A preparation method of cobalt manganese oxide nanoflower-carbon sponge flexible composite material

A composite material, cobalt manganese oxide technology, applied in chemical instruments and methods, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of volume expansion limitation, low specific surface area, low electrical conductivity, etc., and achieve enhanced electrical conductivity. The effect of sex, rich pores, and ingenious design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, and then dry them overnight;

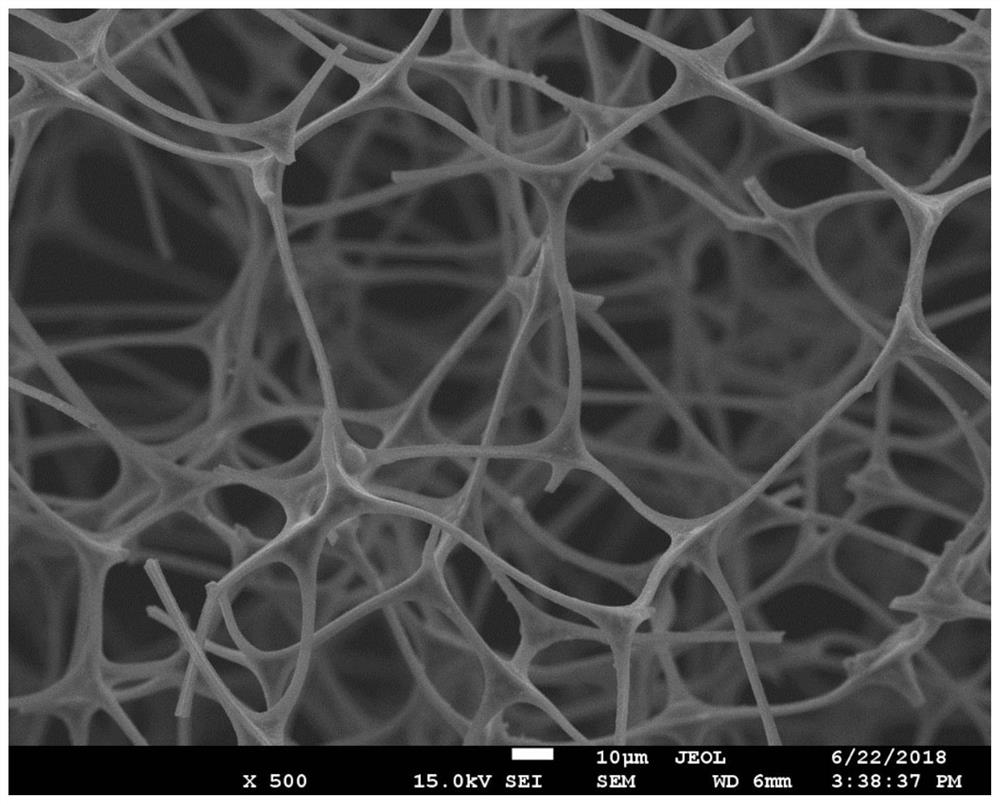

[0028] (2) Put the clean melamine sponge in a programmable temperature-controlled tube furnace, and raise the temperature from 25°C to 500°C at a rate of 5°C / min under a nitrogen atmosphere, and keep it for 0.5h, and obtain a carbon sponge after natural cooling ;

