Weak coagulation type early strength agent for oil well cement

A technology of oil well cement and early-strength agent, which is applied in the field of weak coagulation-accelerating early-strength agent for oil well cement. It can solve the problems of shortening the thickening time and the early strengthening effect of cement stone is not obvious, so as to speed up the development of early strength and promote early strength. Hydration, early strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

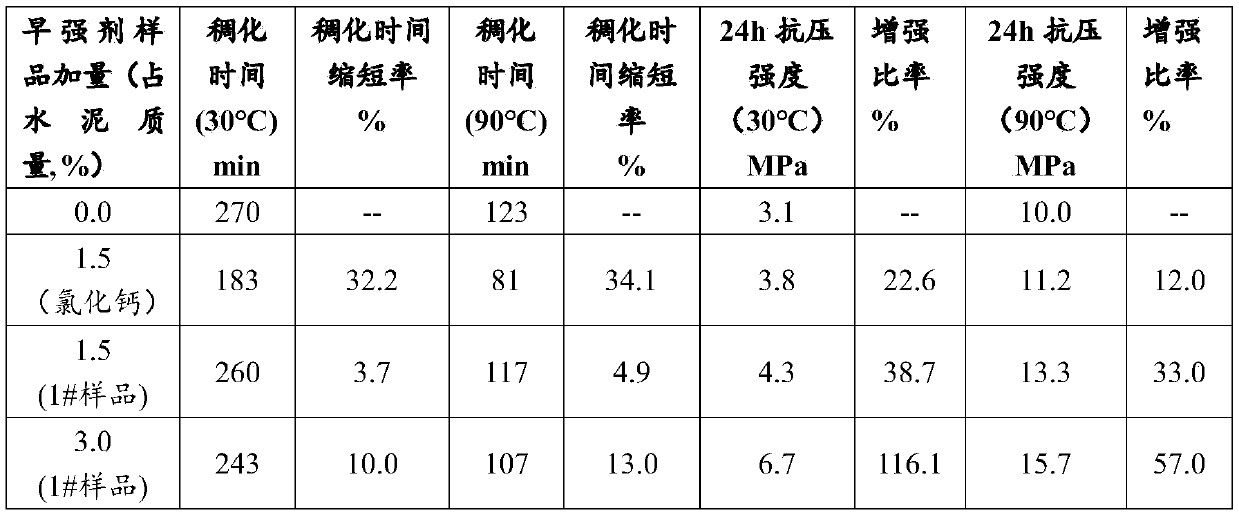

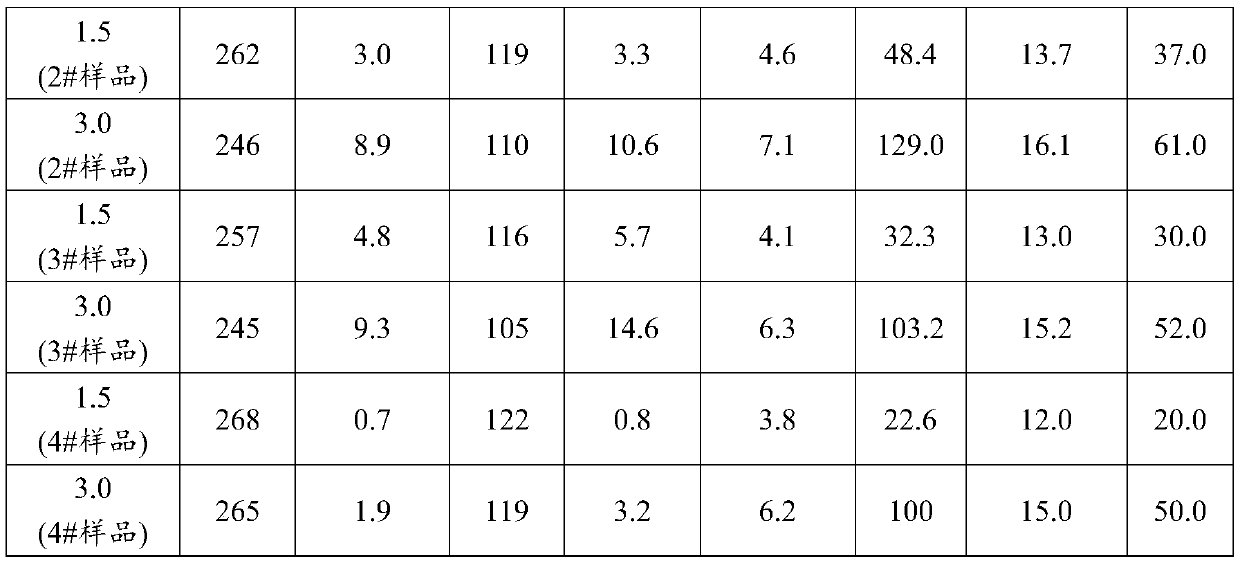

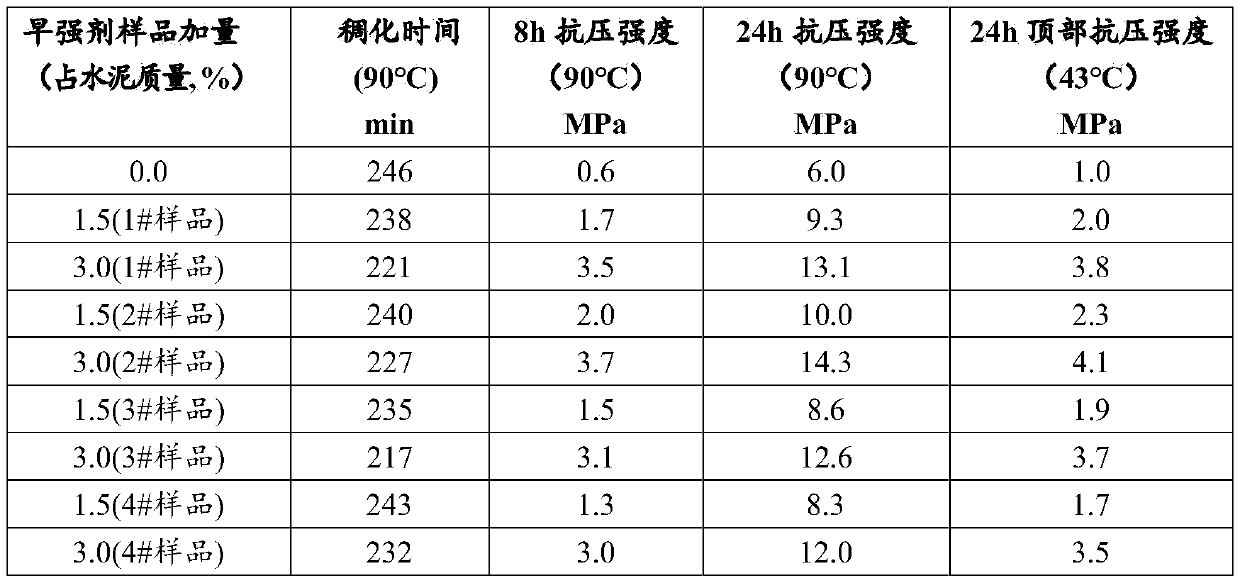

Embodiment 1

[0028] First weigh 70 parts of nanomaterials, wherein the mixing mass ratio of nano silicon carbide and nano magnesium hydroxide is 1:1; a total of 5 parts of the mixture of naphthalene sulfonate formaldehyde condensate and lignin sulfonate, of which naphthalene sulfonate The mass ratio of formaldehyde condensate to lignosulfonate is 2:1, and the above-mentioned nanomaterials and drag reducer are mixed evenly. Then add a total of 20 parts of a mixture of potassium sulfate and sodium nitrate, and 5 parts of sodium acetate, and mix evenly to obtain a powdery weak coagulation accelerator for oil well cement, marked as 1# sample.

Embodiment 2

