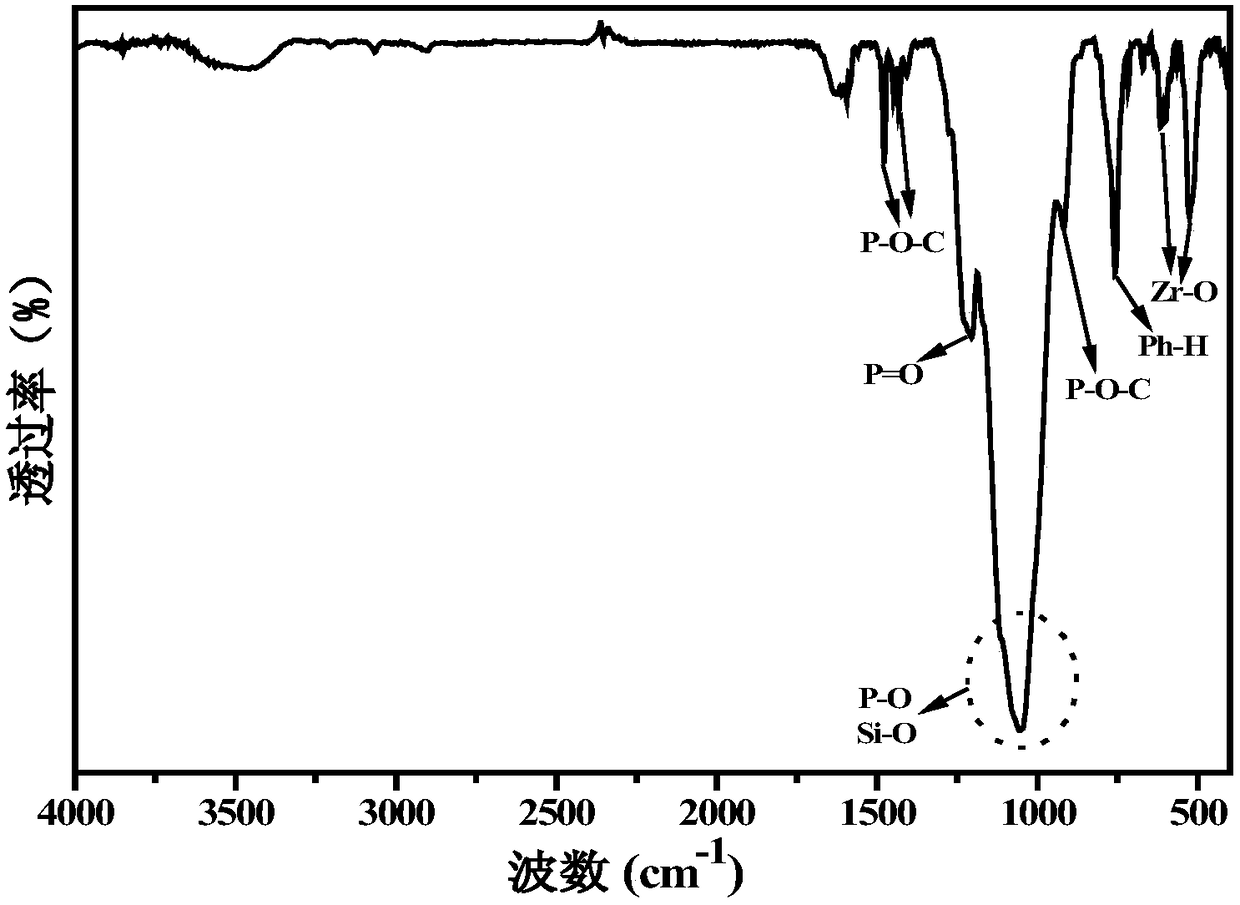

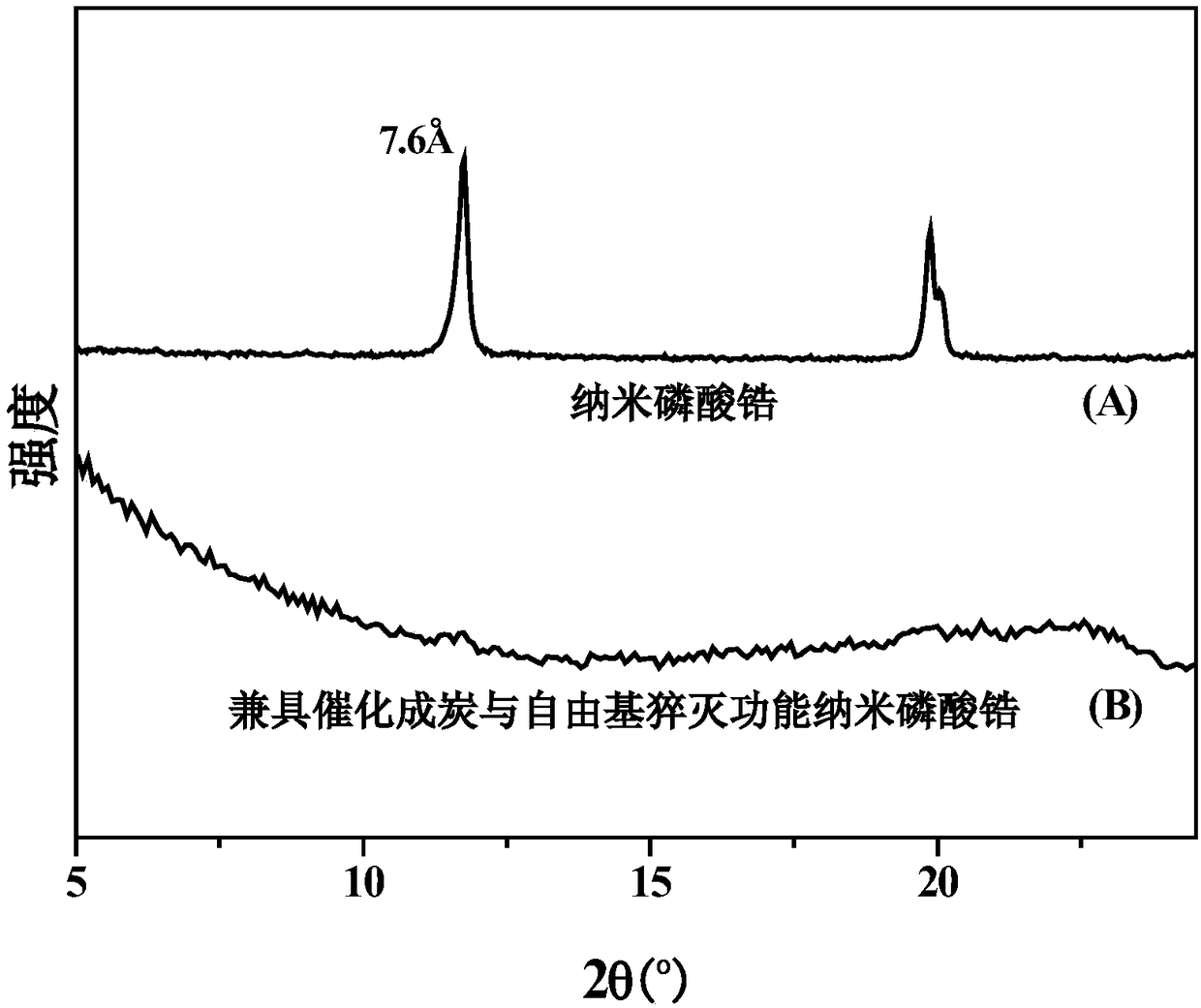

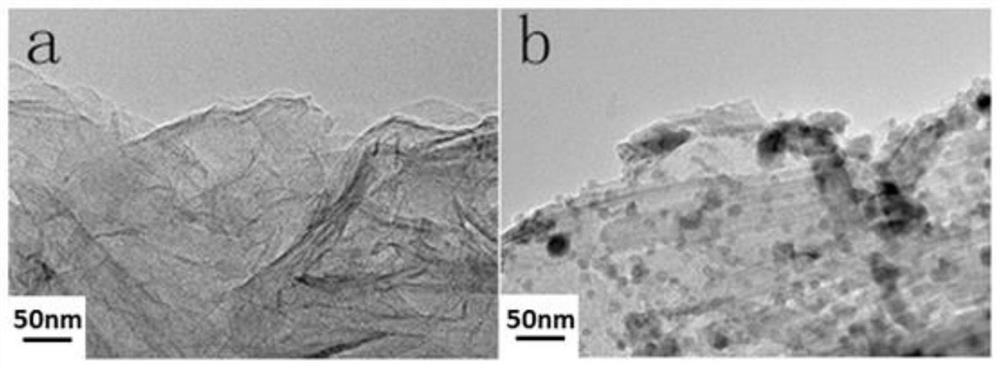

Nano-zirconium phosphate with functions of catalytic char formation and free radical quenching and its preparation method and application

ActiveCN106519736BSolve the problem of easy reunionGood compatibilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsGas phasePolypropylene

The invention discloses nano zirconium phosphate with functions of catalyzing char-forming and quenching free radicals as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly intercalating and stripping nano zirconium phosphate by using an intercalator, carrying out acidification treatment to remove the intercalator and obtain single-laminar nano zirconium phosphate; and then grafting a phosphaphenanthrene group to the single-laminar nano zirconium phosphate through a silane coupling agent to prepare nano zirconium phosphate with the functions of catalyzing char-forming and quenching free radicals. Compared with the prior art, the prepared nano zirconium phosphate has excellent functions of catalyzing char-forming and quenching free radicals, is capable of effectively catalyzing char-forming of polymer under the high-temperature condition and inhibiting free radical chain reaction of polymer in gaseous phase so as to give high flame resistance to the polymer; a prepared flame-resistant polypropylene material can be widely applied to the fields of automotive exteriors, furniture and electric appliance, wires and cables, building materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

