Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Promotes early hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

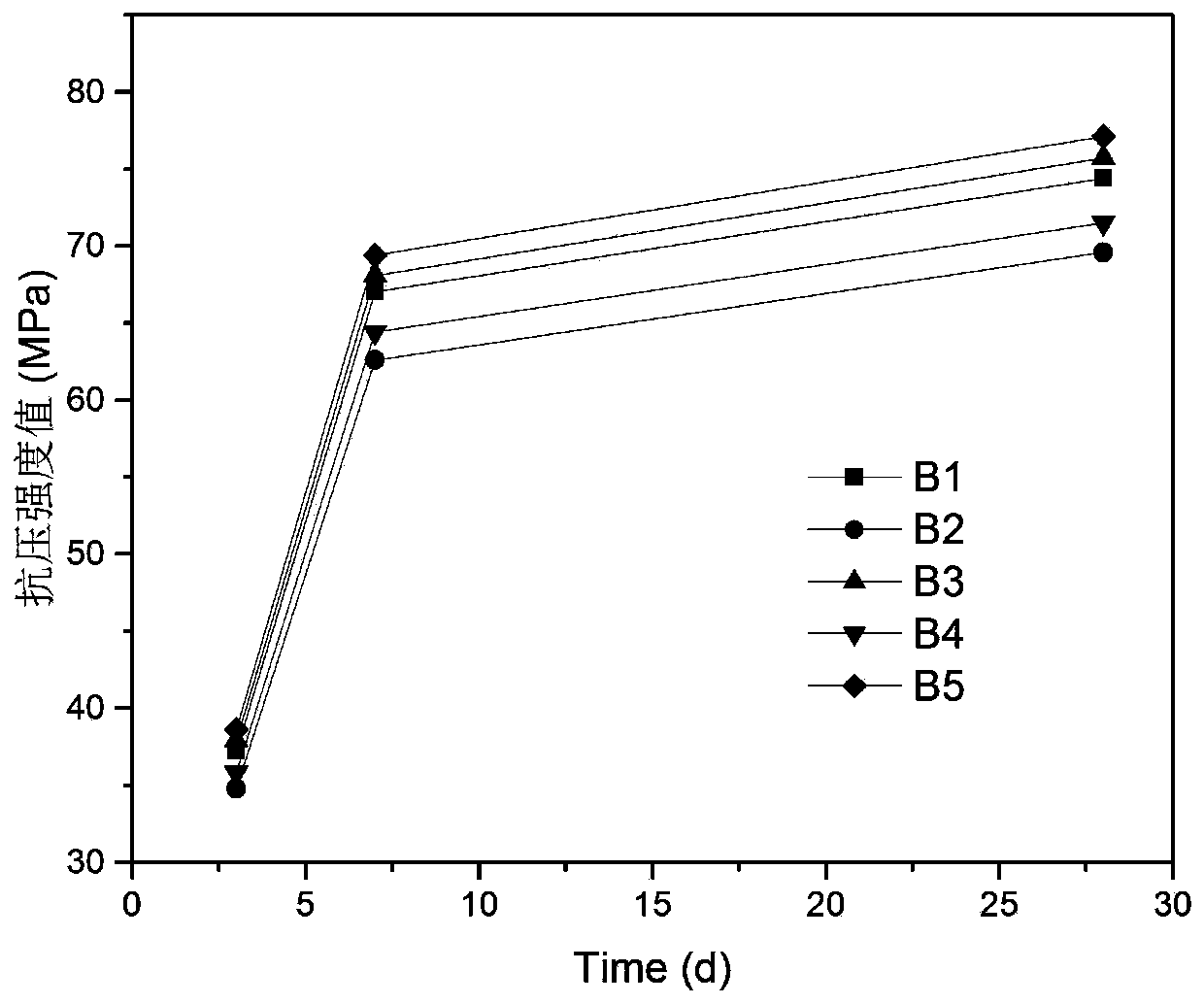

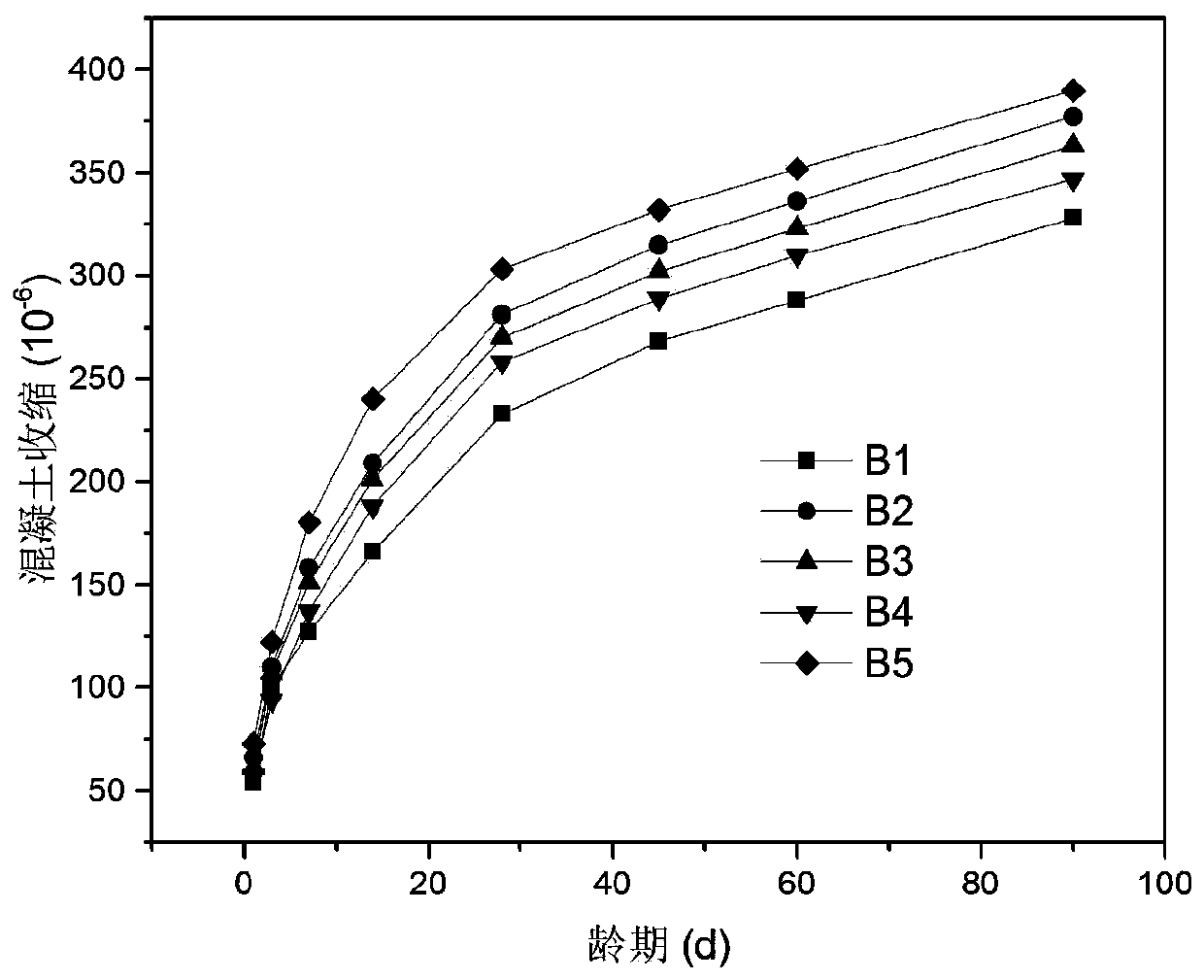

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

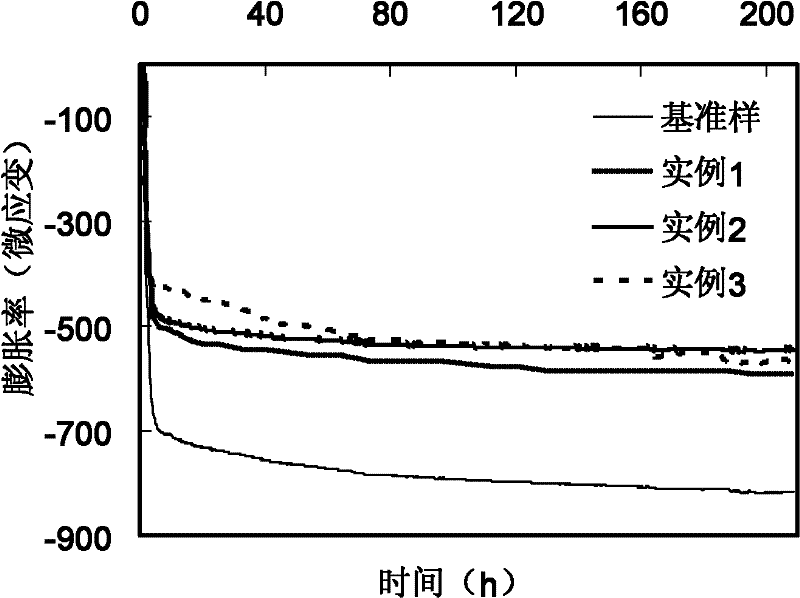

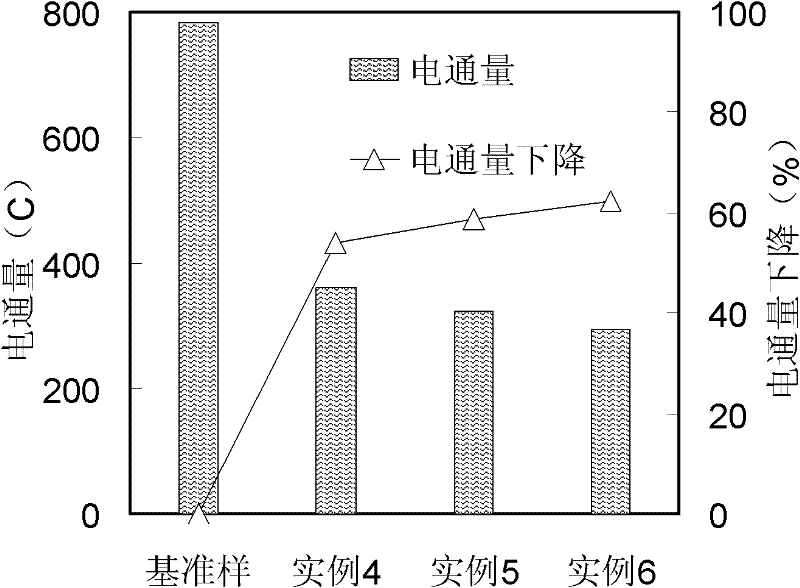

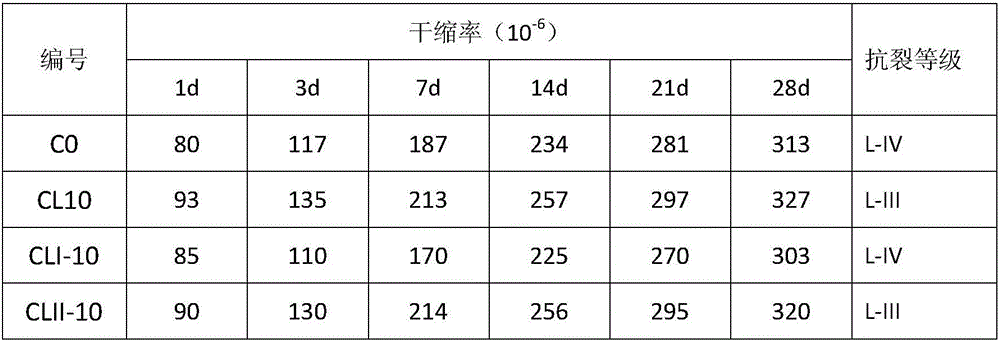

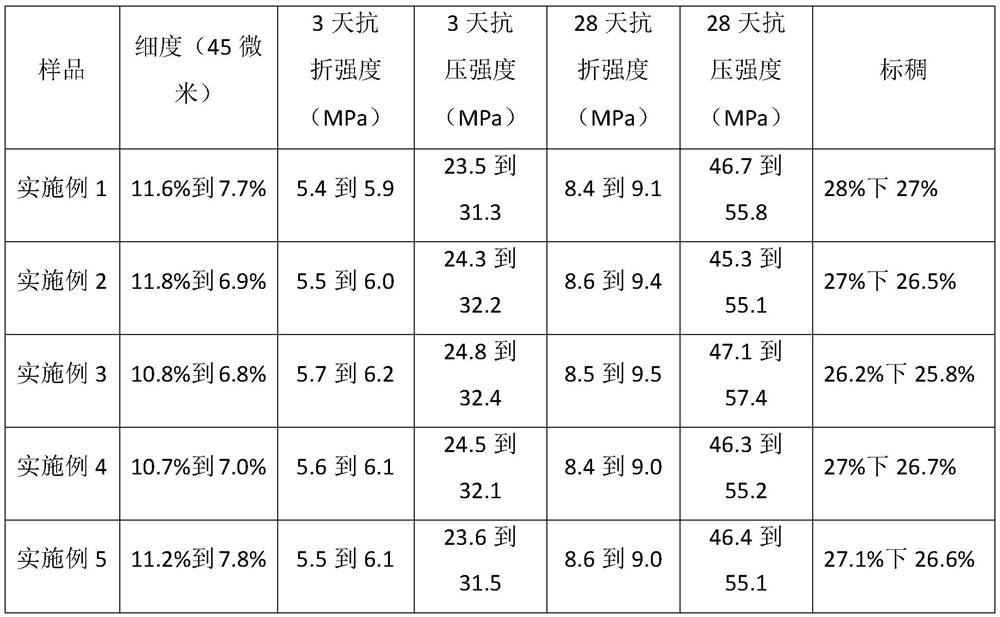

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

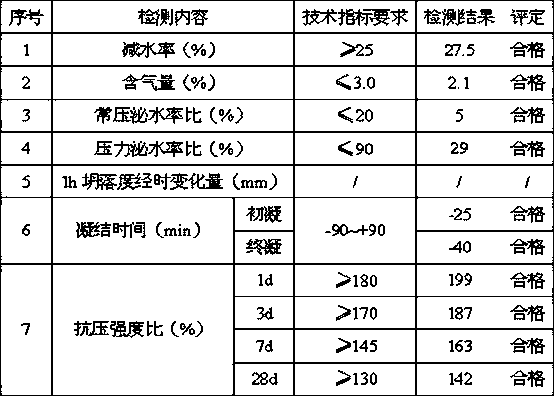

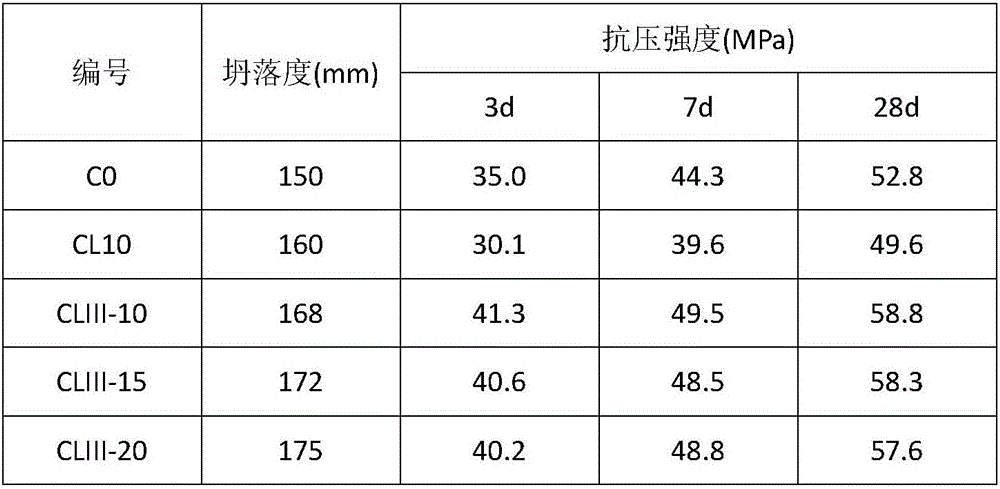

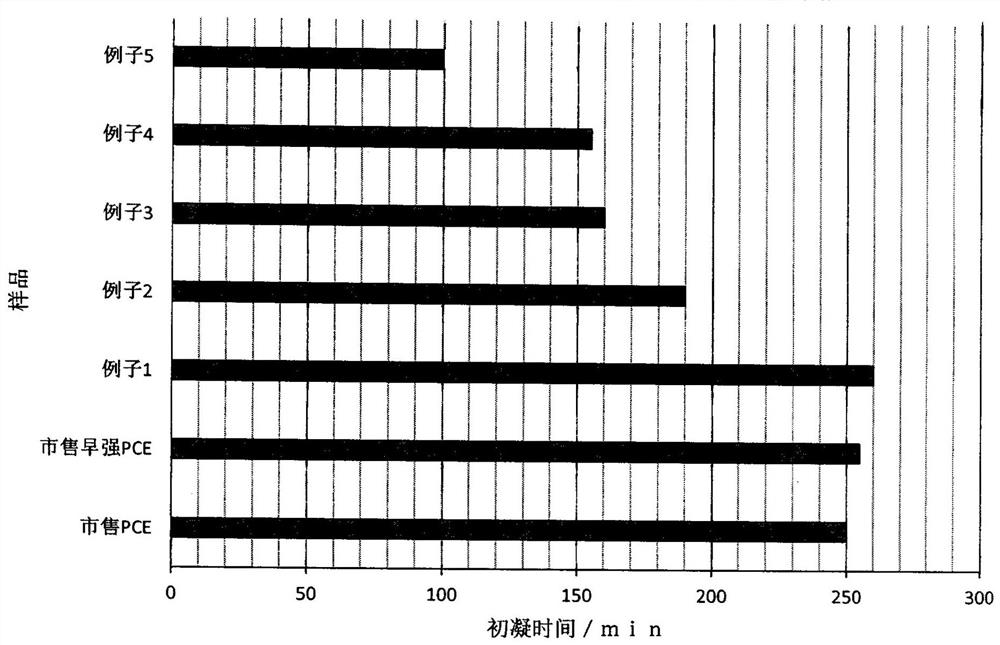

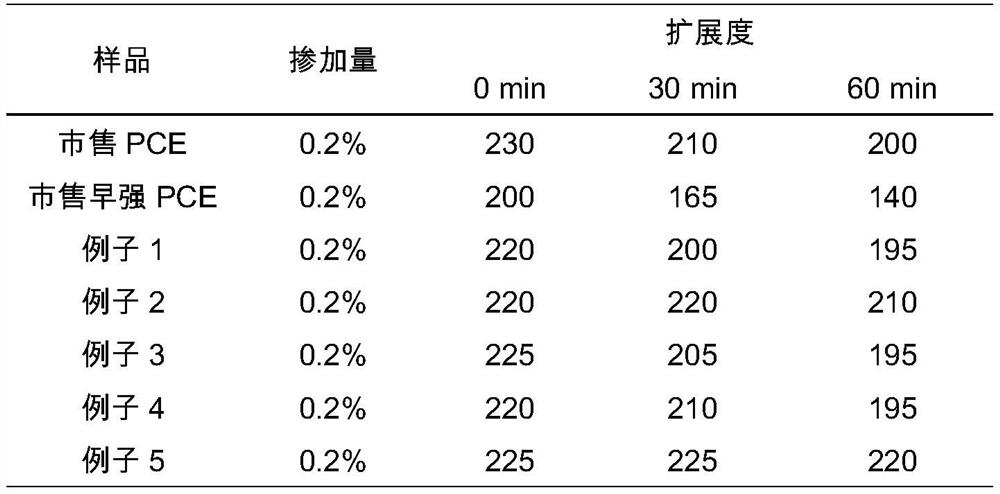

Superplasticizer for facilitating cement hydration, preparation method thereof and application

Owner:JIANGSU SOBUTE NEW MATERIALS

Super plasticizer for precast concrete component

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and preparation process thereof

The invention discloses a reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and a preparation process thereof. The water reducing agent mother liquid is preparedby the free radical copolymerization reaction of a polyether macro-monomer, an anionic active monomer, a cationic active monomer, a shrinkage reducing monomer, a chain transfer agent and an initiator;wherein the polyether macro-monomer is isopentenyl polyoxyethylene ether and / or methyl allyl polyoxyethylene ether; the anionic active monomer is acrylic acid; the cationic active monomer is methacrylatoethyl trimethyl ammonium chloride; the shrinkage reducing monomer is an esterification reaction product of a phenyl alcohol or a methyl phenyl alcohol with acrylic acid; the chain transfer agent is 2-methyl-2-propene-1-sulfonic acid sodium salt; and the initiator comprises an initiator system A and an initiator system B, the initiator system A comprises organic hydrogen peroxide and vitamin C,and the initiator system B comprises sodium bisulfite and a ferrous salt. According to the preparation process, different functional monomers are grafted to the high-performance polycarboxylic acid water reducing agent, and the length of the main chain is adjusted, so that the polycarboxylic acid water reducing agent has excellent water reducing rate, and also has early strength and reduced shrinkage.

