Low-temperature-resistant early-strength dry powder adhesive and bonding slurry

A technology for bonding slurry and adhesives, which is applied in the field of building energy-saving materials, can solve the problems of discontinuous film of redispersible latex powder, slow strength growth rate, and destruction of crystal skeleton, so as to achieve high mineral hydration activity and strength growth Fast, early-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention has no special limitation on the preparation method of the dry powder adhesive, and it only needs to mix various raw materials uniformly according to the proportion.

[0045] The dry powder binder of the present invention is suitable for various external wall thermal insulation systems, and has excellent adhesion to base wall surfaces such as cement concrete and thermal insulation materials such as polystyrene, extruded board, polyurethane and phenolic foam.

[0046]The invention also discloses a bonding slurry, which is obtained by mixing the above-mentioned dry powder adhesive and water in the above technical solution, and the mass ratio of the dry powder adhesive to water is 100:(20~25), preferably 100:(22~ twenty four).

[0047] The dry powder adhesive can be used after being mixed with water to form a bonding slurry. The bonding paste can be directly used for bonding the thermal insulation material of the external wall thermal insulation syst...

Embodiment 1

[0053] Put 300 kilograms of SAC cement, 650 kilograms of washed river sand, 20 kilograms of heavy calcium, 25 kilograms of redispersible latex powder, 2 kilograms of cellulose ether and 3 kilograms of water repellent into the mixing chamber and mix them for 10 minutes. Minutes to get low temperature resistant early strength dry powder adhesive.

[0054] 1000 kg of the dry powder adhesive and 200 kg of water were mixed evenly in an electric mixer, and after stirring thoroughly for 5 minutes, the slurry was allowed to stand for 5 minutes, and a usable bonding slurry was obtained after stirring again.

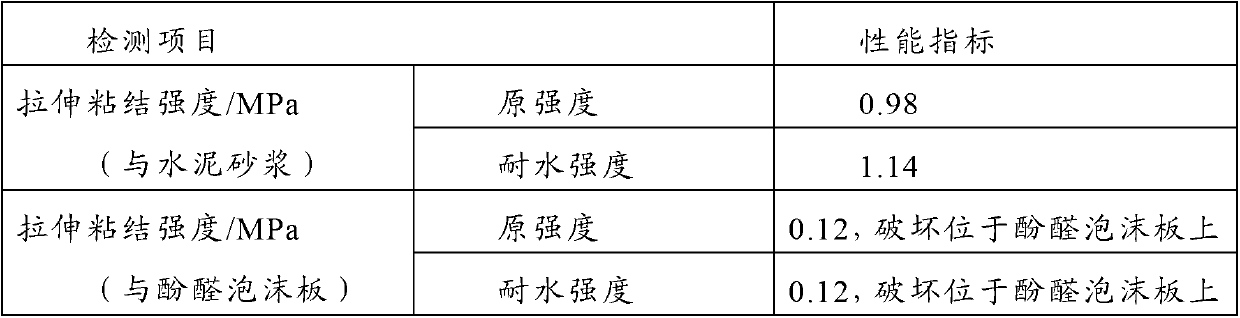

[0055] According to the performance detection method in the standard JG 149-2003 of "Expanded Polystyrene Board Thin Plastering Exterior Wall External Thermal Insulation System", the tensile bonding of the strong water-resistant adhesive mortar, cement mortar and phenolic foam board for external thermal insulation of the present invention is carried out. The intensity was tested, ...

Embodiment 2

[0059] Put 350 kilograms of SAC cement, 600 kilograms of washed river sand, 28 kilograms of heavy calcium, 20 kilograms of redispersible latex powder, 1 kilogram of cellulose ether and 1 kilogram of water repellent into the mixing chamber for mixing, and the mixing time is 10 Minutes to get low temperature resistant early strength dry powder adhesive.

[0060] 1000 kg of the dry powder adhesive and 200 kg of water were mixed evenly in an electric mixer, and after stirring thoroughly for 5 minutes, the slurry was allowed to stand for 5 minutes, and a usable bonding slurry was obtained after stirring again.

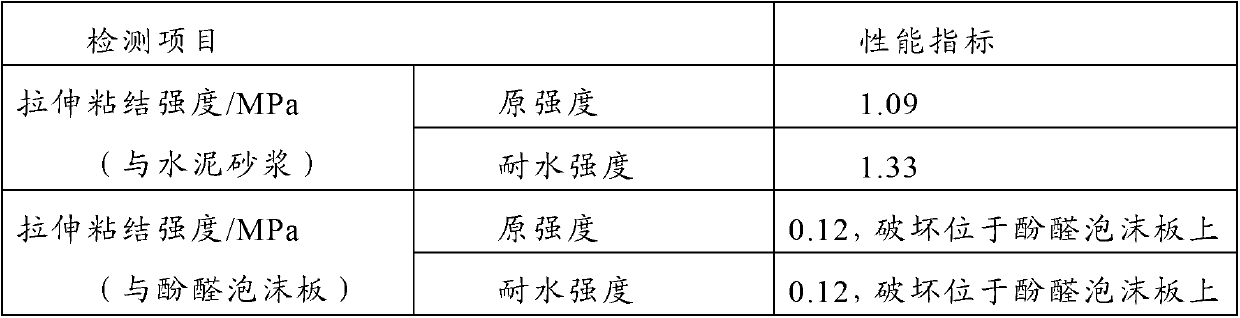

[0061] According to the performance detection method in the standard JG 149-2003 of "Expanded Polystyrene Board Thin Plastering Exterior Wall External Thermal Insulation System", the tensile bonding of the strong water-resistant adhesive mortar, cement mortar and phenolic foam board for external thermal insulation of the present invention is carried out. The intensity was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com