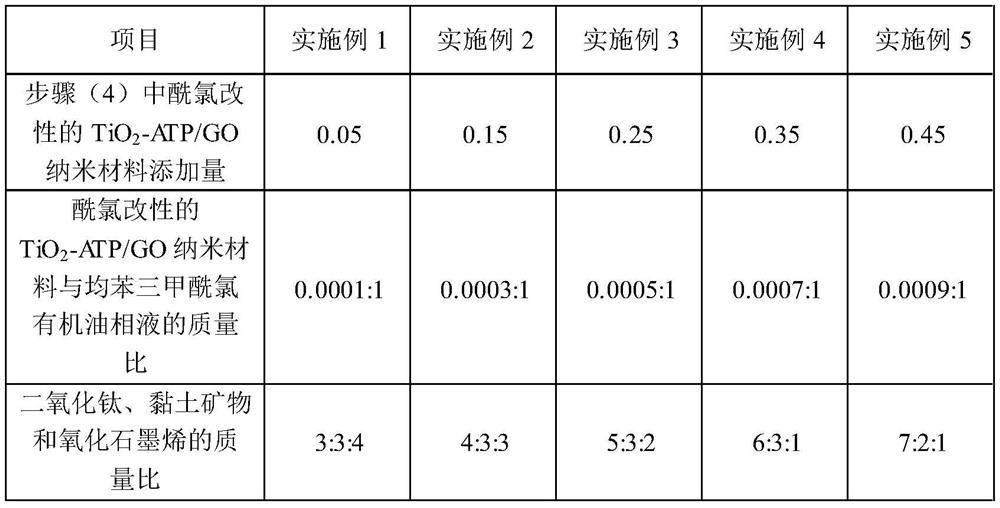

A high-flux anti-pollution nano-hybrid reverse osmosis membrane and its preparation method and application

ActiveCN110876897BLarge specific surface areaImprove hydrophilicitySemi-permeable membranesGeneral water supply conservationReverse osmosisPolyamide

The invention belongs to the technical field of reverse osmosis membranes, and relates to a high-flux anti-pollution nano-hybrid reverse osmosis membrane and a preparation method and application thereof. The nano-hybrid reverse osmosis membrane includes a polysulfone support layer and a hybrid polyamide desalination layer; the hybrid polyamide desalination layer includes acid chloride-modified titanium dioxide-clay mineral / graphene oxide nanomaterials, the titanium dioxide, clay The mass ratio of mineral and graphene oxide is (3-6):(2-3):(1-4). Preparation method: soak the polysulfone support layer in m-phenylenediamine aqueous phase solution for 0.5-1min, and then place it in TiO modified with acid chloride 2 ‑ATP / GO nanomaterials are reacted in the trimesoyl chloride oil phase liquid for 0.5-1min to obtain a reverse osmosis membrane. The desalination layer of the reverse osmosis membrane of the present invention has an excellent combination degree with the polysulfone support layer, which improves the water flux and anti-pollution performance of the reverse osmosis membrane, so that it can maintain a high desalination rate and water retention during the long-term scouring of surface river water. flux.

Owner:恩泰环保科技(常州)有限公司

Jujube cake structure heteropolyacid ionic liquid loaded aminated magnetic composite material, preparation method and application

ActiveCN109908962BSolve the problem of easy reunionUniform particle size distributionOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPtru catalystHeteropoly acid

The invention discloses a heteropolyacid ionic liquid-loaded aminated magnetic composite material with jujube cake type structure, a preparation method and an application thereof. The raw materials for preparing the composite material include a heteropolyacid ionic liquid and an aminated magnetic composite material. The multi-acid ionic liquid is supported on the aminated nano-magnetic material to obtain a composite material. The preparation steps are as follows: firstly adopt substitution reaction to prepare heteropolyacid ionic liquid, solvothermal method to prepare aminated magnetic composite material, and then adopt ultrasonic loading method to prepare heteropolyacid ionic liquid supported aminated magnetic composite material. The product obtained by the method of the invention is powdery, brown in color, uniform in particle size distribution, jujube cake-shaped structure and stable in property. It overcomes the shortcomings of easy agglomeration of magnetic materials, and the obtained materials have good dispersibility, high magnetic properties, easy access to raw materials, and high yield; both magnetic and catalytic activities can be effectively used as catalysts for desulfurization of petroleum samples, and the catalysts can be separated and recycled. .

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A preparation method of cobalt manganese oxide nanoflower-carbon sponge flexible composite material

ActiveCN109671575BEasy to makeEasy to operateHybrid capacitor electrodesCell electrodesArgon atmosphereManganese

The invention belongs to the field of functionalized porous nanomaterials, and in particular relates to a preparation method of a cobalt manganese oxide nanoflower-carbon sponge flexible composite material; the specific steps are: take a commercial melamine sponge, then clean it with distilled water and absolute ethanol, dry it, and then Under a nitrogen or argon atmosphere, heat up the melamine sponge to obtain a carbon sponge after cooling; prepare a mixed solution containing manganese salts and cobalt salts, immerse the carbon sponge in the mixed solution, and perform a hydrothermal reaction. After the reaction, take out the carbon The sponge is washed with distilled water and dried to obtain a manganese-cobalt hydroxide precursor-carbon sponge composite material; further annealing reaction is carried out under an argon atmosphere to obtain a cobalt oxide manganese nanoflower-carbon sponge flexible composite material; the present invention uses flexible , Porous, self-supporting carbon sponge as a growth template successfully solves the problem of easy agglomeration of nanomaterials; and the obtained composite material has a large number of exposed active sites, rich pores and good electrical conductivity.

