Adjustment lever structure for ultra-large-diameter control valve

An ultra-large diameter, adjusting rod technology, applied in valve devices, engine components, mechanical equipment, etc., can solve problems such as increasing project cost and inability to meet, and achieve the effect of reasonable layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

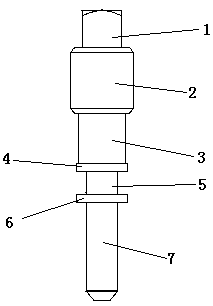

[0017] Example: such as figure 1 A regulating rod structure used as a super-large caliber regulating valve is shown, which is composed of a connecting part and a valve stem 5. The connecting part is divided into three parts from top to bottom, namely the first connecting part 1, the second connecting part 2 and the third connecting part. The connection part 3, the first connection part 1, the second connection part 2 and the third connection part 3 are fixed together by welding process. The valve stem 5 extends outward from the inside of the third connection part 3. The valve stem 5 A welded pressure piece 4 is provided at the junction with the third connecting part 3 , and a conical pin 6 is provided outside the middle part of the valve stem 5 .

[0018] In this embodiment, the inner diameter of the third connecting portion 3 is greater than the inner diameter of the first connecting portion 1, and the inner diameter of the third connecting portion 3 is smaller than the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com