High-temperature oil well plugging agent

A plugging agent, high temperature resistant technology, applied in the field of petroleum drilling materials, can solve the problems of low plugging efficiency, poor high temperature resistance and loss of the plugging agent, and achieves convenient plugging removal, high pressure bearing capacity, and service temperature limit. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

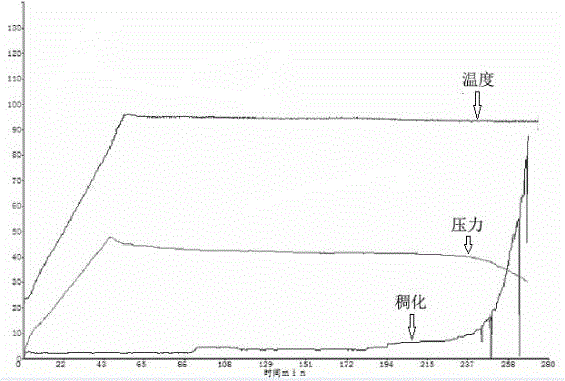

Image

Examples

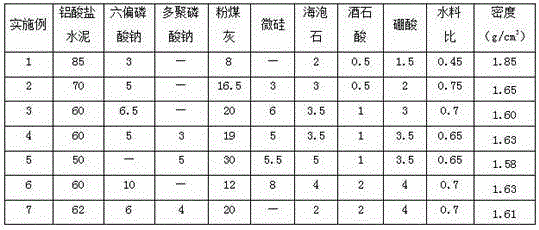

Embodiment 1

[0025] A high temperature resistant oil well plugging agent, including the following raw materials by mass percentage: 85% aluminate cement, 3% sodium hexametaphosphate, 8% fly ash, 2% sepiolite powder, 1.5% boric acid, 0.5% tartaric acid %, water-cement ratio 0.45;

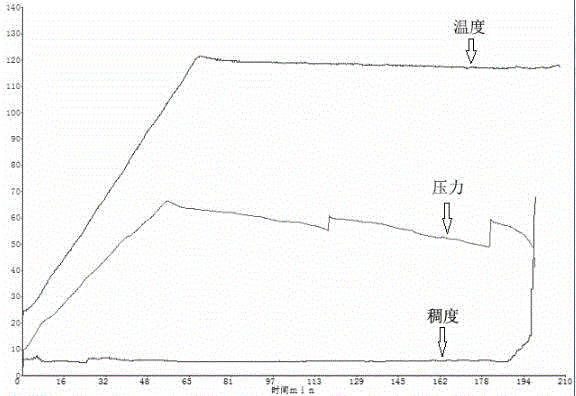

Embodiment 2

[0027] A high temperature resistant oil well plugging agent, comprising the following raw materials by mass percentage: 70% aluminate cement, 5% sodium hexametaphosphate, 16.5% fly ash, 3% micro silicon, 3% sepiolite powder, boric acid 2%, tartaric acid 0.5%, water-cement ratio 0.75;

Embodiment 3

[0029] A high temperature resistant oil well plugging agent, comprising the following raw materials by mass percentage: 60% aluminate cement, 6.5% sodium polyphosphate, 20% fly ash, 6% micro silicon, 3.5% sepiolite powder, boric acid 3%, tartaric acid 1%, water-cement ratio 0.7;

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| acid solubility rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com