Household garbage incineration ash concrete and preparation method thereof

A technology of domestic waste incineration and ash concrete, which is applied in the field of solid waste resource utilization, can solve the problems of reduced sanitary landfill storage capacity, ecological environmental hazards, and technical difficulty, and achieve good solidification of heavy metals and good adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

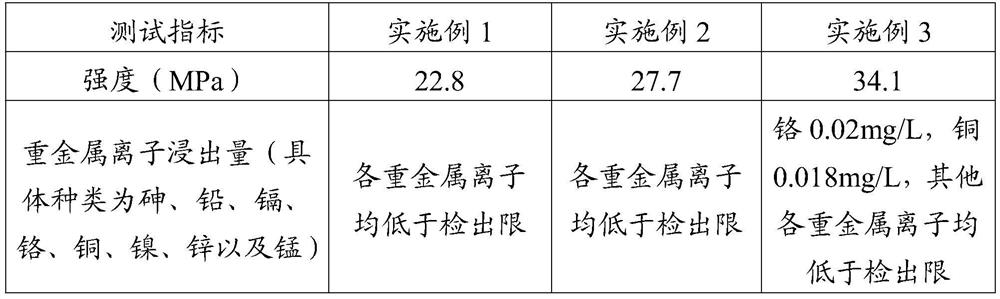

Examples

preparation example Construction

[0050] The preparation method of described modified fly ash sand and modified fly ash comprises the following steps:

[0051] The domestic garbage incineration fly ash, glass powder and limestone powder are mixed and then calcined to obtain calcined materials; the calcined materials are dechlorinated, crushed and screened in sequence to obtain the modified fly ash sand and modified fly ash.

[0052] In terms of parts by mass, the raw materials for the preparation of domestic waste incineration ash concrete in the present invention include 450 to 550 parts of coarse slag, preferably 500 to 500 parts; the particle diameter of the coarse slag is 4.75 to 26.5 mm; the bulk density is preferably 1100~1200kg / m 3 , more preferably 1180kg / m 3 .

[0053] Based on the mass fraction of the coarse slag, the raw materials for the preparation of domestic waste incineration ash concrete in the present invention include 360-440 parts of fine slag, preferably 360-400 parts; the particle size ...

Embodiment 1

[0089] In parts by weight, 1.2 parts of sodium hydroxide, 25 parts of water glass and 60 parts of water are mixed, stirred to dissolve the sodium hydroxide, and the liquid material is obtained after cooling;

[0090] Add 450 parts of coarse slag, 440 parts of fine slag, 60 parts of modified fly ash, 11 parts of modified fly ash and 110 parts of mineral powder into the concrete mixer and stir for 30 seconds to obtain solid materials;

[0091] adding the liquid material to the solid material, stirring in the concrete mixer for 240s to obtain the initial material;

[0092] Put the primary material into a concrete mold and vibrate it. After curing at room temperature (20±5° C.) for 24 hours, the mold is demoulded to obtain domestic waste incineration ash concrete.

Embodiment 2

[0094] In parts by weight, 2 parts of sodium hydroxide, 35 parts of water glass and 68 parts of water are mixed, stirred to dissolve the sodium hydroxide, and the liquid material is obtained after cooling;

[0095] Add 500 parts of coarse slag, 400 parts of fine slag, 40 parts of fly ash, 20 parts of fly ash and 130 parts of ore powder into the concrete mixer and stir for 45 seconds to obtain solid materials;

[0096] adding the liquid material to the solid material, stirring in the concrete mixer for 270s to obtain the initial material;

[0097] Put the primary material into a concrete mold and vibrate it. After curing at room temperature (20±5° C.) for 24 hours, the mold is demoulded to obtain domestic waste incineration ash concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com