Owner:WUHAN SUBO NEW BUILDING MATERIAL CO LTD

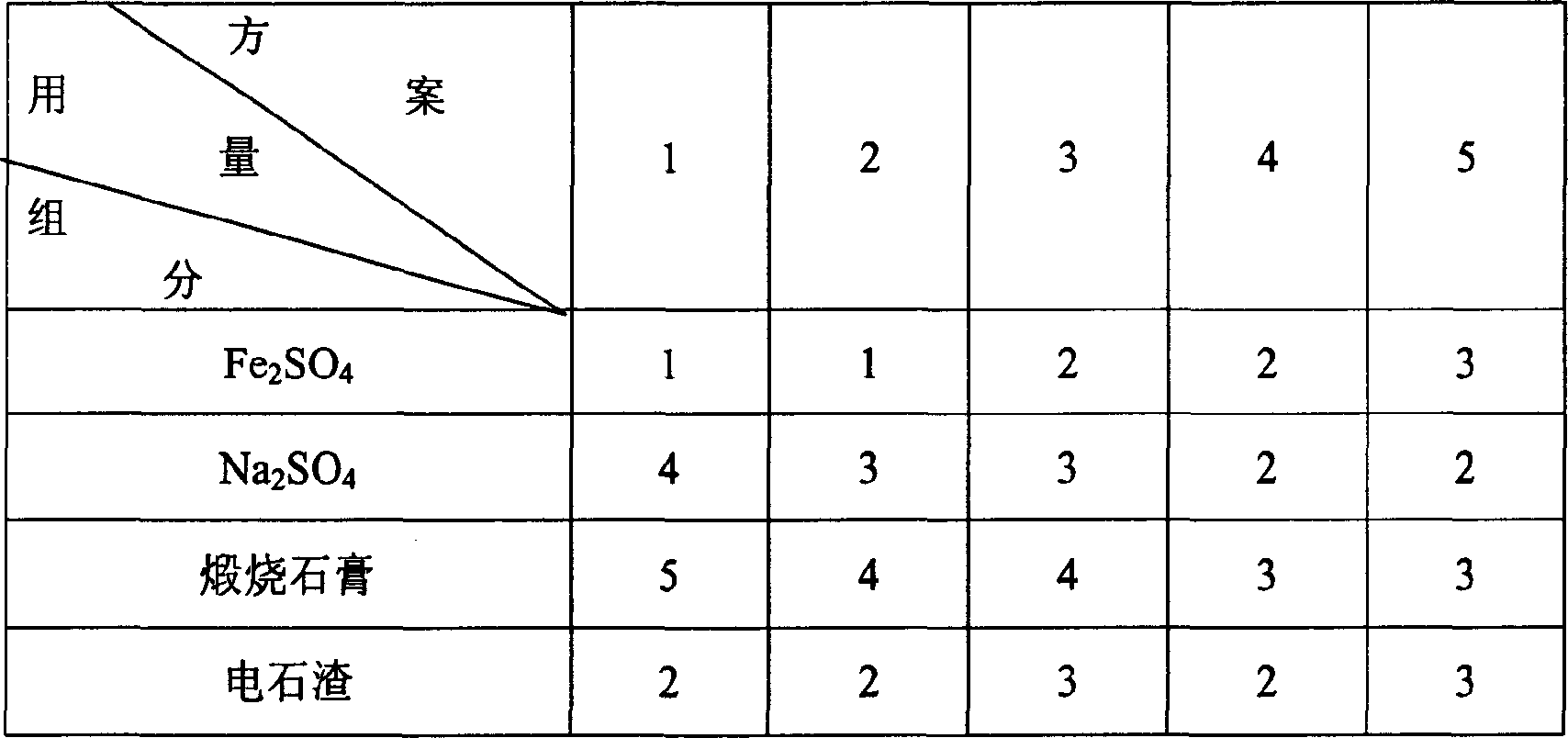

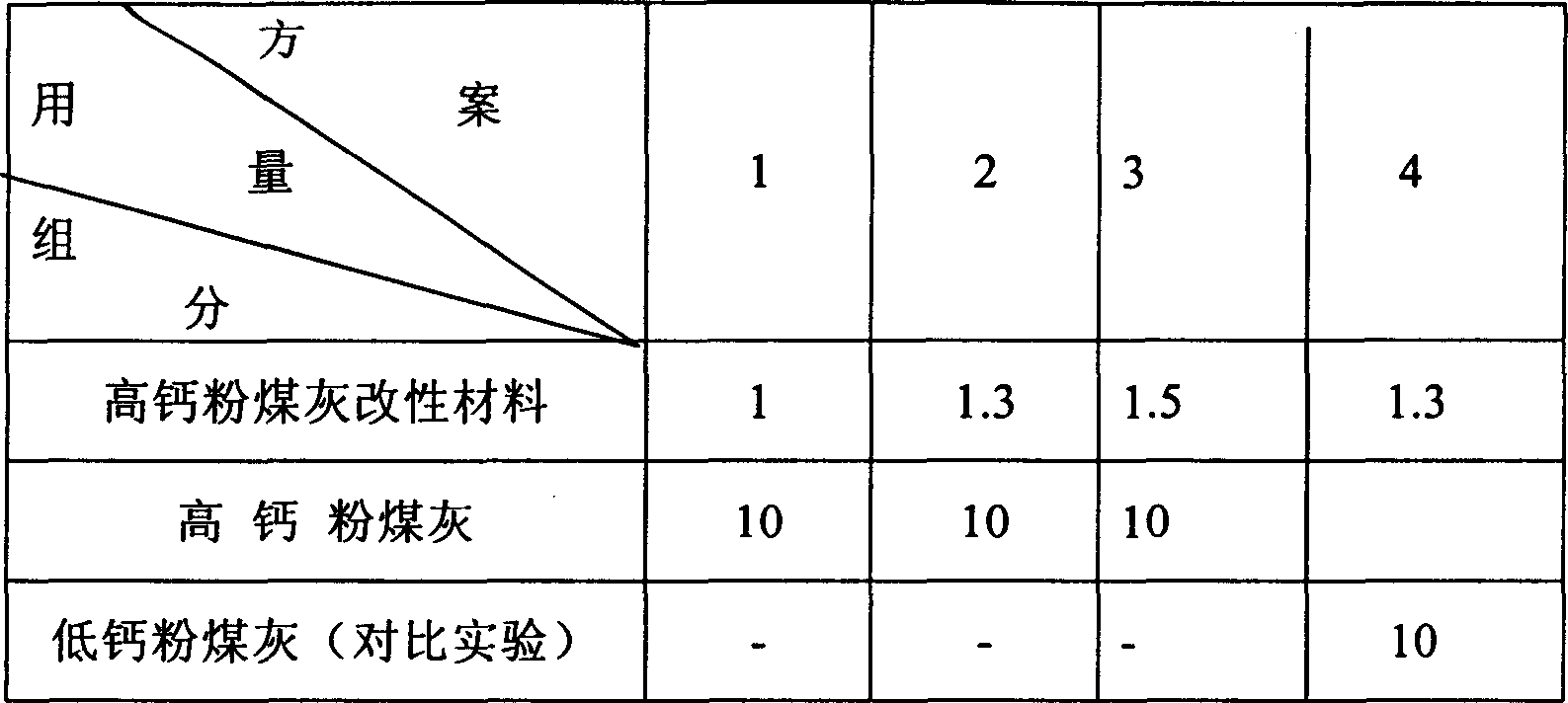

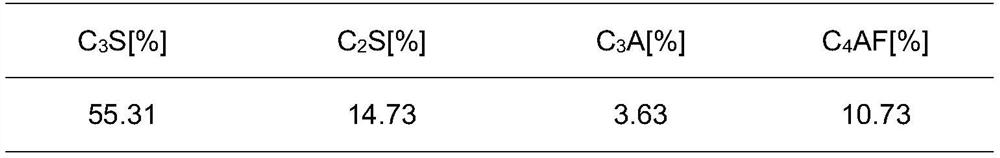

Cement containing large volume of fly ash and preparation method thereof

ActiveCN103553380AIncrease the amount addedPromotes early hydrationCement productionChemical reactionUltimate tensile strength

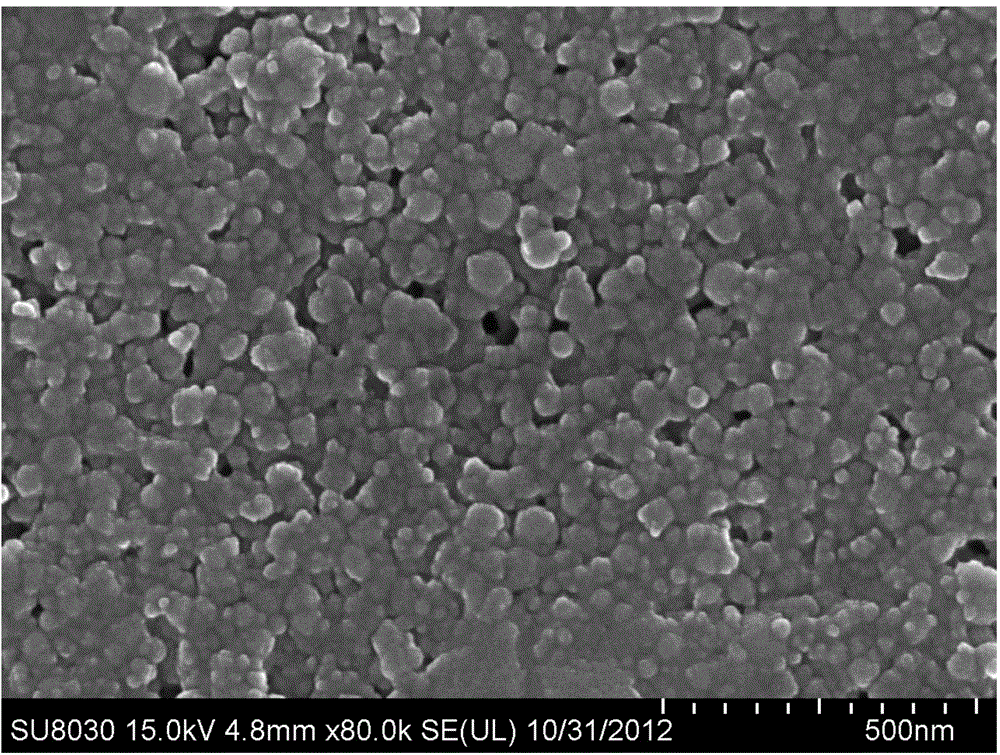

The invention provides a cement containing large volume of fly ash. The cement includes 30-70 wt% of fly ash, 0.01-10 wt% of nano boehmite and the balance of Portland cement. Nano boehmite has small particles, excellent chemical and mechanical properties and good surface activity, and can be filled into the gaps among cement particles to enhance the forces among cement particles; and the nano boehmite can react with a cement clinker and fly ash to generate hydration products and promote the early hydration of cement, thereby improving the early strength of cement, increasing the addition of fly ash and reducing the cost.

Owner:宁夏赛马水泥有限公司

Modified limestone powder-based mineral admixture and preparation method thereof

InactiveCN102659336AImprove early and late strengthIncreased durabilitySolid waste managementSocial benefitsHigh activity

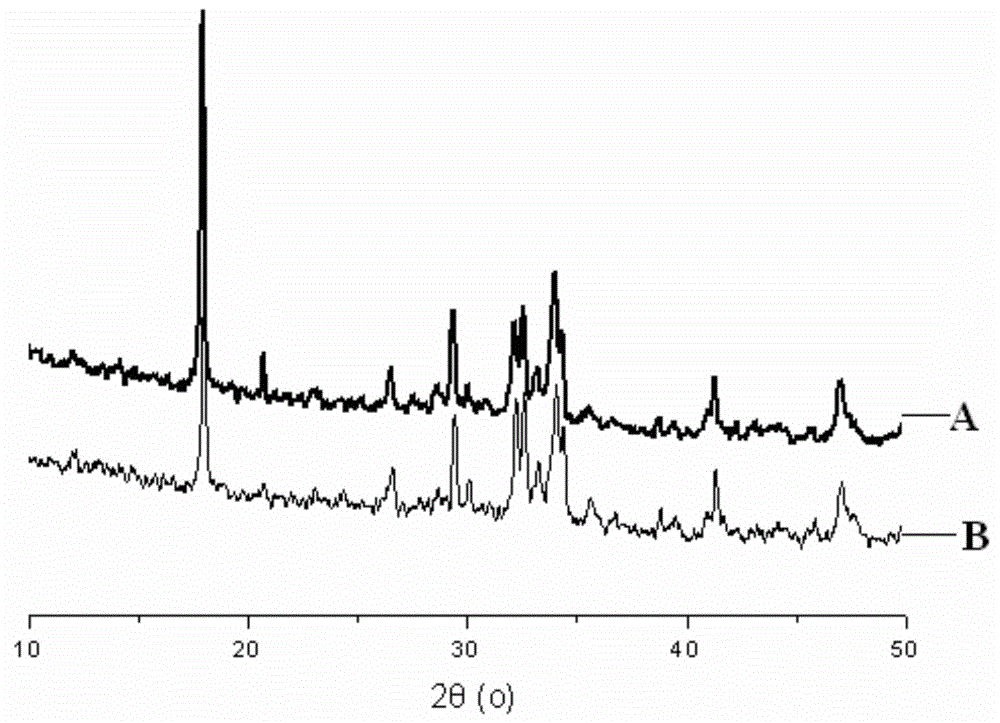

The invention discloses a modified limestone powder-based mineral admixture and a preparation method thereof. The modified limestone powder-based mineral admixture includes, by weight, from 50 to 70 parts of limestone powder, from 30 to 50 parts of mineral waste residue powder, from 3 to 5 parts of calcined gypsum and from 0.01 to 0.03 part of triethanolamine which are used for preparing the modified limestone powder-based mineral admixture by means of stirring and mixing. The modified limestone powder-based mineral admixture has high activity, the strength and the durability of cement concrete can be obviously increased, the mixing amount of the limestone powder in the cement concrete can be increased, cost is reduced, and the modified limestone powder-based mineral admixture has remarkable economic and social benefits.

Owner:CENT SOUTH UNIV

Preparation method of high-thixotropy early-strength type polycarboxylate superplasticizer

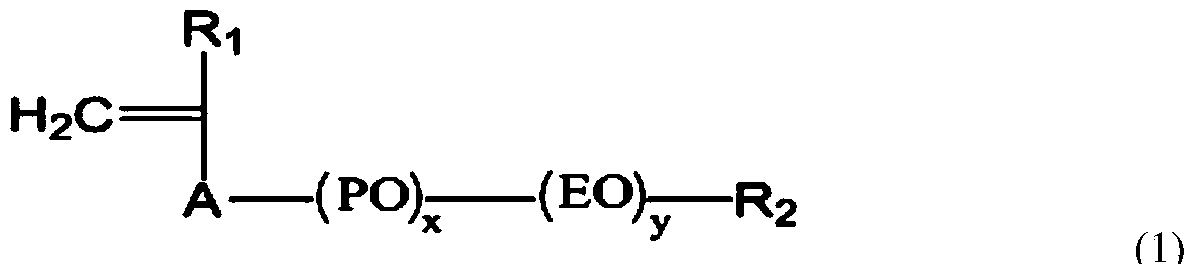

ActiveCN105504180APromotes early hydrationPromotes the function of hydration reactionVinyl etherSuperplasticizer

The invention discloses a preparation method of a high-thixotropy early-strength type polycarboxylate superplasticizer. The preparation method comprises the following steps of (1) adding isobutene polyoxyethylene ether and / or isopentene polyoxyethylene ether, micromolecular polyether, unsaturated fatty acid glyceride, a quaternary ammonium salt monomer and an oxidant into water, and stirring the mixture under 15 to 30 DEG C until the mixture is dissolved; (2) preparing a first solution by a reducing agent and water, preparing a second solution by a chain transfer agent and the water, and preparing a third solution by unsaturated monocarboxylic acid, an unsaturated carboxylic ester monomer and the water; (3) dropping the first solution, the second solution and the third solution in materials in step (1) within 3 to 4 hours at the same time, and carrying out a heat-preservation reaction for 1 to 1.5 hours under 35 to 40 DEG C after dropping is completed; (4) adding an alkaline modifier to neutralize the pH (Potential Of Hydrogen) to be 6 to 7 after the reaction of the materials in step (3) is completed, thus obtaining the high-thixotropy early-strength type polycarboxylate superplasticizer. The high-thixotropy early-strength type polycarboxylate superplasticizer prepared by the invention has an excellent thixotropic property.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Concrete additive, and applications thereof

The invention discloses a concrete additive. The concrete additive is prepared via mixing of an inhibition component 1, an inhibition component 2, an inhibition component 3, and an adjusting component at a ratio of 0.05-1:0.05-0.5:0.05-0.5:0.05-0.3. The invention also discloses applications of the concrete additive in concrete. According to an application method, the concrete additive is added into concrete, and an obtained mixture is mixed to be uniform in a stirring equipment, wherein the weight amount of the concrete additive accounts for 0.2 to 1.8% of the total weight of an obtained concrete cementing material. A preparation method is simple; the concrete additive is convenient to use, is green, is friendly to the environment, is capable of reducing cement 7d hydration heat obviously, reducing concrete early stage adiabatic temperature rise and concrete membrane internal peak temperature rise, and delaying generation of temperature peak by 1 to 2 days, and is beneficial for reducing of concrete early stage temperature stress, reducing of cracking caused by relatively large concrete early stage temperature difference, and increasing of concrete middle-later stage strength.

Owner:武汉三源特种建材有限责任公司

Ultra-high performance cement-based material applied to wet spraying construction

ActiveCN110845190AEasy to sprayPlay a binding roleSolid waste managementBuilding repairsAluminum sulphateSurface-active agents

The invention discloses an ultra-high performance cement-based material applied to wet spraying construction. The ultra-high performance cement-based material comprises the following ingredients in parts by weight: 300-400 parts of cement, 50-100 parts of fly ash floating beads, 50-100 parts of silica fume, 40-70 parts of superfine limestone powder, 5-15 parts of a surfactant, 30-50 parts of a magnesium expanding agent, 300-400 parts of quartz sand, 100-200 parts of coral reef sand, 30-70 parts of microfilament steel fibers, 3-6 parts of ultra-high molecular weight polyethylene fibers, 1-5 parts of a mineral additive, 90-120 parts of mixing water, and 25-45 parts of a setting accelerator; wherein the surfactant is a naphthalene series or aliphatic series organic powder, the mineral additive is attapulgite gel powder with the average particle size of 5-15 microns, and the setting accelerator is an alkali-free accelerating agent with the total alkali content not larger than 1%, and the main components are aluminum sulfate and an organic amine. The ultra-high performance cement-based material can realize continuous wet spraying construction, and the mechanical property and durabilityof sprayed concrete are greatly improved. The ultra-high performance cement-based material can be widely applied to the field of cement-based material preparation.

