Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Pozzolanic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

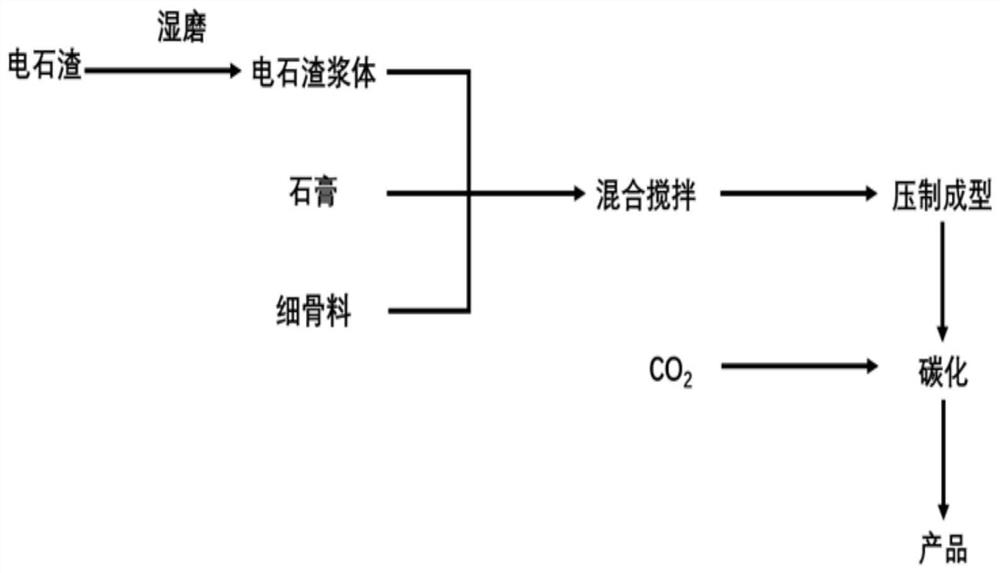

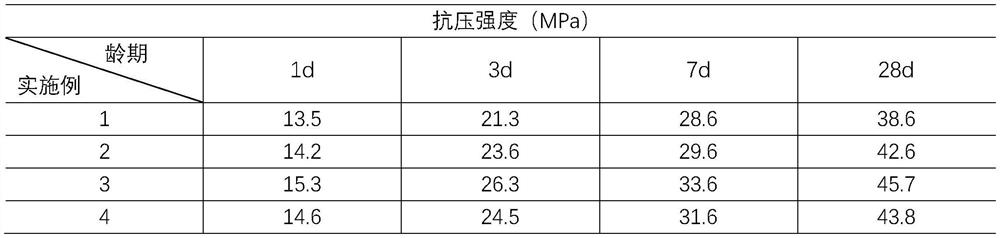

Method for preparing carbonized brick from wet-milling carbide slag

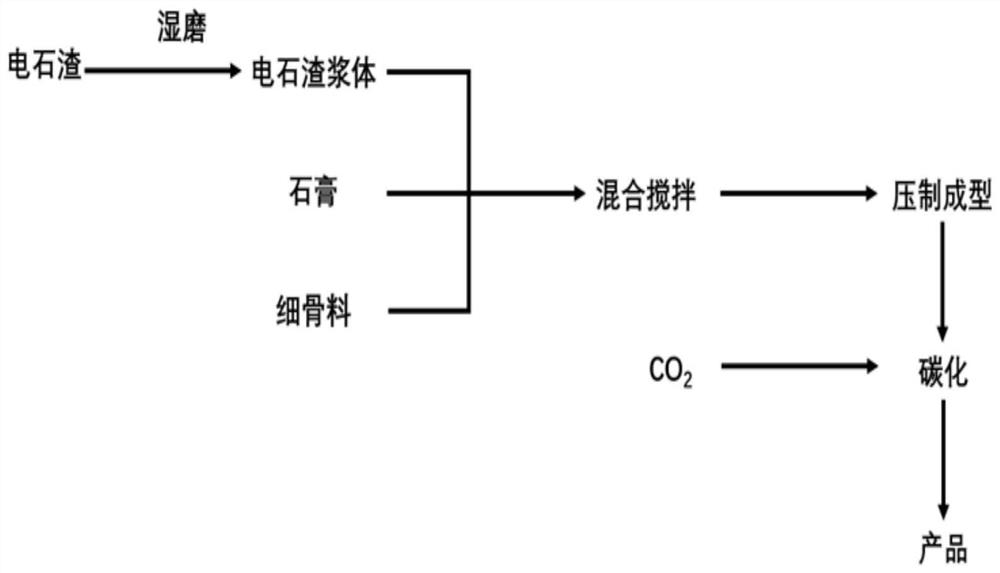

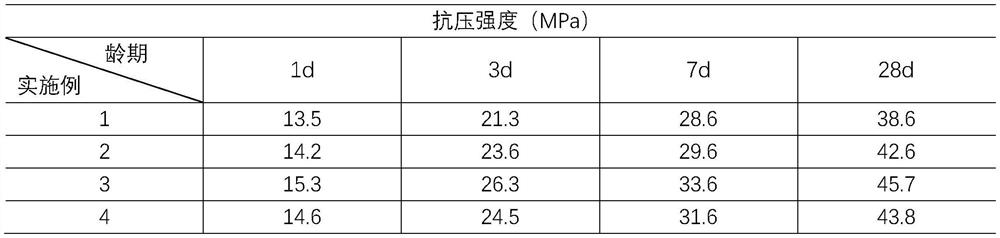

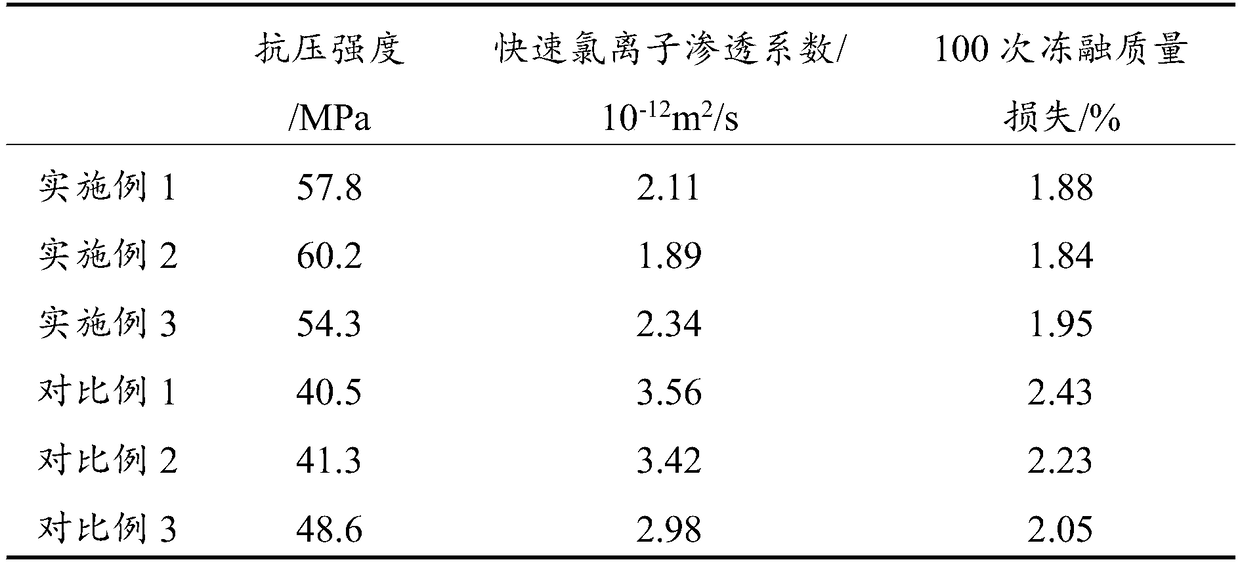

The invention provides a method for preparing a carbonized brick from wet-milling carbide slag. The method comprises the following steps: carrying out wet milling on 150-300 parts of carbide slag and75-150 parts of water to realize refining of carbide slag particles and high alkalinity of a liquid phase; preparing 120-200 parts of wet-milled carbide slag slurry, 10-35 parts of gypsum and 50-120 parts of slag as cementing materials, adding 420-865 parts of fine aggregate and 0-18 parts of wate and fully and evenly stirring the components, press-shaping the the stirred raw materials, and performing maintenance in a carbonization chamber to obtain the wet-milling carbide slag carbonized brick. By adopting the method, gas carbon dioxide can be cured, and environmental pollution caused by industrial waste gas is reduced; by utilizing the advantage that the wet-milling carbide slag is easy to carbonize and is easy to react with carbon dioxide to form calcium carbonate, and precipitate and crystal growth have cohesion, the prepared brick is high in strength and short in curing age, the production efficiency is improved, and the brick can effectively replace a common brick for construction.