Owner:JIANGSU UNIV

A self-standing adhesive-free flexible sio 2 Preparation methods and applications of @c composite materials

ActiveCN111463422BThe synthesis process is simpleEasy to operateSecondary cellsNegative electrodesCarbon fibersNanoparticle

The invention discloses a self-supporting flexible SiO without binder 2 Preparation method and application of @C composite materials, using a one-step hydrothermal method to prepare free-standing binder-free flexible SiO 2 @C composite material, the synthesis process is simple and easy to operate. Moreover, carbon cloth is selected as the carbon substrate, and the material is cheap and easy to obtain. In addition, nanoscale SiO 2 There are more lithium ion contact sites on the particle surface, which can fully react with lithium, and the carbon cloth acts as SiO 2 The particle carrier makes the nanoparticles evenly distributed on the surface of the carbon fiber, which solves the problem that the nanoparticles are easy to agglomerate, and the carbon fiber can form a conductive carbon fiber network, which is easy to transmit electrons, making the electrons unimpeded on the entire flexible substrate.

Owner:SHAANXI UNIV OF SCI & TECH

Laser irradiation PbS quantum dot embedded SnSe thermoelectric material and preparation method and application thereof

ActiveCN113540334AThe synthesis process is simpleEasy to operateThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsSolvothermal reaction

The invention discloses a laser irradiation PbS quantum dot embedded SnSe thermoelectric material and a preparation method and application thereof, which belong to the technical field of thermoelectric materials and devices. The preparation method comprises the following steps of uniformly dispersing PbS in a solvent to obtain a solution A, and performing irradiation treatment on the solution A through a non-focused laser in ultrasound to obtain a solution B, uniformly dispersing SnCl2.2H2O in a solvent to obtain a solution C, and uniformly dispersing NaSeO3 in the solution C to obtain a solution D, uniformly mixing the solution B and the solution D to obtain a solution E, uniformly dispersing NaOH into the solution E, then carrying out solvothermal reaction, and cleaning and drying an obtained product system to obtain a solid product, and carrying out spark plasma sintering pressing treatment on the solid product to prepare the laser irradiation PbS quantum dot embedded SnSe thermoelectric material. The prepared laser irradiation PbS quantum dot embedded SnSe thermoelectric material improves the conductivity and Seebeck coefficient, and can be applied to preparation of a deep space spacecraft ultra-long life power supply or preparation of a self-powered infinite sensor and other application occasions.

Owner:SHAANXI UNIV OF SCI & TECH

A beaded MOF-filled mixed matrix membrane with silicone rubber

ActiveCN112316741BSolve the problem of easy reunionGood dispersionMembranesDistillationPolymer sciencePtru catalyst

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

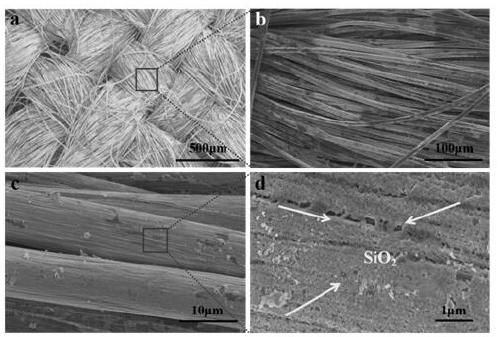

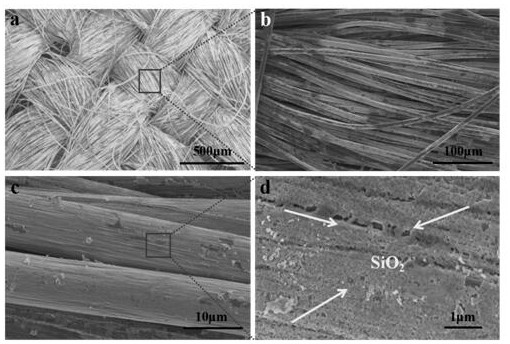

Softening modifier for inorganic fiber and preparation method thereof

ActiveCN110592945AGood dispersionSolve the problem of easy reunionGrip property fibresFiberMaterials science

The invention discloses a softening modifier for inorganic fiber and a preparation method thereof. The method comprises the following steps that S10, a dispersant A is prepared; S20, a softener B is prepared; S30, the dispersant A and the softener B are separately packaged to obtain the softening modifier for the inorganic fiber. After the softening modifier for the inorganic fiber is used for modifying the inorganic fiber, the dispersibility and softness of the inorganic fiber can be remarkably improved, the strength of the inorganic fiber is enhanced, the inorganic fiber is not likely to break, and the application range of the inorganic fiber is enlarged.

