Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Thickening time adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

ActiveCN102994058AAdjustable density and thickening timeGood liquidityDrilling compositionSilicate CementHeat regulation

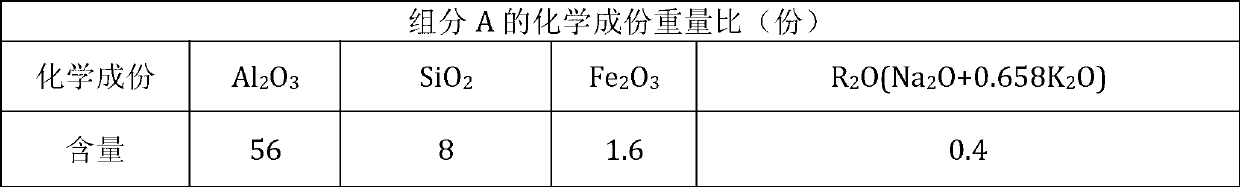

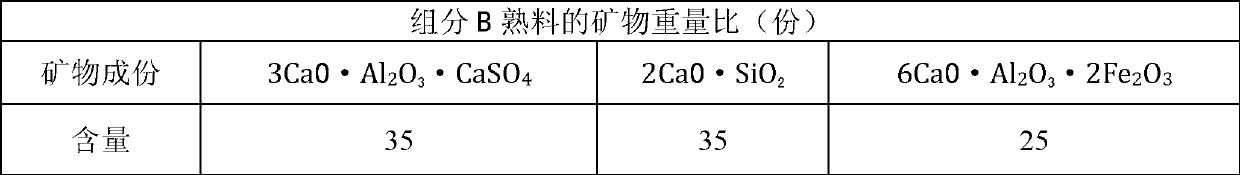

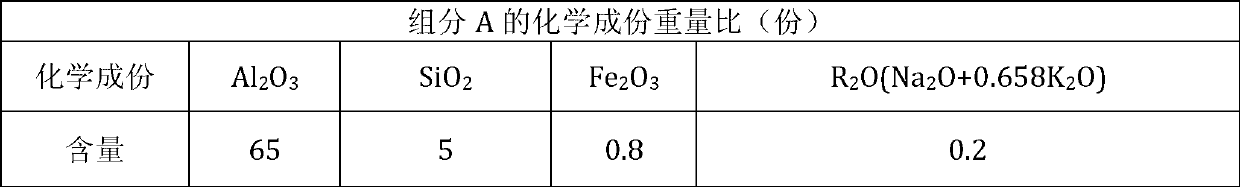

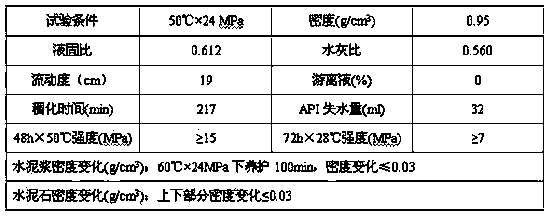

The invention relates to a high-temperature-resistant non-silicate cement paste system for cementing a thermal production well for thickened oil. The high-temperature-resistant non-silicate cement paste system is composed of the following components in parts by weight: 100 parts of high-temperature-resistant cement, 1.0-4.0 part(s) of fluid loss agent, 1.0-4.0 part(s) of dispersant, 0.5-3.0 part(s) of thickening time control agent, 60-120 parts of water and 15-80 parts of heat regulators, wherein the high-temperature-resistant cement is formed by mixing components A and B, the component A comprises 50-77 parts of Al2O3, 0.5-8.0 part(s) of SiO2, 0.5-2.5 part(s) of Fe2O3 and 0-0.4 part of R2O(Na2O+0.658K2O), and the component B comprises 33-63 parts of 3CaO.Al2O3.CaSO4, 14-37 parts of 2CaO.SiO2 and 15-35 parts of 6CaO.Al2O3.2Fe2O3. The high-temperature-resistant non-silicate cement paste system disclosed by the invention has great significance to enhancement of safe and efficient development of the thickened oil and has broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

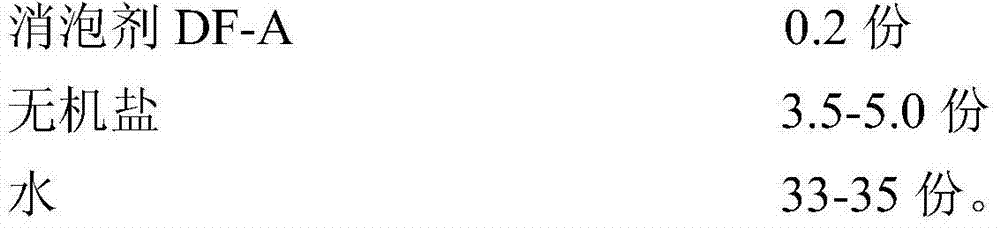

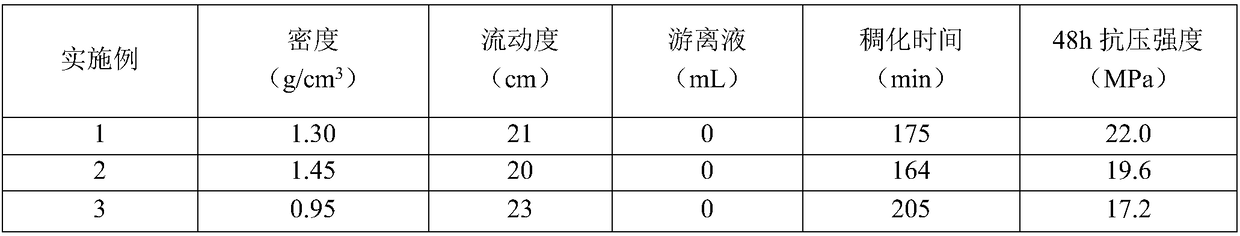

High-temperature-resistant high-strength low-density well-cementing cement slurry

InactiveCN104263332ALow densityImprove bearing strengthDrilling compositionPhysical chemistryWell cementing

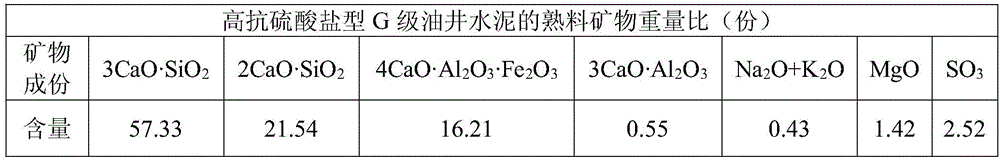

The invention discloses high-temperature-resistant high-strength low-density well-cementing cement slurry. The high-temperature-resistant high-strength low-density well-cementing cement slurry is prepared from the following components in parts by weight: 100 parts of G-level oil well cement, 15-76 parts of a lightening admixture, 20-40 parts of micro-silicon, 2-10 parts of a fluid loss agent, 1-8 parts of a dispersing agent, 0-5 parts of a retarder, 0-1.25 parts of a coagulant, 0-5 parts of an anti-fluid-channeling agent, 0.2-0.8 part of an antifoaming agent and 50-120 parts of fresh water, wherein the G-level oil well cement is high sulfate-resistant oil well cement, the lightening admixture is high-performance hollow glass beads. According to the grain grading principle, a series of low-density well-cementing cement slurries with densities of 0.90-1.50g / m<3> are prepared. The low-density well-cementing cement slurry can be used for lowering the density of the cement slurry on the premise of guaranteeing comprehensive performances such as cement slurry strength, good high-temperature high-pressure stability and low water loss, increasing the scope of application of the low-density cement slurry in complex wells such as a deep well, an ultra-deep well and a low-pressure easy-leakage well, and improving the well-cementing quality.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Well-cementing and self-healing cement slurry for oil-gas field

ActiveCN102746836AGood settlement stabilityThickening time adjustableDrilling compositionCement slurrySelf-healing

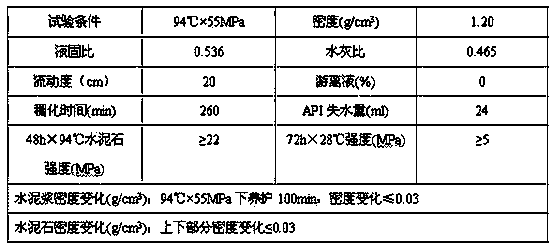

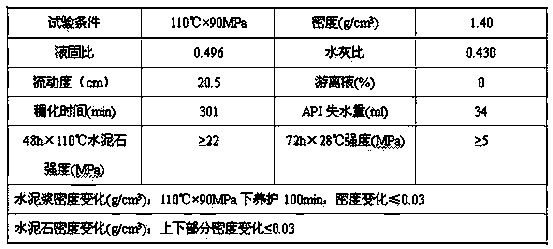

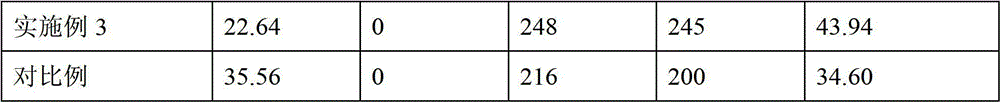

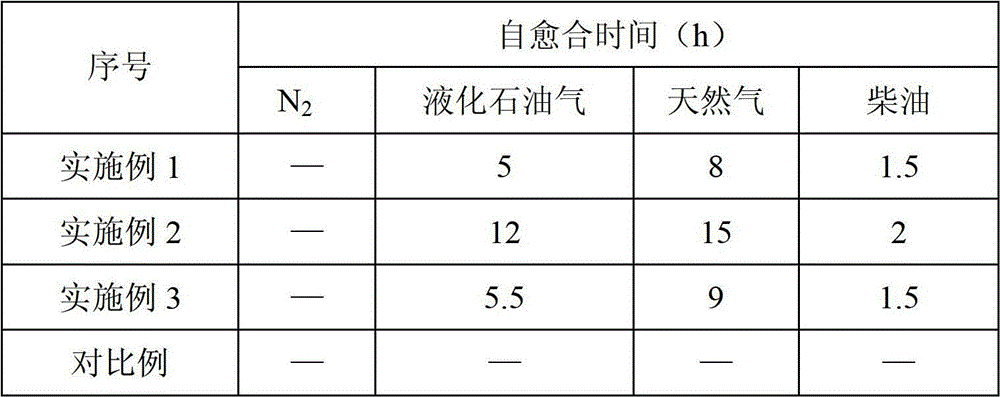

The invention relates to well-cementing and self-healing cement slurry for an oil-gas field, which is suitable for the field of oil well cementation. The well-cementing and self-healing cement slurry comprises the following additives percentage by weight: 2-4% of fluid loss agent, 5-40% of self-healing component, 0.2-1.0% of stabilizing agent, 0.5-2.0% of dispersing agent, 0.3-1.0% of de-foaming agent, and 0.03-0.5% of retarding agent by taking the weight of cement as benchmark. A preparation method of the well-cementing and self-healing cement slurry is as follows: controlling the water cement ratio to be 0.44, uniformly mixing the additives at a low shearing speed, weighing a certain amount of cement, adding into slurry preparation liquid, and mixing with API (American petroleum institute) standards to obtain the well-cementing and self-healing cement slurry. The well-cementing and self-healing cement slurry has the characteristics of low water loss, adjustable thickening time, gas channeling prevention and excellent impervious performance and the like, has the functions of crack prevention and self healing, and remarkably improves the mechanical property of the cement.