Owner:HUBEI UNIV OF TECH

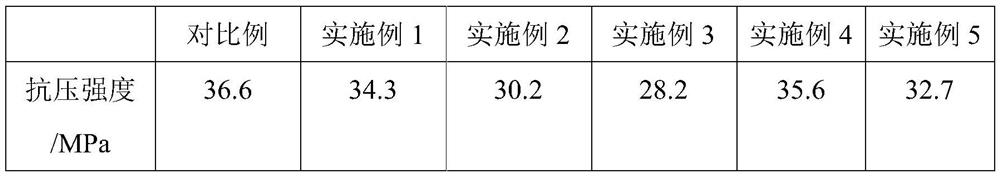

Modified recycled concrete and preparation method thereof

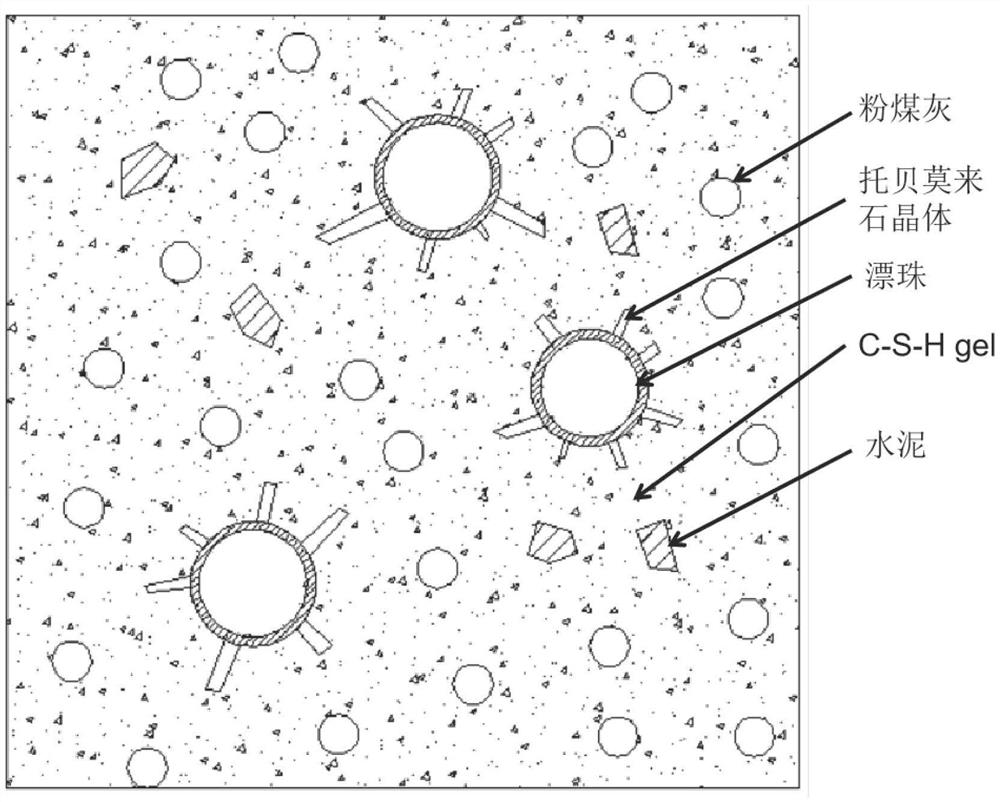

The invention discloses modified recycled concrete and a preparation method thereof. The concrete is prepared from the following raw materials in parts by weight: 100 parts of cement, 235 to 260 partsof recycled aggregate, 145 to 165 parts of sand, 35 to 45 parts of water, 3 to 10 parts of silica fume, 0.5 to 2.5 parts of nano-silica, 0.5 to 2.5 parts of a water reducing agent, and 0.5 to 1.5 parts of cellulose ether. According to the modified recycled concrete and the preparation method thereof, the recycled aggregate is mechanically activated to remove particles and corners which can easilypeel off, so that the performance of the recycled aggregate is improved. Both nano-silica and silica fume have pozzolanic activity, can react with calcium hydroxide produced by cement hydration to form C-S-H gel, and can effectively improve the performance of the recycled aggregate concrete. The raw material components have a synergistic effect, and the obtained concrete has excellent mechanicalproperties and durability.

Owner:YOUNGWOO CHEMTECH

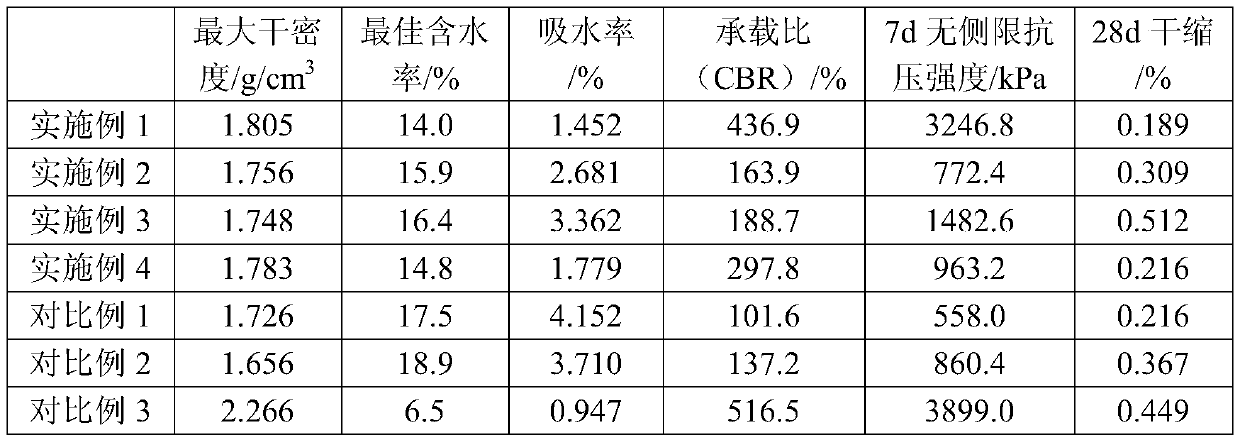

Building rubbish pavement base material and preparation method thereof

The invention relates to a building rubbish pavement base material and a preparation method thereof. The pavement base material is prepared from the components in parts by mass: 95 to 96 parts of building rubbish recycled aggregate, 4 to 5 parts of binding material, 9.4 to 12.2 parts of water relative to the sum of the components i.e. the building rubbish recycled aggregate and the binding material, and 3.5 to 5.5 parts of alkali-activator relative to the mass of water. The pavement base material provided by the invention adopts building rubbish and industrial waste residues as main raw materials, and the material has the advantages of high strength, dry shrinkage, long construction working time and the like. By applying the building rubbish pavement base material provided by the inventionin a large scale, not only can considerable economic benefit be produced, but also a huge environmental protection benefit can be produced.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

