A beaded MOF-filled mixed matrix membrane with silicone rubber

A technology of mixed matrix membrane and silicone rubber, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor permeability and selectivity, difficult continuous MOFs transmission channel, low efficacy of additive MOFs, etc. Polar interaction, solve the effect of cumbersome preparation method and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a mixed matrix membrane filled with PPy silicone rubber, the specific preparation steps are as follows:

[0041]1) Add 0.21 g of methyl orange into 250 mL of ultrapure water, and stir at 320 rpm for 1 hour to obtain solution 1. Then, 1.2 g of ferric chloride and 460 μL of pyrrole were added to solution 1 to obtain reaction solution 2. The reaction solution 2 was stirred and reacted in the dark at 320 rpm for 24 hours, and washed three times with ethanol and water respectively. Drying under vacuum at 60°C until constant weight is achieved to obtain polypyrrole nanotubes (PPy).

[0042] 2) Disperse 1 g of PPy obtained in step 1 in 100 g of n-heptane, stir for 1 hour, and treat in an ultrasonic ice bath for 30 minutes to obtain dispersion 7. Add 20 g of polydimethoxysiloxane, 4 g of ethyl orthosilicate and 2 g of dibutyltin dilaurate to the dispersion, and stir for 40 minutes to obtain dispersion 8.

[0043] 3) The dispersion liquid 8 was coated o...

Embodiment 2

[0045] A method for preparing a silicon rubber pervaporation membrane, the specific preparation steps are as follows:

[0046] 1) Add 20 g of polydimethoxysiloxane, 4 g of ethyl orthosilicate and 2 g of dibutyltin dilaurate into 100 g of n-heptane solution, and stir for 40 minutes to obtain solution 1.

[0047] 2) The solution 1 was coated on a polyvinylidene fluoride flat film using a flat film scraping machine, and left to stand in an air atmosphere for 24 hours, and then placed in a blast drying oven at 80° C. for 6 hours to obtain a PDMS film.

Embodiment 3

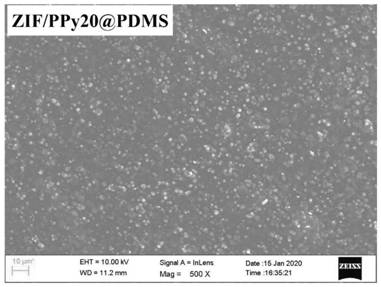

[0049] A method for preparing a mixed matrix membrane filled with beaded MOF filled with silicone rubber, the specific preparation steps are as follows:

[0050] 1) Add 0.21 g of methyl orange into 250 mL of ultrapure water, and stir at 320 rpm for 1 hour to obtain solution 1. Then, 1.2 g of ferric chloride and 460 μL of pyrrole were added to solution 1 to obtain reaction solution 2. The reaction solution 2 was stirred and reacted in the dark at 320 rpm for 24 hours, and washed three times with ethanol and water respectively. Drying under vacuum at 60°C until constant weight is achieved to obtain polypyrrole nanotubes (PPy).

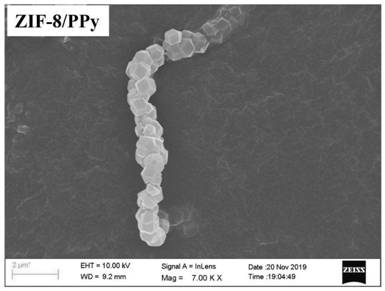

[0051] 2) Disperse 0.4 g of PPy obtained in step 1 in 250 mL of methanol solution, and perform ultrasonic treatment for 30 minutes to obtain dispersion 3. 7.8 g of zinc nitrate hexahydrate was added to the dispersion 3, and ultrasonically assisted stirring was performed for 30 minutes to obtain the dispersion 4. 17.3 g of dimethylimidazole was dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com