Owner:古莱特科技股份有限公司

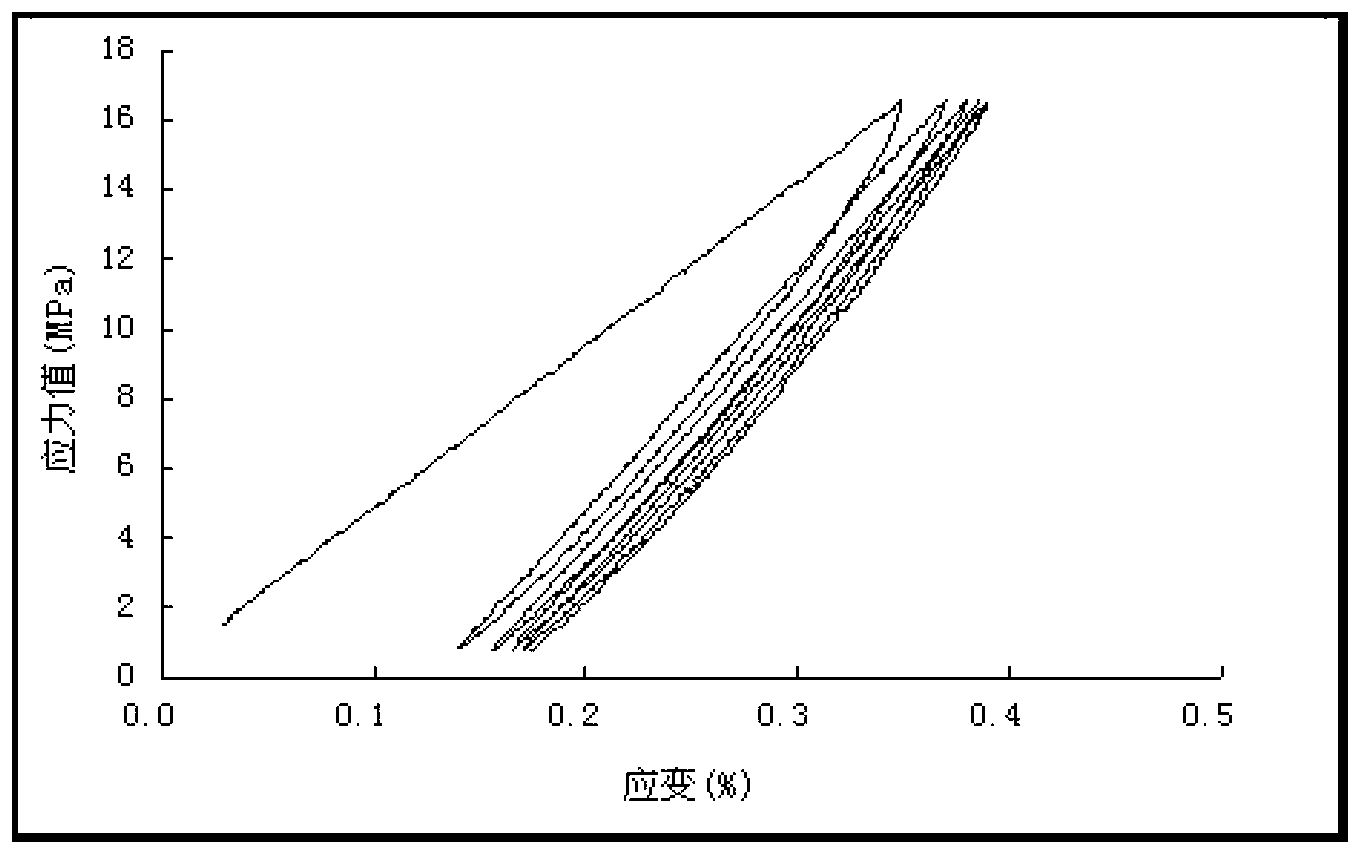

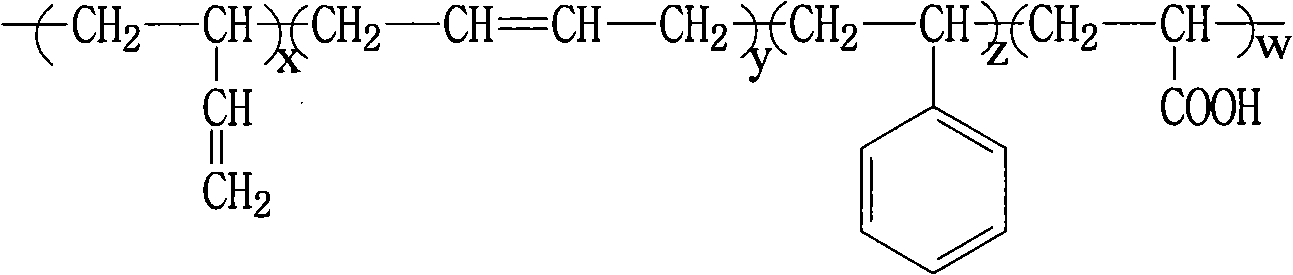

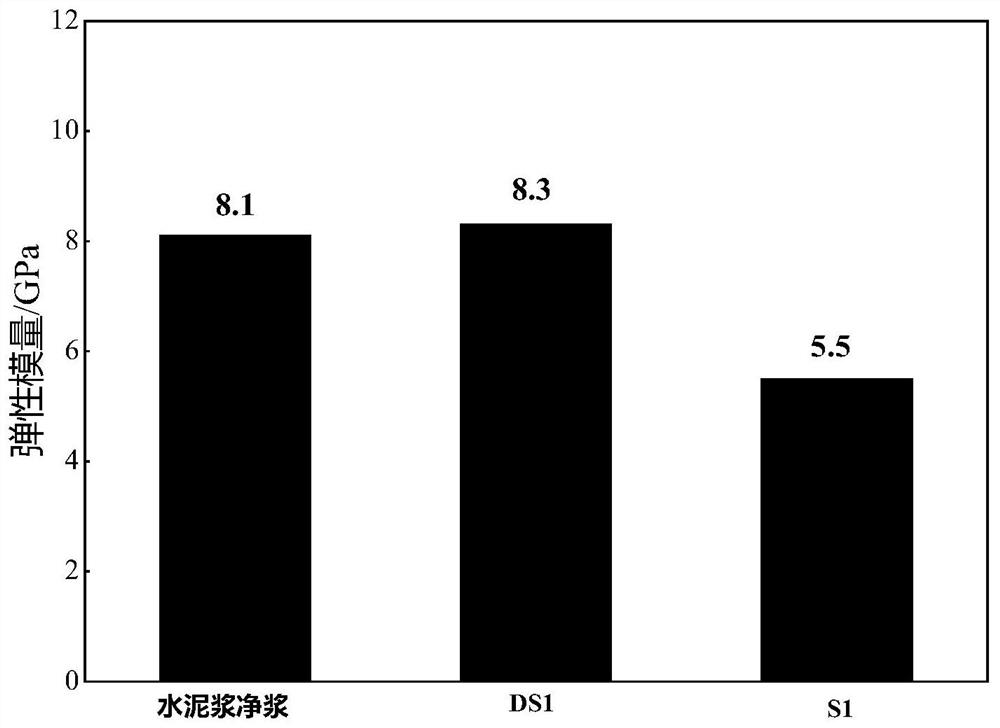

Oil well cement flexibilizer

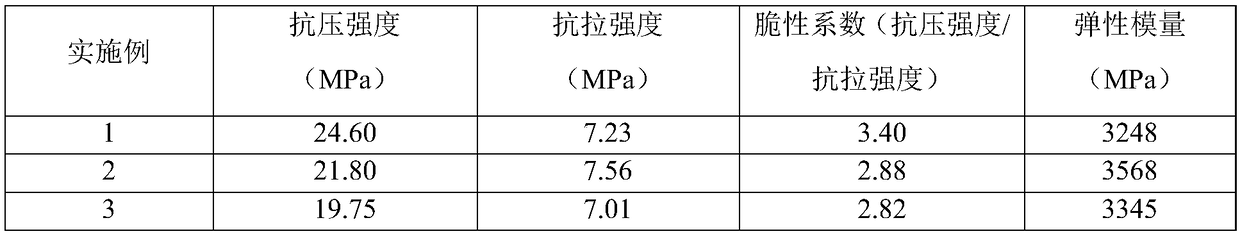

The invention discloses an oil well cement flexibilizer. The oil well cement flexibilizer can be used as an admixture for oil well cement of oil-gas well cementing, and is prepared from the following components in parts by mass: 15-50 parts of a temperature-resistance rubber material, 0-20 parts of surface modified fibers, 10-20 parts of a stabilizer and 10-50 parts of a rheolobic modifier. The flexibilizer can be used for reducing the elasticity modulus of annulus set cement and improving the impact resistance of set cement, and is well compatible with other cement admixtures. The flexibilizer has stable normal-temperature and high-temperature performances, and can be used for improving the rheological property of cement paste, solving the problem that the annulus set cement in an oil-gas well has poor stress resistance and cannot adapt to big-frac treatment in the oil and gas exploitation process, and prolonging the service life of the oil-gas well.

Owner:CNPC BOHAI DRILLING ENG

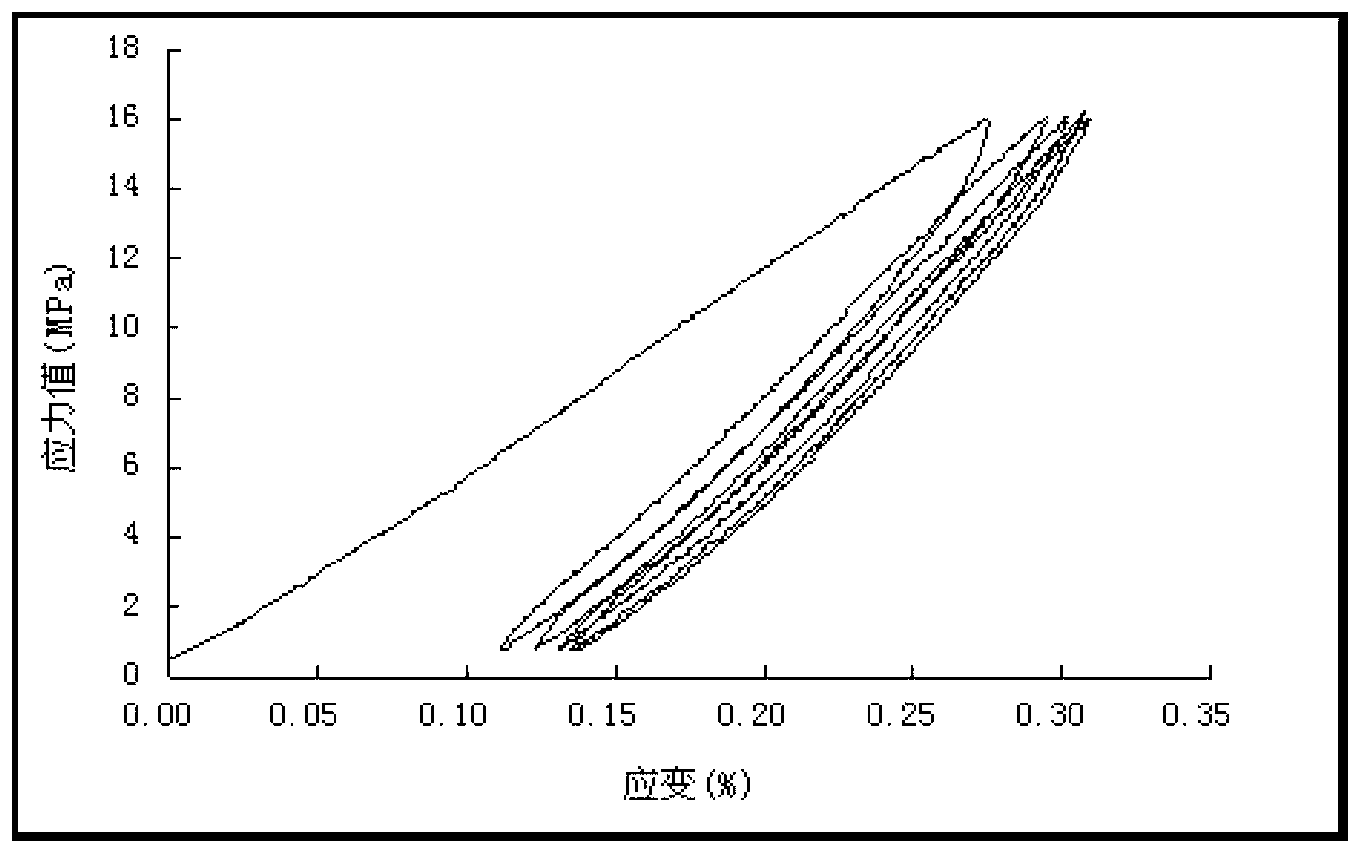

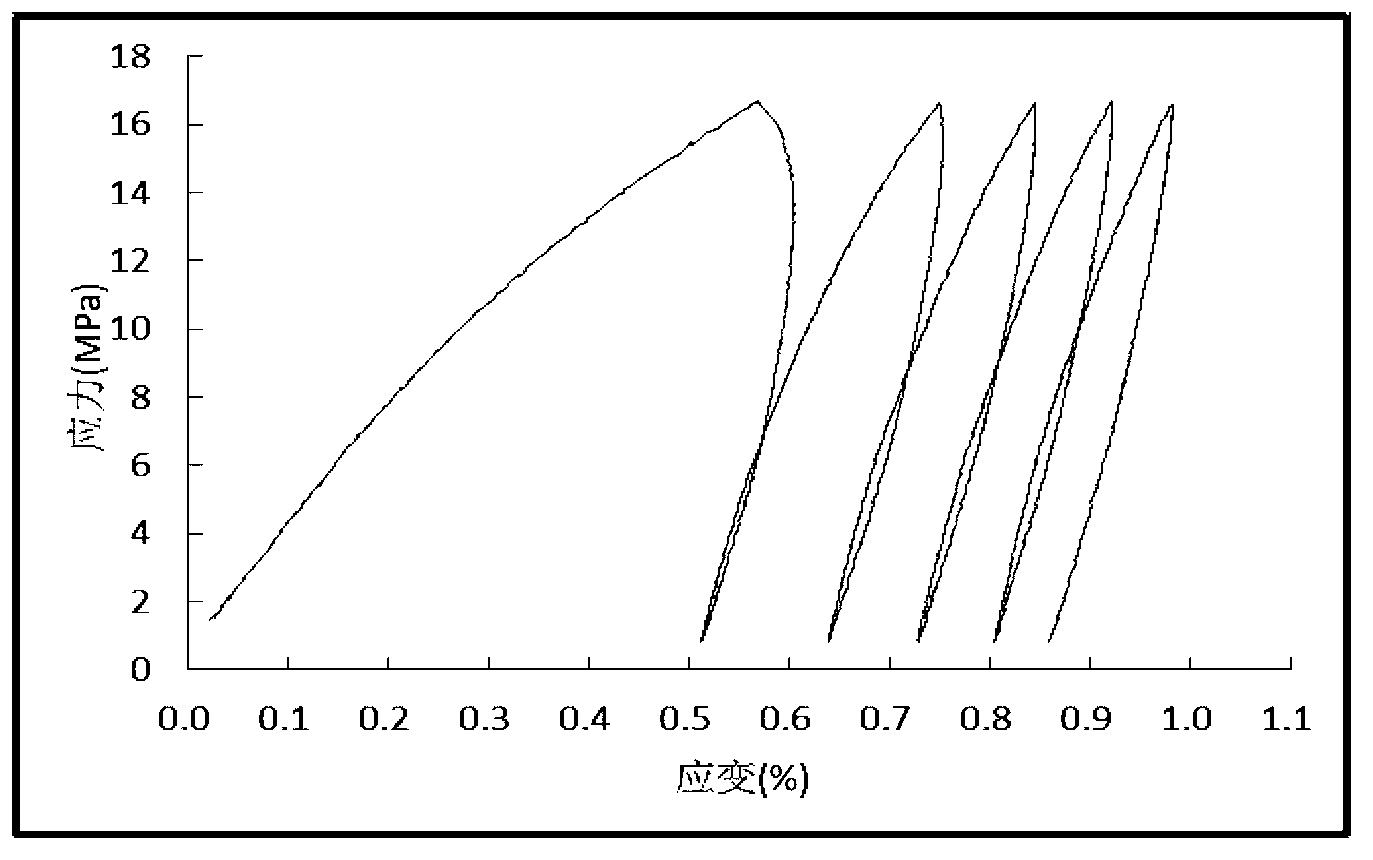

Cement paste toughening agent and application of cement paste toughening agent in preparation of cementing flexible cement paste