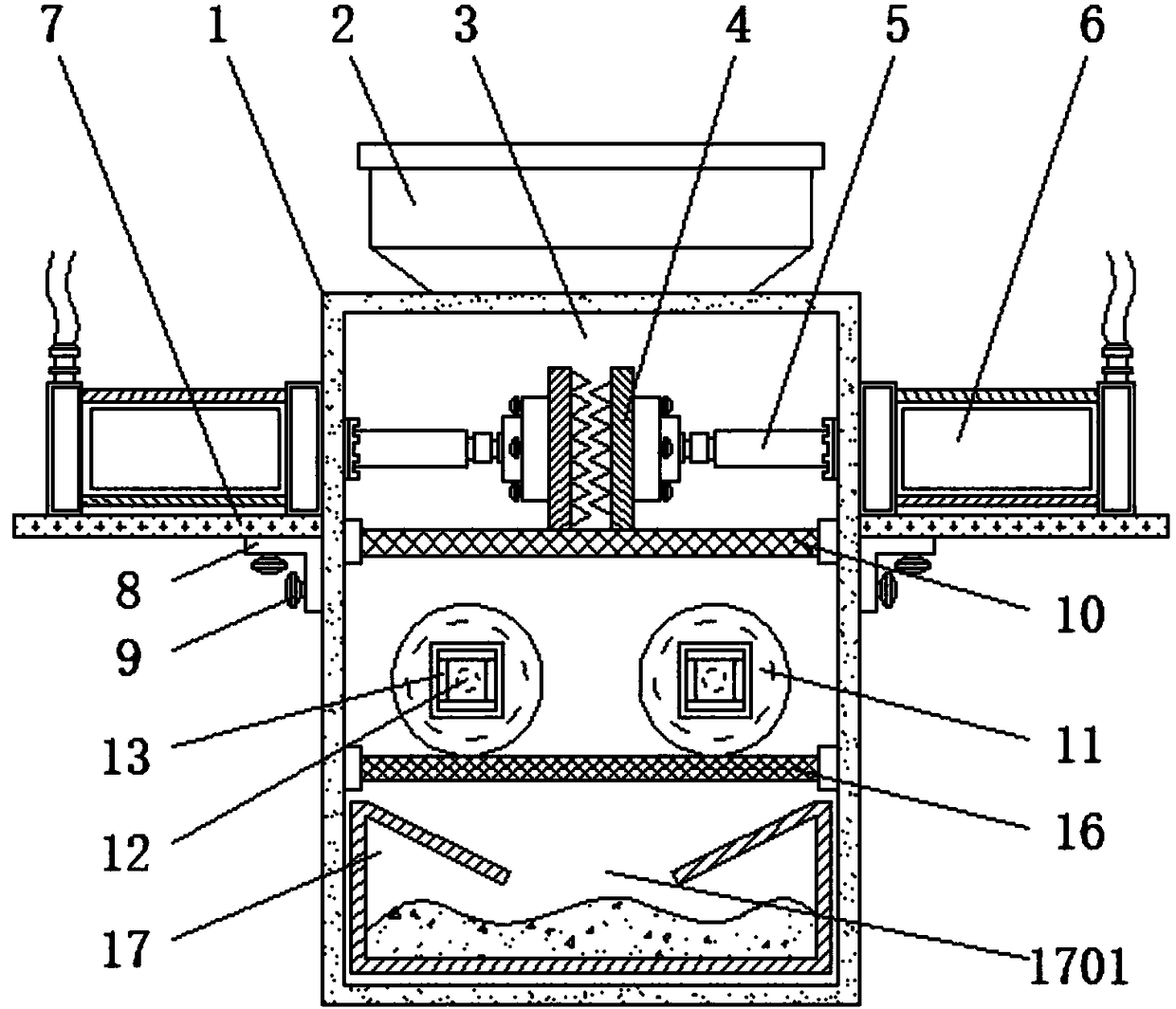

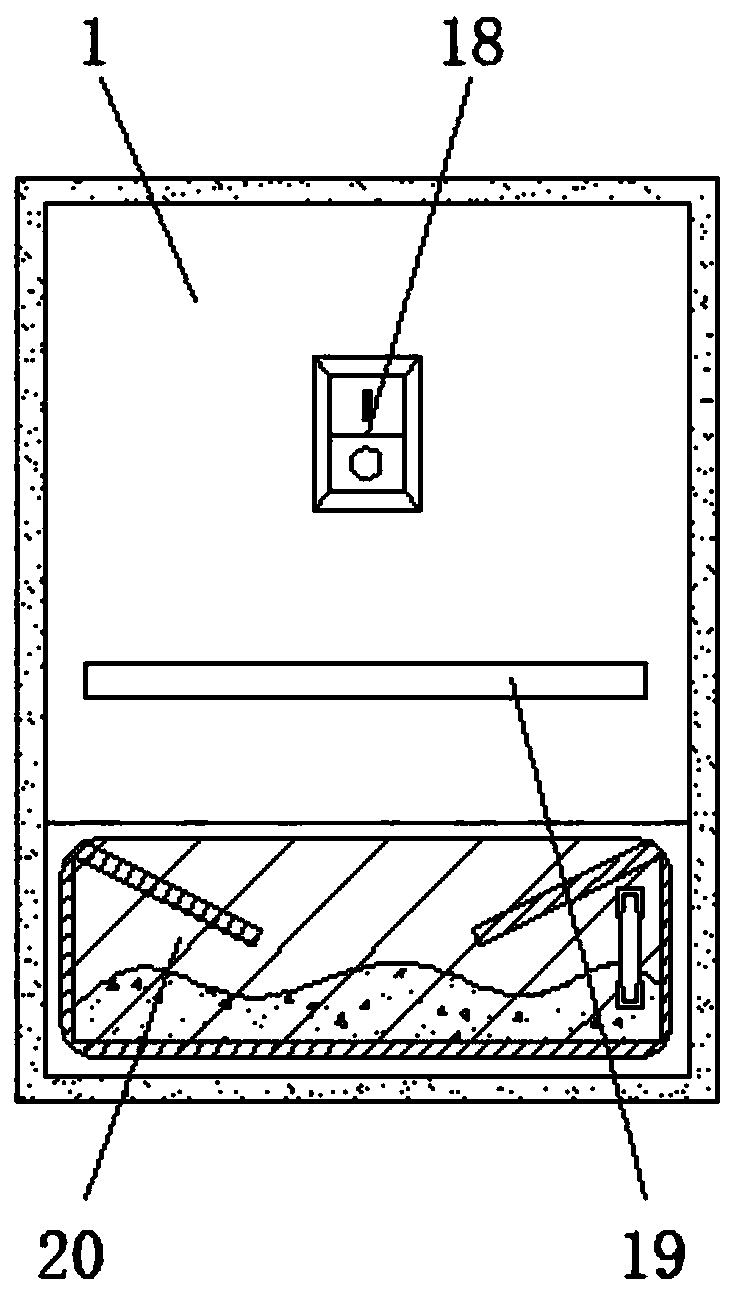

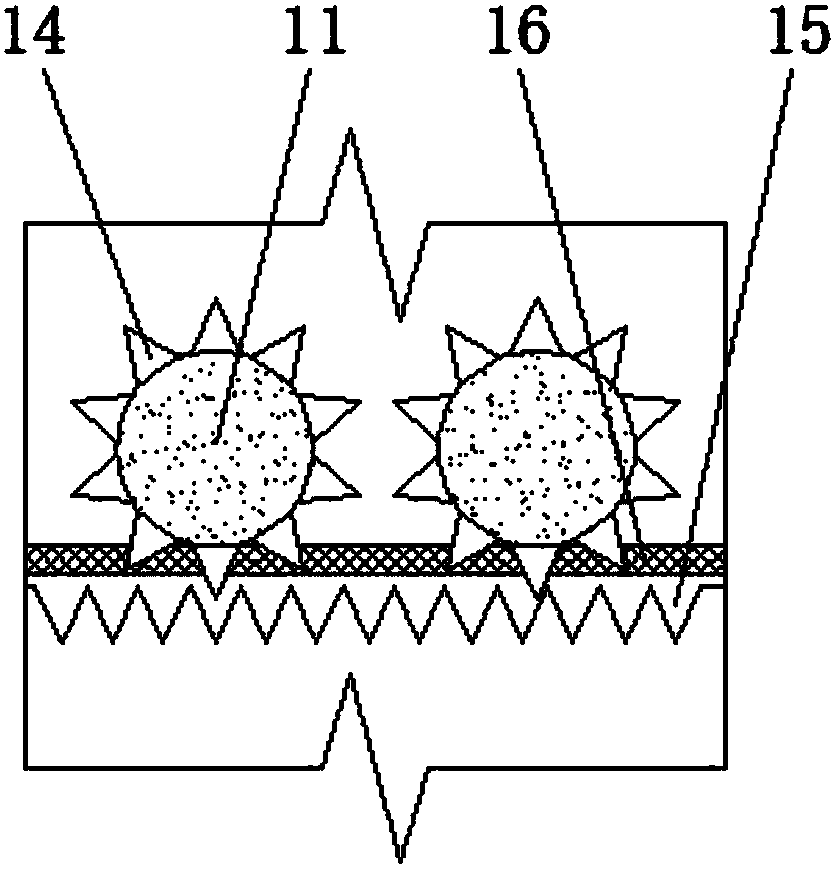

Waste brick and tile recovery device for constructional engineering

The invention discloses a waste brick and tile recovery device for constructional engineering. The waste brick and tile recovery device for constructional engineering comprises a recovery tank body, afirst filtering screen, a second filtering screen and a collecting box body. A feeding inlet is installed above the recovery tank body. The first filtering screen is installed at the bottom of a smashing cavity, and the outer sides of breaking plates and hydraulic cylinders are connected with each other through piston rods. Object placement plates are welded to the left side and the right side ofthe recovery tank body, the second filtering screen is installed below the first filtering screen, the outer sides of grinding rollers are connected with motors in a rotating mode through rotating shafts, and a sliding groove is formed in the front surface of the recovery tank body. Clamping combination plates are fixedly arranged at the front end and the rear end of each grinding roller, and thecollecting box body is installed below the second filtering screen. By the adoption of the waste brick and tile recovery device for constructional engineering, waste bricks and tiles can be smashed and ground before the waste bricks and tiles are recovered, after the waste bricks and tiles are ground to form powder, the waste bricks and tiles have the pozzolanic activity and can serve as the concrete admixture to be used, and therefore resource recycling is achieved.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