Owner:CCCC SECOND HARBOR ENG +3

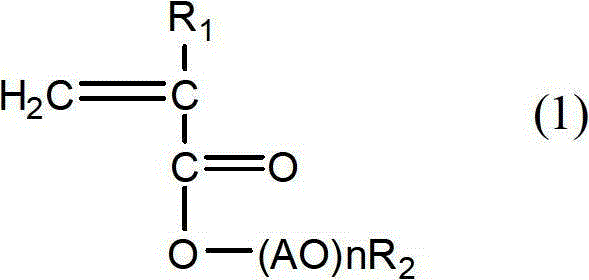

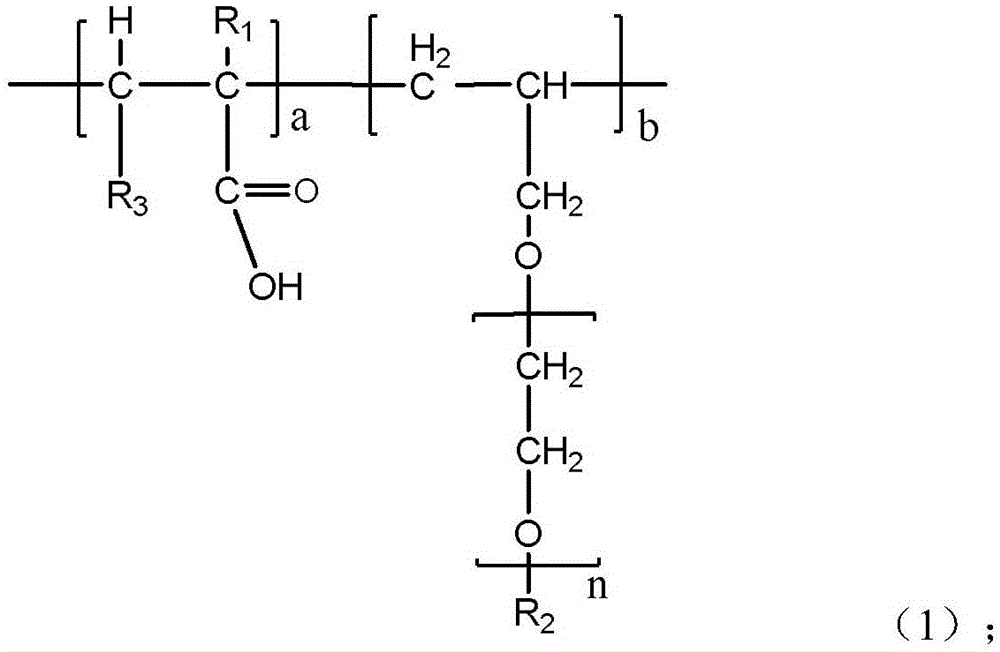

Method for preparing special functional polycarboxylate water reducer for PHC pipe pile

ActiveCN104292397AIdeal molecular weightIdeal molecular weight distributionApparent viscosityChemistry

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

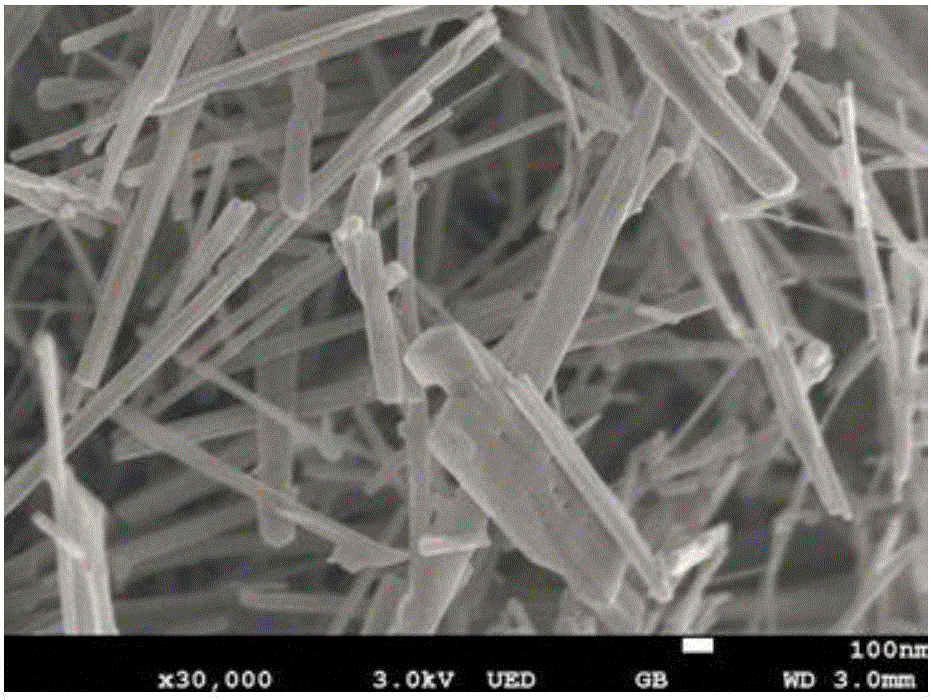

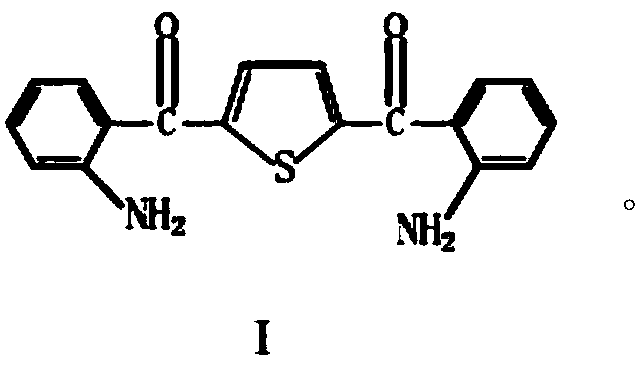

Fibrous nano silicate concrete admixture and preparation method thereof

ActiveCN106277901AImprove early strengthImprove toughnessMagnesium silicatesAlkaline-earth metal silicatesCalcium silicateMagnesium salt

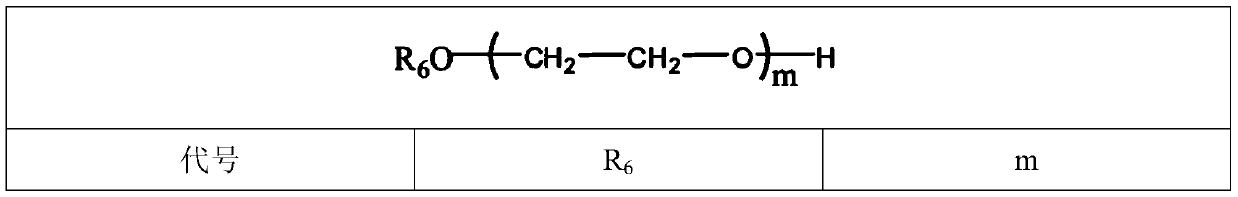

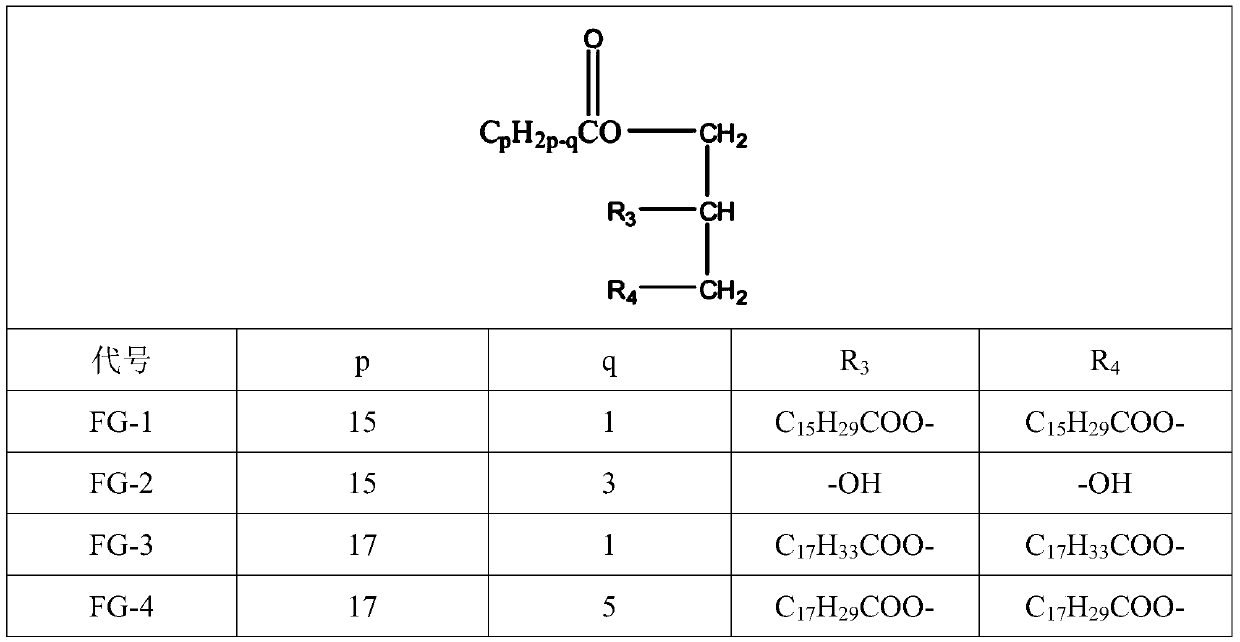

The invention discloses a fibrous nano silicate concrete admixture. The fibrous nano silicate concrete admixture is a compound prepared by magnesium silicate and calcium silicate in a high molecular polymer dispersing agent water solution, wherein the magnesium silicate is prepared by soluble magnesium salt and soluble silicate according to the mole ratio of 1: 1.2 to 1: 1.6, the calcium silicate is prepared from soluble calcium salt and soluble silicate according to the mole ratio of 1: 1 to 1: 1.5, the soluble calcium salt is magnesium nitrate, the soluble calcium salt is calcium nitrate, the soluble silicate is sodium silicate, a high molecular polymer dispersing agent is shown by a formula shown in the description. The fibrous nano silicate concrete admixture can remarkably improve the early strength of concrete. In addition, the concrete toughness has an obvious improving effect, early hydration of cement can be accelerated, and improvement of bending resistance and tension resistance capability of a cement-based material is promoted.

Owner:JIANGSU SOBUTE NEW MATERIALS

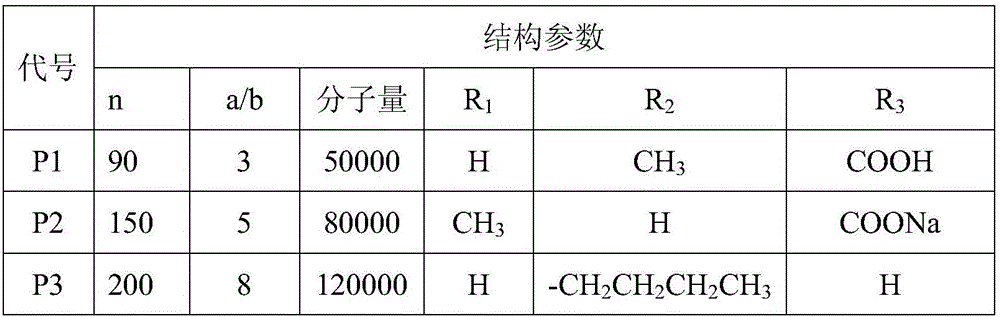

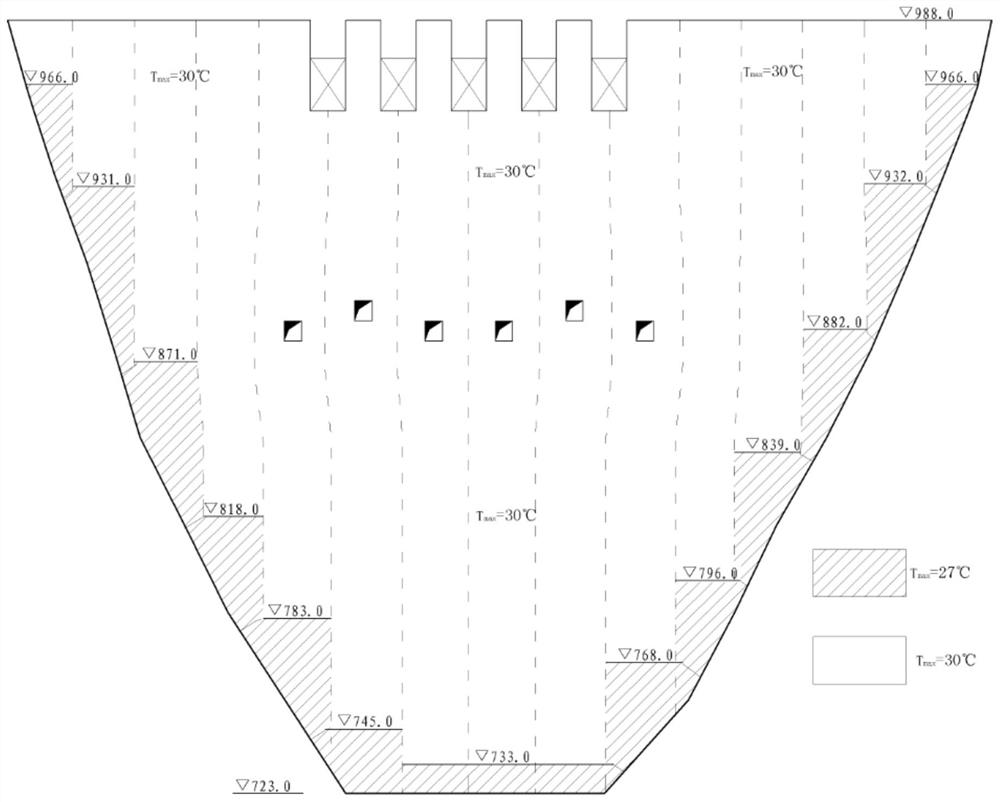

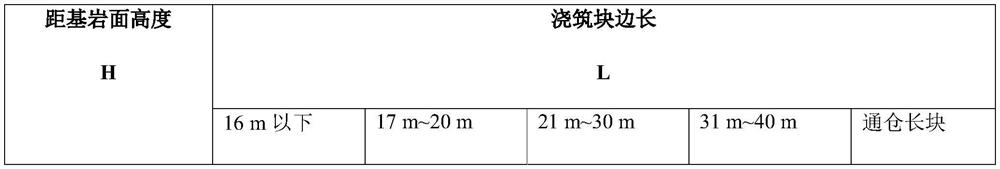

Control method for highest temperature interval of high-arch-dam low-heat cement concrete

