Preparation method of ferrocobalt sulfide nanotube loaded carbon sponge flexible composite material

A composite material, cobalt iron sulfide technology, applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve non-lightweight and other problems, achieve the effects of enhancing conductivity, solving easy agglomeration, and ingenious design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, then dry them overnight and set aside;

[0033] (2) Put the clean melamine sponge in a programmable temperature-controlled tube furnace, and raise the temperature from 25°C to 500°C at a rate of 5°C / min under a nitrogen atmosphere, and keep it for 0.5h, and obtain a carbon sponge after natural cooling ;

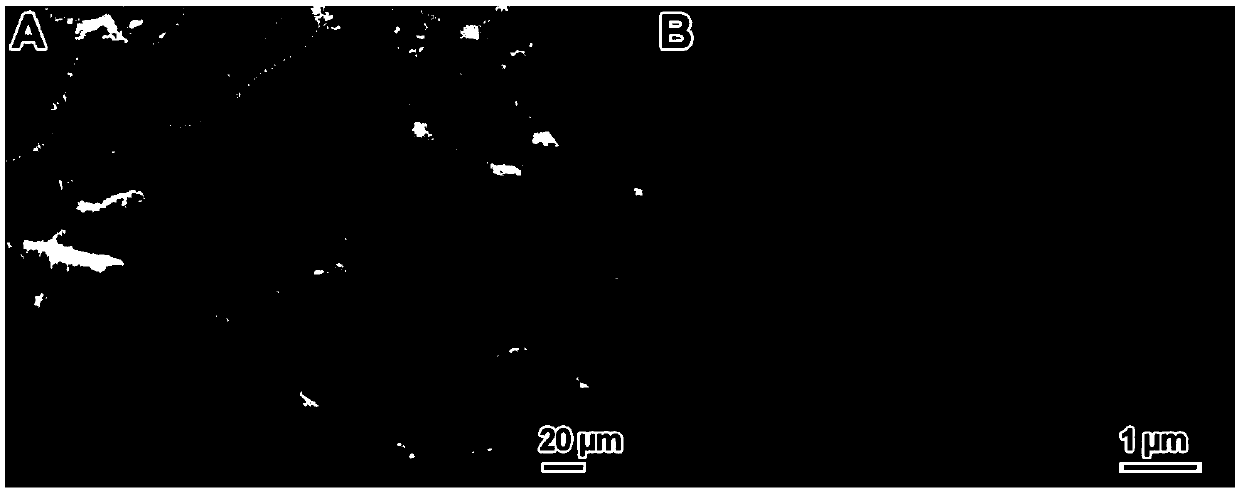

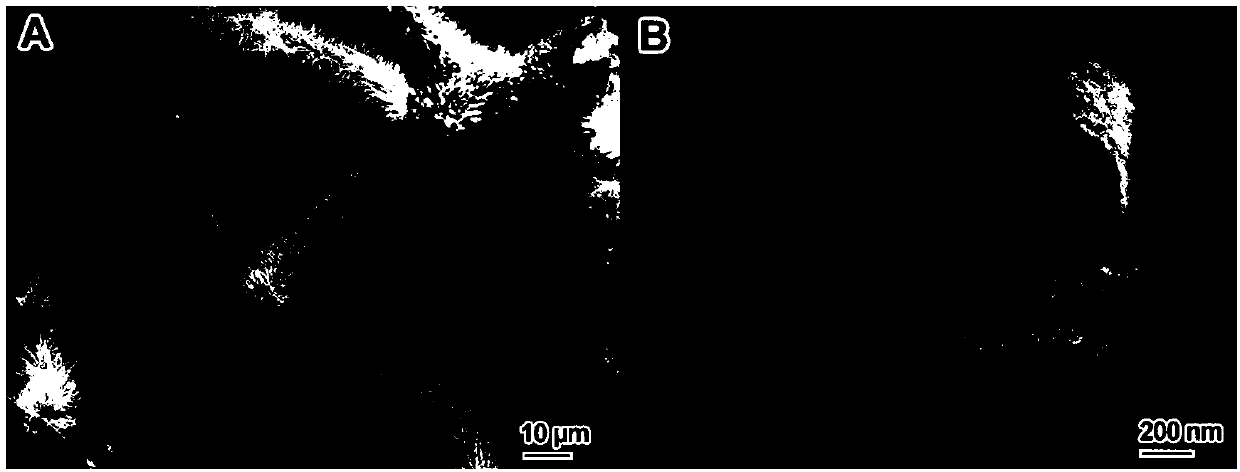

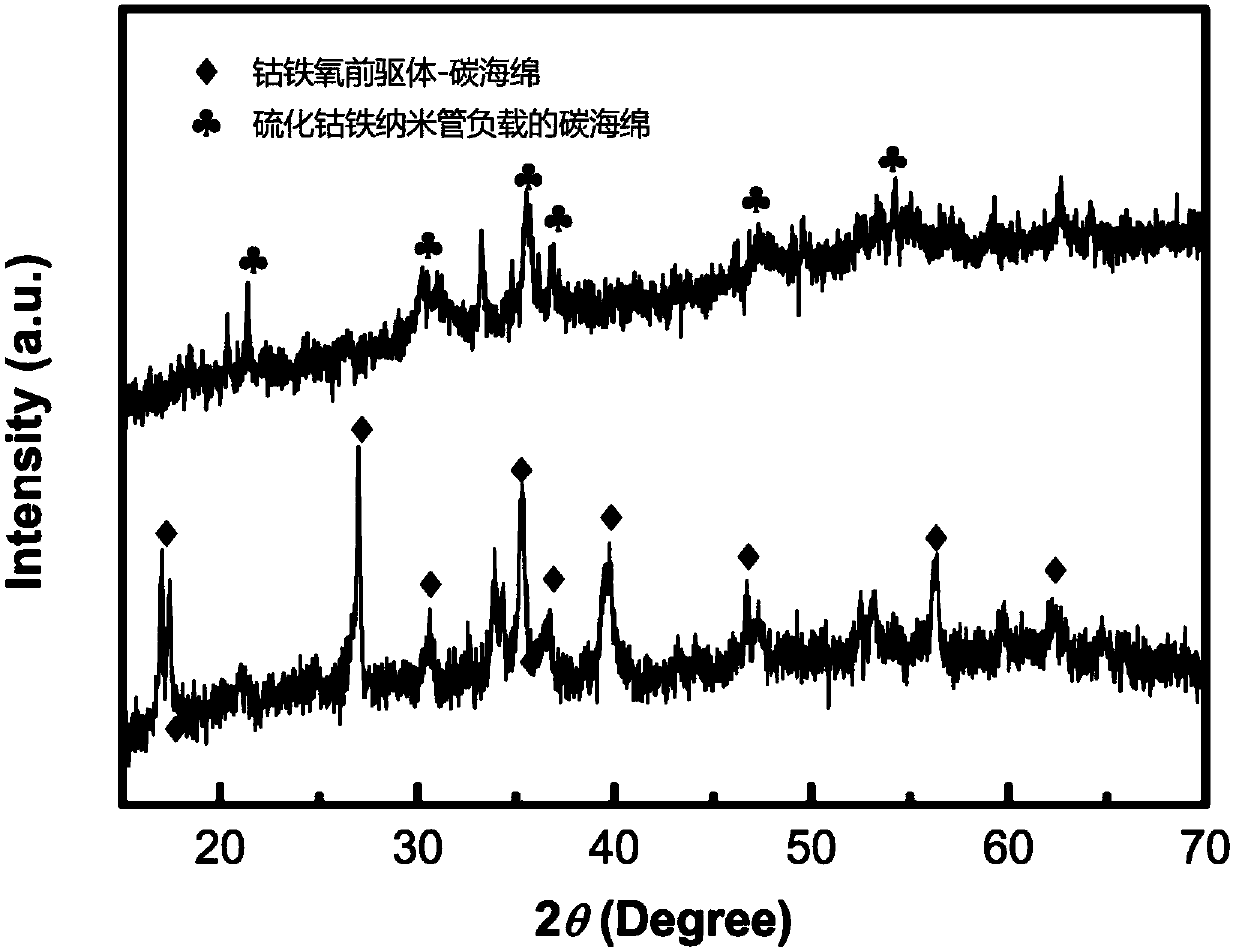

[0034] (3) take deionized water as solvent, add ferric nitrate and cobalt nitrate, obtain mixed solution; Wherein in mixed solution, ferric nitrate concentration is 10mM, cobalt nitrate concentration is 20mM; Add carbon sponge, and add urea and ammonium fluoride; Make The concentration of urea in the mixed solution is 30mM, and the concentration of ammonium fluoride is 30mM; it is transferred to a polytetrafluoroethylene-lined reaction kettle, reacted at 100°C for 12h, and after cleaning and drying, the iron cobalt oxide precursor- carbon spong...

Embodiment 2

[0037] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, then dry them overnight and set aside;

[0038] (2) Put the clean melamine sponge in a temperature-programmed tube furnace, and raise the temperature from 25°C to 700°C at a rate of 8°C / min under a nitrogen atmosphere, and keep it for 1.5h, and obtain a carbon sponge after natural cooling ;