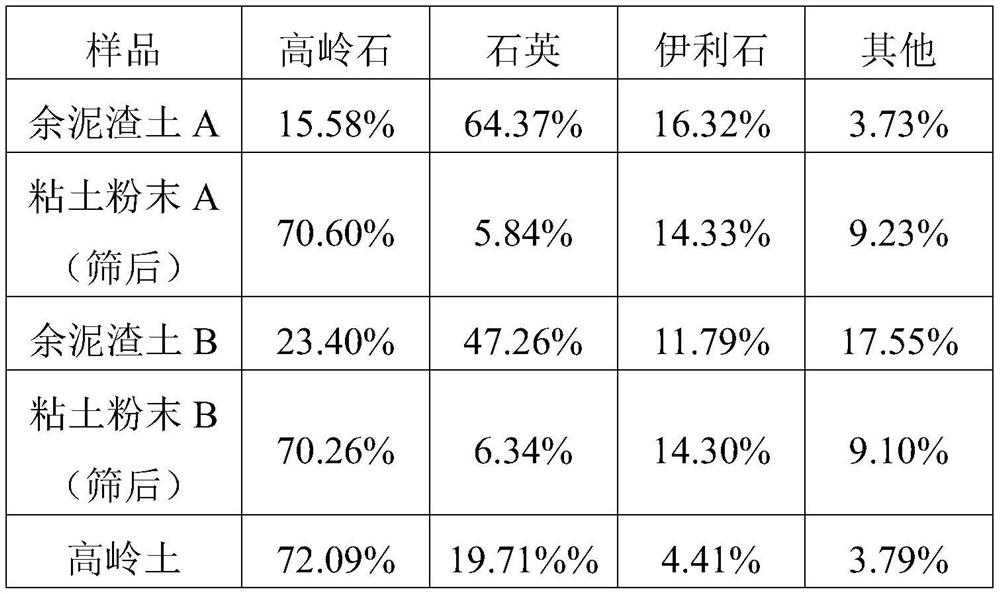

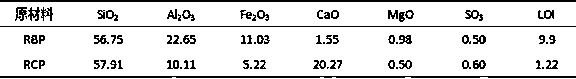

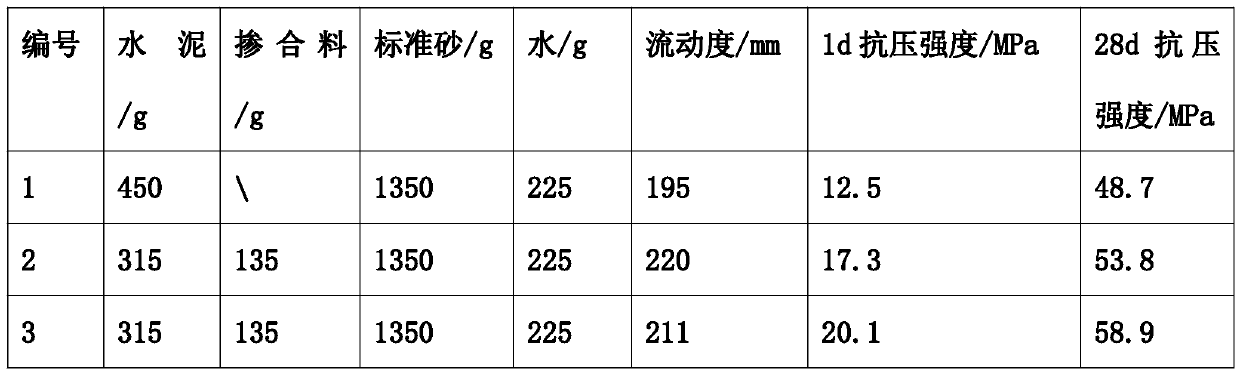

Calcined clay, preparation method thereof, and limestone calcined clay cement

The invention relates to calcined clay, a preparation method thereof, and limestone calcined clay cement. The preparation method of the calcined clay comprises the following steps: sieving residual mud and muck, and removing coarse particles with the particle size of more than 75 microns in the residual mud and muck to obtain clay powder; and calcining the clay powder at the temperature of 700-850DEG C to obtain calcined clay. According to the preparation method, the waste residue mud and muck is used as the raw material, so that the residue mud and muck is effectively utilized, and the costof the obtained calcined clay is lower than that of the traditional common kaolin. Besides, coarse particles with the particle size larger than 75 microns in the residual mud and muck are removed, thecontent of kaolinite in the residual mud and muck is increased; the kaolinite becomes metakaolinite after calcination treatment, wherein the kaolinite has volcanic ash activity and can serve as calcined clay to be applied to the preparation process of limestone calcined clay cement, and the strength of the limestone calcined clay cement is improved.

Owner:SHENZHEN UNIV

Regenerated powder concrete with good durability, and preparation method thereof

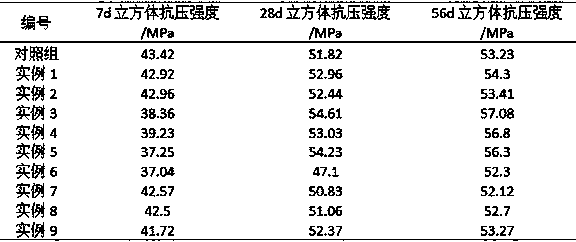

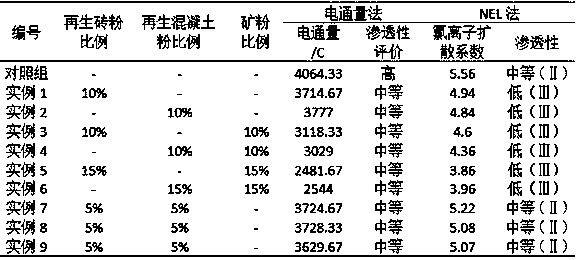

The invention particularly relates to a preparation method of recycled concrete for improving chlorine ion resistance by utilizing regenerated powder. The method comprises: respectively grinding powders in waste concrete and waste clay brick breaking processes to prepare regenerated powder, partially replacing cement with the regenerated powder, and stirring to prepare the recycled concrete by adopting a neat paste stone-wrapping method. According to the invention, the prepared recycled concrete can fully utilize the construction waste and reduce the cement consumption, has good chlorine ion penetration resistance, and further has remarkable economic benefits, social benefits and environmental benefits.

Owner:FUZHOU UNIVERSITY

Concrete admixture based on iron tailing powder and preparation method of concrete admixture

The invention discloses a concrete admixture based on iron tailing powder and a preparation method of the concrete admixture. The concrete admixture is prepared from the following components specifically in percentage by weight: 59.7% of the iron tailing powder and natural gypsum, 25% of level-I coal powder ashes, 15% of S105 mineral powder, and 0.3% of a liquid functional conditioning agent. Irontailings used are prepared from the following components in percentage by weight: 62.13% of SiO2, 5.12% of CaO, 4.36% of MgO, 10.23% of Fe2O3 and 9.65% of Al2O3. According to the concrete admixture based on the iron tailing powder and the preparation method of the concrete admixture, through certain activating treatment, the pozzolanic activity of the iron tailings is shown, the iron tailings andother mineral admixtures are compounded in proportion to produce a synergistic effect, the different mineral admixtures are made to exert respective advantages, the effect of complementary to each other is reached, the iron tailings can be developed to be the concrete admixture, then the additional value of the iron tailings is improved, and the cost of cement concrete is further lowered.

Owner:江苏金木土科技有限公司

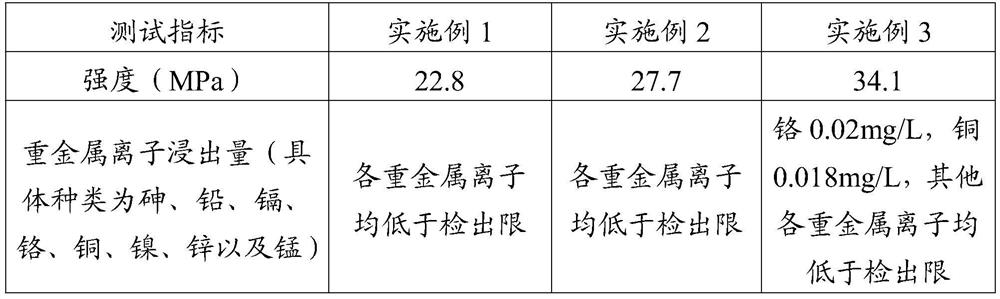

Household garbage incineration ash concrete and preparation method thereof

The invention provides household garbage incineration ash concrete and a preparation method thereof, and belongs to the technical field of solid waste resource utilization. In the household garbage incineration ash concrete provided by the invention, the coarse slag and the fine slag are prepared from the household garbage incineration slag, and the modified fly ash sand and the modified fly ash are prepared from the household garbage incineration fly ash, so that the trouble that the household garbage incineration ash occupies land and pollutes the land can be solved, and waste is turned into wealth; meanwhile, natural gravel resources and cementing materials can be saved, and the finally prepared household garbage incineration ash concrete can meet the use requirements of non-structural concrete. Results of the embodiment show that after the household garbage incineration ash concrete provided by the invention is subjected to standard curing for 28 days, the strength is 22.8-34.1MPa, and the leaching results of all heavy metal ions are qualified.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Concrete solid pile body

The invention provides a concrete solid pile body, belongs to the technical field of building, and solves the problems of conventional pile bodies all have insufficient bearing strength and poor tension stability, and raw materials are lack of activity and self-hardening property. The concrete solid pile body comprises a steel reinforcement cage as a central skeleton and a concrete entity poured in the steel reinforcement cage; the concrete entity comprises cement, gravels, slag, sand, high-calcium fly ash and low-calcium fly ash, the content proportion of the high-calcium fly ash is 25%-40%, the calcium content in the high-calcium fly ash is 10%-15%, the content proportion of the low-calcium fly ash is 10%-40% that of the high-calcium fly ash, and the calcium content in the low-calcium fly ash is 1%-5%. In a whole base pile manufacturing process, a number of process control indexes can be achieved, and the compressive strength and the tension stability of base piles are enhanced with utilization of characteristics of the high-calcium fly ash; and with utilization of the ability of the low-calcium fly ash to inhibit AAR, the concrete harm caused by an alkali aggregate reaction can be eliminated.