ActiveCN103305197ADoes not change inherent performanceGood settlement stabilityDrilling compositionPolymer sciencePortland cement

The invention relates to a cement paste toughening agent and application of the cement paste toughening agent in preparation of a cementing flexible cement paste. The toughening agent is prepared by modification of rubber powder; the modification of rubber powder includes the steps of cleaning, activating, etching and grafting; the cementing flexible cement paste prepared by the toughening agent is prepared from the following components in parts by weight: 100 parts of portland cement, 5-50 parts of modified rubber powder, 10-40 parts of a toughing agent, 15-80 parts of a density regulator, 35-65 parts of water, 0.5-2 parts of a dispersing agent, 0.5-3 parts of a fluid loss agent, 1.5-4 parts of a retarder and 0.1-2 parts of a defoamer. The inherent performance of a substrate is not changed by plasma treatment on the rubber powder; no pollution is generated; the cement paste toughening agent is simple in process, convenient to operate, stable in hydrophilism through the grafted rubber powder, small in effect from timeliness, and low in handling expense; the flexible cement paste prepared from the modified rubber is good in sedimentation stability; the mechanical property is obviously improved; the cement construction requirements of the scene can be completely met.

Owner:SOUTHWEST PETROLEUM UNIV

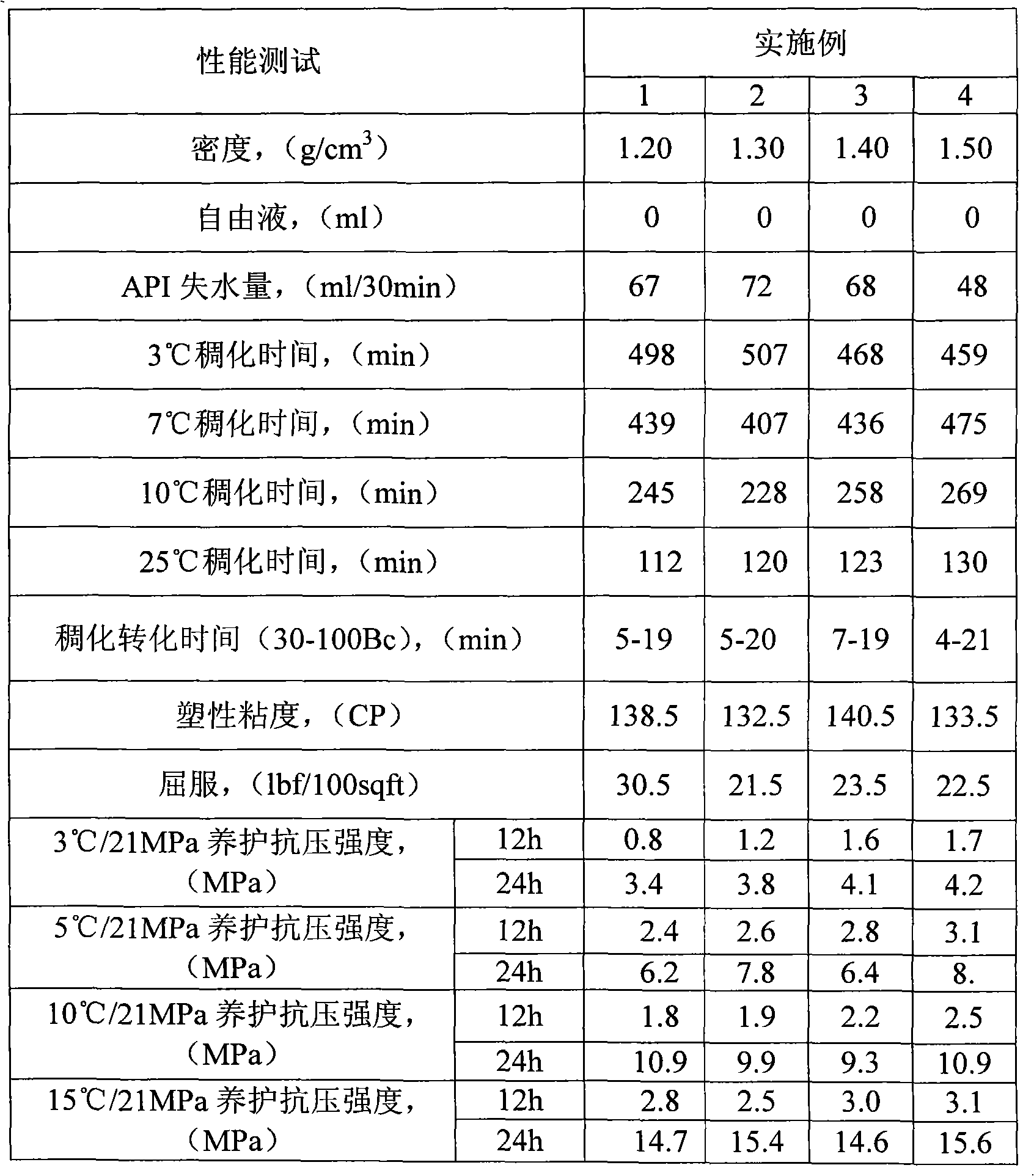

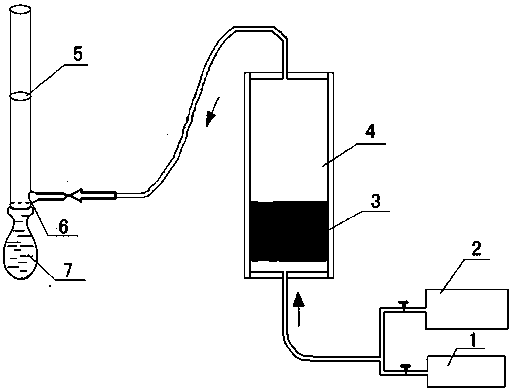

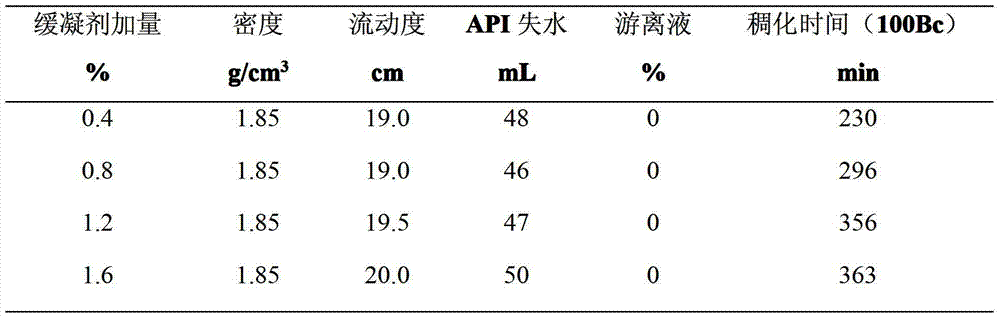

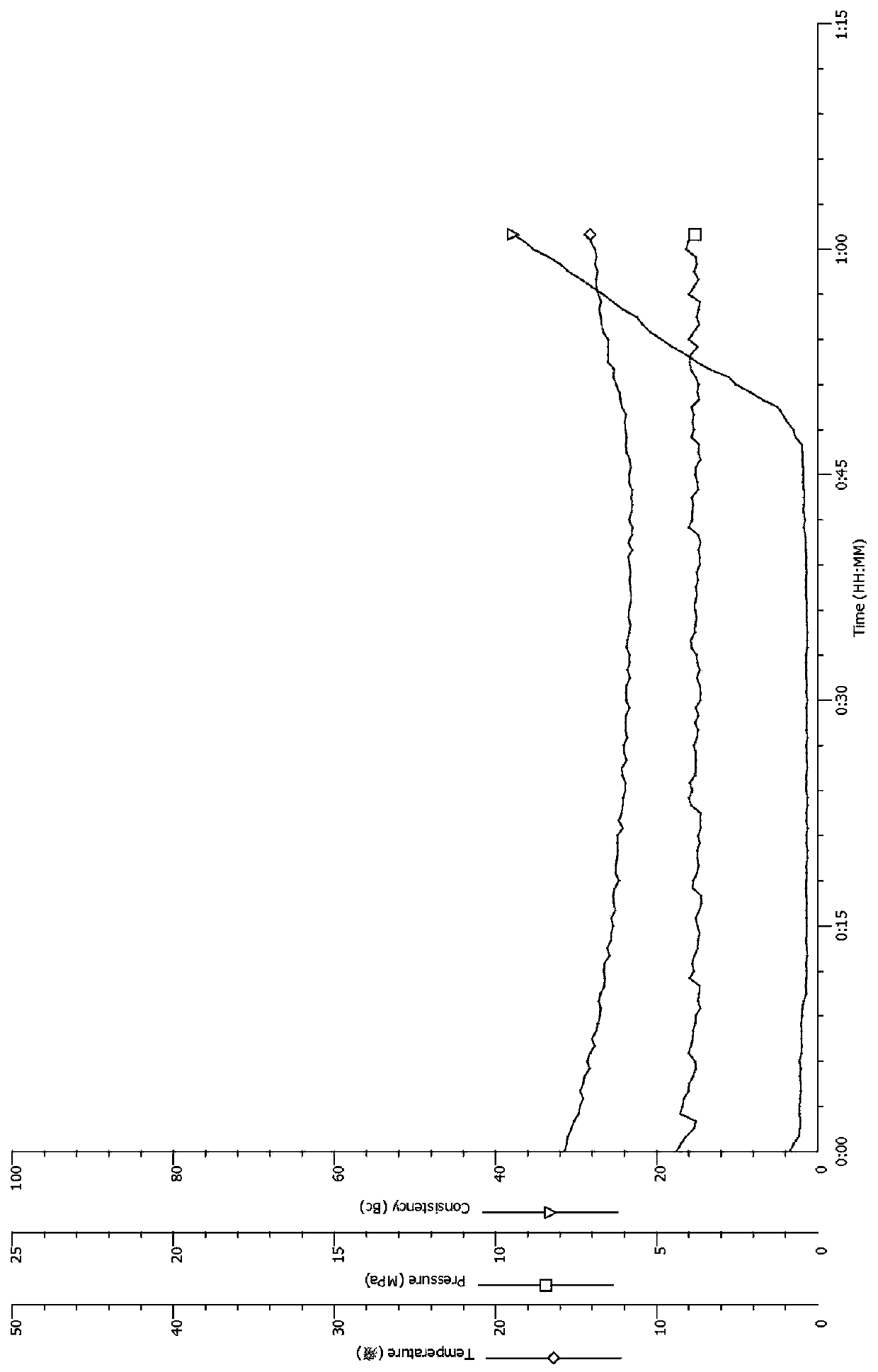

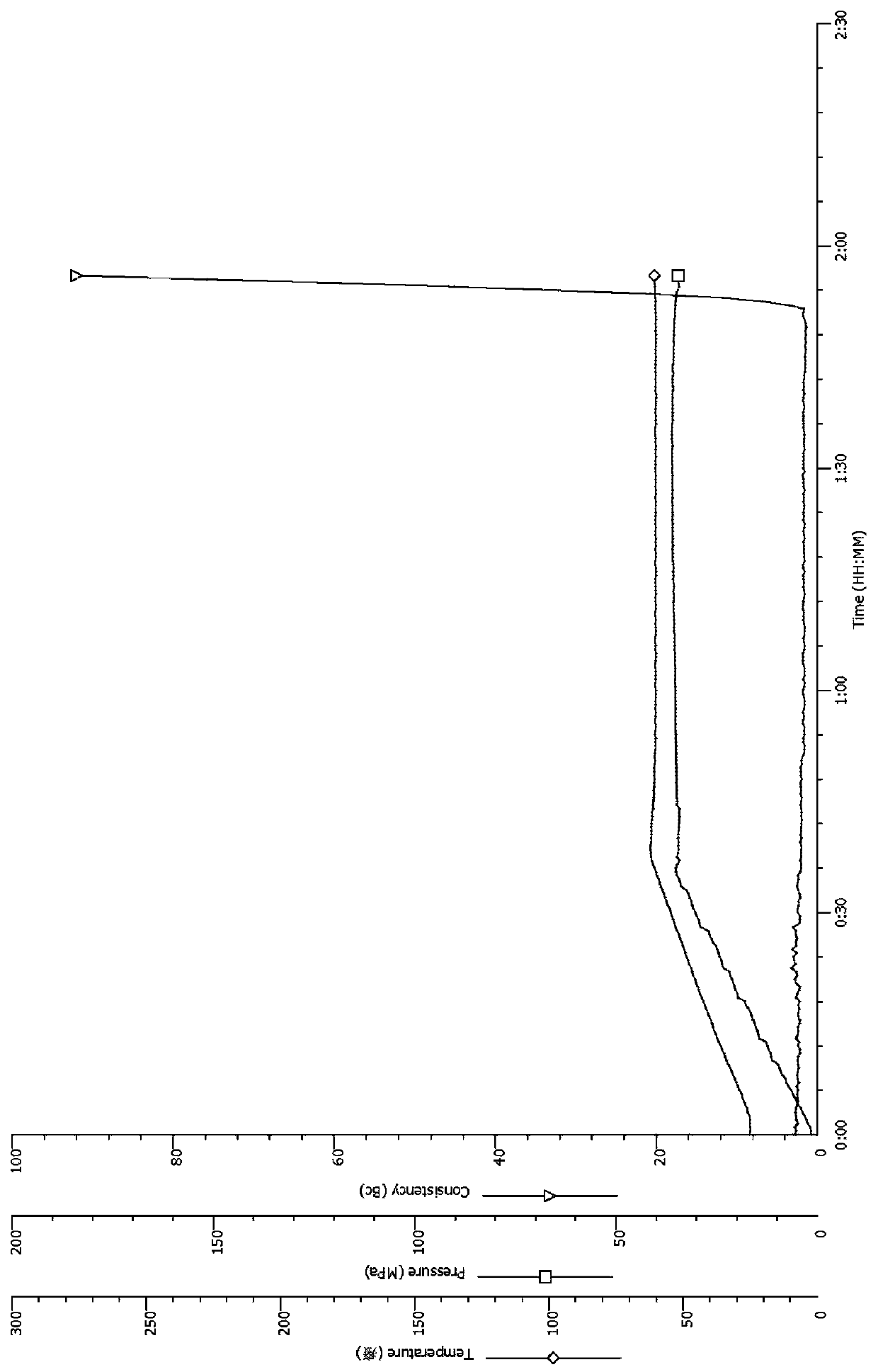

Sulphoaluminate cement paste for deepwater cementing

InactiveCN101974317AFast development of low temperature strengthHigh compressive strengthDrilling compositionCompressive strengthCement paste