[0039] (3) take deionized water as solvent, add ferric nitrate and cobalt nitrate, obtain mixed solution; Wherein in mixed solution, ferric nitrate concentration is 30mM, and cobalt nitrate concentration is 60mM; Add carbon sponge, and add urea and ammonium fluoride; Make The concentration of urea in the mixed solution is 80mM, and the concentration of ammonium fluoride is 80mM; it is transferred to a polytetrafluoroethylene-lined reaction kettle, reacted at 120°C for 10h, and after cleaning and drying, the iron cobalt oxide precursor- carbon sponge composi...

Embodiment 3

[0043] (1) Divide the commercial melamine sponge into strips of 5cm×2cm×0.5cm, clean them with distilled water and absolute ethanol, then dry them overnight and set aside;

[0044] (2) Put the clean melamine sponge in a temperature-programmed tube furnace, and raise the temperature from 25°C to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere, and keep it for 3 hours, and then cool down naturally to obtain a carbon sponge;

[0045](3) take deionized water as solvent, add ferric nitrate and cobalt nitrate, obtain mixed solution; Wherein in mixed solution, ferric nitrate concentration is 60mM, and cobalt nitrate concentration is 120mM; Add carbon sponge, and add urea and ammonium fluoride; Make The concentration of urea in the mixed solution is 180mM, and the concentration of ammonium fluoride is 180mM; it is transferred to a polytetrafluoroethylene-lined reaction kettle, reacted at 140°C for 12h, and after cleaning and drying, the iron cobalt oxide precursor- car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com