Owner:QINGDAO XINGHE BUILDING MATERIAL

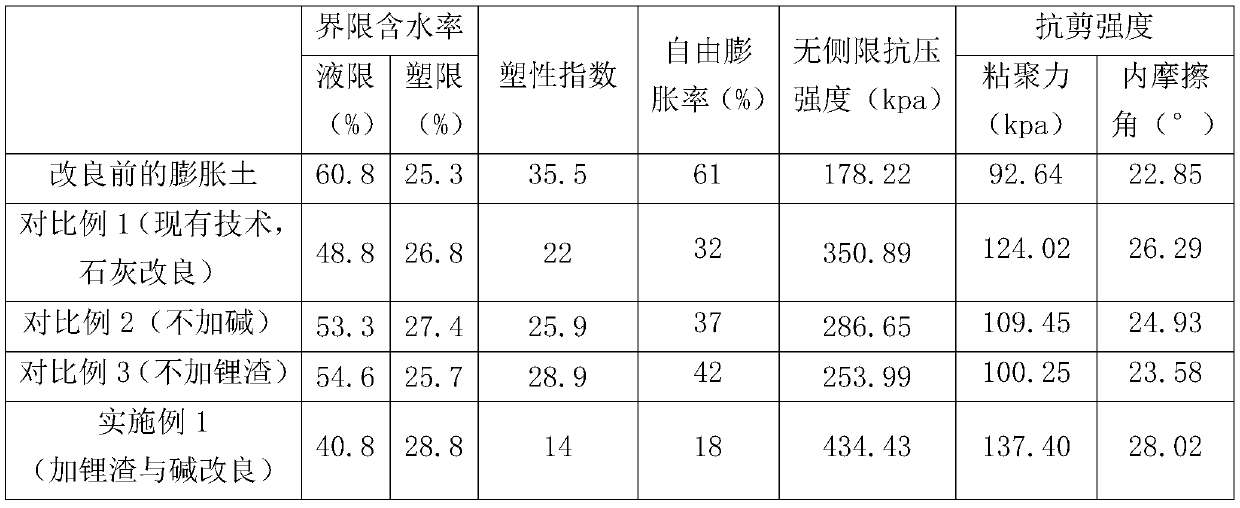

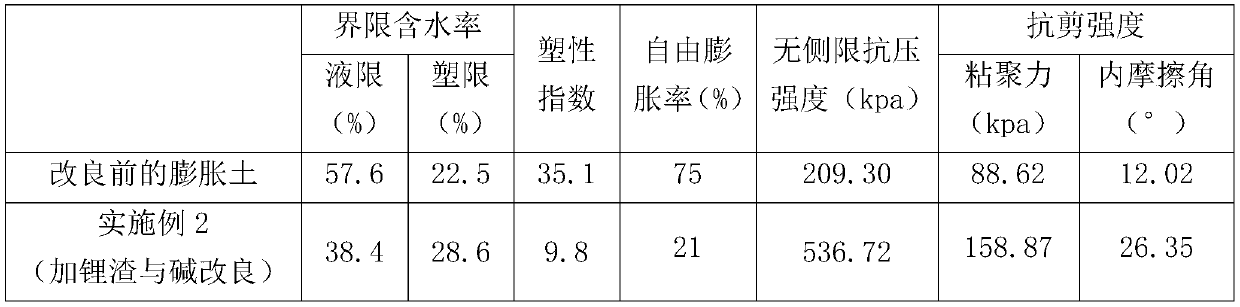

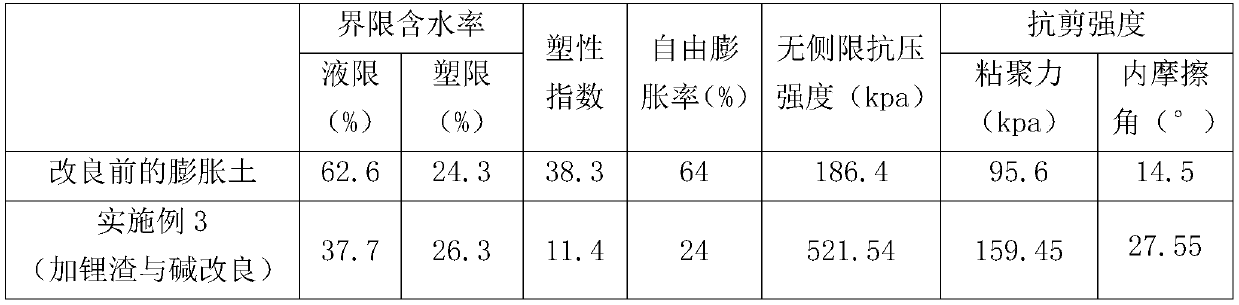

Improved expansive soil, and preparation method, construction method and application thereof

ActiveCN111139078AEvenly distributedGood physical propertiesRoadwaysBuilding constructionsSoil scienceEnvironmental engineering

The invention relates to improved expansive soil, and a preparation method, a construction method and application thereof. The improved expansive soil comprises 12-16% by mass of lithium slag, 4% by mass of alkali and 80-84% by mass of expansive soil of a to-be-improved soil body, and the improved expansive soil is formed by uniformly mixing the lithium slag, the alkali and the expansive soil. According to the invention, the waste lithium slag is used for improving the expansive soil under the condition of alkali doping, so engineering cost is saved, the lithium slag is reutilized, environmentis protected, and a novel improvement method is developed for reducing engineering disasters caused by expansive soil; the waste lithium slag is added as coarse aggregate to function as a skeleton effect and to improve mixture gradation, and can be uniformly distributed in the expansive soil, so excellent physical performance is obtained and physical improvement is realized; and the improved expansive soil is substantially reduced in expansibility, cracks caused by a dry-wet cycle can be eliminated, water stability can be improved, and strength required by engineering can be met.

Owner:HOHAI UNIV

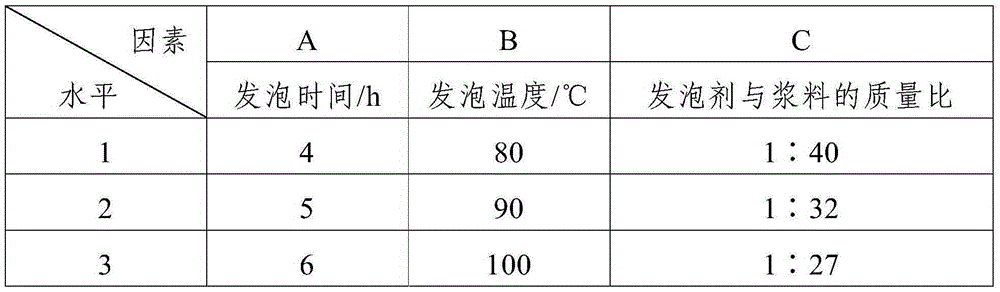

Method for preparing foamed concrete by using coal gangue

InactiveCN105294155AHigh compressive strengthReduce pollutionSolid waste managementCeramicwareFoam concreteFoaming agent

The invention provides a method for preparing foamed concrete by using coal gangue. The method comprises the following steps: I, crushing the coal gangue by adopting a jaw crusher, and then carrying out ball milling on the crushed coal gangue in a ball mill to obtain coal gangue powder; II, activating the coal gangue powder in a muffle furnace; III, mixing and stirring bean powder and deionized water to obtain a foaming agent; and IV, uniformly mixing the coal gangue powder, cement, sand, broken stone and a water reducing agent to obtain a mixture, then uniformly mixing the mixture and water to obtain slurry, adding the foaming agent into the slurry, uniformly mixing, pouring and forming, demolding and maintaining to obtain the foamed concrete. The coal gangue is adopted as a raw material, the coal gangue is activated and then is mixed with the foaming agent to prepare the foamed concrete, and a product has the characteristics of light weight and good sound insulation and heat insulation effect. The coal gangue is used for preparing the foamed concrete, so that not only is the additional value of the coal gangue sufficiently realized, but also the environmental pollution caused by the coal gangue can be reduced.