The invention discloses a sulphoaluminate cement paste for deepwater cementing, comprising cement, a lightening admixture, a fluid loss agent, a dispersing agent, a coagulant, a retarder and water. The ratio by weight of the cement to the lightening admixture to the fluid loss agent to the dispersing agent to the coagulant to the retarder and to the water is 100: (13-35): (2-5): (0.5-2): (0.5-3): (0.1-1): (48-75). The sulphoaluminate cement paste can be used at lower temperature, and has better thickening time and higher compressive strength.

Owner:CHINA NAT OFFSHORE OIL CORP +2

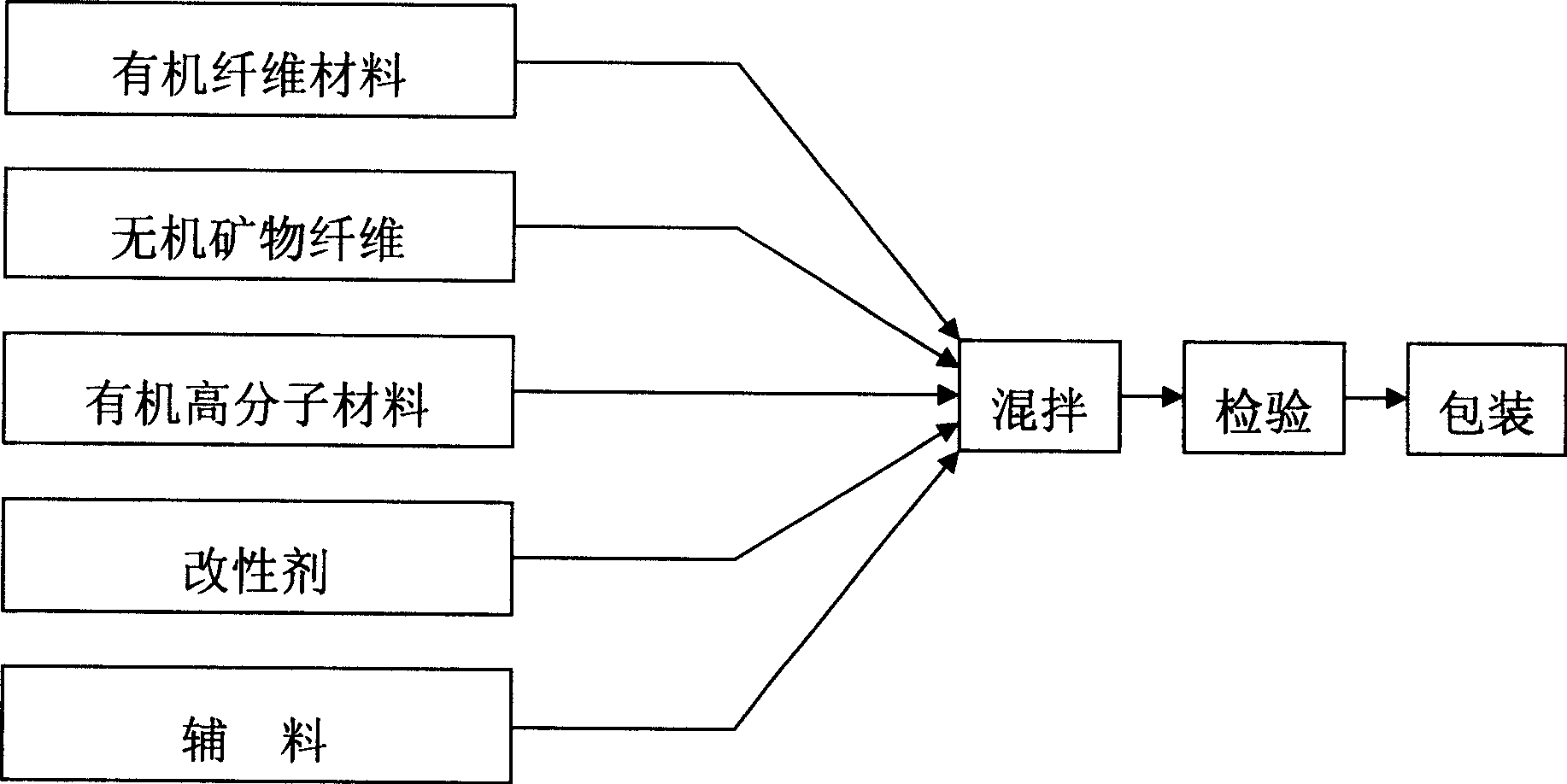

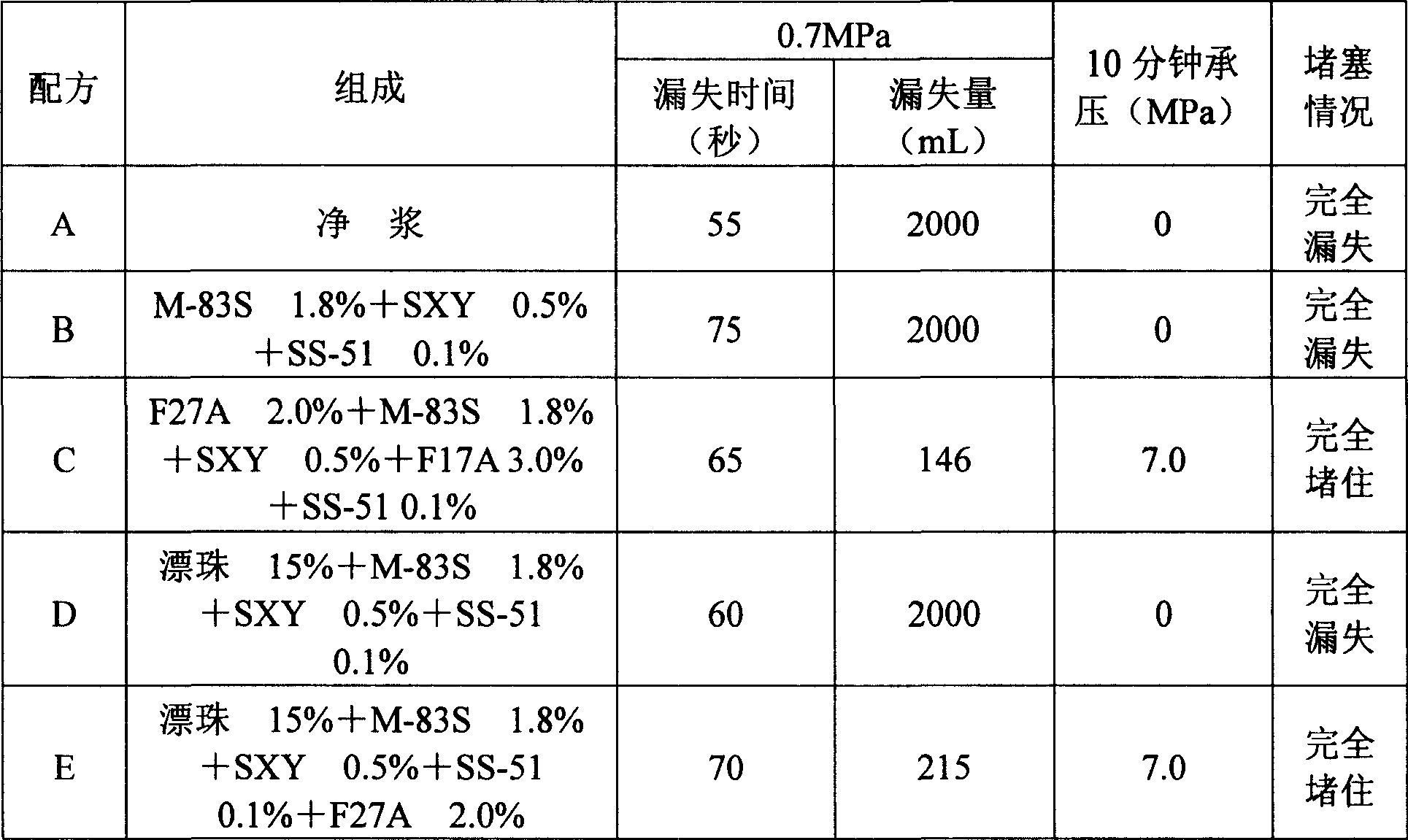

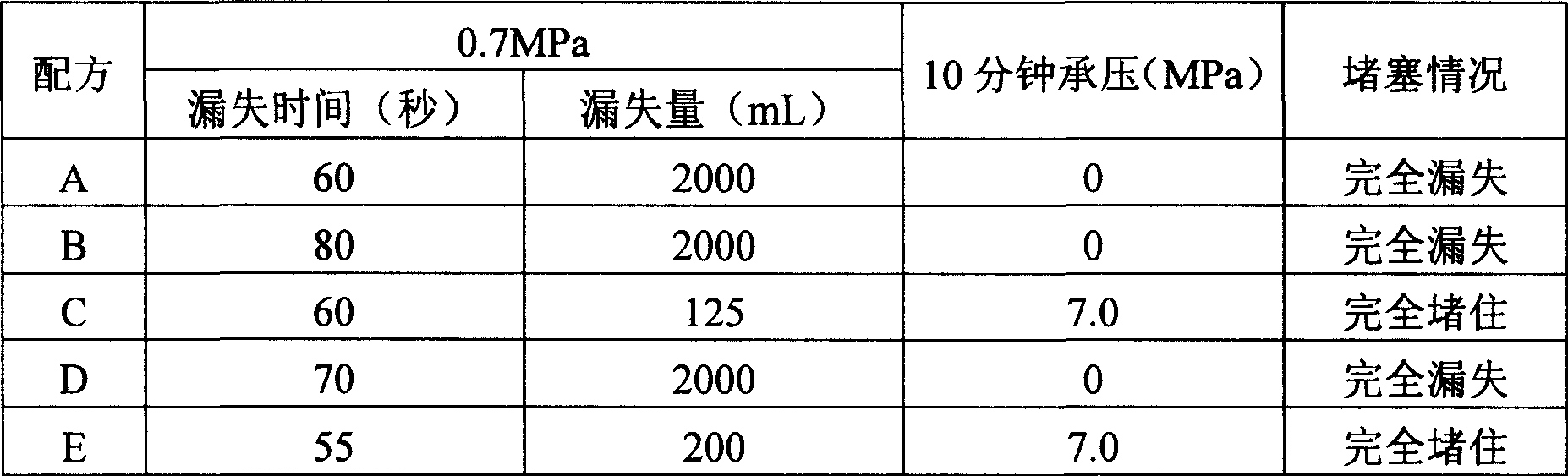

Oil well cement leak-proof toughening agent

The invention discloses an oil-well cement leakage-proof toughener which not only has leakage-proof function and improves the toughness of cement rocks, but also has good multiple-purpose project performance, so as to have double effects and solve the technical problems of slurry loss and the inherent brittleness of the cement rocks in the process of well cementation; the oil-well cement leakage-proof toughener comprises the components based on the weight percentage: 5-30% of organic fiber material, 35-70% of special type inorganic fiber, 1.0-10% of organic polymer material, 5.0-15% of modifying agent and 1.0-10% of auxiliary material.