ActiveCN112462818AIncreased safety against crackingEnsure arch integrityTemperature control using electric meansTemperature controlCrack resistance

The invention provides a control method for a highest temperature interval of high-arch-dam low-heat cement concrete. The characteristics of the low-heat cement concrete are combined, and the advantages of the low-heat cement concrete can be exerted to improve the crack resistance safety of dam concrete, the influence on the joint grouting quality of the transverse joint due to too small opening degree of the transverse joint in the construction period of the arch dam caused by too low maximum temperature control of concrete can be prevented, and the arch sealing integrity of the arch dam is ensured; too low maximum temperature control of concrete can be prevented, and particularly, when the environment temperature in autumn and winter is low, the highest temperature of the low-heat cementconcrete is easier to be too low. After the lower limit value of the highest temperature of the concrete is set, the highest temperature can be properly increased by adjusting a concrete pre-coolingmeasure, a water cooling measure and the like, so that the temperature control cooling engineering quantity and investment are obviously saved; and after the highest temperature interval control standard is set, the temperature control operation on the concrete in the actual construction process is more flexible, and field construction control is facilitated.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

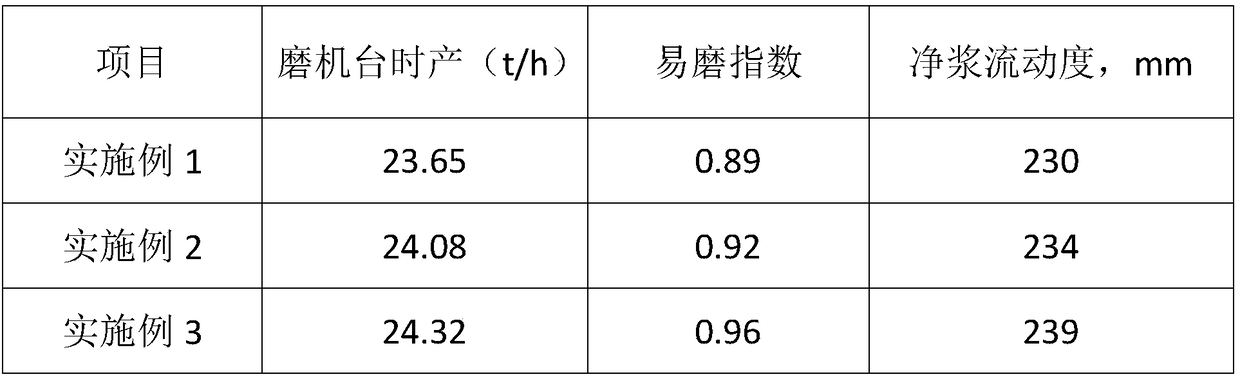

Cement grinding aid and preparation method thereof

The invention discloses a cement grinding aid. The cement grinding aid is made of the following raw materials by weight: 50-60 parts of aqueous polyhydroxy copolymer and 30-40 parts of modified hyperbranched polyethyleneimine. A preparation method of the cement grinding aid is further disclosed. The preparation method includes the following steps: mixing the raw materials uniformly in proportion,and then grinding to obtain the cement grinding aid. The cement grinding aid has the advantages of low production cost, low dosage, effective improvement of cement lubricity and output per machine, remarkable improvement of grinding aid effects, safety and environmental protection.

Owner:吉林省希普水泥助磨剂有限公司

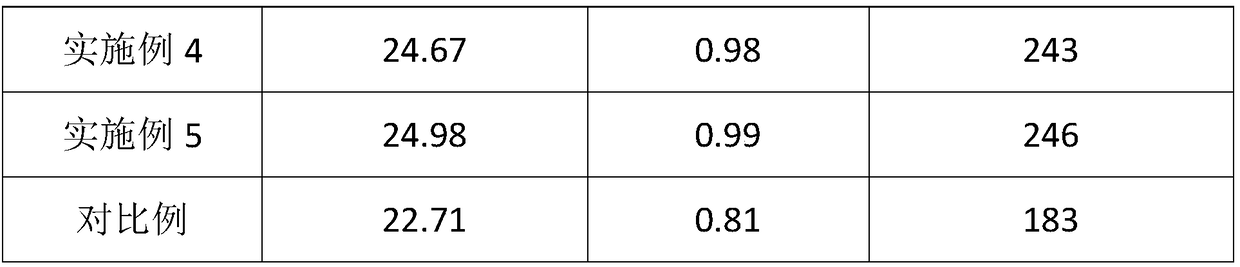

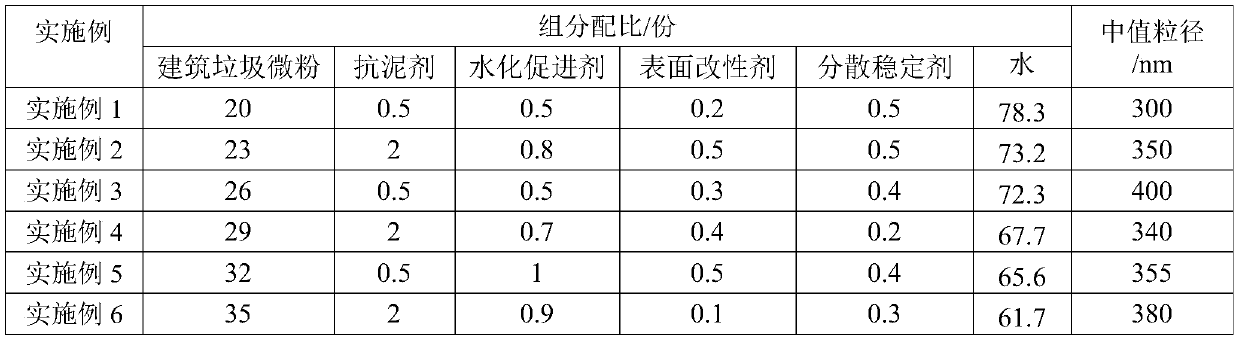

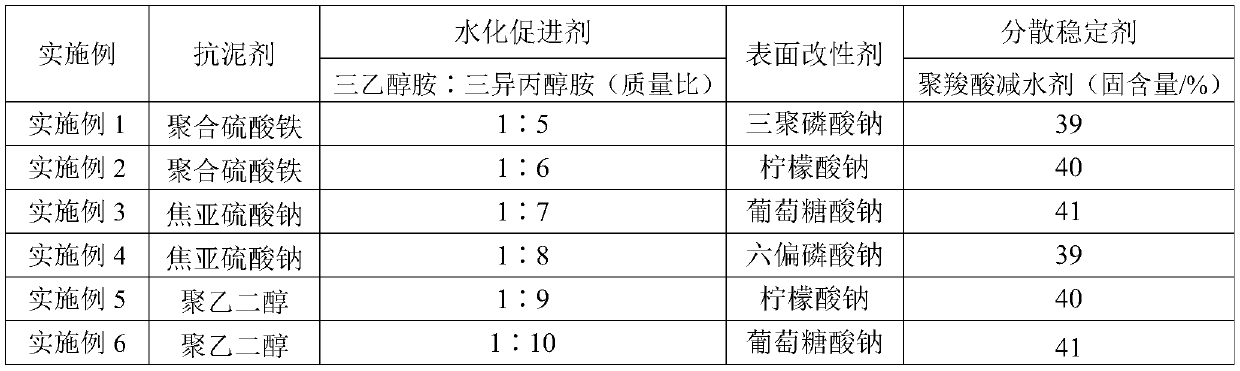

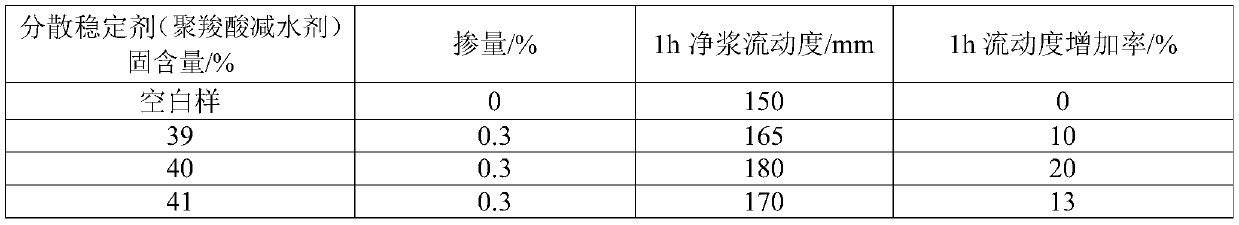

Building garbage nanometer crystal nucleus, preparation method and applications thereof

The invention provides a building garbage nanometer crystal nucleus, a preparation method and applications thereof, wherein 100 parts of the raw materials comprise, by weight, 20-35 parts of building garbage micro-powder, 0.5-2 parts of an anti-mud agent, 0.5-1 part of a hydration accelerator, 0.1-0.5 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and the balance of water. According to the present invention, with the building garbage nanometer crystal nucleus, the pore structure can be substantially improved, the nucleation acceleration hydration can be induced, and the early strength can be significantly improved; when 5-15% of the cement is replaced with the building garbage nanometer crystal nucleus, the 1 d compressive strength of ordinary Portland cement mortar can be improved by more than 20%, the 3 d compressive strength can be increased by more than 10%, and the 28 d compressive strength is not decreased; and the building garbage nanometer crystal nucleus provides the new direction for the resource utilization of building garbage, and greatly improve the resource utilization rate of building garbage.

Owner:WUHAN UNIV OF TECH

Dry powder gypsum mortar and preparation method thereof

The invention relates to a dry powder gypsum mortar and a preparation method thereof, wherein the dry powder gypsum mortar comprises the following components by weight percent: 25%-40% of calcined desulfurization gypsum, desulfurization gypsum less than 10%, 3.0%-8.0% of cement, 5.0%-25% of coal ash, 1.0%-5.0% of lignocellulose, 0.5%-2.0% of inorganic gel, 0.2%-0.5% of a water retention agent, 0.1%-0.2% of a water-reducing agent, a retarding agent less than 0.5%, 0.1%-1.0% of inorganic salt, sodium hydroxide less than 1.0% and 45%-65% of dried building sand with the fineness being 2.5-0.15mm.

Owner:SHANGHAI YINFAN NEW MATERIAL +1

Liquid alkali-free accelerator and preparation method

The invention provides a liquid alkali-free accelerator and a preparation method. The liquid alkali-free accelerator comprises mother liquor, a modifier, an activator and water, totaling 100% by weight. The mother liquor 45% by mass mother liquor which is prepared by mixing beta-chitosan and polystlicate aluminum ferric in a mass ratio of 1: 1 and adding water. The modifier is prepared by proportioning calcium sulphoaluminate micropowder, dibutyl phthalate, polydiallyldimethylammonium chloride, carrot antifreeze protein and diatom powder in a mass ratio of 10: (1-2): (1-2): (3-5): (5-6). The activator is prepared by proportioning hydroxyethyl cellulose and 1,2-epoxy octodecane in a mass ratio of 1: 1. The accelerator is simple to prepare, low in alkali content, high in early strength of concrete, small in loss of later strength, good in solution stability and adaptability and chlorine and fluorine free, is a green and pollution-free product, and has an excellent effect in large temperature difference areas particularly.

