High-barrier polyurethane self-repairing composition and preparation method thereof

A polyurethane and self-healing technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor dispersion stability and achieve high barrier properties and enhanced anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

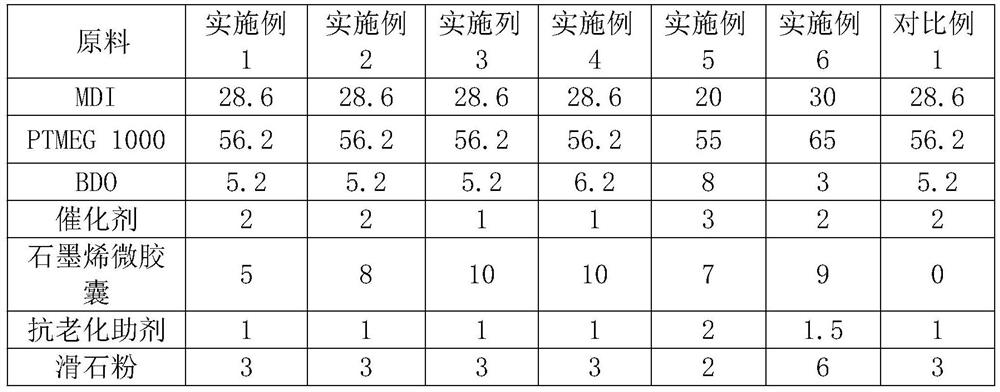

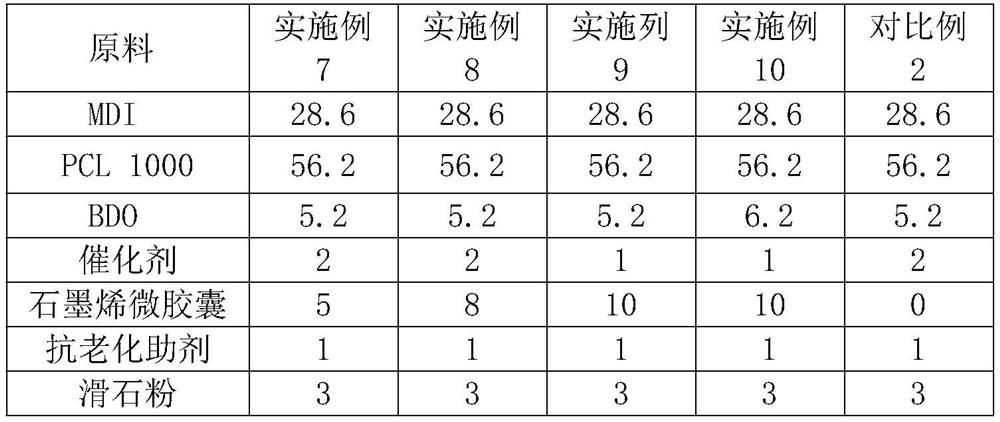

[0034] The high-barrier polyurethane self-healing composition includes: polyisocyanate, polyol, chain extender, graphene microcapsule, anti-aging additive, talcum powder and catalyst.

[0035] The mass ratio of the above-mentioned substances is:

[0036] Polyisocyanate: polyol: chain extender: graphene microcapsule: anti-aging additive: talcum powder: catalyst=28.6:56.2:5.2:5:1:3:2.

[0037] In this embodiment, the polyisocyanate is selected from diphenylmethane diisocyanate (MDI, Wanhua Chemical), the polyol is selected from polytetramethylene ether glycol (PTMEG1000, BASF Chemical), and the chain extender is selected from 1, 4-Butanediol (BDO), the catalyst is selected from dibutyltin dilaurate (Your Chemical) and triethylamine (Hualu Hengsheng), wherein the mass ratio of dibutyltin dilaurate to triethylamine is 1.3:1 .

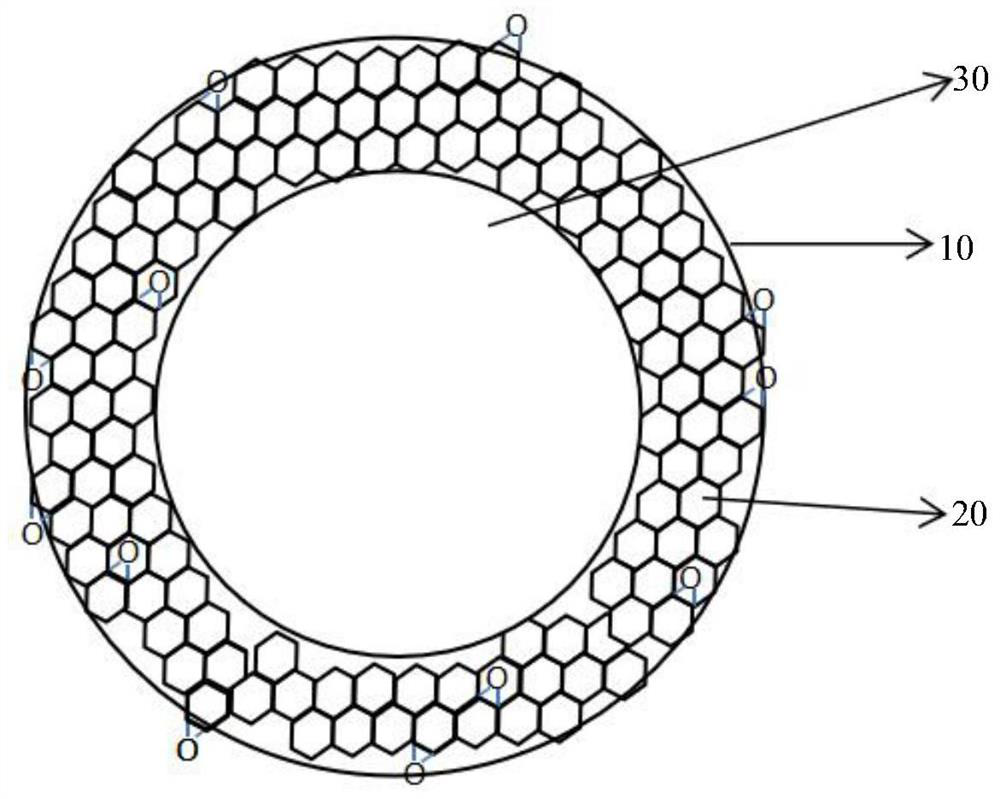

[0038] Such as figure 1 As shown, the graphene microcapsule has a double-wrapped structure, the wall material 10 is methacrylonitrile, the central core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com