Owner:NANJING UNIV OF TECH +1

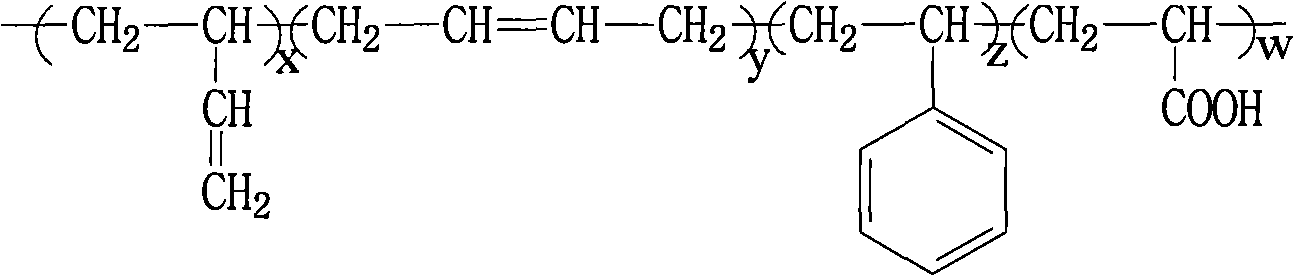

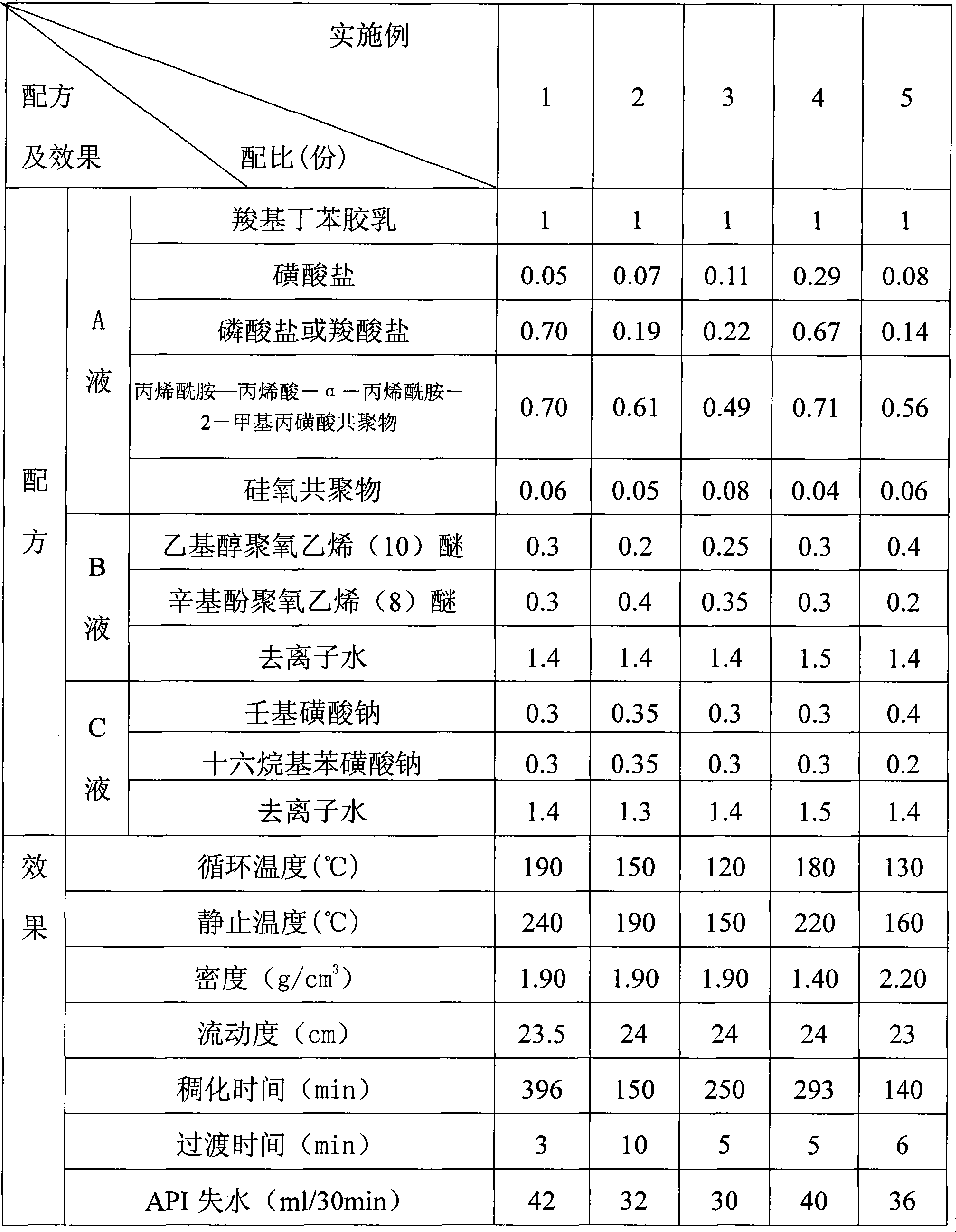

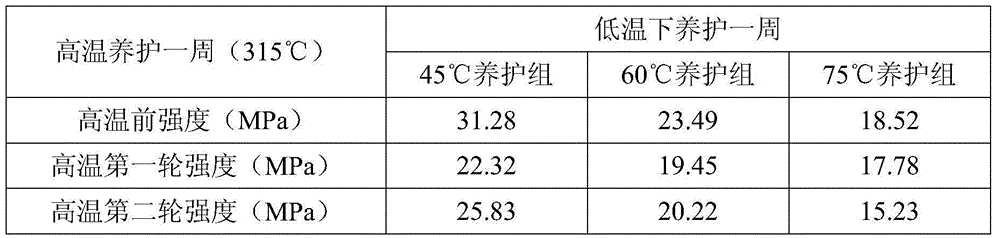

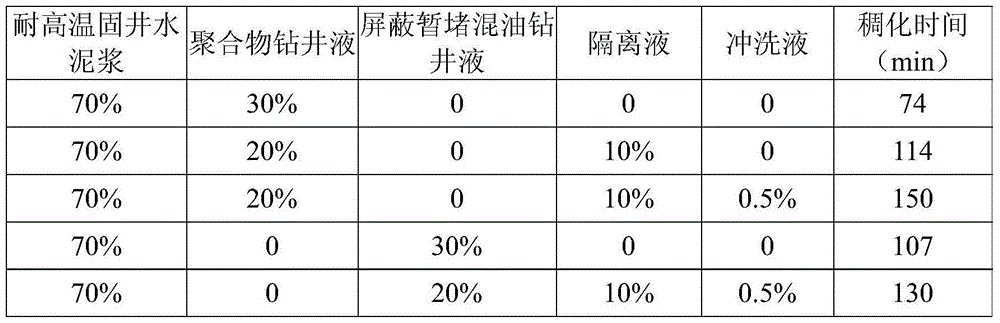

High temperature toughcementing carboxyl butadiene-styrene latex additive

ActiveCN101328401AHigh compressive strengthReduce water lossDrilling compositionPhosphateButadiene-styrene rubber

The invention relates to a high temperature ductility well cementing carboxylic styrene butadiene latex additive. The additive consists of 1 portion of a liquid A, 0.067 to 0.133 portion of a liquid B and 0.067 to 0.133 portion of a liquid C. The liquid A comprises 1 portion of carboxylic styrene butadiene latex, 0.03 to 0.3 portion of sulfonate, 0.0 to 0.8 portion of phosphate, carboxylate or a mixture thereof, and 0.1 to 0.8 portion of an acrylamide-acrylic acid-alpha-acrylamide-2-methylpropanesulfonic acid copolymer; the liquid B contains two nonionic surfactants and deionized water; and the liquid C contains two anionic surfactants and the deionized water. When a well bottom temperature reaches between 190 and 240 DEG C, cement slurry is also characterized in low water loss, adjustable thickening time and high compressive strength; and the hardened cement formed by the cement slurry can ensure good well cementing quality with ductility.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

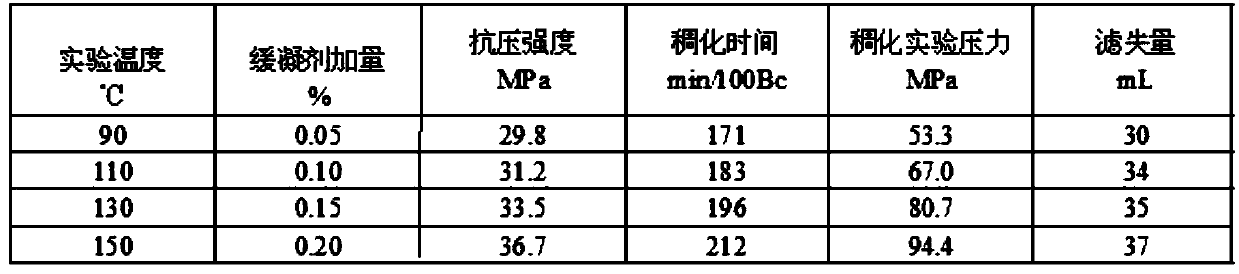

High temperature resistant well cementation cement paste used for steam injection thermal production well

InactiveCN104059622AMeet the requirements of rapid condensationHigh strengthDrilling compositionTime controlThermal stability

The invention provides high temperature resistant well cementation cement paste used for a steam injection thermal production well, and the cement paste comprises the following components by weight: 100 parts of high temperature resistant cement, 30-40 parts of a high temperature stabilizer, 0.5-1.2 parts of a thickening time control agent, 2.5-4.5 parts of an oilwell cement fluid loss agent, 0.02-0.15 part of an anti sedimentation agent, 0.02-0.15 part of a defoaming agent, and 45-100 parts of water. The high temperature resistant well cementation cement paste can effectively solve the problems of quick reduction in strength, fast rising in permeability and the like of well cementation cement paste systems in the prior art, can improve the thermal stability, reduces the possibility of channeling and casing damage, can make oilwells long-term sealed, improves production efficiency, and reduces production cost.

