High-early-strength concrete mixture and winter construction method thereof

An early strength and concrete technology, which is applied in building structure, building material processing, construction, etc., can solve the problems of insufficient concrete strength in the later stage, increase the cost of concrete production, and the early strength effect is not obvious, so as to improve the retarding effect, Improves late strength and durability, frost damage resistance, and early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

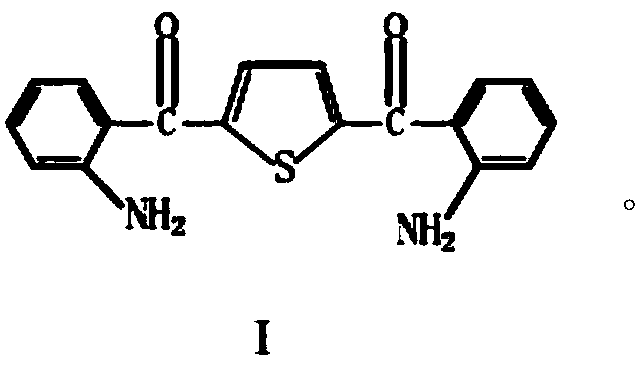

[0038] The preparation of formula I compound:

[0039]Get 8.4g of dry thiophene and join in the three-necked flask protected by argon, add 60ml of freshly steamed tetrahydrofuran into the flask, place the flask in an ice-water bath, slowly add 76.4ml of butyllithium in hexane, After the butyl lithium was added, it was removed in an ice-water bath, and the temperature was raised to reflux in an oil bath, and the heating was stopped after 2 hours of reaction. After the reactants cooled down, 51.3 g of anthraniloyl was added to the bottle at one time. After continuous stirring for 1 h, the reaction was stopped, the reactant was poured into 250 ml of cold water, extracted 3 times with ether, washed with water 3-5 times, the solvent was removed by rotary evaporation, and the compound of formula I was obtained by drying.

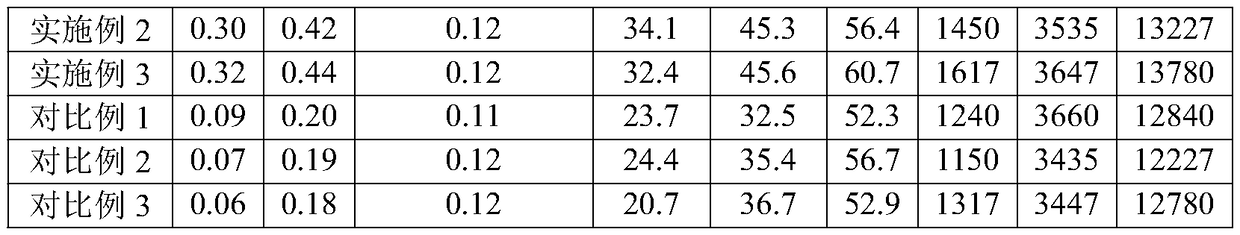

[0040] Preparation Example 1 of Composite Early Strength Agent: Mix 1Kg of (L+)-tartaric acid, 5Kg of sodium sulfate, 0.1Kg of formula I compound, 5Kg of nano-ca...

preparation example 3

[0045] Preparation example 3 of the expansion agent: Prepared by uniformly mixing 8Kg of calcium aluminate expansion agent, 1.2Kg of polyoxyethylene lauryl ether, and 0.8Kg of tea saponin.

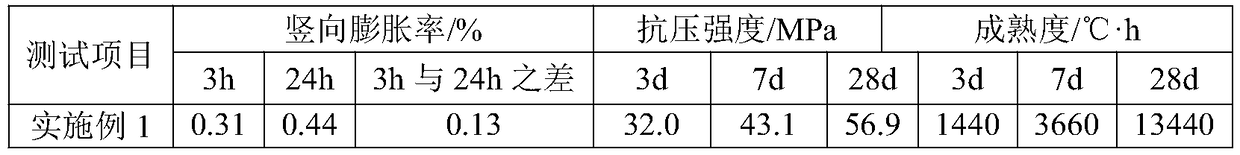

Embodiment 1

[0047] (1) Preparation before construction: check and accept the base, chisel the surface of the base, erect concrete formwork on the base, and clean the form;

[0048] (2) Taking raw materials: taking each component in the concrete mixture;

[0049] (3) Stirring of raw materials: P.O42.5 ordinary Portland cement 193Kg, 20-40 mesh quartz sand 209Kg, 40-70 mesh quartz sand 126Kg, gravel 784Kg, fly ash 48Kg, S95 blast furnace slag powder 69Kg, polycarboxylate superplasticizer 5Kg, compound early strength agent 0.05Kg provided by compound early strength agent preparation example 1, organic silicon defoamer 0.3Kg, compound expansion agent 7Kg and 124Kg provided by compound expansion agent preparation example 1 Put the water into the mixer and stir for 10 seconds to obtain a concrete mixture.

[0050] (4) Pouring and vibrating: use the concrete mixture discharged from the mixer (the discharge temperature is controlled within 23-25°C) for pouring, and the sequence is continuously p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com