A preparation method of fiber-doped waste mud alkali-activated phosphorus slag geopolymer

A geopolymer and optical fiber technology, applied in cement production and other directions, can solve problems such as unfavorable promotion, and achieve the effects of reducing production costs, strong adsorption capacity, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

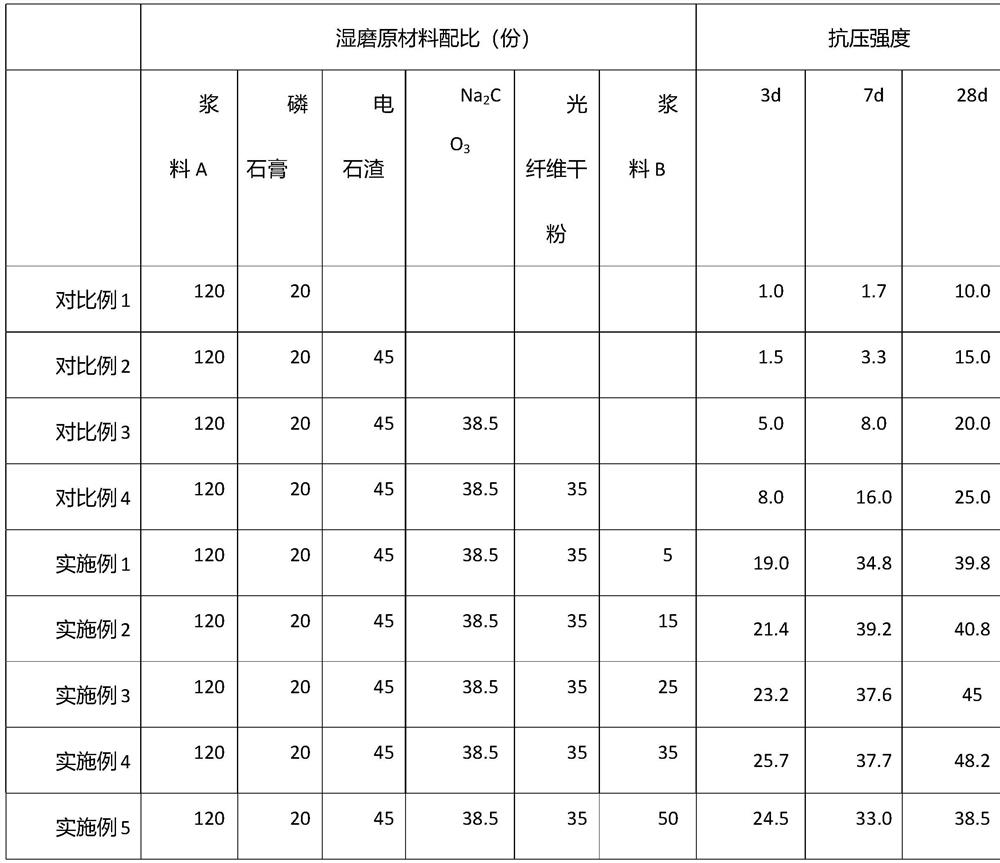

Examples

Embodiment 1

[0031] (1) 140 parts of phosphorus slag, 60 parts of nickel slag and 100 parts of water are sent to a planetary ball mill for grinding at a water-material ratio of 0.5, the grinding time is 40min, and the rotational speed of the planetary ball mill is 100-400rad / s to obtain slurry A .

[0032] (2) After pulverizing the optical fiber waste mud, pass through a 1.18mm screen to obtain a dry powder of the optical fiber waste mud.

[0033] (3) 200 parts of optical fiber waste mud dry powder and 100 parts of water were sent to a planetary ball mill at a water-material ratio of 0.5 for wet grinding, the grinding time was 40 min, and the rotational speed of the planetary ball mill was 400 rad / s to obtain slurry B.

[0034] (4) 120 parts of slurry A obtained in step (1), 35 parts of optical fiber waste sludge dry powder obtained in step (2), 5 parts of slurry B obtained in step (3), 20 parts of phosphogypsum, and 45 parts of calcium carbide slag part, Na 2 CO 3 38.5 parts and 900 pa...

Embodiment 2

[0036] (1) 140 parts of phosphorus slag, 60 parts of nickel slag, and 100 parts of water are sent to a planetary ball mill for grinding at a water-material ratio of 0.5, the grinding time is 40 min, and the rotational speed of the planetary ball mill is 400 rad / s to obtain slurry A.

[0037] (2) After pulverizing the optical fiber waste mud, pass through a 1.18mm screen to obtain a dry powder of the optical fiber waste mud. (3) 200 parts of optical fiber waste mud dry powder and 100 parts of water were sent to a planetary ball mill at a water-material ratio of 0.5 for wet grinding, the grinding time was 40 min, and the rotational speed of the planetary ball mill was 400 rad / s to obtain slurry B.

[0038] (4) 120 parts of slurry A obtained in step (1), 35 parts of optical fiber waste mud dry powder obtained in step (2), 15 parts of slurry B obtained in step (3), 20 parts of phosphogypsum, and 45 parts of calcium carbide slag Parts,, Na 2 CO 3 38.5 parts and 900 parts of sand ...

Embodiment 3

[0040](1) 140 parts of phosphorus slag, 60 parts of nickel slag, and 100 parts of water are sent to a planetary ball mill for grinding at a water-material ratio of 0.5, the grinding time is 40 min, and the rotational speed of the planetary ball mill is 400 rad / s to obtain slurry A.

[0041] (2) After pulverizing the optical fiber waste mud, pass through a 1.18mm screen to obtain a dry powder of the optical fiber waste mud.

[0042] (3) 200 parts of optical fiber waste mud dry powder and 100 parts of water were sent to a planetary ball mill at a water-material ratio of 0.5 for wet grinding, the grinding time was 40 min, and the rotational speed of the planetary ball mill was 400 rad / s to obtain slurry B.

[0043] (4) 120 parts of slurry A obtained in step (1), 35 parts of optical fiber waste mud dry powder obtained in step (2), 25 parts of slurry B obtained in step (3), 20 parts of phosphogypsum, and 45 parts of calcium carbide slag part, Na 2 CO 3 38.5 parts and 900 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com