Owner:PETROCHINA CO LTD

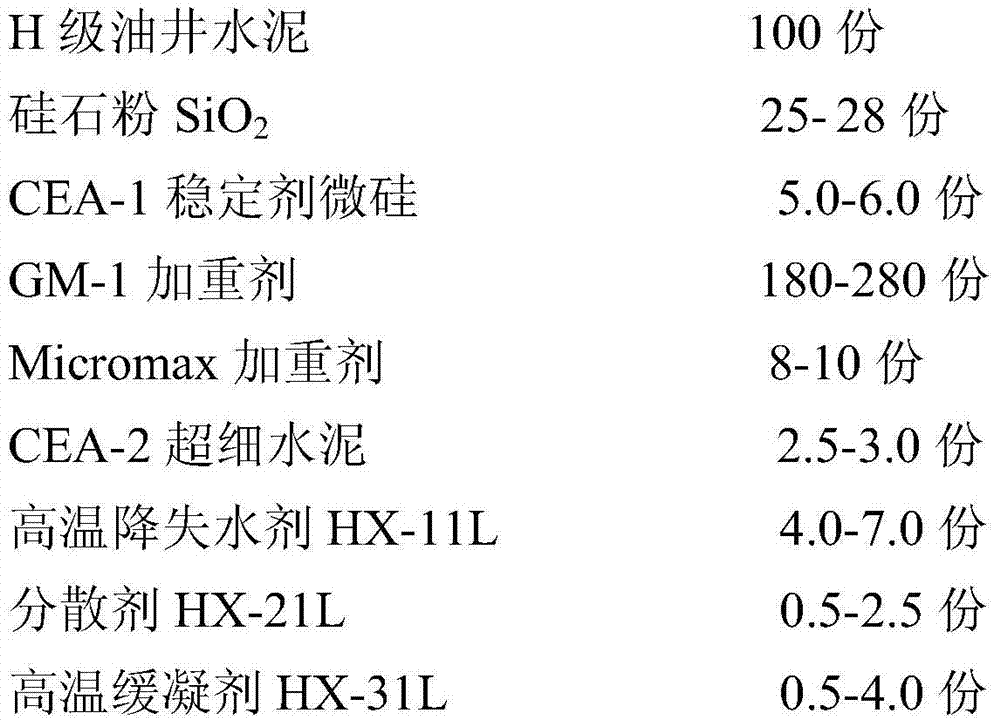

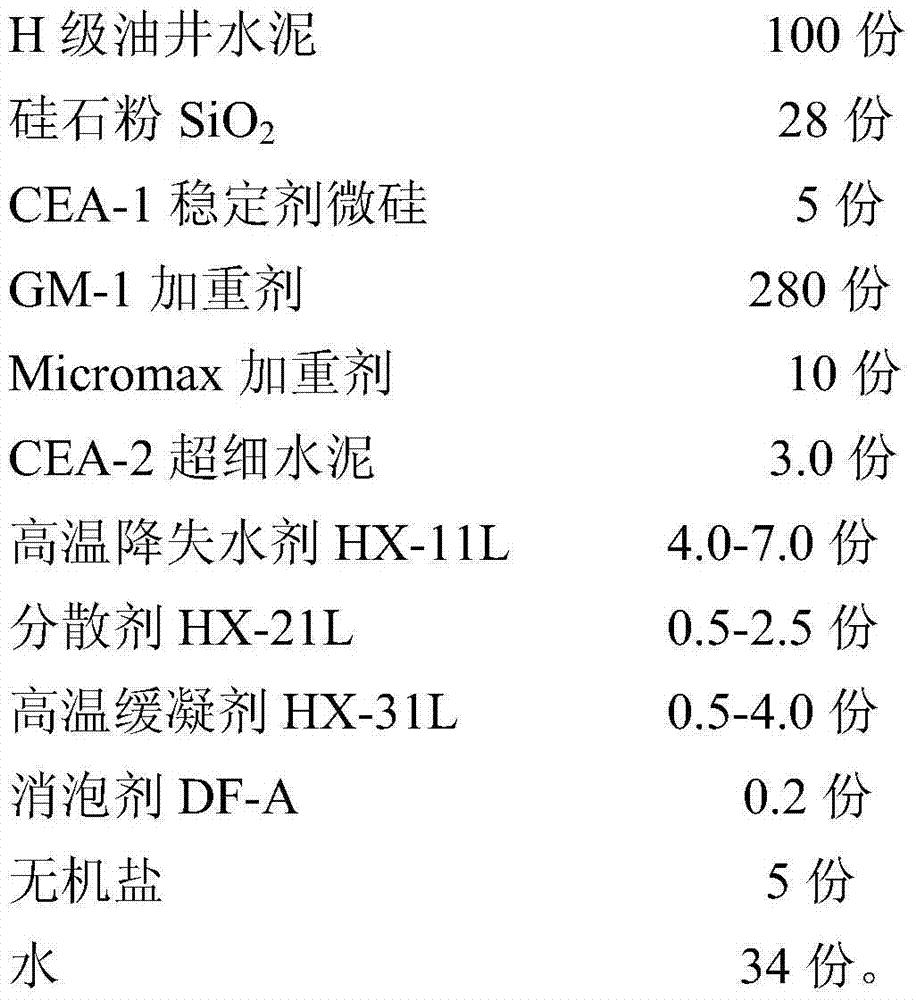

Cementing slurry with high temperature, high density and high toughness

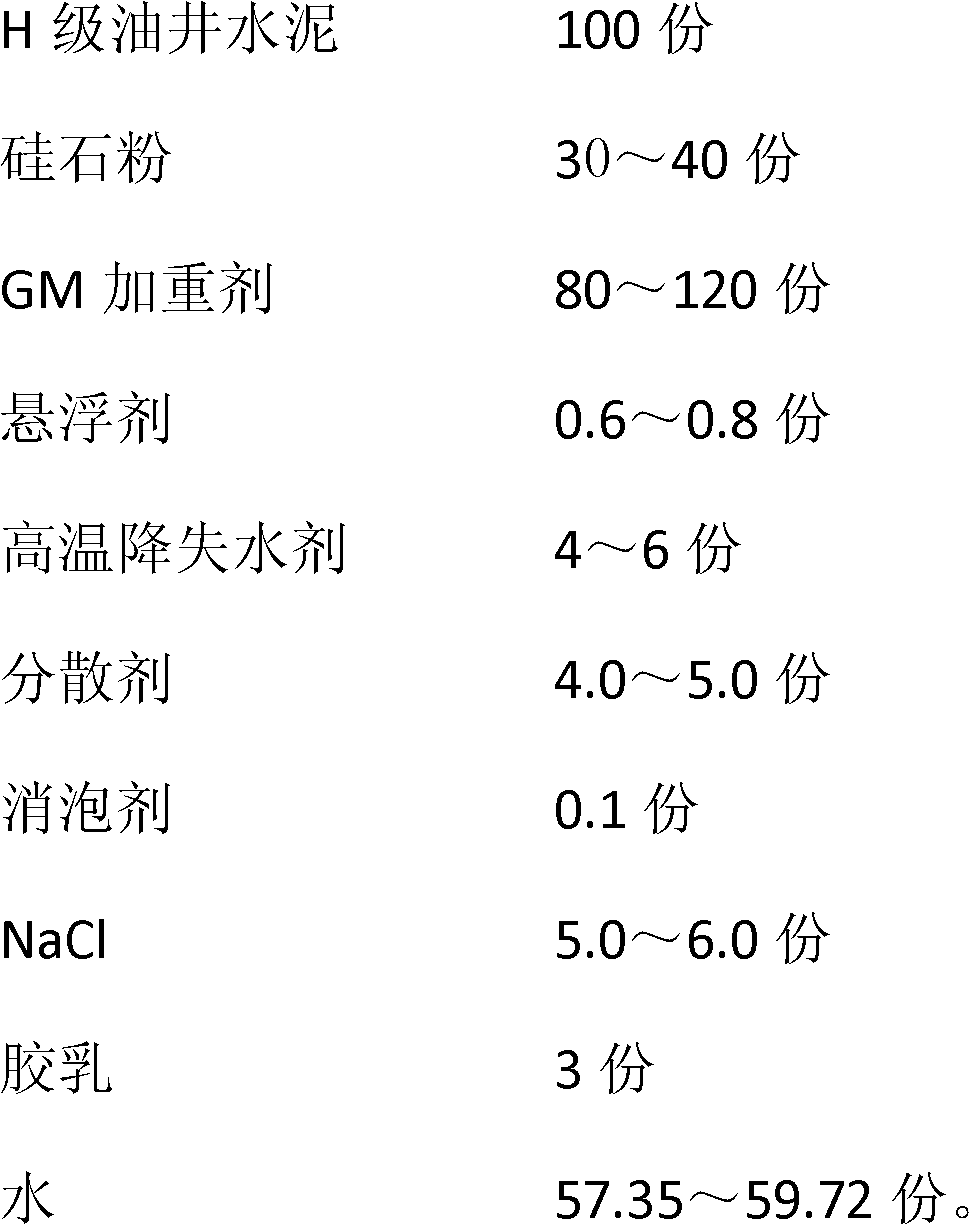

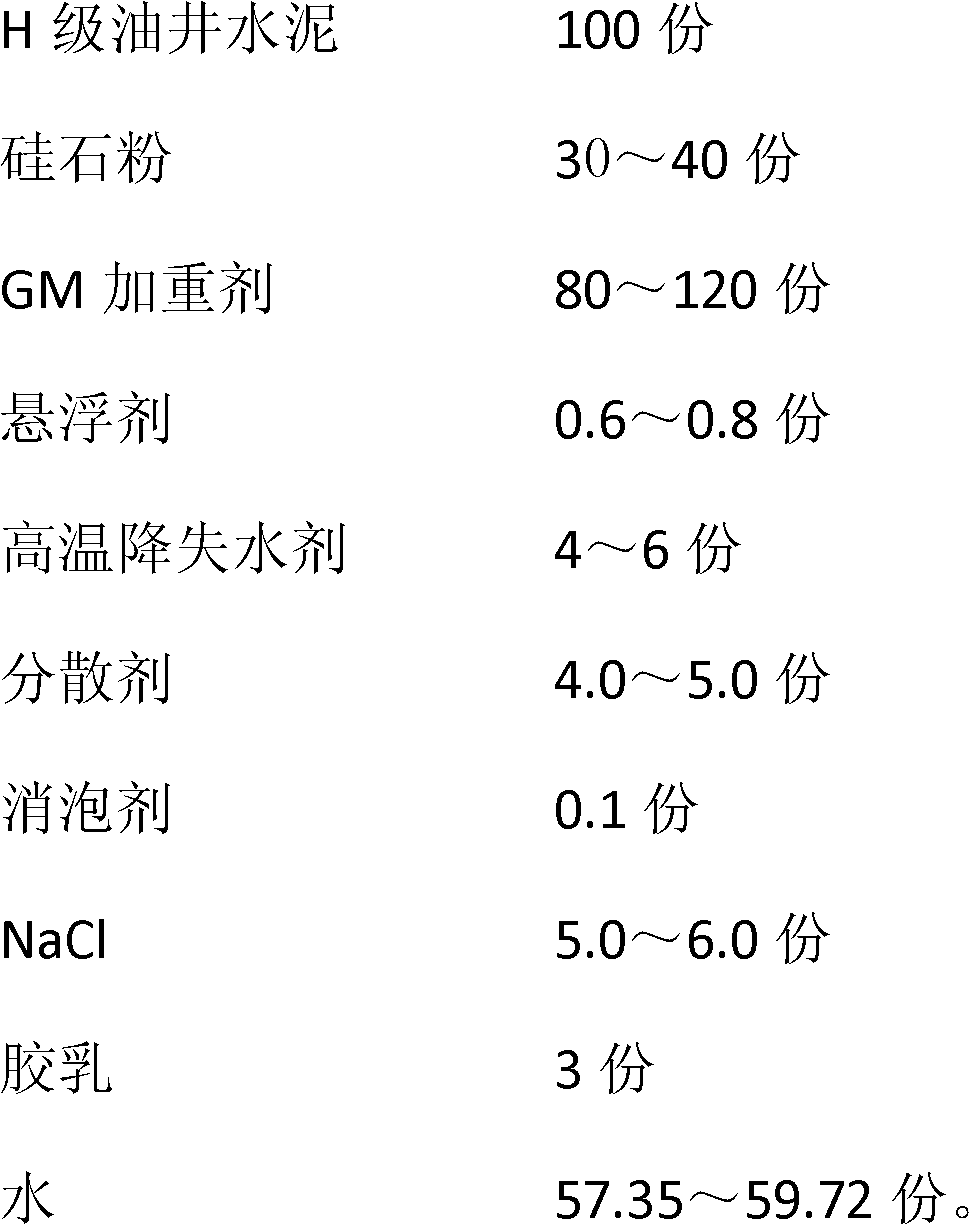

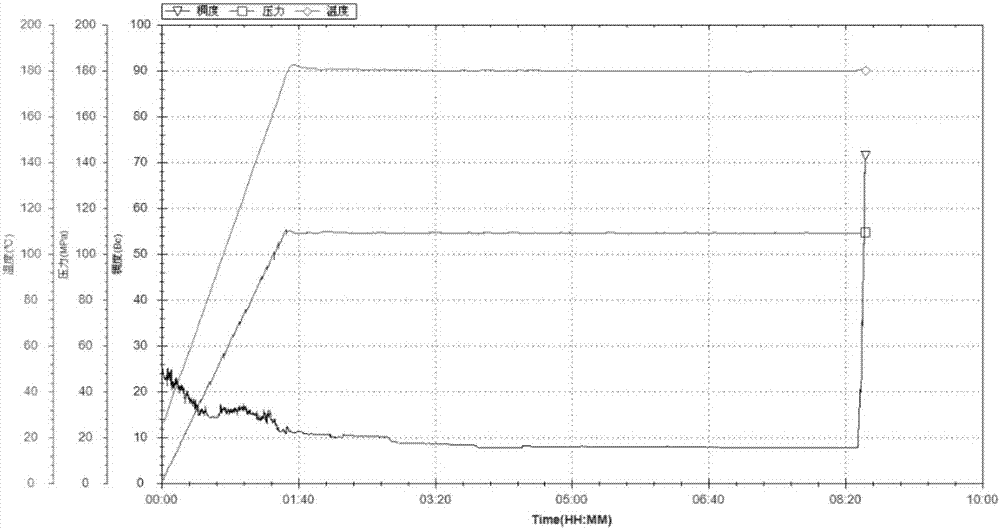

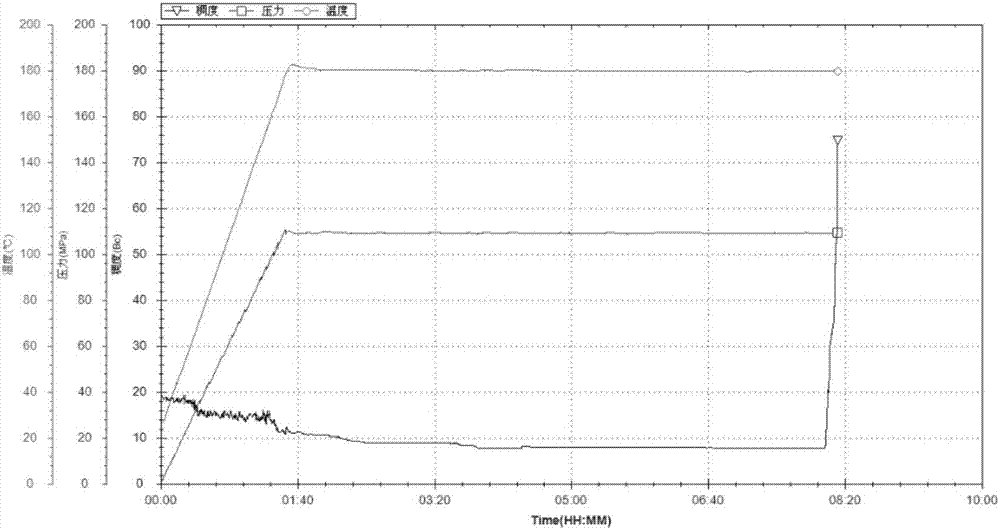

ActiveCN102516965AHigh densityGood settlement stabilityDrilling compositionHigh densitySuspending Agents

The invention discloses a cementing slurry with high temperature, high density and high toughness, which comprises the following ingredients by weight 100 parts of H grade oil well cement, 30-40 parts of silicon powder, 80-120 parts of a GM weighting agent, 0.6-0.8 parts of a suspending agent, 4-6 parts of a high temperature fluid loss reducer, 4.0-5.0 parts of a dispersant, 0.1 parts of an antifoaming agent, 5.0-6.0 parts of NaCl, 3 parts of latex and 57.35-59.72 parts of water. The density of the cementing slurry can reach 2.40-2.50gcm3, the cementing slurry can resist a temperature of 160 DEG C, and the cementing slurry has the advantages of good rheological property under high temperature, good settlement stability and good cement stone toughness, is suitable for cementing depth wellsand ultra-deep wells, and is in favor of improving the sealing quality and raising the quality of the wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-temperature-resisting, anti-fluid-channeling and high-density well cementing slurry and its preparation method

InactiveCN107418536AHigh compressive strengthTechnical Issues to Prevent Stability DeteriorationDrilling compositionHigh densityPhysical chemistry