Owner:保蓝行福建环保技术研究院有限责任公司

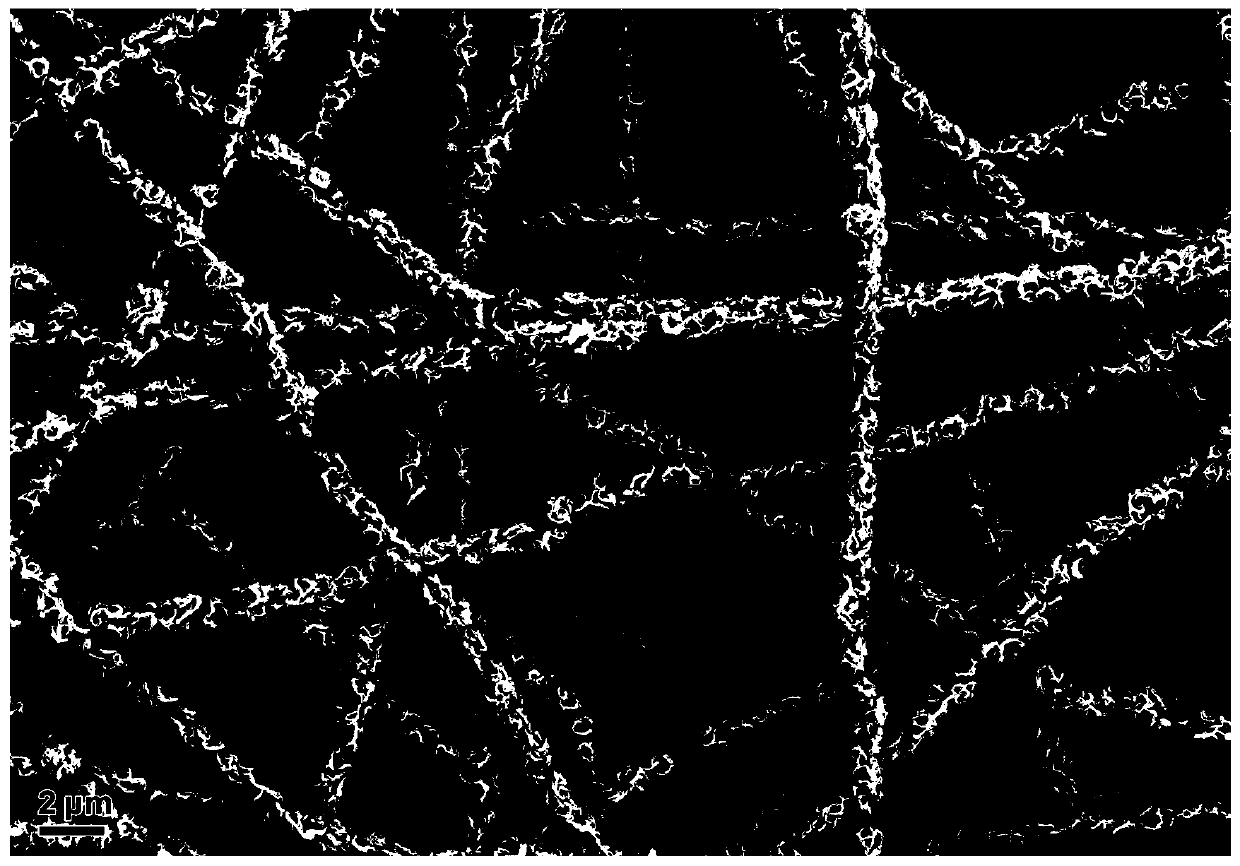

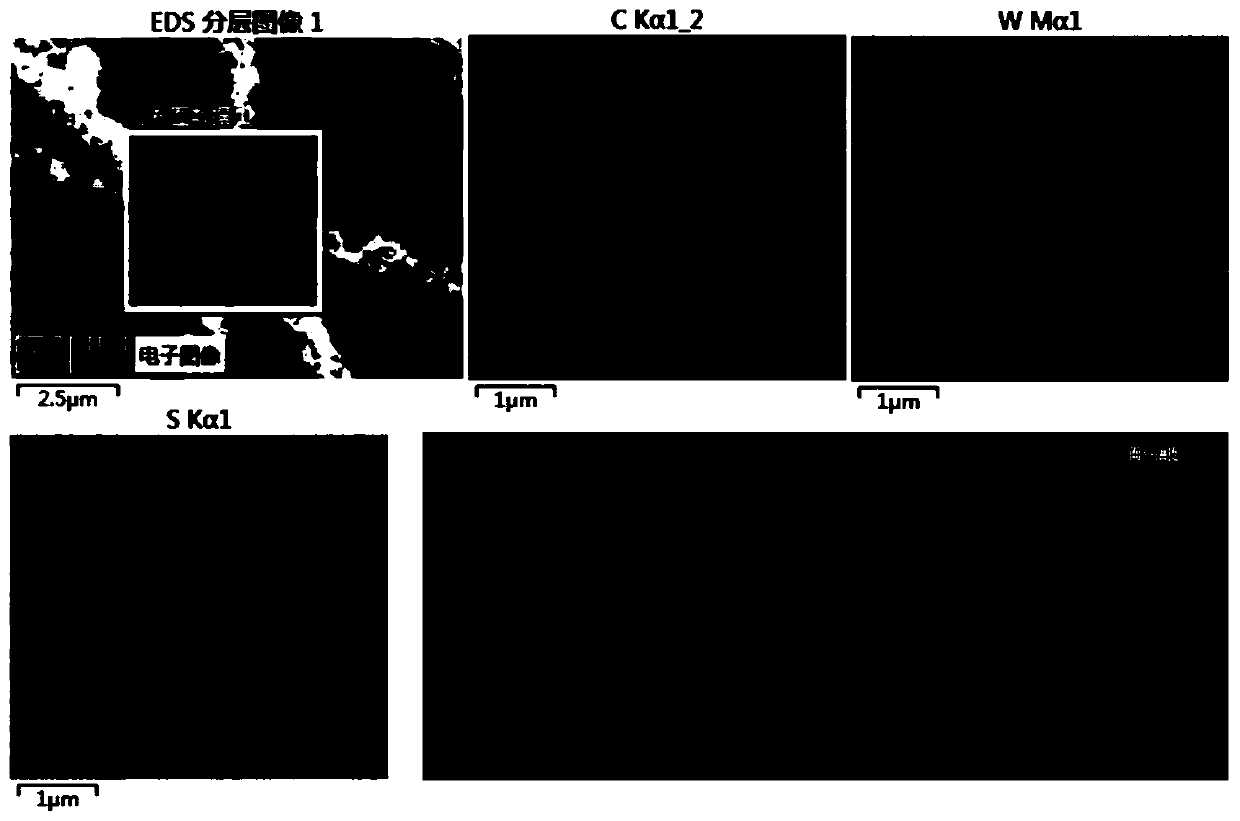

A kind of tungsten disulfide/carbon nanofiber composite material and its preparation method and application

InactiveCN107034663BEnvironmentally friendlyEasy to makeMaterial nanotechnologyPhysical/chemical process catalystsElectrospinningNanofiber

The invention provides a tungsten disulfide / carbon nanofiber composite material and its preparation method and use. The preparation steps are as follows: (1) Under high-speed stirring and oil bath conditions, prepare a polyacrylonitrile spinning solution; (2) Use Preparing polyacrylonitrile nanofibers by electrospinning; (3) Pre-oxidizing the polyacrylonitrile nanofibers in step (2) through programmed temperature control; (4) Pre-oxidizing the polyacrylonitrile nanofibers in step (3) through staged temperature rise The treated polyacrylonitrile nanofibers are carbonized; (5) Add a certain amount of tungsten disulfide precursor compound to the solvent, and obtain a tungsten disulfide precursor solution by ultrasonic; (6) Dip the carbon nanofiber membrane into the tungsten disulfide precursor into a bulk solution, and then placed in a high-pressure reactor to perform a solvothermal reaction at a certain temperature to obtain a tungsten disulfide / carbon nanofiber composite material. The preparation process of the invention is simple, easy to operate, and the polymers and reagents used are environmentally friendly.

Owner:JIANGSU UNIV

A method for preparing nano zno-go/waterborne polyurethane superamphiphobic coating by spraying method

ActiveCN109647680BSolve the problem of easy reunionEasy to prepareCoatingsSpecial surfacesNano zinc oxideHydrophobe

A method for preparing nano-ZnO-GO / waterborne polyurethane super-amphiphobic coating by spraying method, adopting the method of ultrasonic hydrothermal compounding, first modifying nano-zinc oxide by perfluorooctyl trichlorosilane, and then applying the modified nano- ZnO and GO were loaded to obtain a nano-ZnO-GO composite. A water-based polyurethane layer was prepared on the surface of the substrate, and then a low-surface-energy nano-ZnO-GO composite layer was constructed on the surface of the water-based polyurethane layer. After the coating was cured, its surface morphology and static contact angle. The invention reduces the surface energy of nano-zinc oxide, improves the hydrophobicity and oleophobicity of the surface of the nano-ZnO-GO composite layer after fluorination treatment, achieves a super-amphiphobic effect, and improves the stability of the coating. The invention has the advantages of low production cost, simple preparation method, low requirements on reaction equipment, mild reaction conditions, no environmental pollution and large-scale production.

