Super plasticizer for precast concrete component

A technology of prefabricated components and superplasticizers, applied in the field of concrete admixtures, can solve the problems that cannot meet the development needs of energy saving, low carbon, and emission reduction in the construction industry, large slump loss, and high energy consumption

Active Publication Date: 2013-02-06

JIANGSU SOBUTE NEW MATERIALS +1

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Invention patents (EP1547986, US723287, EP2128110, ZL200710024394.4, ZL200710024392.5) use the technical approach of ultra-long side chain polyether to invent a super-early-strength admixture to improve the early strength of concrete, although the early strength of concrete has been greatly improved , but the increase in the length of the polyether side chain accelerates the early hydration of the cement, which intensifies the early slump loss of the fresh concrete

[0003] To sum up, it is unsatisfactory to use traditional inorganic salt or organic early strength agent to improve the early strength of concrete, and its high dosage reduces the later strength of concrete; the early strength technology of traditional cement composition or fineness control is

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

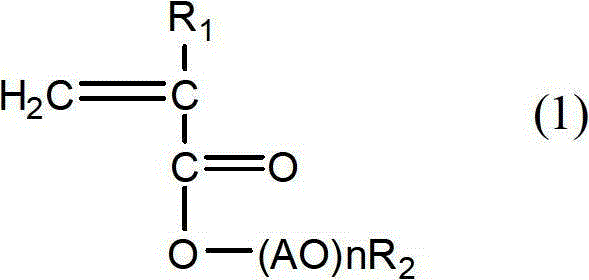

The invention relates to a super plasticizer for a precast concrete component, and the super plasticizer is prepared by carrying out free radical copolymerization reaction on monomer a, monomer b, monomer c and monomer d in an aqueous medium, and adding alkali compound into the reaction product for neutralization, wherein the molar ratio among the monomer a, the monomer b, the monomer c and the monomer d is 1.0:(5.0-16.0):(1.0-4.0):(2.0-6.0). Compared with the traditional high efficiency water reducing agent, the admixture has the characteristics that (1) the early hydration of the cement is obviously improved, the compression strength of the concrete is improved, and especially the early strength is improved; (2) the problem of slump loss caused by polyether long side chain belt can be greatly improved, so that the slump loss resistance of the concrete is improved, and the requirements of pumping pipe pile concrete can be met; and (3) under the condition of low amount of admixture, the super plasticizer for the precast concrete component has remarkable dispersing performance, slump-retaining capability and enhancement effect, is especially remarkable in early enhancement effect, is very remarkable in the early enhancement effect at the room temperature or low temperature, and is stable in later strength increment, thus being conductive to accelerating the turnover of templates, and accelerating the construction progress.

Description

technical field [0001] The invention relates to an ultra-early-strength superplasticizer suitable for concrete prefabricated components. The superplasticizer can not only significantly improve the early strength of concrete without delaying the setting time of cement, but also has excellent The invention relates to slump retention capacity, belonging to the technical field of concrete admixtures. Background technique [0002] Concrete prefabricated components are key products developed in the "12th Five-Year Development Plan for Building Materials Industry". During the Eleventh Five-Year Plan period, the output of traditional prefabricated components such as concrete prefabricated piles, drainage pipes, pressure pipes and poles in my country maintained a rapid growth. At the same time, a large number of infrastructure construction projects in the country have higher and higher requirements on the technical level and quality of concrete products, which promotes the rapid dev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/26C08F290/06C04B103/32

CPCC04B24/2647C04B24/2652C04B24/2694C04B2103/32

Inventor 冉千平刘金芝刘加平周栋梁杨勇张建纲

Owner JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com