Owner:XIAN UNIV OF SCI & TECH

Method for producing prefabricated member of concrete ditch by using coal gangue

InactiveCN106045423AImprove anti-seepage effectImprove flexibilityCeramic shaping apparatusSuperplasticizerWater resources

The invention relates to a method for producing a prefabricated member of a concrete ditch by using coal gangue. The method is characterized in that the prefabricated member of the concrete ditch is prepared from the following raw materials in parts by weight: 50-60 parts of coarse and fine aggregates, 5-10 parts of coal gangue powder, 10-15 parts of 42.5 sulfoaluminate cement, 2-5 parts of early strength agent, 2-5 parts of thickening and reinforcing agent, 1-3 parts of efficient water reducing agent and 0.1-0.5 part of antifoamer, wherein the efficient water reducing agent is a calcium lignosulfonate water reducing agent. According to the method, the prefabricated member of the concrete ditch is low in cost, excellent in performance and stable in quality and has excellent compressive strength and antifreeze and impervious performance; and the standardized construction of farmland water conservancy is further strengthened, the construction level and management level of farmland water conservancy projects in China are comprehensively increased, the utilization ratio of irrigation water is increased, and the efficient utilization of water resources is achieved.

Owner:象州县科学技术局

Functional master batch added to polyethylene for underground cable

The invention relates to the field of functional master batches, and discloses a functional master batch added to polyethylene for an underground cable. The functional master batch added to the polyethylene for the underground cable is prepared from the following components in parts by weight: 80 to 100 parts of a carrier resin, 20 to 25 parts of micron-grade volcanic ash, 10 to 15 parts of polystyrene foam, 5 to 7 parts of an antibacterial agent, 10 to 15 parts of a curing agent and 0.8 to 1.2 parts of a dispersing agent, wherein the carrier resin is polyethylene resin; the antibacterial agent is prepared from the components of copper sulfate and silver ion antibacterial agent in the weight part ratio of 1:(0.5-0.7); a curing agent is sulfur preferably; the dispersing agent is oxidized polyethylene wax preferably. According to the functional master batch disclosed by the invention, calcium oxide and volcanic ash are utilized, so that a polyethylene material for the underground cable is gradually hardened to form a hardened protective layer in use; therefore, the polyethylene material for the underground cable has good properties of moisture and cold heat resistance, bacterial resistance, water soaking resistance and corrosion resistance; the use safety of the underground cable is ensured; the service life of the underground cable is prolonged.

Owner:长兴天晟能源科技有限公司

Ground coal gangue powder concrete as well as preparation and application methods thereof

InactiveCN104177003AAvoid uncontrollabilityAvoid pollutionSolid waste managementResearch ObjectChemical composition

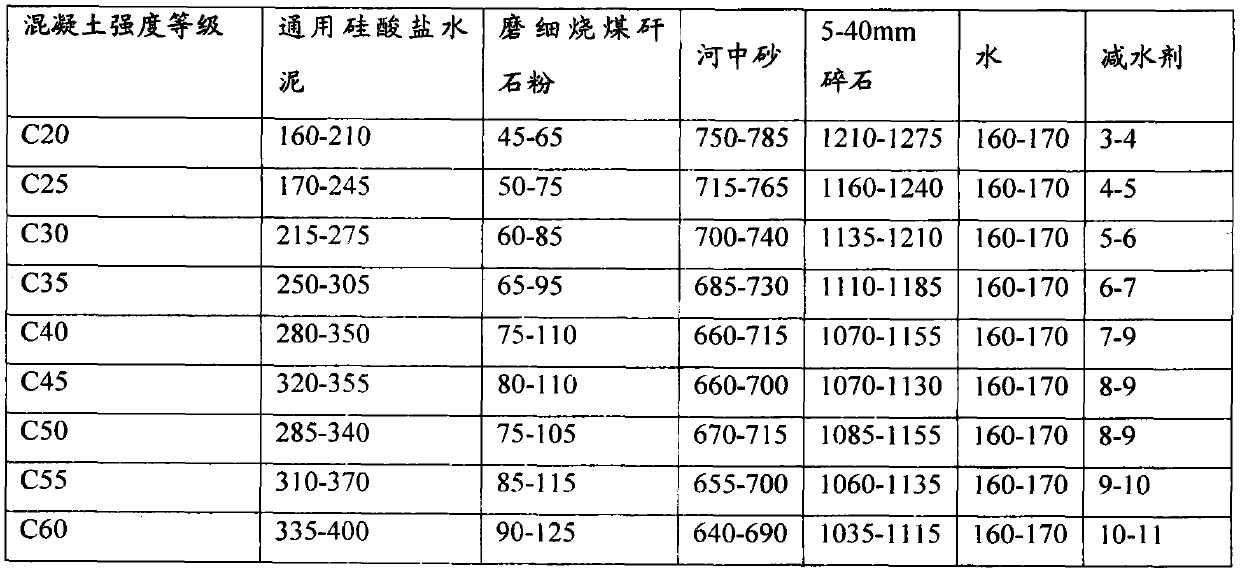

The invention discloses ground coal gangue powder concrete as well as preparation and application methods thereof. The concrete comprises the following components in parts by mass: 150-450 parts of cement, 30-130 parts of ground coal gangue powder, 630-800 parts of sand, 1000-1270 parts of stones, 150-210 parts of water and 3-12 parts of water reducing agent. The preparation method of the ground coal gangue powder concrete comprises the steps of uniformly mixing and stirring the components in parts by mass. The chemical component, the size distribution and the micromorphology of the ground coal gangue powder are studied and the performances of the ground coal gangue powder are detected through referencing fly ash used in cement and concrete GB / T 1596-2005; and 20-30% of ground coal gangue powder is doped into the concrete by taking C20-C60 concrete as study objects so as to study the workability, the strength and the durability (containing the permeability resistance, the freezing resistance, carbonization, the sulfate corrosion resistance, the chloride ion penetration resistance and the shrinkage ratio) of the ground coal gangue powder concrete.

Owner:廖昌兴 +1

Reinforced concrete internal curing high-water-absorption microsphere material and preparation method thereof

The invention provides an enhanced concrete internal curing high-water-absorption microsphere material and a preparation method thereof. The enhanced concrete internal curing high-water-absorption microsphere material is prepared from the following raw materials: nano silicon dioxide, chitosan, glutaraldehyde, Arabic gum, methacrylic acid, glacial acetic acid, cumene hydroperoxide, ferrous chloride and sodium ethoxide. By improving the transition area of the cement paste and the aggregate and modifying the microstructure in the cement-based material, the porosity is reduced, and the mechanicalproperty is improved. The whole preparation process flow is relatively simple, professional technicians do not need to operate and guide, and only the operation is carried out according to the description of the invention. The strength, durability, service life and the like of cement concrete are obviously improved by the reinforced concrete internal curing high-water-absorption microsphere prepared by the method disclosed by the invention.

Owner:CHANGAN UNIV

Impact-resistant and wear-resistant concrete and construction method thereof

InactiveCN110803899AImprove abrasion resistanceReduce water demandIn situ pavingsCalcium silicateCalcium hydroxide

The invention discloses impact-resistant and wear-resistant concrete and a construction method thereof. The invention relates to the technical field of concrete, in particular to the impact-resistantand wear-resistant concrete and the construction method thereof. Silicon powder is adopted, the average particle size of the silicon powder is 0.1 micron, and the impact-resistant and wear-resistant concrete has the great specific surface area, filling performance and volcanic ash activity effect; various properties of the concrete are greatly improved, so that the concrete is compact in structure, tiny cracks and bubbles in the structure are greatly reduced, the wear resistance and cavitation resistance can be improved by doping the silicon powder, and the wear resistance and cavitation resistance of the concrete added with the silicon powder can be improved by 3 times and 4 times through tests; fly ash is adopted, the fly ash has a volcanic ash activity effect and reacts with calcium hydroxide to generate calcium silicate gel, and the calcium silicate gel becomes a part of the gel; microbead spherical particles have the effects of increasing the flowability of concrete, reducing bleeding and improving the workability of the concrete.

