A kind of cobalt nickel oxide/tin dioxide composite nanotube and its preparation method and application

A technology of tin dioxide and cobalt-nickel oxide, applied in the direction of hybrid capacitor electrodes, structural parts, inorganic raw material artificial filaments, etc., can solve the problems of low conductivity, low specific surface area, volume expansion limitation, etc., and achieve easy operation and preparation. The process is simple and the effect of easy reunion is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps:

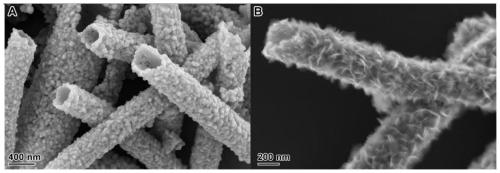

[0036] Weigh 1g of polyvinylpyrrolidone powder and add it into a mixed solvent of 5mL of ethanol + 5mL of deionized water, and stir at a high speed for 7 hours under heating in an oil bath at 80°C to obtain a clear polyvinylpyrrolidone solution. Then, 1 g of tin dichloride powder was added to the above solution, and the mixture was stirred for 5 hours under an oil bath to obtain a milky white spinning solution. Electrospinning was performed on the above mixed spinning solution, and the spinning parameters were set as follows: flow rate 0.3 mm / min, voltage 20 kV, receiving distance 15 cm. The prepared tin dichloride-polyvinylpyrrolidone nanofibers were finally deposited on the roller receiver in the form of nanofiber films, and the fiber films were peeled off and stored in a vacuum oven for 12 hours to remove residual solvents. The dried tin dichloride / polyvinylpyrrolidone fiber membrane was transferred to a muffle furnace...

Embodiment 2

[0042] This embodiment includes the following steps:

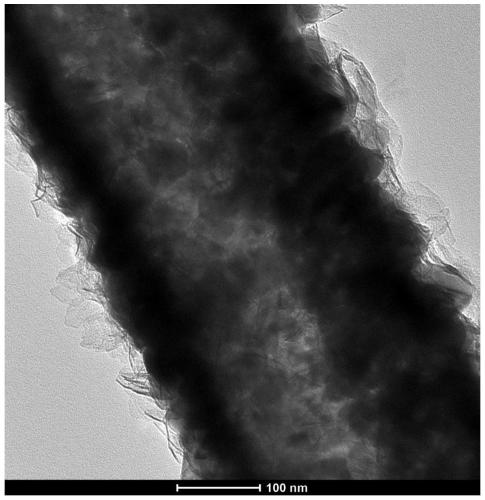

[0043]Prepare 4mM nickel nitrate aqueous solution and 8mM cobalt nitrate aqueous solution respectively, take 50mL of the above solutions and mix them, weigh 30mg of tin dioxide nanotube powder and a certain amount of urea and add them to the above mixed solution, and after ultrasonic mixing for 30s, the The dispersion was placed in a water bath at 80°C and reacted for 12 hours under magnetic stirring. After the reaction was completed, the dispersion was left to stand for 24 hours, the supernatant was poured, and the gray cobalt-nickel oxide precursor / tin dioxide composite nanotube was separated by centrifugation, and the product was dried in an oven at 70°C for use.

[0044] The dried cobalt-nickel oxide precursor / tin dioxide composite nanotubes were transferred to a programmable temperature-controlled tube furnace, and in a nitrogen atmosphere, the temperature was raised to 250°C at a rate of 1°C / min and kept for 1.5h, an...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Prepare 4mM nickel nitrate aqueous solution and 8mM cobalt nitrate aqueous solution respectively, take 50mL of the above solutions and mix them, weigh a certain amount of urea and add it to the above mixed solution and wait for it to completely dissolve, place the mixed solution in a water bath at 80°C. The reaction was performed under magnetic stirring for 12 h. After the reaction was completed, the dispersion was left to stand for 24 hours, the supernatant was poured, and the white cobalt-nickel oxide precursor was separated by centrifugation. The product was dried in an oven at 70°C, and then transferred to a programmable temperature-controlled tube furnace. , under a nitrogen atmosphere, the temperature was raised to 250°C at a rate of 1°C / min and maintained for 1.5h, and pure cobalt-nickel oxide powder was obtained after natural cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com