The invention discloses a high-temperature-resisting, anti-fluid-channeling and high-density well cementing slurry and its preparation method, wherein the well cementing slurry is prepared from, by weight, 100 parts of oil well cement, 80-120 parts of weighting agent, 30-35 parts of silica powder, 3-6 parts of silica fume, 2-4 parts of suspension stabilizer, 6-10 parts of high-temperature fluid loss agent, 6-10 parts of high-temperature retarder, 1-2 parts of dispersing agent, 3-5 parts of anti-fluid-channeling agent, 1-2 parts of defoaming agent, and 55-65 parts of water. The high temperature resistance can reach 180-200DEG C, and the well cementing slurry is featured by good flowing property, low filter loss, good sedimentary stability, and strong anti-fluid-channeling performance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Well cementation cement paste with high water-cement ratio, low cost and low density and preparation method thereof

InactiveCN109437710AShort thickening transition timeImprove cementing effectDrilling compositionDefoaming AgentsCoal

The invention discloses well cementation cement paste with a high water-cement ratio, low cost and a low density. The well cementation cement paste is prepared from the following raw materials in parts by weight: 40 to 100 parts of oil well cement, 25 to 60 parts of coal ash, 30 to 40 parts of silica fume, 2 to 3 parts of an early strength agent, 2 to 8 parts of a ternary exciting agent, 3 to 3.5parts of a fluid loss agent, 0 to 0.2 part of a dispersing agent, 0.2 part of a defoaming agent and 180 to 272 parts of clean water, wherein the ternary exciting agent is a mixture of soda lime and magnesium sulfate, the mass ratio of the soda lime to the magnesium sulfate is 9 to 1, and the soda lime and the magnesium sulfate are both sieved by a 100-mesh sieve. Meanwhile, the invention further discloses a preparation method of the well cementation cement paste preparation method. The well cementation cement paste has low cost; after the ternary exciting agent is added, the compressive strength is improved, and a requirement of well cementation for the strength of low-density cement paste is met; furthermore, expansibility is improved, cement paste micro annular spaces caused by the inherent shrinkage character are reduced, and the risk of poor wellhole sealing safety is reduced.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

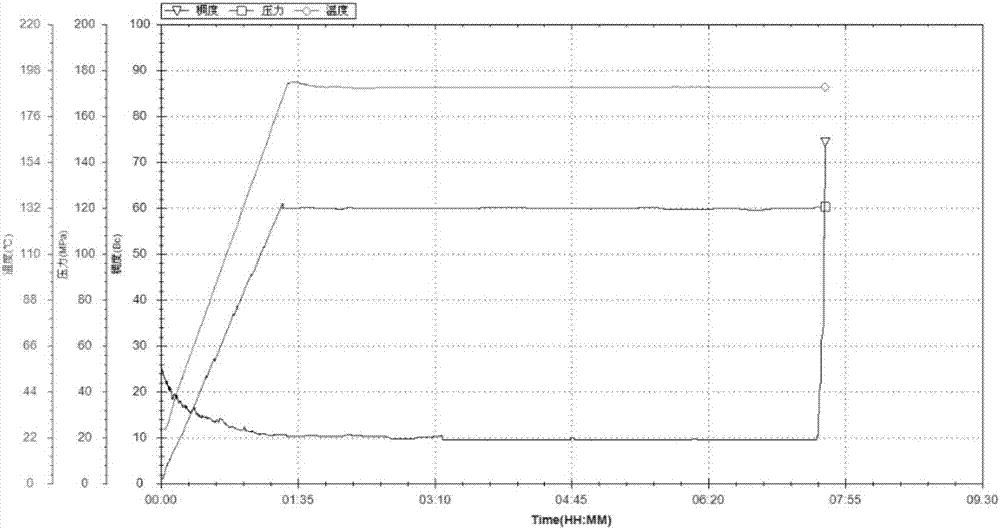

High-temperature high-density cement slurry for oil field high-temperature high-pressure well cementation and preparation method thereof

InactiveCN104293331AImprove convenienceImprove temperature resistanceDrilling compositionHigh densityCement slurry

The invention discloses a high-temperature high-density cement slurry for oil field high-temperature high-pressure well cementation and a preparation method thereof. The high-temperature high-density cement slurry includes oil well cement, a weighting agent, an anti-high temperature strength degradation agent, a stabilizer, a fluid loss agent, a dispersing agent, a retarder, a defoaming agent and the like. A particle gradation principle is employed in the invention, and the particle sizes and the dosages of various materials are optimized, thus achieving close packing of solid phase materials. A weighted blended slurry solution is mixed with the solid phase materials, secondary weighting is carried out on the cement slurry, and by cooperating with the regulation of an excellent performance high temperature salt resistant treatment agent, a high-temperature high-density liquid mixture with good comprehensive performance can be formed, thus solving the contradiction of influence between high-temperature high-pressure well cementation cement slurry density, high temperature resistance, rheological property and sedimentation stability.

Owner:CNPC BOHAI DRILLING ENG

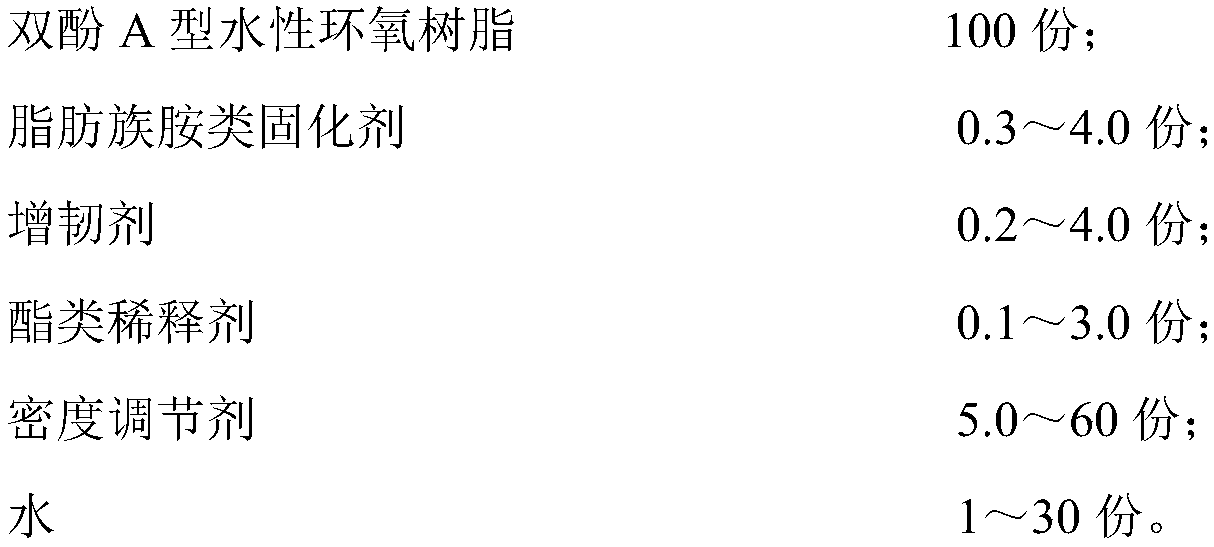

Thermosetting epoxy resin well cementation working solution

The invention discloses a thermosetting epoxy resin well cementation working solution which is prepared from the following ingredients in parts by weight: 100 parts of bisphenol A type waterborne epoxy resin, 0.3 to 4.0 parts of an aliphatic amine curing agent, 0.2 to 4.0 parts of a flexibilizer, 0.1 to 3.0 parts of an ester diluent, 5.0 to 60 parts of a density modifier and 1 to 30 parts of water, wherein the flexibilizer is a mixture of modified carbon nanotube and modified magnesium borate crystal whisker according to a part-by-weight proportion of 0.2 to 3.0; the modified nanotube is prepared by a carbon nanotube surface modifying method, the carbon nano tube is oxidized at first, and the carbon nano tube is treated by sodium hypochlorite; the modified magnesium borate crystal whiskeris prepared by a magnesium borate crystal whisker coupling treatment method. The thermosetting epoxy resin well cementation working solution disclosed by the invention has the characteristics of hightensile strength, high rupture strength and good toughness, can be directly applied to oil gas well cementation, also can be applied to repairing of damaged cement sheaths on which micro cracks arre generated and has a wide market application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Toughened cement paste used for gas storage wells

InactiveCN107699216AThickening time adjustableEnhanced ability to block channelingDrilling compositionEpoxyTemperature resistance

Toughened cement paste used for gas storage wells is disclosed. A problem that present cement paste toughened with rubber particles cannot resist high temperatures is solved. The toughened cement paste includes oil well cement, a cement admixture and water. The toughened cement paste is characterized in that the toughened cement paste also includes sintered epoxy resin powder. The toughened cementpaste ensures temperature resistance, reduces the elasticity modulus of set cement, improves channeling sealing capability of the cement paste and compressive strength of the set cement, and meets technical needs on gas storage wells in oilfield development.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Natural gas horizontal well completion method

ActiveCN106285617AIncrease the number ofAvoid or reduce downhole complicationsConstructionsLiquid/gas jet drillingSoil scienceCement slurry

The invention relates to a natural gas horizontal well completion method. According to the technical scheme, the natural gas horizontal well completion method comprises the steps that the target well depth is drilled at a time with a large-size drill bit, and a large hole is formed; a plurality of horizontal branch holes are drilled out in a natural gas hydrate reservoir through the horizontal well technology; and the contact surface area between the reservoir and the holes is increased to the greatest extent. The natural gas horizontal well completion method has the beneficial effects that the downhole complex conditions in the exploitation process is avoided or decreased; the number of the holes can be greatly increased; the bare area and the depth of the natural gas hydrate reservoir are increased to the greatest extent by the holes; the recovery ratio is greatly increased; the well spacing number and the development investment are decreased; and a window sealant is adopted, thus, a cement slurry system is stable, strength development is rapid, the thickening time is adjustable, hydrate layer sealing shallow water-gas channeling can be effectively prevented, and the construction performance is good.

Owner:HUAXIN TANGSHAN PETROLEUM EQUIP CO LTD

Elastic modified resin for oil well cement and preparation method and application thereof

InactiveCN110845705AHigh cementing construction safetyLow costDrilling compositionPolymer scienceFirming agent