Owner:CHANGAN UNIV

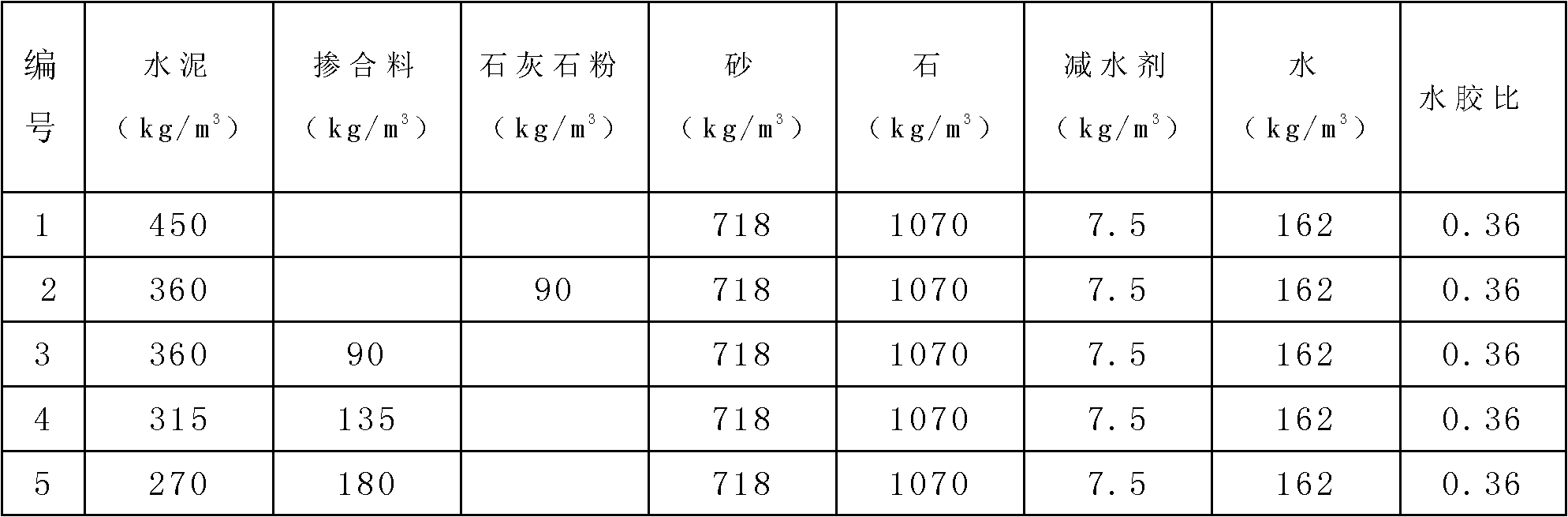

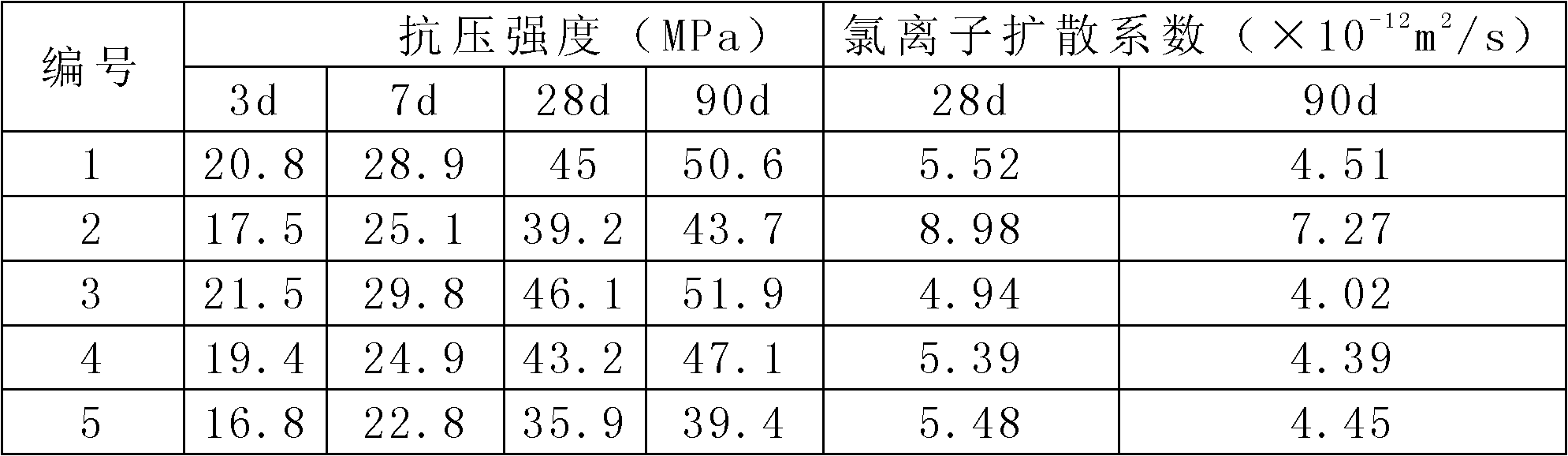

Compound admixture for anti-crack limestone powder and preparation method of compound admixture

The invention provides a compound admixture for anti-crack limestone powder and a preparation method of the compound admixture. The compound admixture comprises, by mass, 60-70 parts of limestone powder, 28-40 parts of coal ash, 1-2 parts of polypropylene fibers and 0.1-0.2 part of triethanolamine. By the compound admixture for the anti-crack limestone powder, concrete contraction can be reduced and concrete anti-crack performance can be improved while working performance and mechanical performance of concrete are guaranteed, so that durability of limestone powder concrete is improved, and application of the limestone powder to the concrete is widened.

Owner:CENT SOUTH UNIV

A kind of nano-suspension concrete early strength agent and preparation method thereof

The invention provides a nano-suspension concrete early-strength agent and a preparation method thereof. The nano-suspension concrete early-strength agent is made of a nano-calcium silicate suspension doped with transition metal elements, and the main composition of the suspension is It is nano silicon particles, the chemical structure of nano silicon particles is aCaO bAl2O3 cZnO SiO2 6H2O, where 1≤a≤2; 0.50≤b≤1; 0.25≤c≤0.50; the nano silicon particles are composed of soluble calcium salt , Soluble silicate, soluble aluminum salt, soluble zinc salt and polymer dispersant. On the one hand, the early strength agent does not contain chlorine salt and has no corrosion effect on the steel bars in the concrete; on the other hand, it is an extremely stable suspension system, which is easy to add and evenly disperse in the concrete preparation process; it can significantly improve the early strength of concrete, The effect of early strength of concrete using large amount of mineral admixture is particularly obvious, especially suitable for the production of concrete prefabricated components, which can reduce or even eliminate the steam curing process.

Owner:JIANGSU SOBUTE NEW MATERIALS

Super early strength concrete water reducing agent

The invention belongs to the technical field of concrete additives, and particularly relates to a super early strength concrete water reducing agent. The super early strength concrete water reducing agent is prepared from, by weight, 35-60 parts of a polycarboxylic acid water reducing agent, 1-2.2 parts of glyceryl monostearate, 0.5-1.5 parts of alkyl glycoside, 0.5-2.8 parts of sodium carboxymethylcellulose, 0.3-0.9 part of sodium tripolyphosphate, 0.2-0.8 part of polytetrafluoroethylene and 10-25 parts of water. The super early strength concrete water reducing agent has the superhigh early strength ratio and the high later strength increase speed and is good in adaptability with concrete, beneficial for durability of the concrete and few in slump time loss.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Reinforced concrete internal curing high-water-absorption microsphere material and preparation method thereof

The invention provides an enhanced concrete internal curing high-water-absorption microsphere material and a preparation method thereof. The enhanced concrete internal curing high-water-absorption microsphere material is prepared from the following raw materials: nano silicon dioxide, chitosan, glutaraldehyde, Arabic gum, methacrylic acid, glacial acetic acid, cumene hydroperoxide, ferrous chloride and sodium ethoxide. By improving the transition area of the cement paste and the aggregate and modifying the microstructure in the cement-based material, the porosity is reduced, and the mechanicalproperty is improved. The whole preparation process flow is relatively simple, professional technicians do not need to operate and guide, and only the operation is carried out according to the description of the invention. The strength, durability, service life and the like of cement concrete are obviously improved by the reinforced concrete internal curing high-water-absorption microsphere prepared by the method disclosed by the invention.

