Method for preparing nano ZnO-GO/waterborne polyurethane super-amphiphobic coating through spraying method

A water-based polyurethane, spraying technology, applied in the field of materials, can solve the problems of loss of super-hydrophobic properties, damage, etc., and achieve the effects of low reaction equipment requirements, strong adhesion, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

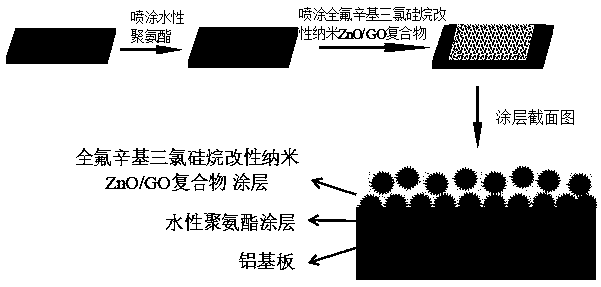

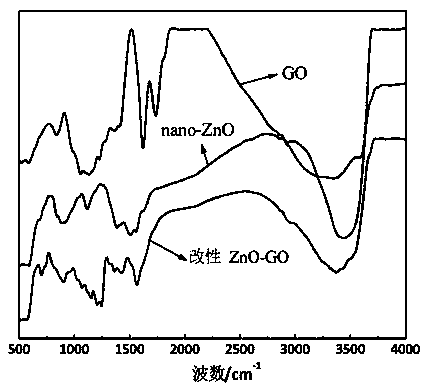

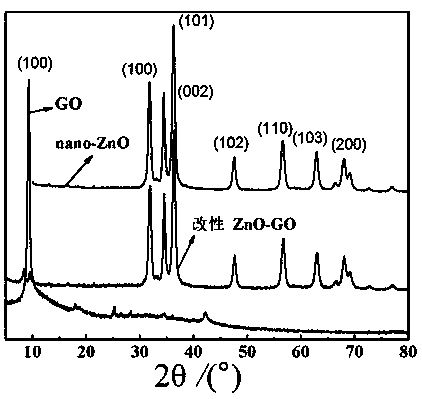

[0035] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2 O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added t...

Embodiment 2

[0037] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2 O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added t...

Embodiment 3

[0039] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com