[0030] First take by weighing 50 parts of nanomaterials, wherein the mixing mass ratio of nanometer silicon carbide, nanometer aluminum hydroxide and nanometer magnesium hydroxide is 1:0.3:0.7; Parts, wherein the mass ratio of naphthalenesulfonate formaldehyde condensate to lignosulfonate is 2:1, and the above-mentioned nanomaterials and drag reducer are mixed evenly. Then add a total of 25 parts of a mixture of potassium sulfate and calcium sulfate, a total of 15 parts of a mixture of sodium acetate and calcium formate, and mix well to obtain a powdered oil well cement with a weak coagulation accelerator, marked as 2# sample.

Embodiment 3

[0032] First take 30 parts of nanomaterials, wherein the mixing mass ratio of nano-silicon carbide and nano-aluminum hydroxide is 1:1; a total of 15 parts of the mixture of naphthalenesulfonate formaldehyde condensate and lignosulfonate, of which naphthalenesulfonate The mass ratio of formaldehyde condensate to lignosulfonate is 2:1, and the above-mentioned nanomaterials and drag reducer are mixed evenly. Then add a total of 35 parts of a mixture of sodium nitrate and calcium sulfate, a total of 20 parts of a mixture of sodium acetate and calcium formate, and mix well to obtain a powdery weak coagulation accelerator for oil well cement, marked as 3# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com