Owner:湖南华意项目管理有限公司

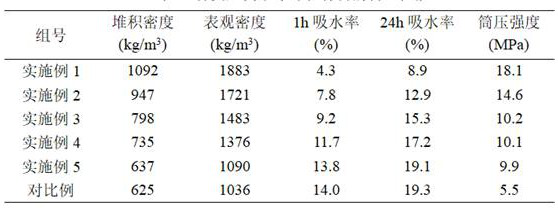

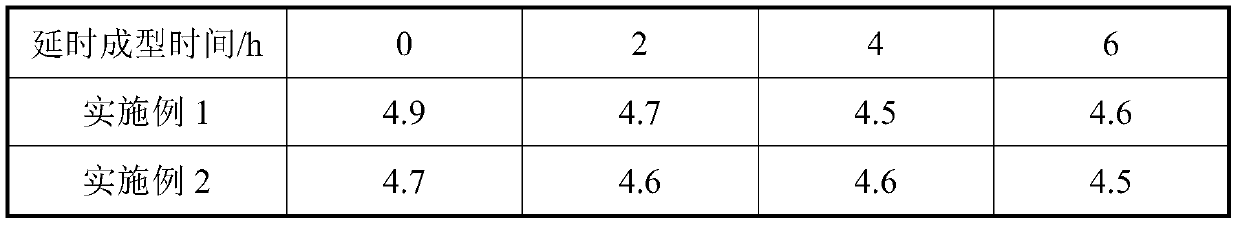

Method for preparing high-strength lightweight aggregate by using floating beads

ActiveCN112919868AMeet different industrial production needsIncrease flexibilityCeramicwareSolid waste managementUltimate tensile strengthFly ash

The invention discloses a method for preparing a high-strength lightweight aggregate by using floating beads. The method comprises the following four steps: pre-wetting and stirring a mixture, balling the mixture, standing and pre-curing a lightweight aggregate, and carrying out hydrothermal reaction, and specifically comprises the following steps: firstly, pre-wetting and stirring the raw materials such as the floating beads, fly ash, cement, water, water glass and the like to prepare the mixture, feeding the mixture into a rolling balling disc, performing centrifugal rolling to gradually form the lightweight aggregate, and subjecting the lightweight aggregate to static curing and hydrothermal reaction, so that the strength of the lightweight aggregate is further improved, and the lightweight high-strength floating bead lightweight aggregate is obtained.

Owner:NANJING UNIV OF SCI & TECH +1

Dry powder interface treating agent for aerated concrete and preparation method thereof

The invention discloses a dry powder interface treating agent for aerated concrete. The dry powder interface treating agent is prepared from the following ingredients in parts by weight: 100 parts of cement, 30 to 50 parts of fly ash, 20 to 30 parts of slag powder, 1 to 5 parts of redispersible latex powder, 200 to 300 parts of sand, 0.1 to 0.3 part of hydroxypropyl methyl cellulose, 2 to 5 parts of a sulphoaluminate expanding agent, 1 to 3 parts of cellulose fibers, 2 to 5 parts of polyvinyl alcohol fibers, and 2-3 parts of nano silicon oxide. The invention further discloses a preparation method of the dry powder interface treating agent for the aerated concrete. The interface treating agent prepared by the invention not only has good adhesive property, but also has good impermeability.

Owner:临海市忠信新型建材有限公司

Production process for separating and recycling metal smelting slag

The invention provides a production process for separating and recycling metal smelting slag, which belongs to the technical field of metal smelting solid waste utilization, and is characterized in that slag harmless treatment is carried out through sequential cooling treatment, secondary metal recovery and tailing comprehensive recovery and utilization processes, so that sustainable development of enterprises is realized; firstly, slag granulation and dehydration are carried out through a Jiaheng process to replace hydraulic conveying in a traditional process, the process is simple and reliable, environmental pollution is small, and the quality of finished slag is good; according to the invention, residual metal is removed through high-temperature reduction, and the smelting slag is activated through a modification treatment method and is used as a binding material admixture, so that the hardening strength of the binding material is improved, the slag waste is effectively utilized, and the comprehensive utilization rate of the slag waste is improved.

Owner:吴联权

A construction waste pavement base material and preparation method thereof

The invention relates to a building rubbish pavement base material and a preparation method thereof. The pavement base material is prepared from the components in parts by mass: 95 to 96 parts of building rubbish recycled aggregate, 4 to 5 parts of binding material, 9.4 to 12.2 parts of water relative to the sum of the components i.e. the building rubbish recycled aggregate and the binding material, and 3.5 to 5.5 parts of alkali-activator relative to the mass of water. The pavement base material provided by the invention adopts building rubbish and industrial waste residues as main raw materials, and the material has the advantages of high strength, dry shrinkage, long construction working time and the like. By applying the building rubbish pavement base material provided by the inventionin a large scale, not only can considerable economic benefit be produced, but also a huge environmental protection benefit can be produced.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

Building solid waste regenerated composite roadbed filler and preparation method thereof

The invention relates to a building solid waste recycled composite roadbed filler and a preparation method thereof, the roadbed filler is composed of the following materials by mass percentage: 5-70%of brick-concrete recycled aggregate, 5-75% of mud cake filler, 1-10% of slaked lime, 1-10% of fly ash, 0.5-4% of HEC, and 10-20% of water. The building solid waste recycled composite roadbed filler is high in strength and small in drying shrinkage, resource utilization of building solid waste such as waste clay bricks, waste concrete and mud cakes is achieved, the pollution problem of building solid waste landfill disposal and damage of natural filler exploitation to the environment are solved, and the current situation of shortage of natural resources is relieved.

Owner:SOUTHEAST UNIV

A method for preparing carbonized bricks by wet grinding carbide slag

The invention provides a method for preparing carbonized bricks by wet grinding calcium carbide slag: 150-300 parts of carbide slag and 75-150 parts of water are wet-ground to realize the refinement of carbide slag particles and the high alkalinity of the liquid phase; Wet ground calcium carbide slag slurry, 10-35 parts of gypsum, 50-120 parts of slag as cementing material, add 420-865 parts of fine aggregate, 0-18 parts of water and mix well, and press the raw materials after mixing. , and cured in the carbonization chamber to obtain wet-ground carbide slag carbide bricks. This method can solidify gaseous carbon dioxide and reduce the pollution of industrial waste gas to the environment; taking advantage of the advantage of easy carbonization of wet-ground carbide slag, it is easier to react with carbon dioxide to form calcium carbonate, and the precipitation and crystal growth have cohesive force; the prepared bricks have high strength and are easy to maintain The age is short, the production efficiency is improved, and it can effectively replace ordinary bricks in construction.

Owner:HUBEI UNIV OF TECH

Method for producing inorganic cementing material by using solid wastes such as fly ash, mineral powder and desulfurized gypsum

The invention relates to an inorganic cementing material produced from solid wastes such as fly ash, mineral powder and desulfurized gypsum. According to the invention, the solid wastes such as the fly ash, the mineral powder and the desulfurized gypsum are adopted, and a large amount of silicon dioxide and other raw materials for producing building materials such as cement exist in the solid wastes; a retarder of a cement raw material is prepared from a small part of the desulfurized gypsum to delay solidification of cement, and the desulfurized gypsum is used as an excitant of the fly ash and the mineral powder to excite the pozzolanic activity of the fly ash and the mineral powder so as to allow the fly ash and the mineral powder to react with water, thereby preparing the inorganic cementing material; and the inorganic cementing material can be prepared through simple process steps, cost is low, the wastes are turned into the \wealth, the environment is protected, and the method issuitable for industrial production.

Owner:山东华杰新型环保建材有限公司

Concrete solid pile

InactiveCN104418550AAdjustable clotting timeHigh compressive strengthSolid waste managementSlagEngineering

The invention provides a concrete solid pile, belonging to the technical field of buildings. The concrete solid pile solves the problems that an existing pile body has insufficient bearing strength, poor tension stability, lack of activity and self-hardening property in raw materials, incapability of realizing multiple process regulation and control indexes in manufacturing processes and the like. The concrete solid pile comprises a steel bar cage as a middle framework and a concrete solid poured onto the steel bar cage, wherein the concrete solid comprises cement, gravel, slag, sand and high-calcium fly ash, the content by specific weight of high-calcium fly ash is 30%-45%, and the calcium content in high-calcium fly ash is 10%-15%. According to the concrete solid pile, high-calcium fly ash and a corresponding modifier are added in the traditional component formula and are subjected to specific weight adjustment again, so that multiple process regulation and control indexes can be realized in the manufacturing processes of a whole base pile, the compressive strength and tension stability of the whole base pile are effectively strengthened by utilizing the characteristics of high-calcium fly ash, and the concrete solid pile further has the characteristics of activity of volcanic ash, small fineness, small weight of screen residue and the like.