Owner:CHANGAN UNIV

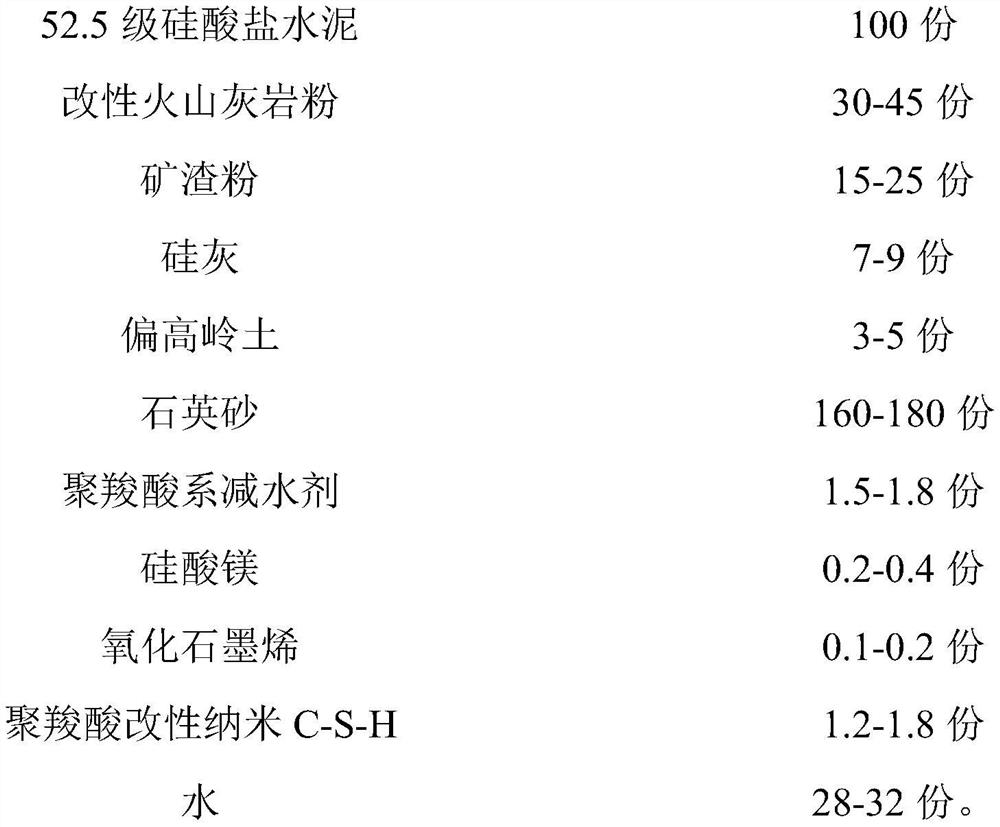

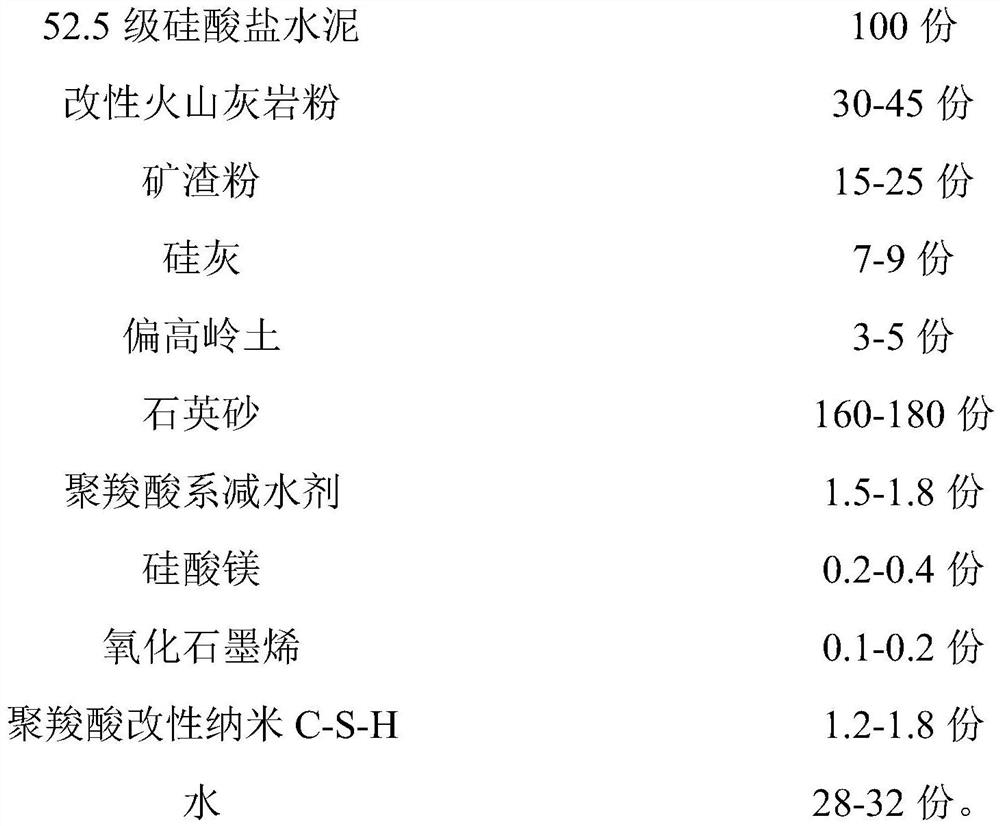

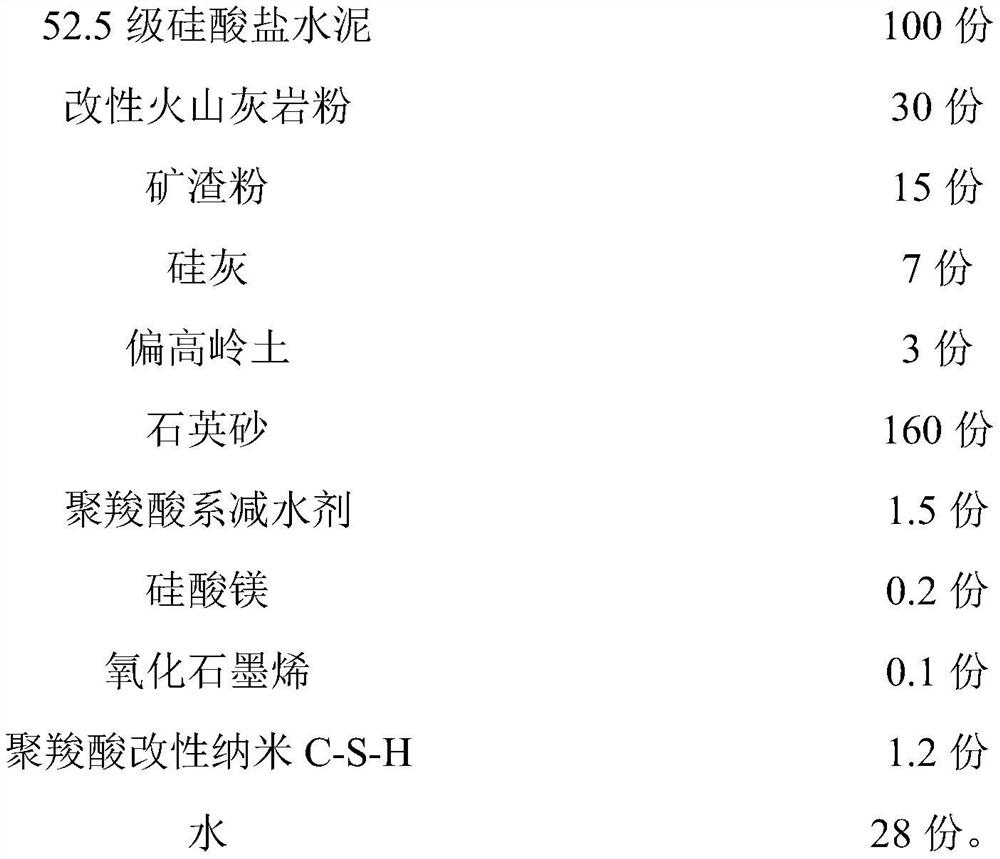

Ultra-high performance concrete prepared from modified volcanic limestone powder

The invention discloses ultra-high performance concrete prepared from modified volcanic limestone powder. The ultra-high performance concrete is prepared from 52.5-grade Portland cement, modified volcanic limestone powder, slag powder, silica fume, metakaolin, quartz sand, a polycarboxylic water reducer, magnesium silicate, graphene oxide, polycarboxylic acid modified nano C-S-H and water. The modified volcanic limestone powder is utilized to enhance the characteristics of of the ultra-high performance concrete including good fluidity, high strength and low preparation cost, so that the popularity and market competitiveness of the ultra-high performance concrete prepared by the invention are favorably improved. Therefore, the ultra-high performance concrete prepared by the invention is concrete with high comprehensive performance.

Owner:乌兰浩特市圣益商砼有限公司

High-early-strength concrete mixture and winter construction method thereof

ActiveCN109095850AImprove solubilityPromotes early hydrationBuilding material handlingUltimate tensile strengthWater reducer

The invention discloses a high-early-strength concrete mixture and a winter construction method thereof, and belongs to the field of building materials. The high-early-strength concrete mixture is prepared by mixing and evenly stirring the following components in parts by weight: 193-256 parts of cement, 335-456 parts of sand, 784-885 parts of broken stone, 48-79 parts of fly ash, 69-105 parts ofmineral powder, 5-10 parts of a water reducer, 0.05-0.5 part of a compound early-strength agent, 0.3-0.6 part of a defoamer, 7-10 parts of a compound expanding agent and 124-198 parts of water. The high-early-strength concrete mixture has the advantages that the initial setting time and the final setting time of concrete are shortened, the early strength of concrete is improved, and the use efficiency of a template is accelerated.

Owner:北京建工新型建材有限责任公司

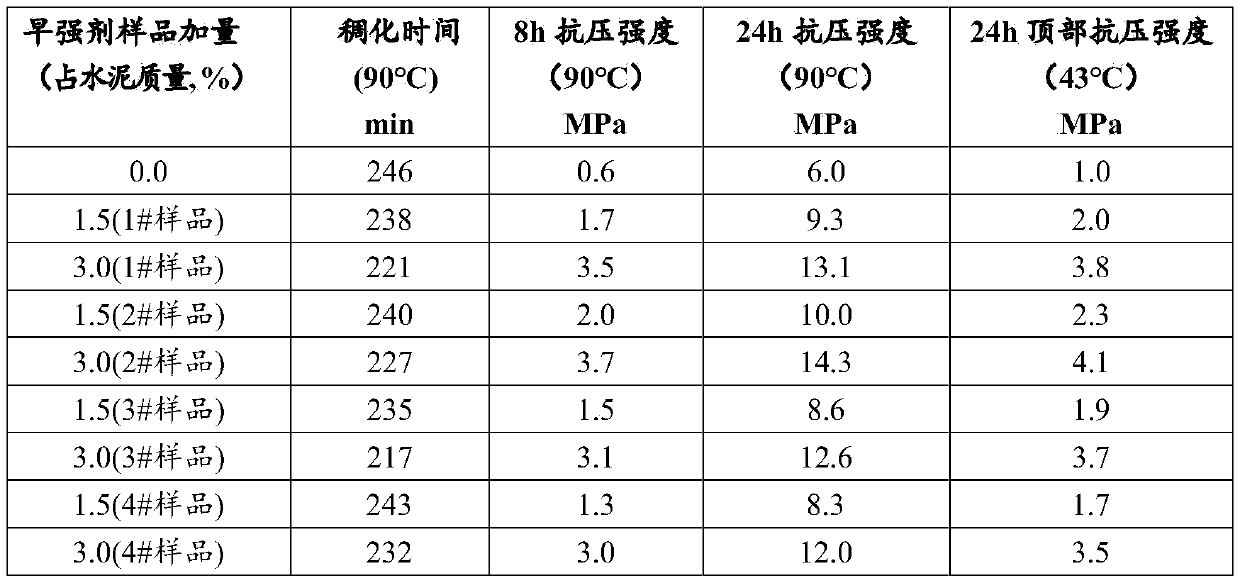

Weak coagulation type early strength agent for oil well cement

ActiveCN109880604AIncreases hydration activityImprove early strengthDrilling compositionInorganic saltsReducer