Owner:NANCHANG HANGKONG UNIVERSITY

A kind of flexible n/snox@rgo composite material based on biomaterial substrate and its preparation method and application

ActiveCN111403746BSimple processEasy to operateFinal product manufactureCylindrical casing cells/batteryFiberCarbon fibers

The invention discloses a flexible N / SnOx@rGO composite material based on a biological material substrate and its preparation method and application. N / SnO is prepared by a freeze-drying method x @rGO composites. The biomaterial absorbent cotton is selected as the carbon base, the material is cheap and easy to obtain, the synthesis process is simple, and it is easy to operate. Synthetic N / SnO x The particle size is small and the crystallinity is strong. In addition, the carbon substrate acts as a conductive carbon network, which is conducive to the transmission of electrons. The rGO wrapped in carbon fiber can not only prevent the N / SnO x The shedding of particles can also serve as an "electronic transport bridge" to connect the carbon fiber network.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of underground filling cementitious material and its preparation method and application

A preparation method for underground filling cementitious material, characterized in that it comprises the following steps: crushing 40-70 parts of waste glass, 30-40 parts of slag and 10-20 parts of steel slag to an average particle size of 1-15 mm, and mixing uniformly , to obtain a solid mixture; water is added to the solid mixture, the weight ratio of water to the solid mixture is 0.4-0.6, and then 1-2 parts of water reducing agent are added for wet grinding, and the average particle size of the ball mill until the slurry is 1 ‑5 μm to obtain a liquid slurry; add water to the liquid slurry, the weight ratio of water to liquid slurry is 0.5, then add 3‑8 parts of activator, mix and stir evenly, and vibrate completely to obtain underground filling cementitious material . The invention utilizes the characteristic that the slurry is alkaline after wet grinding, and the glass in the mixed slurry excites the slag while completing the self-excitation, fully utilizes the solid waste, improves the utilization rate of the solid waste, reduces the preparation cost, and is energy-saving and environment-friendly. The multifunctional, economical and efficient underground filling cementitious material is prepared, the preparation process is simple, and the cement mortar can be gradually replaced and widely used.