Owner:QINGDAO XINGHE BUILDING MATERIAL

High-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and preparation method thereof

The invention discloses high-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and a preparation method thereof. The high-volume mixed glass powder C190UHPC is prepared from the following components in proportions: 773.4kg / m<3> of cement, 154.7kg / m<3> of silica fume, 38.7kg / m<3> of pulverized fuel ash, 154.7kg / m<3> of fine glass powder, 46.4kg / m<3> of a superplasticizer, 216.6kg / m<3> of coarse glass powder, 866.2kg / m<3> of quartz sand, 193.4kg / m<3> of water and 156kg / m<3> of steel fiber. The invention also discloses the preparation method of the high-volume mixed glass powder C190UHPC. A maintenance mode is characterized by tightly coating a concrete test block by using wet cotton cloth, and intermittently spraying water at a high frequency for maintaining, or maintaining in water. Not only a maintenance system is simplified, but also evaporation of water in concrete is effectively prevented. The high-volume mixed glass powder C190UHPC disclosed by the invention hasthe following technical advantages that waste glass can be recycled, consumption of natural materials is reduced, and the effect of environmental protection is achieved; the glass powder has pozzolanic activity, so that the strength and the durability of the concrete are increased; due to the doping of the glass powder in different grain diameters, accumulation gaps between the quartz sand is remedied, and the structure is tighter; a water-glue ratio and the superplasticizer are preferably selected, so that the high-volume mixed glass powder C190UHPC has the advantage of self-compaction.

Owner:XIANGTAN UNIV

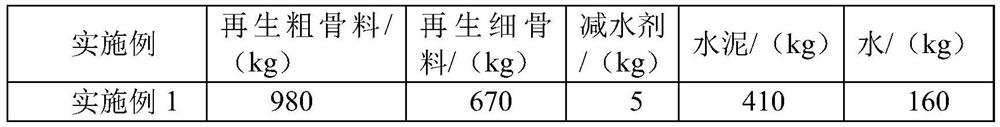

Reinforcing method of recycled coarse aggregate, obtained reinforced recycled coarse aggregate and concrete

PendingCN114716211AEasy to operateHigh strengthSolid waste managementGrain treatmentsSilica fumeBuilding material

The invention discloses a reinforcing method of recycled coarse aggregate, the obtained reinforced recycled coarse aggregate and concrete, and belongs to the technical field of building materials.The reinforcing method of the recycled coarse aggregate comprises the steps that firstly, the recycled coarse aggregate is placed in a concrete mixer to be mechanically ground and then taken out to be screened, and the physically-reinforced recycled aggregate is obtained; then preparing silica fume slurry, putting the recycled coarse aggregate into the silica fume slurry, and stirring and wrapping the slurry, so as to obtain reinforced recycled coarse aggregate; the preparation method of the recycled concrete comprises the following steps: adding the reinforced recycled coarse aggregate, the stones, the sand, the cement, the water and the polycarboxylate superplasticizer into a concrete mixer according to a mixing process, and stirring to obtain the recycled concrete. The strength of the recycled coarse aggregate can be improved, the performance of the prepared recycled concrete is effectively improved, the treatment strengthening method is simple, aggregate strengthening and concrete mixing connection are compact, and the application range of the recycled aggregate can be expanded.

Owner:UNIV OF JINAN

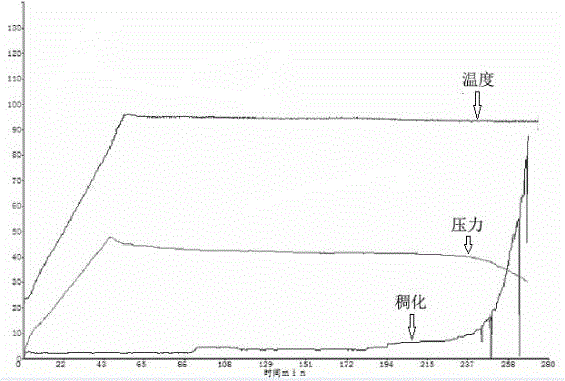

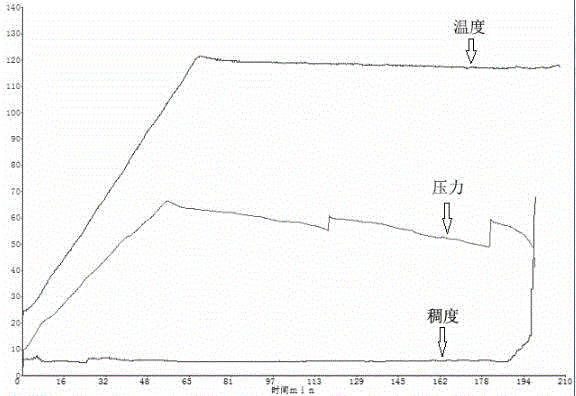

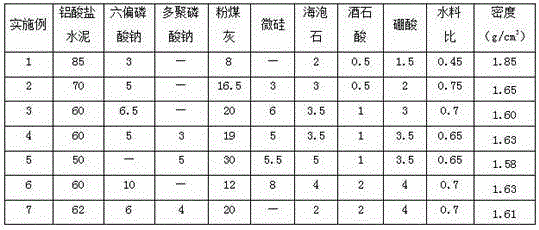

High-temperature oil well plugging agent

ActiveCN106747130AHigh strengthNo pollution in the processDrilling compositionPhosphateCement slurry

The invention discloses a high-temperature oil well plugging agent and belongs to the technical field of petroleum drilling materials. The high-temperature oil well plugging agent is prepared from raw materials in percentage by mass as follows: 60%-85% of a cementing material, 2%-10% of phosphate, 10%-35% of an active admixture, 0-5% of a filling material and 3%-6% of a retarder; the cementing material is aluminate cement. Properties of the cementing material are selected, phosphate, the active admixture and the retarder in a specific proportion are added, so that after cement slurry reaches a leaking layer position and loses fluidity, the strength of set cement is quickly increased, plugging is realized by the aid of self strength, and the plugging agent has the characteristic of early strength, meets the requirement of plugging at 80-120 DEG C and has the advantages of good high-temperature resistance and good plugging effect.

Owner:JIAHUA SPECIAL CEMENT

High-strength recycled concrete and preparation method thereof

ActiveCN112624674AReduce processing costsTake advantage ofSolid waste managementCompressive resistanceEnvironmental engineering

The invention relates to the technical field of recycled concrete, and particularly discloses high-strength recycled concrete and a preparation method of the high-strength recycled concrete. The high-strength recycled concrete comprises treated recycled coarse aggregate, recycled fine aggregate, a water reducer, cement and water. The preparation method comprises the following steps: premixing the recycled coarse aggregate, the cement and the water reducing agent, and adding water to obtain a pasty concrete mixture; and finally, adding the recycled fine aggregate, and uniformly stirring to obtain the high-strength recycled concrete. The waste concrete is used as aggregate of the concrete, resources are effectively saved, building waste is fully utilized, and the influence of the waste concrete on the environment is reduced. After bionic treatment is conducted on the waste concrete, the waste concrete has the structural stability and durability of natural gravel, and when the treated waste concrete serves as aggregate to prepare concrete, high compressive strength and breaking strength are achieved.

Owner:东莞市建业混凝土有限公司

Hydraulic high-performance concrete and preparation method thereof

The invention discloses hydraulic high-performance concrete, and belongs to the technical field of concrete. The concrete is prepared from the following components: a fine aggregate, coarse aggregate,cement, slag, fly ash, silica fume, a water reducing agent, water, superfine natural zeolite powder, gypsum, a polymer emulsion, a dihydric alcohol compound, modified lignosulfonate, a lamellar silicate mineral material, polysiloxane, oxalic acid, a styrene-acrylic emulsion, a crystalline hydrated magnesium aluminosilicate mineral, a reinforcing agent, an air entraining agent, steel fibers, tert-butyl peroxypivalate, nano montmorillonite and an ettringite-lime composite expanding agent, wherein the dosage ratio of the tert-butyl peroxyvalerate to the nano montmorillonite to the ettringite-lime composite expanding agent is (0.4-0.8): (2-4): (0.5-0.8). According to the invention, a reinforcing system composed of the tert-butyl peroxypivalate, the nano montmorillonite and the ettringite-limecomposite expanding agent is adopted in the hydraulic high-performance concrete disclosed by the invention, so that the anti-freezing performance of the hydraulic high-performance concrete is improved.

Owner:JIANGSU PROVINCE WATER ENG SCI TECH CONSULTING

Composite cement using carbide slag and fly ash as admixture

The invention provides a composite cement using carbide slag and fly ash as admixture, wherein the composite cement comprises the following raw materials in percentage by weight: 5-10% of dry carbideslag, 20% of fly ash, 10% of mineral slag, 55-60% of portland cement clinker and 5% of gypsum, and the sum of the weight percentage of each component is 100 percent. At first, that carbide slag is dried and crushed, then the dry carbide slag, the fly ash, the portland cement clinker, the mineral slag and the gypsum are weighed according to the formula, and the composite cement can be prepared by sequentially adding the raw materials into a mill and grinding together. As that carbide slag and the fly ash are used as admixtures to prepare the composite cement, the waste is changed into treasure,not only environmental pollution is reduced, but also the preparation process of the product is simple, the production cost is low, the early strength of the prepared composite cement is high, and the composite cement has good social and economic benefit.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com