The invention discloses a weak coagulation type early strength agent for oil well cement. The early strength agent comprises the following components in parts by weight: 30-70 parts of a nano material, 20-50 parts of an inorganic salt, 5-20 parts of an organic salt and 5-30 parts of a drag reducer, wherein the nano material is selected from a mixture of a fibrous structure nano material and a flaky structure nano material. The weak coagulation type early strength agent for the oil well cement disclosed by the invention has slight influence on the thickening time of cement paste, but can obviously increase the early strength of cement stone, shows weak coagulation high early strength properties, can improve the stability of the cement paste, has no adverse effects on other performances of the cement paste, and has good comprehensive performance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

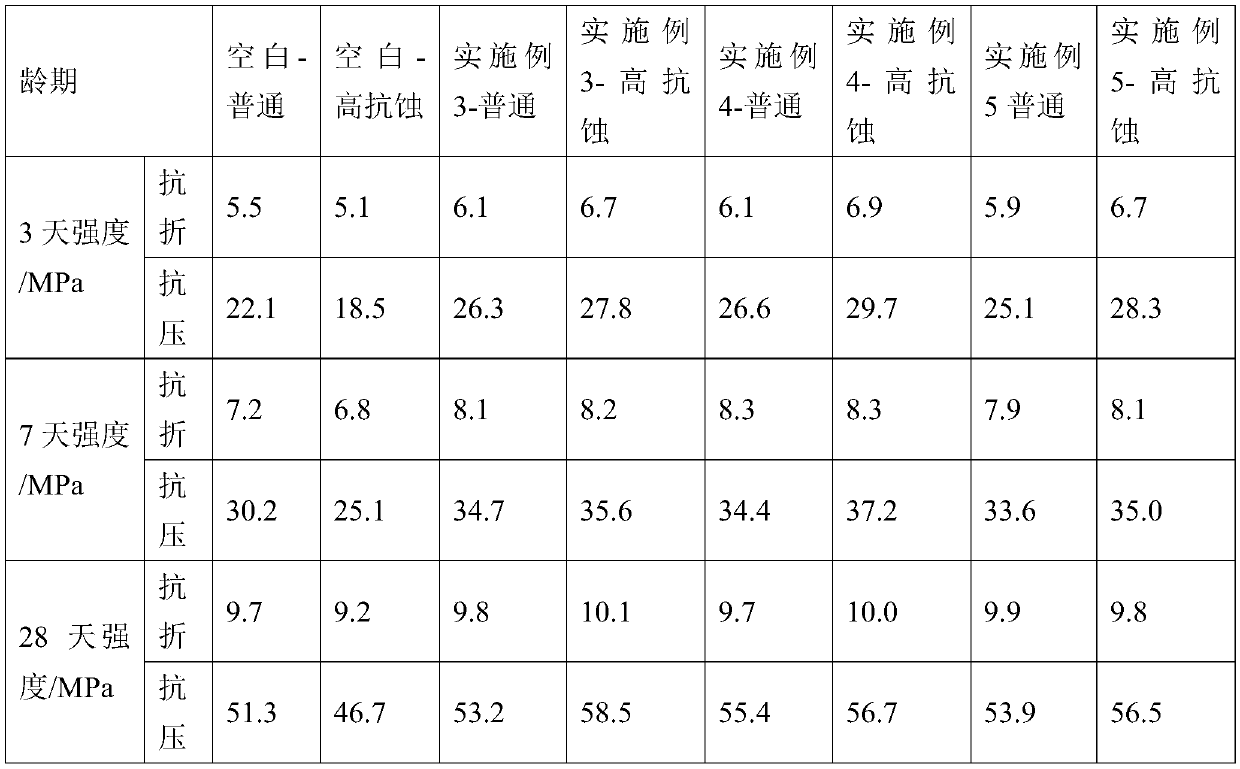

High corrosion-resistant Portland cement early strength agent and preparation method thereof

The invention discloses a high corrosion-resistant Portland cement early strength agent and a preparation method thereof. The high corrosion-resistant Portland cement early strength agent comprises the following components in part by weight: 20-60 parts of gypsum, 10-20 parts of quicklime, 20-40 parts of sulfate, 10-30 parts of alcohol amine compound and 1-20 parts of calcium formate. The preparation method comprises the following steps: firstly uniformly mixing the gypsum, the quicklime, the sulfate, citrate and the calcium formate in a mixing machine in proportion, then adding the alcohol amine compound, grinding together in a vibrating mill and sieving to obtain the high corrosion-resistant Portland cement early strength agent. The high corrosion-resistant Portland cement early strengthagent and the preparation method thereof have the benefits that the targeted design is performed on a high corrosion-resistant Portland cement system, and the problem of no targeted early strength agent for existing high corrosion-resistant Portland cement is solved by the utilization of an inorganic and organic synergistic mechanism; in addition, the early strength agent does not contain corrosive ions such as chloride ions, has no influence on the use of the high corrosion-resistant Portland cement and can meet the needs of various erosion environments and construction conditions.

Owner:WUHAN UNIV OF TECH

Fair-faced concrete

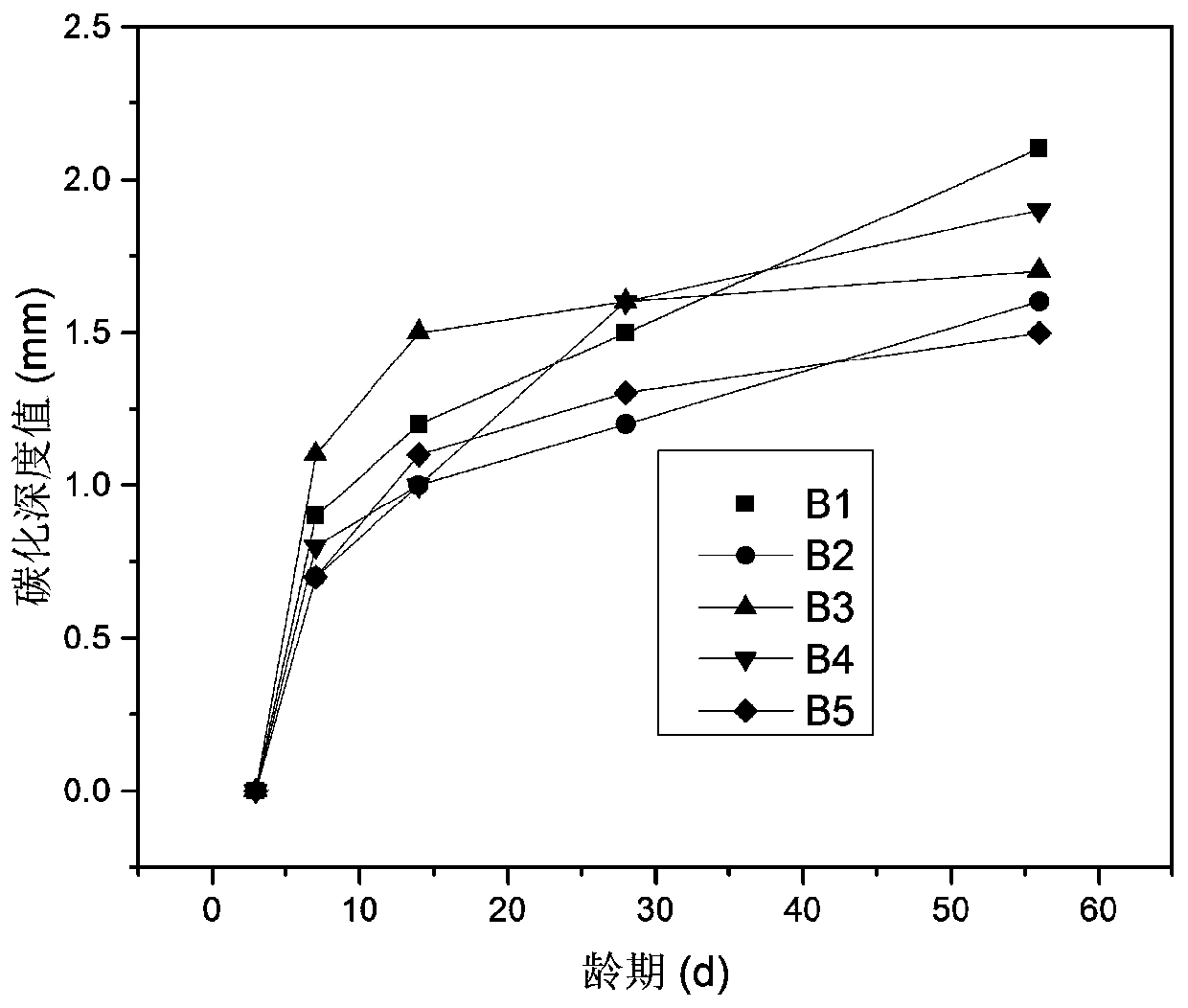

InactiveCN111559890AIncrease densityImprove mechanical propertiesBuilding materialEnvironmental geology