Owner:HUBEI UNIV OF TECH

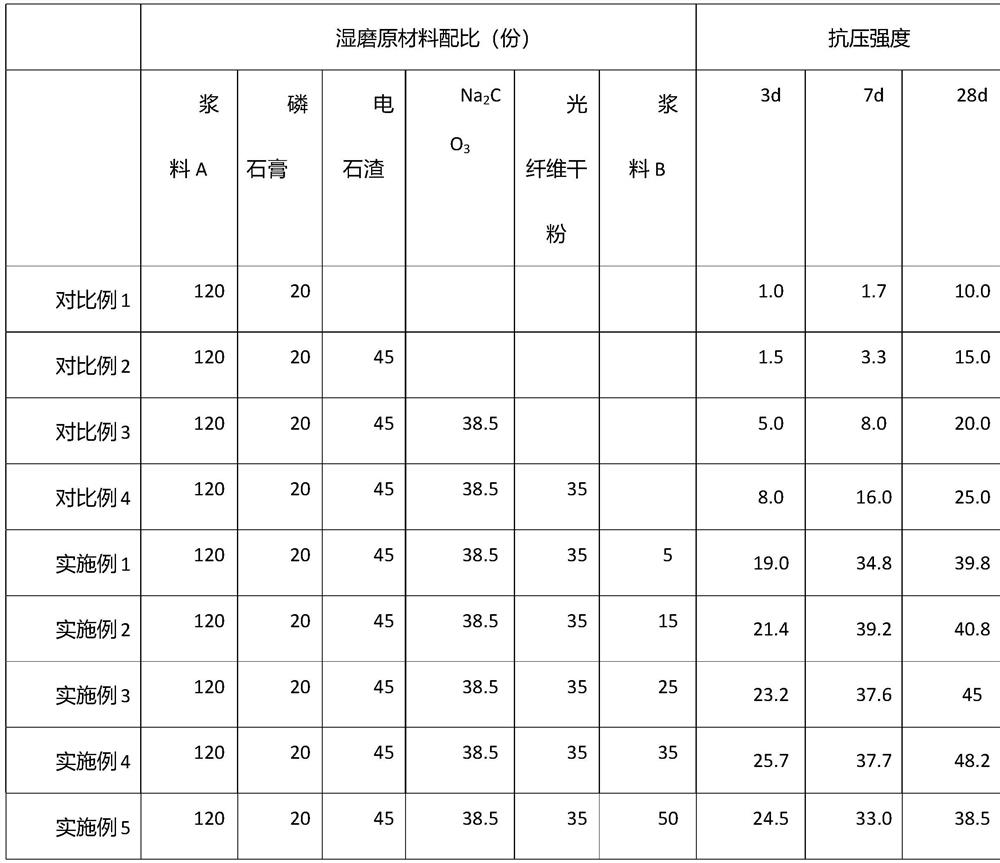

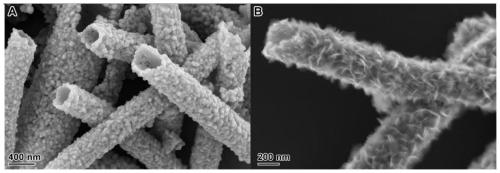

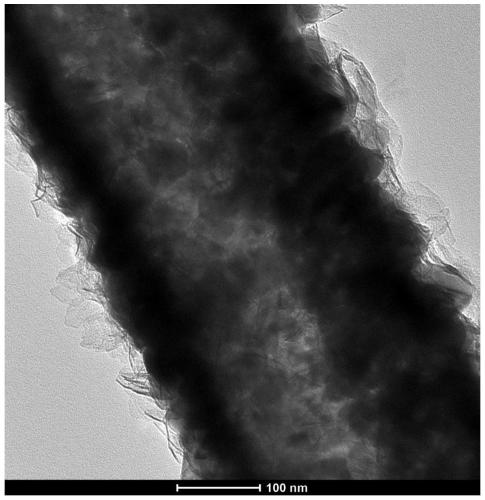

A preparation method of fiber-doped waste mud alkali-activated phosphorus slag geopolymer

The invention discloses a preparation method of alkali-activated phosphorus slag geopolymer doped with fiber waste mud. Grind until the median particle size is 1-4 μm to obtain slurry A; pulverize the optical fiber waste sludge and pass through a 1.18mm sieve to obtain the optical fiber waste sludge dry powder; take the optical fiber dry powder according to the water material of 0.3-0.7 Specific wet grinding to a median particle size of 100-800nm, to obtain slurry B; get 120 parts of slurry A, 35 parts of optical fiber waste sludge dry powder, 5-50 parts of slurry B, 10-40 parts of phosphogypsum, 20 ‑50 parts of carbide slag, 20‑50 parts of Na 2 CO 3 Mix and stir other materials, and use a mortar mixer with a cement-sand ratio of 1:3 to obtain a fiber-doped waste mud alkali-activated phosphorus slag geopolymer. The invention has simple operation, greatly reduces the production cost, solves the problems of land occupation by solid waste stockpiling, environmental pollution and the like, and has high economic and environmental benefits.

