A method for preparing nano zno-go/waterborne polyurethane superamphiphobic coating by spraying method

A water-based polyurethane, spraying technology, applied in the field of materials, can solve the problems of loss of superhydrophobicity, damage, etc., and achieve the effects of low reaction equipment requirements, strong adhesion, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

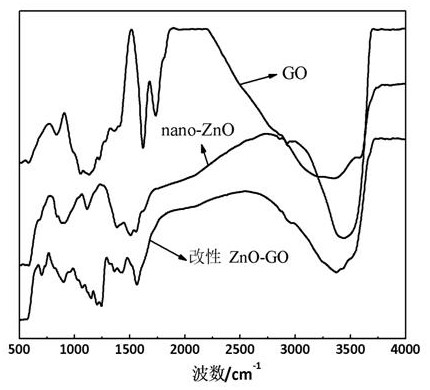

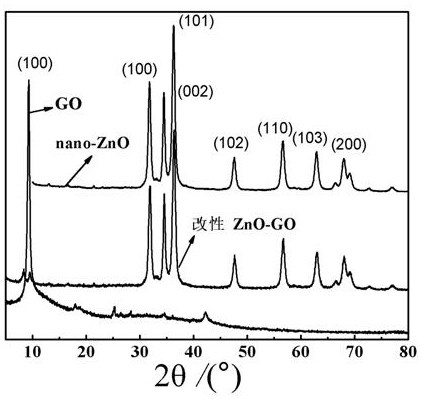

[0035] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2 O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added t...

Embodiment 2

[0037] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2 O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added t...

Embodiment 3

[0039] Weigh 1.6 g of ZnO (30 nm grade) and disperse it in 40 mL of absolute ethanol, and add 0.2 mL of perfluorooctyltrichlorosilane and 10 drops of H 2O, and magnetically stirred for 30 min to obtain solution A; weigh 0.1 g of GO and disperse it in 25 mL of absolute ethanol, and ultrasonically treat it for 30 min to form a uniformly dispersed suspension B; mix solution A and suspension B to obtain solution C, heating in a water bath at 60 °C, magnetic stirring for 6 h; washing with deionized water and absolute ethanol for 2-3 times, and suction filtration to obtain nano-ZnO-GO composites, vacuum drying at 80 °C for 12 h, and grinding for later use. Weigh an appropriate amount of water-based polyurethane A and B components in a ratio of 5:1, stir evenly, and cure at room temperature for 30 minutes, then spray on the surface of the treated aluminum substrate, spray two layers, and construct a water-based polyurethane coating; the prepared The nano-ZnO-GO composite was added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com