Method for preparing high-strength lightweight aggregate by using floating beads

A lightweight aggregate and floating beads technology, applied in the field of concrete lightweight aggregate, can solve the problems of high requirements for production equipment, high sintering temperature, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

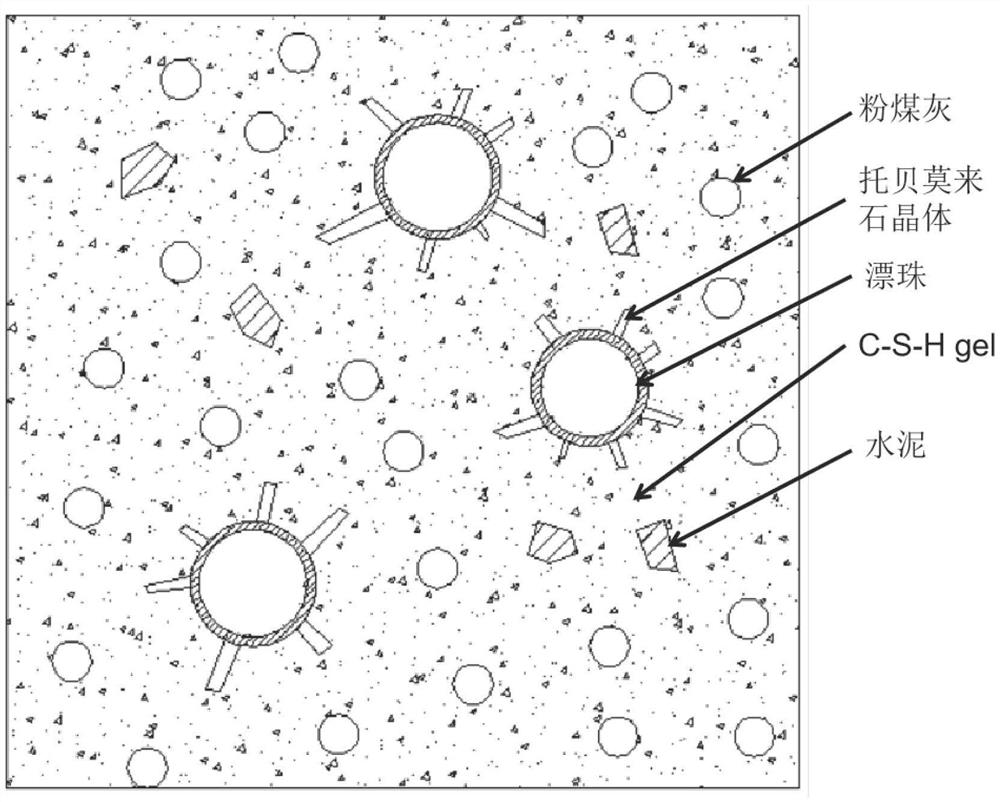

Method used

Image

Examples

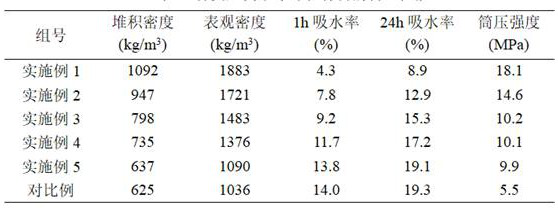

Embodiment 1

[0036] In this embodiment, a method for preparing high-strength lightweight aggregate by using floating beads is as follows:

[0037] The first step is to weigh according to the mass percentage of fly ash floating beads: cement: fly ash: water: water glass (modulus 2, concentration greater than 35wt%) = 3.5: 224: 1381: 402: 2.3, first weigh the Pour the dry powder of the material into the stirring pot and stir for 2 minutes, then weigh the ball water and the water glass solution in proportion, mix them evenly, pour them into the stirring pot, and continue stirring for 2 minutes to obtain the wet mixture;

[0038] In the second step, pour the prepared wet mixture into the pelletizing pan and roll it centrifugally, until the pellets with a size of 5-30 mm are formed in the pelletizing tray, then unload the pellets;

[0039] The third step is to place the unloaded balls in a cool place indoors for 24 hours for pre-curing to make them have a certain initial strength;

[0040] The...

Embodiment 2

[0042] In this embodiment, a method for preparing high-strength lightweight aggregate by using floating beads is as follows:

[0043] The first step is to weigh according to the mass percentage of fly ash floating beads: cement: fly ash: water: water glass (modulus 1.6, concentration greater than 35wt%) = 90: 240: 1093: 356: 4.6, first weigh the Pour the dry powder of the material into the stirring pot and stir for 2 minutes, then weigh the ball water and the water glass solution in proportion, mix them evenly, pour them into the stirring pot, and continue stirring for 2 minutes to obtain the wet mixture;

[0044] In the second step, pour the prepared wet mixture into the pelletizing pan and roll it centrifugally, until the pellets with a size of 5-30 mm are formed in the pelletizing tray, then unload the pellets;

[0045] The third step is to place the unloaded balls in a cool place indoors for 24 hours for pre-curing to make them have a certain initial strength;

[0046] Th...

Embodiment 3

[0048] In this embodiment, a method for preparing high-strength lightweight aggregate by using floating beads is as follows:

[0049] The first step is to weigh according to the mass percentage of fly ash floating beads: cement: fly ash: water: water glass (modulus 1.4, concentration greater than 35wt%) = 135: 256: 914: 326: 6.3, first weigh the Pour the dry powder of the material into the stirring pot and stir for 2 minutes, then weigh the ball water and the water glass solution in proportion, mix them evenly, pour them into the stirring pot, and continue stirring for 2 minutes to obtain the wet mixture;

[0050] In the second step, pour the prepared wet mixture into the pelletizing pan and roll it centrifugally, until the pellets with a size of 5-30 mm are formed in the pelletizing tray, then unload the pellets;

[0051] The third step is to place the unloaded balls in a cool place indoors for 24 hours for pre-curing to make them have a certain initial strength;

[0052]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com