Owner:HUBEI UNIV OF TECH

A kind of cobalt nickel oxide/tin dioxide composite nanotube and its preparation method and application

ActiveCN107099880BLow costEasy to makeHybrid capacitor electrodesCell electrodesTin dioxideNickel salt

Owner:JIANGSU UNIV

A kind of softening modifier for inorganic fiber and preparation method thereof

ActiveCN110592945BGood dispersionSolve the problem of easy reunionGrip property fibresFiberPolymer science

The invention discloses a softening modifier for inorganic fibers and a preparation method thereof, comprising the following steps: step S10, preparing dispersant A; step S20, preparing softener B; step S30, mixing dispersant A and softener B is packaged separately to obtain the softening modifier for inorganic fibers. The softening modifier for inorganic fibers prepared by the present invention can significantly improve the dispersibility and softness of the inorganic fibers after the inorganic fibers are modified, and enhance the strength of the inorganic fibers so that they are not easy to break and increase the strength of the inorganic fibers. application range.

Owner:保蓝行福建环保技术研究院有限责任公司

Preparation method of optical fiber-doped waste mud alkali-activated phosphorous slag geopolymer

The invention discloses a preparation method of an optical fiber-doped waste mud alkali-activated phosphorous slag geopolymer. The technical scheme comprises the steps of carrying out synergistic wet grinding on 90-200 parts of phosphorus slag and 50-100 parts of nickel slag according to a water-material ratio of 0.3-0.7 until the median particle size is 1-4 [mu]m to obtain slurry A; crushing the optical fiber waste mud, and sieving the crushed optical fiber waste mud through a 1.18 mm sieve to obtain optical fiber waste mud dry powder; carrying out wet grinding on the optical fiber dry powder according to a water-material ratio of 0.3-0.7 until the median particle size is 100-800nm to obtain slurry B; mixing and stirring 120 parts of the slurry A, 35 parts of the optical fiber waste mud dry powder, 5-50 parts of the slurry B, 10-40 parts of phosphogypsum, 20-50 parts of carbide slag, 20-50 parts of Na2CO3 and other materials, and preparing the optical fiber-doped waste mud alkali-activated phosphorous slag geopolymer through a mortar stirring machine according to the mortar ratio of 1: 3. The method is simple to operate, greatly reduces the production cost, solves the problems of solid waste stockpiling land occupation, environmental pollution and the like, and has high economic benefits and environmental benefits.

Owner:HUBEI UNIV OF TECH

A kind of masterbatch and preparation method for graphene anticorrosion coating

ActiveCN107641433BImprove anti-corrosion performanceGood effectAnti-corrosive paintsEpoxy resin coatingsMasterbatchPorosity

The invention provides a masterbatch for a graphene anticorrosive coating and a preparation method of the masterbatch. The preparation method comprises the following steps: carrying out depth etchingon rubber powder particles by using laser for improving porosity of the rubber powder particles; then filling graphene into holes of a porous rubber powder material for carrying out high-speed stirring, enabling the porous rubber powder to effectively adsorb and carry graphene and finally obtaining the masterbatch. The prepared masterbatch is added into a waterborne resin coating for reacting withwater and quickly dispersing, and a continuous film is formed inside the coating, so that the graphene is driven to be uniformly dispersed into the coating, and further the problem that the grapheneis easy to overlap and aggregate in the application of anticorrosive coatings is effectively solved. Furthermore, porous emulsion powder particles are used as a carrier, has good compatiblity with thecoating and does not contain any impurity components; besides, the graphene anticorrosive masterbatch prepared by the method, disclosed by the invention, has the advantages of convenience in storage,no environmental pollution and remarkable market application value.

Owner:湖南邦泽科技有限公司

Method for preparing waterborne silicate zinc-enriched antirust and antiseptic paint from surface-activated and grafted glass flakes

InactiveCN109439201AGood compatibilityImprove adhesionAnti-corrosive paintsHydrolysateToluene diisocyanate

The invention discloses a method for preparing a waterborne silicate zinc-enriched antirust and antiseptic paint from surface-activated and grafted glass flakes. The method comprises adding and mixingxylene into the glass flakes for dispersion, under nitrogen protection, dropwise adding in KH560 hydrolysate, increasing the temperature for reaction, washing reaction products with xylene and tetrahydrofuran, performing Soxhlet extraction and vacuum drying to obtain surface-activated and grafted KH560 glass flakes, adding and mixing mica iron oxide into absolute methylbenzene, performing ultrasonic treatment, under nitrogen protection, dropwise adding in a mixture of toluene diisocyanate, dibutyltin dilaurate and absolute methylbenzene for reaction, increasing the temperature for further reaction, filtering and repeatedly washing reaction products with absolute methylbenzene to obtain a toluene diisocyanate-modified mica iron oxide filler; mixing film forming materials into a sanding anddispersing mixer, then mixing in deionized water and zinc powder, and then continuing to mixing in the toluene diisocyanate-modified mica iron oxide filler to obtain the waterborne silicate zinc-enriched antirust and antiseptic paint.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com