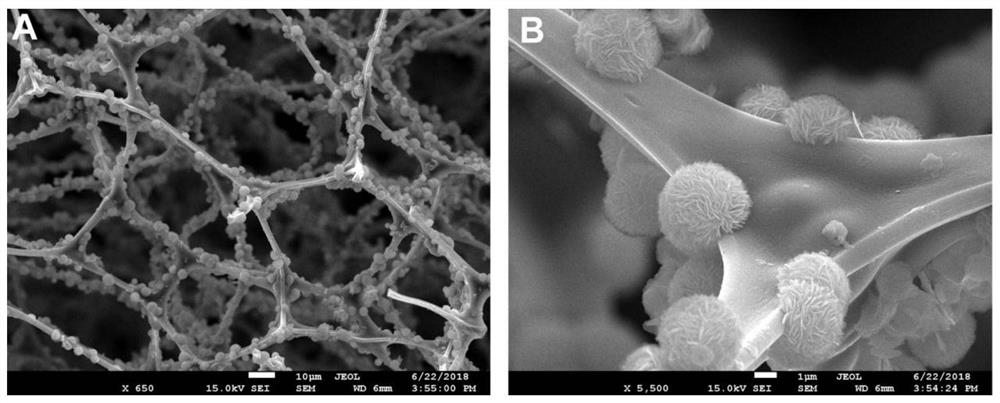

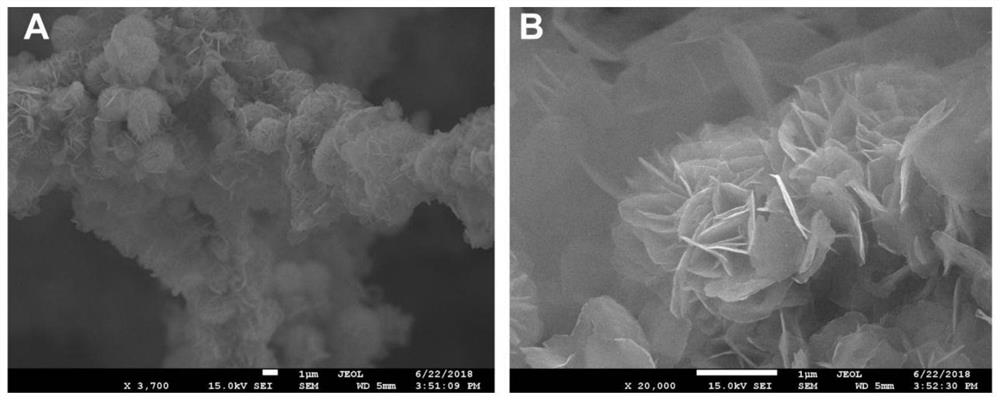

[0029] (3) Take ethylene glycol as solvent, add manganese acetate and cobalt acetate, obtain mixed solution; Wherein the concentration of manganese acetate in the mixed solution is 10mM, and the concentration of cobalt acetate is 20mM; Add carbon sponge, transfer to polytetrafluoroethylene lining In the reaction kettle, react at 140°C for 6 hours, wash and dry to obtain the manganese-cobalt oxide precursor-carbon sponge composite material, put it into a tube furnace, and in an argon atmosphere, the temperature is 1°C / min. The heating rate was increased t...

Embodiment 2

[0031] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, and then dry them overnight;

[0032] (2) Put the clean melamine sponge in a programmable temperature-controlled tube furnace, and raise the temperature from 25°C to 800°C at a rate of 3°C / min under a nitrogen atmosphere, and keep it for 1.5h, and obtain a carbon sponge after natural cooling ;

[0033] (3) Take ethylene glycol as solvent, add manganese acetate and cobalt acetate, obtain mixed solution; Wherein the concentration of manganese acetate in the mixed solution is 40mM, and the concentration of cobalt acetate is 60mM; Add carbon sponge, transfer to polytetrafluoroethylene lining In the reaction kettle, react at 170°C for 8 hours, wash and dry to obtain the manganese-cobalt oxide precursor-carbon sponge composite material, put it into a tube furnace, and in an argon atmosphere, at a rate of 3°C / min The heating rate was raised to 400°C an...

Embodiment 3

[0036] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, and then dry them overnight;

[0037] (2) Put the clean melamine sponge in a temperature-programmed tube furnace, raise the temperature from 25°C to 900°C at a heating rate of 5°C / min under a nitrogen atmosphere, keep it for 3 hours, and obtain a carbon sponge after natural cooling;

[0038] (3) Take ethylene glycol as solvent, add manganese acetate and cobalt acetate, obtain mixed solution; Wherein the concentration of manganese acetate in the mixed solution is 60mM, and the concentration of cobalt acetate is 120mM; Add carbon sponge, transfer to polytetrafluoroethylene lining In the reaction kettle, react at 200°C for 12h, wash and dry to obtain the manganese-cobalt oxide precursor-carbon sponge composite material, put it into a tube furnace, and in an argon atmosphere, at a rate of 5°C / min The heating rate was increased to 450°C and kept for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com