The invention provides a fair-faced concrete, belongs to the technical field of building materials, and concretely provides a fair-faced concrete containing alkaline electrolyzed water. The influenceof factors such as the water-binder ratio, the admixture mixing amount and the age on the strength, the crack resistance and the durability of the concrete is changed, the mix proportion design of thefair-faced concrete is optimized, and the cement consumption is reduced, so a green, efficient, low-cost, non-toxic and pollution-free facing fair-faced concrete preparation technology is realized, and the purpose of meeting the requirements of fair-faced, high-durability and economic concrete is achieved.

Owner:QINGDAO QINGJIAN NEW MATERIAL GRP CO LTD +2

Limestone flour mineral composite agent

The invention provides a limestone flour mineral composite agent. The limestone flour mineral composite agent is prepared from the following raw materials in parts by weight: 30 to 80 parts of limestone flour, 10 to 30 parts of slag powder, 5 to 10 parts of magnesia powder, 3 to 8 parts of nitrate, 20 to 50 parts of gypsum powder and 5 to 15 parts of triethanolamine. According to the composite agent, the early strength and long-term strength of concrete can be improved, the early hydration of cement is promoted due to the limestone flour, and moreover, the triethanolamine is also beneficial for the development on the early strength of concrete; the durability of concrete is improved, the porosity of concrete can be effectively reduced due to combined addition of the limestone flour and mineral powder, so that the pore structure is refined, the pore structure is improved, the chloride ion diffusion coefficient of concrete can be effectively reduced, and moreover, the triethanolamine enables a cement hydration product to be compact in structure. The composite agent is simple in preparation technology and low in cost, and is applicable for large-scale industrial production.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

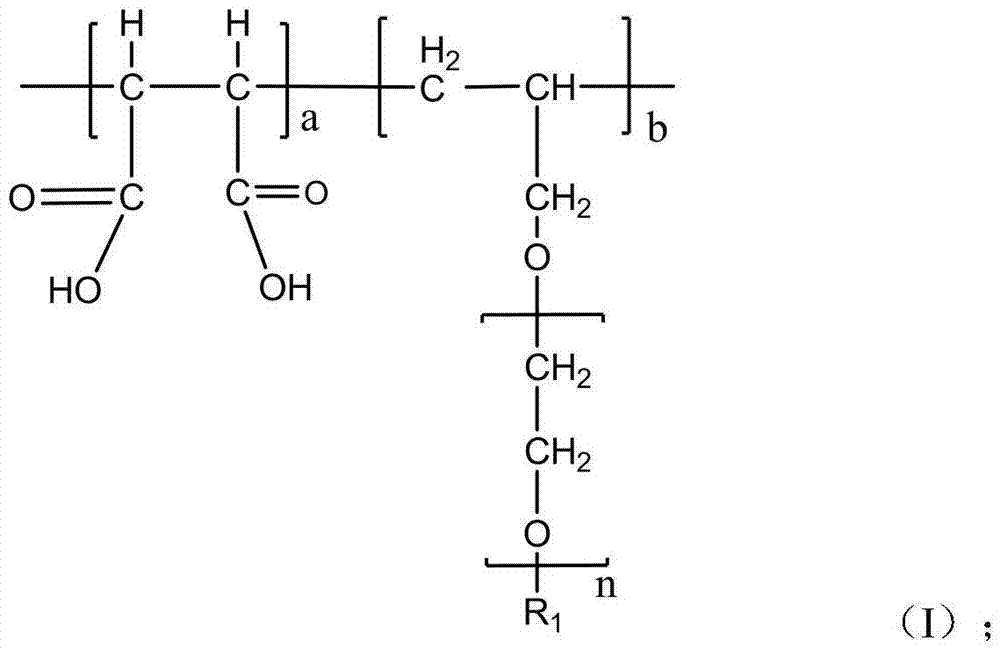

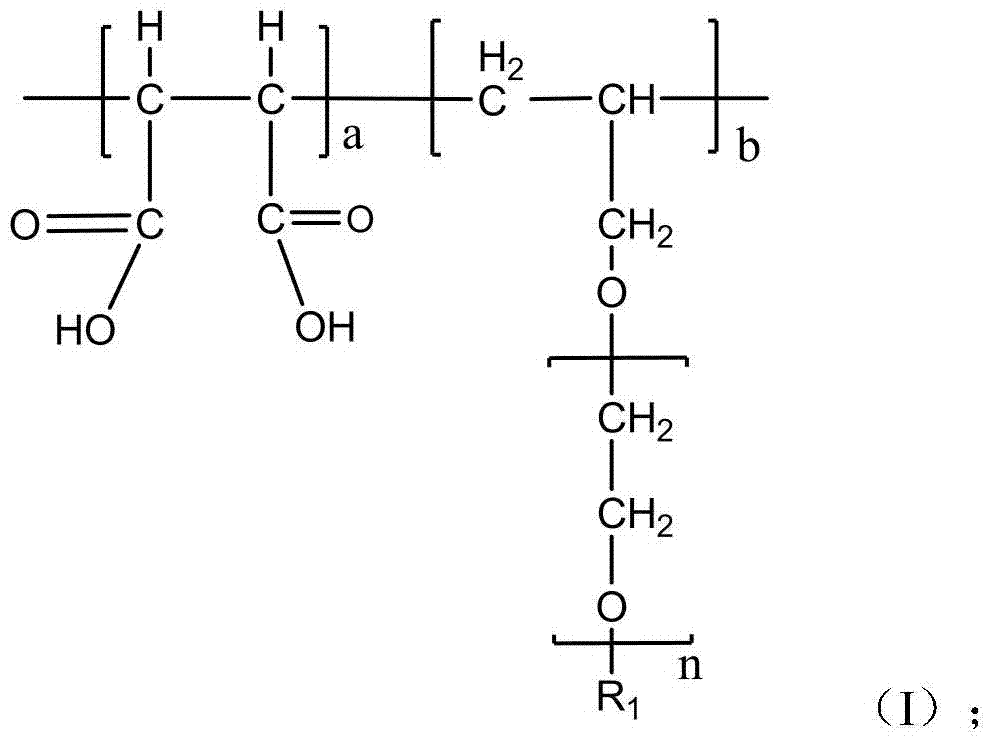

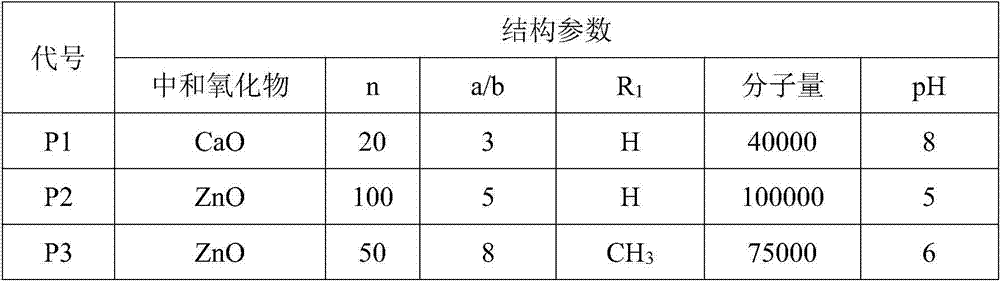

A kind of coagulation-promoting early-strength polycarboxylate superplasticizer and preparation method thereof

ActiveCN109134784BPromotes early hydrationActs as a condensation catalystPlasticizerSuperplasticizer

The invention discloses a coagulating and early-strength-type polycarboxylic acid superplasticizer and a preparing method thereof. The polycarboxylic acid superplasticizer is prepared from, by mass, 70-80 parts of polyoxyethylene ether macromonomer, 1-1.5 parts of reducing agent, 1-1.5 parts of water-based initiator, 40-50 parts of deionized water, feed liquid A and feed liquid B; the feed liquidA is prepared by mixing 7-9 parts of acrylic acid, 0.1-2 parts of coagulating and early-strength monomer, namely unsaturated alhylol amine ester, 0.1-1 part of unsaturated amide and 15-25 parts of deionized water; the feed liquid B is prepared by mixing 0.08-0.15 part of reducing agent Y, 0.3-0.5 part of chain transfer agent and 18-28 parts of deionized water. The preparing method comprises the steps of putting the polyoxyethylene ether macromonomer, the reducing agent and the deionized water into a reaction kettle, raising the temperature, and stirring the materials; adding the water-based initiator into the reaction kettle, dropwsie adding the feed liquid A and the feed liquid B, after dropwise addition is finished, conducting heat preservation for a reaction, cooling to the room temperature, and adding caustic soda liquid to adjust the pH value to 7. By means of the coagulating and early-strength-type polycarboxylic acid superplasticizer and the preparing method thereof, the early strength of concrete is effectively improved, and the coagulating time of the concrete is shortened.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Mineralized material used in cement grinding process

The invention is suitable for the technical field of cement grinding aids, and provides a mineralized material used in a cement grinding process, the mineralized material is composed of the following substances by mass: 2-5% of sodium sulfate, 4-7% of sodium thiosulfate, 0-3% of sodium sulfite, 1-3% of maleic anhydride dimer acid triethanolamine ester, 1-3% of ethylene glycol, and 79-92% of fly ash. By determining proper substances and content, promoting early hydration of cement and greatly improving the early hydration rate of cement particles, the early strength is improved, the hydration durability is considered, the later hydration of the cement is promoted through sodium thiosulfate, maleic anhydride dimer acid triethanolamine ester and ethylene glycol, the strength of cement paste is improved, and the cement paste can also wrap the surface of cement particles to form a protective film to eliminate bonding and adsorption agglomeration, the maleic anhydride dimer acid triethanolamine ester can form an oxidation protection film on the metal surface to retard the corrosion of steel bars so that the machine-hour yield of a mill is increased, the comprehensive performance of the product is improved, the power consumption of cement grinding is reduced, and the damage to the cement concrete caused by excessive chloride ions is avoided.

Owner:山西天润恒德新材料有限公司

Concrete admixture and preparation method thereof

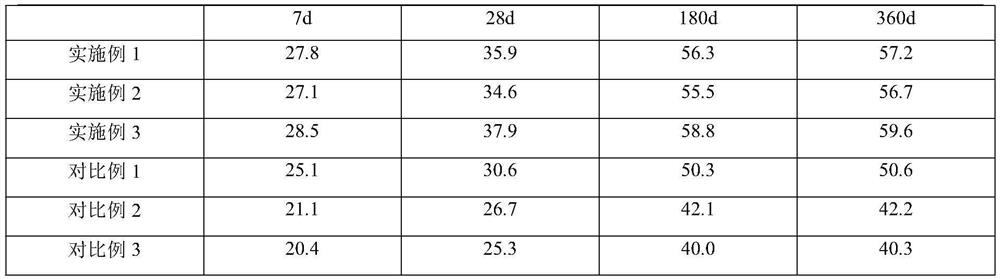

The invention provides a concrete admixture and a preparation method thereof. The preparation method comprises the following steps: preparing calcium silicate and magnesium silicate nanoparticles by taking a magnesium nitrate aqueous solution, a sodium silicate aqueous solution, tetraethyl orthosilicate, calcium nitrate and the like as raw materials; modifying the halloysite nanotube by using N-([beta]-aminoethyl-[gamma]-aminopropyl triethoxysilane to obtain a modified halloysite nanotube, and reacting the modified halloysite nanotube with the epoxidized bark powder to obtain modified bark powder; and finally, taking acrylamide and N-(4-aminophenyl)acrylamide as raw materials to carry out polymerization reaction, and adding calcium silicate and magnesium silicate nanoparticles and the modified bark powder in the polymerization process. The concrete admixture is helpful for greatly accelerating early hydration of cement, has a good early strength effect, has a very good adsorption and solidification effect on chloride ions, and prevents concrete from being eroded and damaged by the chloride ions.

Owner:凌池英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com