Preparation method and application of self-supporting binder-free flexible SiO2@C composite material

A binder-free, composite material technology, applied in structural parts, active material electrodes, electrical components, etc., to achieve the effect of small size, favorable for electron transmission, and strong crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

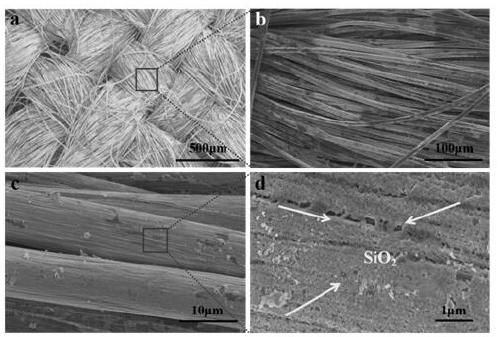

[0018] The present invention provides a free-standing binder-free flexible SiO 2 The preparation method and application of @C composite material, comprising the following steps:

[0019] S1. Acidification treatment of carbon cloth;

[0020] Pretreat the carbon cloth, cut the carbon cloth into a cube of 3cm×3cm×0.1cm, soak it in a hydrochloric acid solution with a concentration of 1mol / L for 12 hours, and then wash it alternately with deionized water and ethanol for 3 times and then 60°C Dry to obtain acidified carbon cloth A;

[0021] S2, preparation of precursor solution;

[0022] Mix 0.1~0.5mL tetraethyl tetrasilicate (TEOS) and 10~60ml deionized water, and stir for 1~2 hours to obtain solution B; mix solution B with 0.05~0.2ml 25% ammonia water and stir for 1~ Solution C was obtained after 2 hours;

[0023] S3, free-standing flexible SiO without binder 2 Preparation of @C composite materials

[0024] Put the carbon cloth A and solution C into the reaction kettle toget...

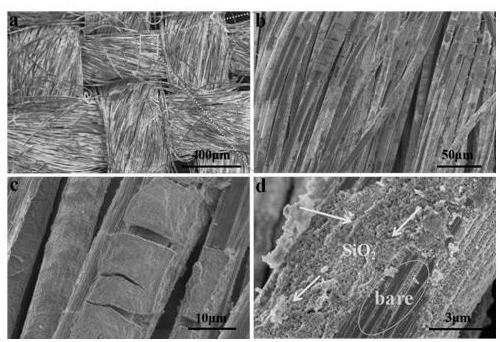

Embodiment 1

[0031] S1. Acidification treatment of carbon cloth;

[0032] Pre-treat the carbon cloth, cut the carbon cloth into a cube of 3cm×3cm×0.1cm, soak it in a hydrochloric acid solution with a concentration of 1mol / L for 12 hours, and then wash it alternately with deionized water and ethanol for 3 times before 60°C Obtain acidified carbon cloth A after drying;

[0033] S2, preparation of precursor solution;

[0034] Mix 0.1mL tetraethyl orthosilicate (TEOS) and 10ml deionized water, and stir for 1 hour to obtain solution B; mix solution B with 0.05ml 25% ammonia water and stir for 1 hour to obtain solution C;

[0035] S3, free-standing flexible SiO without binder 2 Preparation of @C composite materials

[0036] Put the carbon cloth A and the solution C into the reaction kettle together, and react at 180°C for 10 hours; after the reaction, take out the carbon cloth, wash it with water and alcohol three times, and then dry it at 80°C to obtain a self-supporting non-adhesive flexib...

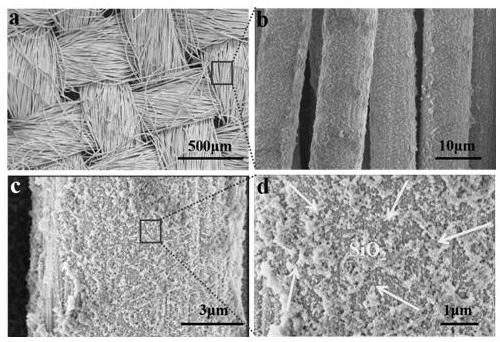

Embodiment 2

[0042] S1. Acidification treatment of carbon cloth;

[0043]Pre-treat the carbon cloth, cut the carbon cloth into a cube of 3cm×3cm×0.1cm, soak it in a hydrochloric acid solution with a concentration of 1mol / L for 12 hours, and then wash it alternately with deionized water and ethanol for 3 times before 60°C Obtain acidified carbon cloth A after drying;

[0044] S2, preparation of precursor solution;

[0045] Mix 0.53mL tetraethyl orthosilicate (TEOS) and 40ml deionized water, and stir for 2 hours to obtain solution B; mix solution B with 0.15ml 25% ammonia water and stir for 1 hour to obtain solution C;

[0046] S3, free-standing flexible SiO without binder 2 Preparation of @C composite materials

[0047] Put the carbon cloth A and solution C into the reaction kettle together, and react at 200°C for 10 hours; after the reaction, take out the carbon cloth, wash with water and alcohol three times, and then dry at 80°C to obtain a self-supporting non-adhesive flexible SiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com