Mineralized material used in cement grinding process

A technology of cement powder and fly ash, which is applied in the field of cement grinding aids, can solve problems such as excessive chloride ions, inability to ensure the durability of concrete, the stability of concrete buildings, and corrosion of steel bars, so as to prolong life, eliminate bonding and adsorption Agglomeration, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

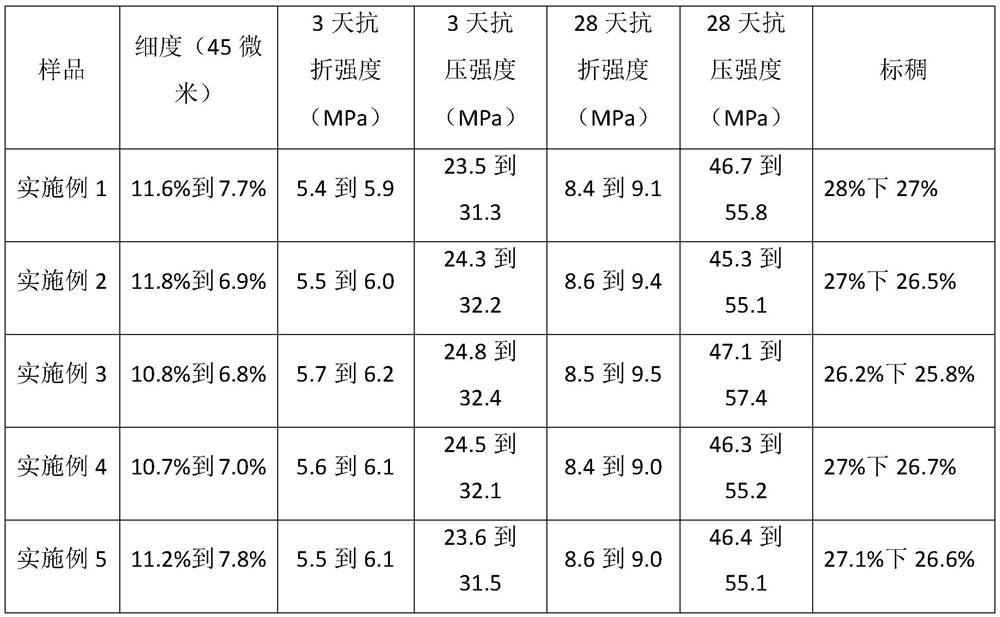

Examples

Embodiment approach

[0024] As an embodiment of the present invention, the mineralization material further includes sulfite, and the sulfite is selected from one or more of sodium sulfite, potassium sulfite, and ammonium sulfite. Sodium sulfate, sodium thiosulfate, sodium sulfite, and fly ash are powders in the mineralized material, maleic anhydride dimer acid triethanolamine ester and ethylene glycol are liquid, and maleic anhydride dimer acid triethanolamine ester is market to buy. Considering the comprehensive performance and cost of the mineralized material, the sulfite is sodium sulfite, the sulfate is sodium sulfate, the thiosulfate is sodium thiosulfate, and the polyol is a molecule containing two Alcohols with one or two or more hydroxyl groups are generally soluble in water, have strong solubility in polar substances, are low in volatility, and are viscous liquids or crystalline solids whose viscosity and boiling point increase with the increase in molecular weight. In one embodiment of ...

Embodiment 1

[0042] In the present embodiment, adopt the following preparation method to obtain a kind of mineralized material used in the cement grinding process, and its preparation method comprises the following steps: (1) prepare raw material sodium sulfate, sodium thiosulfate, sodium sulfite, maleic anhydride Dimer acid triethanolamine ester, ethylene glycol, fly ash; (2) The liquid raw materials in step (1) are sprayed on the mixer with a liquid metering pump for metering, and the powder raw materials are matched by the automatic feeding system according to the proportion Feeding, the feeding process is prepared according to the following mass percentages, sodium sulfate 2%, sodium thiosulfate 7%, sodium sulfite 1%, maleic anhydride dimer acid triethanolamine ester 3%, ethylene glycol 2%, pulverized coal Ash 85%, transported to the mixer and fully mixed with liquid raw materials to obtain cement mineralized material products, the admixture in the cement grinding process is 0.5% of the...

Embodiment 2

[0044] In the present embodiment, adopt the following preparation method to obtain a kind of mineralized material used in the cement grinding process, and its preparation method comprises the following steps: (1) prepare raw material sodium sulfate, sodium thiosulfate, sodium sulfite, maleic anhydride Dimer acid triethanolamine ester, ethylene glycol, fly ash; (2) The liquid raw materials in step (1) are sprayed on the mixer with a liquid metering pump for metering, and the powder raw materials are matched by the automatic feeding system according to the proportion Feeding, the feeding process is prepared according to the following mass percentages, sodium sulfate 3%, sodium thiosulfate 7%, sodium sulfite 2%, maleic anhydride dimer acid triethanolamine ester 2%, ethylene glycol 2%, pulverized coal Ash 84%, transported to the mixer and fully mixed with liquid raw materials to obtain cement mineralized material products, the amount of admixture in the cement grinding process is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com