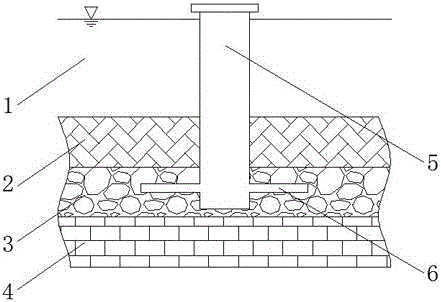

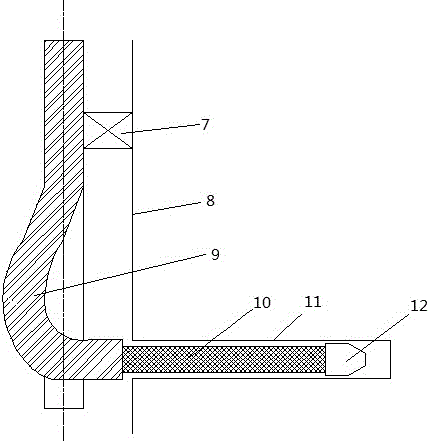

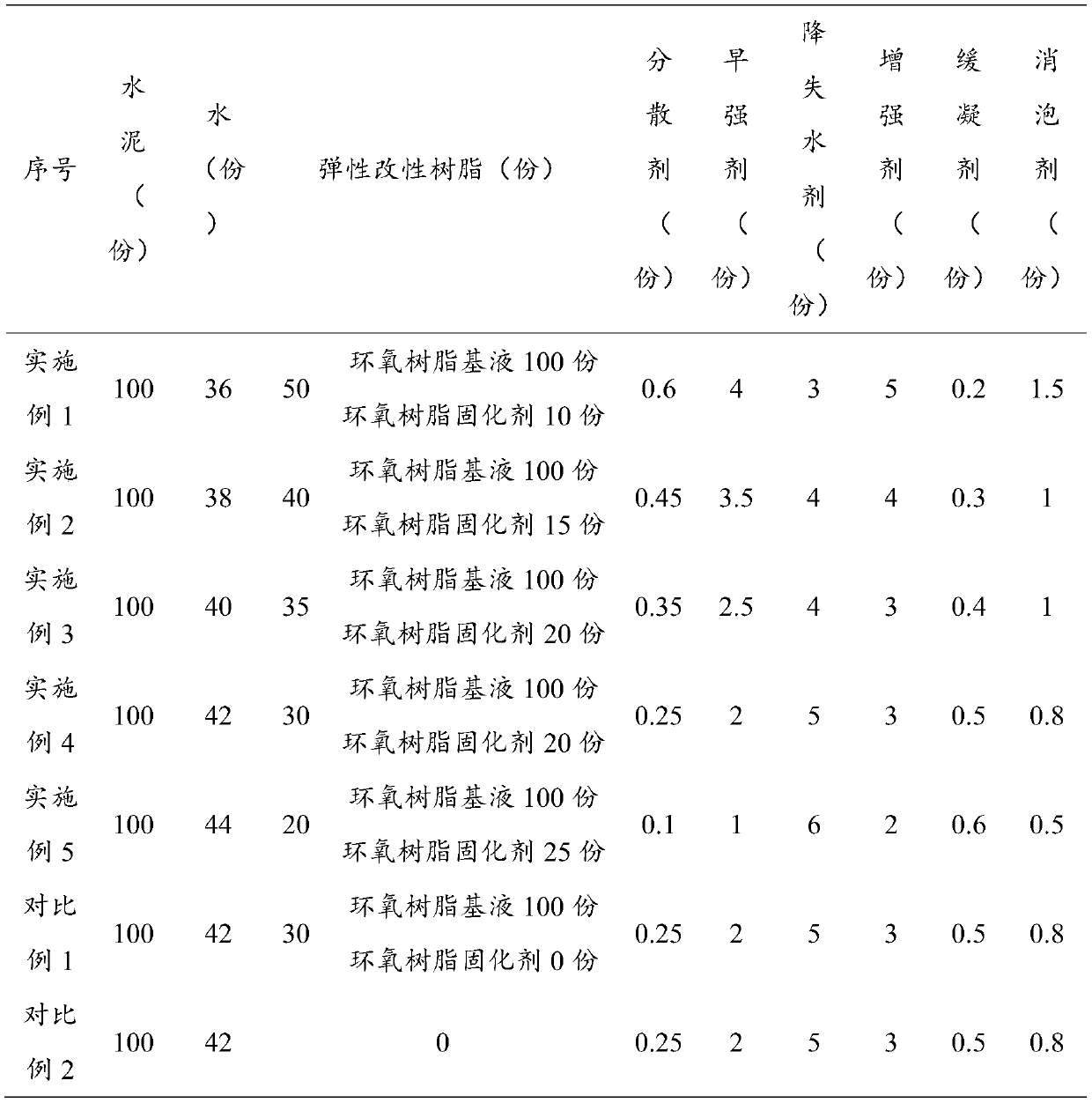

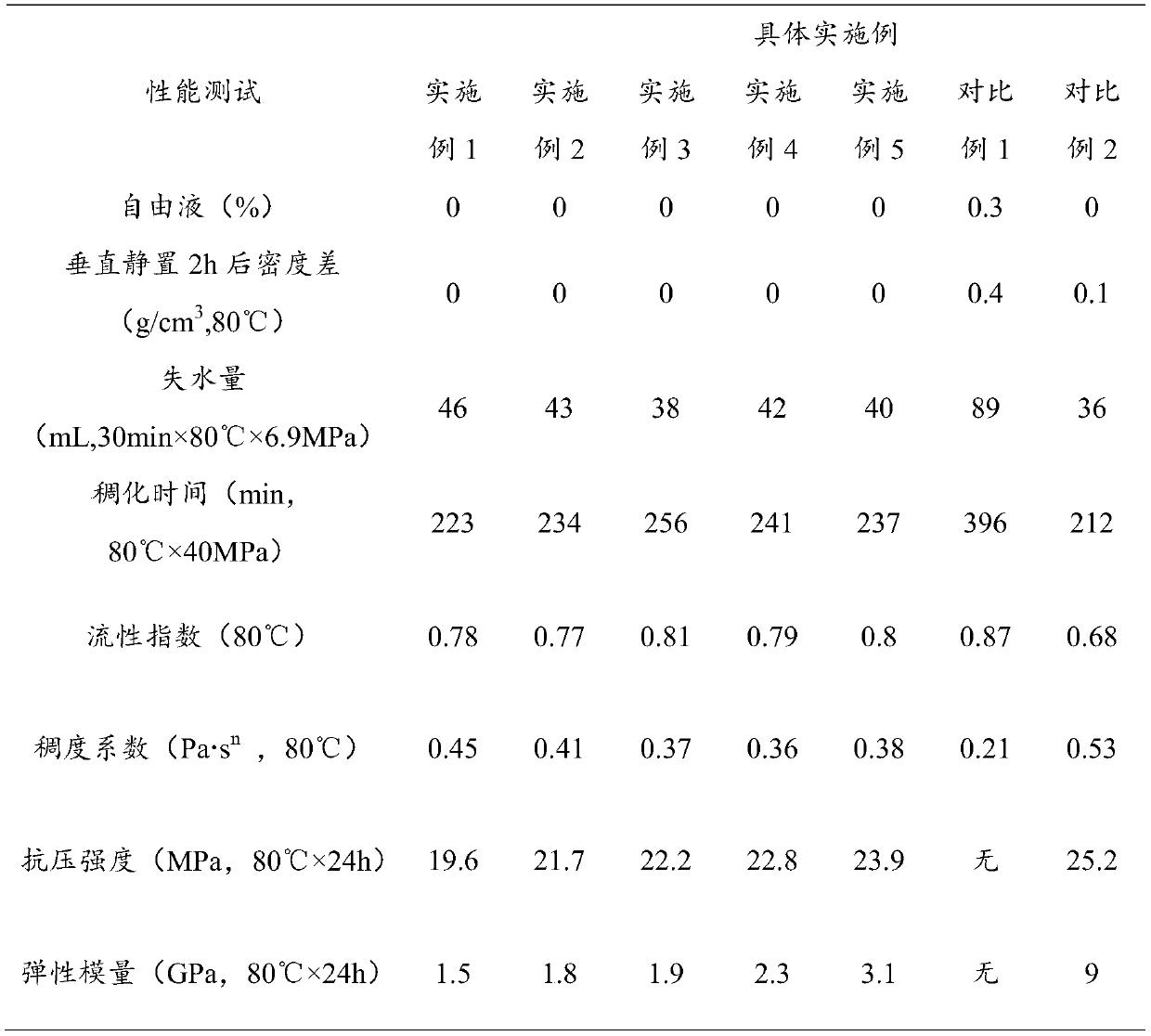

The invention discloses elastic modified resin for oil well cement. The elastic modified resin comprises the following raw materials in parts by weight: 100 parts of an epoxy resin-based solution and10-25 parts of an epoxy resin curing agent. The invention further discloses well cementation cement paste. The ell cementation cement paste comprises the following raw material s in parts by weight: 100 parts of cement, 36-44 parts of fresh water, 3-6 parts of a fluid loss agent, 0.1-0.6 part of a dispersing agent, 1-4 parts of an early strength agent, 2-5 parts of a reinforcing agent, 0.2-0.6 part of a retarder, 0.5-1.5 parts of a defoaming agent and 20-50 parts of elastic modified resin. According to the invention, the elastic modified resin is used as an admixture functional material for oil well cement and is mixed with the oil well cement for use, so the damage resistance of a cement sheath is enhanced, and the cement paste has the advantages of good stability, no sedimentation phenomenon, good fluidity, adjustable thickening time and low water loss, and meets the requirements of cementing construction operation.

Owner:YANGTZE UNIVERSITY +1

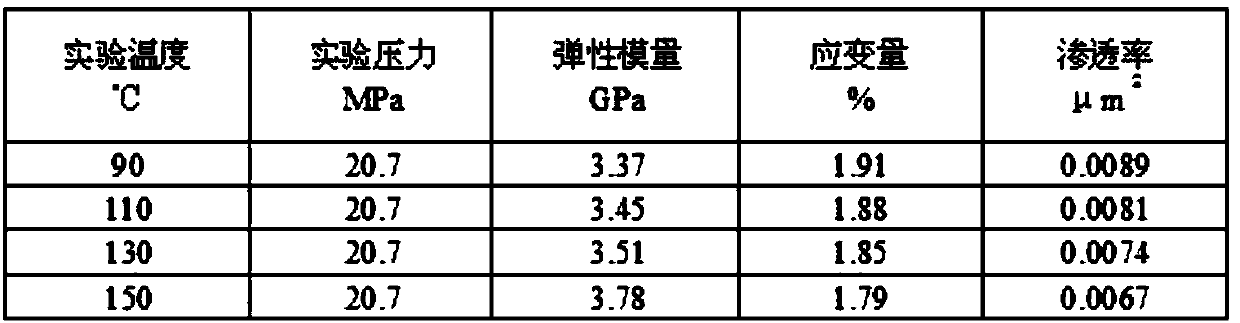

Endogenous toughened corrosion-resistant cement mortar system

ActiveCN105967600AGood settlement stabilityReduce water lossDrilling compositionPorosityPolyvinyl alcohol

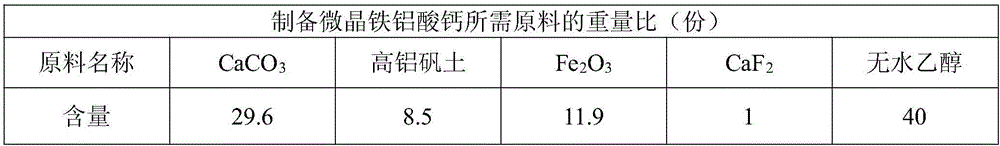

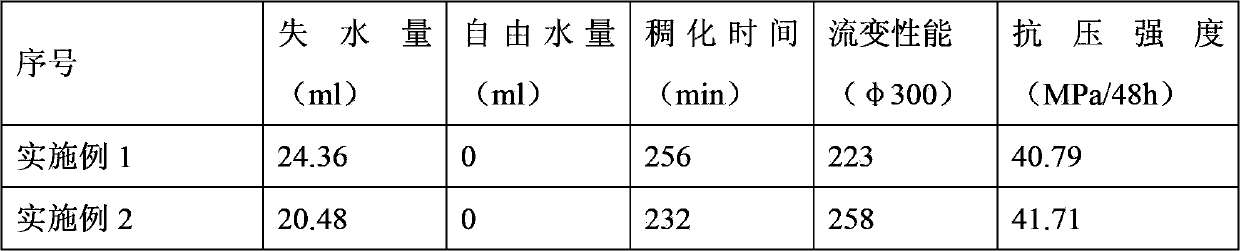

The invention discloses an endogenous toughened corrosion-resistant cement mortar system which is composed of the following components in parts by weight: 100 parts of high-sulfate-resistance Grade-G oil well cement, 5-35 parts of microcrystal calcium aluminoferrite, 0-25 parts of micro silicon, 1.0-4.5 parts of water-loss control agent, 0.5-3.0 parts of dispersing agent, 0.2-3.0 parts of thickening time control agent and 44-80 parts of water. The microcrystal calcium aluminoferrite is prepared by high-temperature calcination and shock cooling. The micro silicon is a density regulator. The water-loss control agent is polyvinyl alcohol, polyacrylamide or carboxymethyl cellulose. The dispersing agent is sodium hexametaphosphate, melamine formaldehyde resin, sodium lignosulfonate or methyl cellulose. The thickening time control agent is boric acid, gypsum, sodium borate or a mixture thereof. The endogenous toughened corrosion-resistant cement mortar system has the advantages of excellent impact resistance, higher compression strength, high volume stability and small changes of porosity and permeability, has important meanings for ensuring safe and efficient development of shale gas, and thus, has broad market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

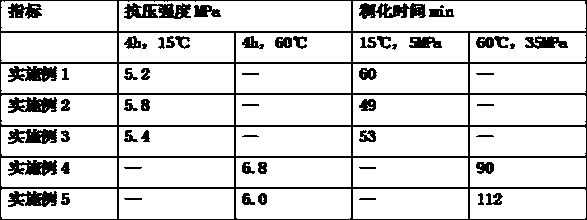

Frozen ground region negative-temperature well cementation cement slurry, preparation method and applications thereof

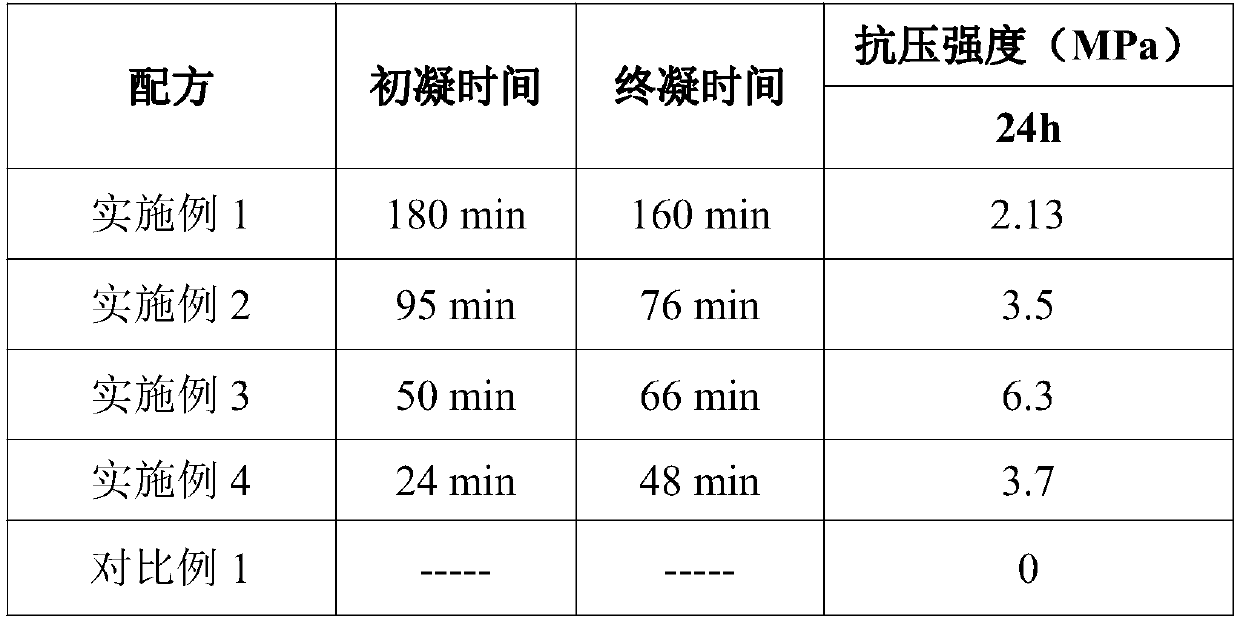

ActiveCN110668765AIncreased hydration rateIncrease the speed of negative temperature hydrationDrilling compositionAluminateCompressive resistance

The invention relates to the technical field of oil field well cementation, particularly to a frozen ground region negative-temperature well cementation cement slurry, a preparation method and applications thereof, wherein the frozen ground region negative-temperature well cementation cement slurry comprises, by weight, 100 parts of modified aluminate cement, 6-15 parts of a negative-temperature anti-freezing early strength agent, 0.05-3 parts of an alcohol-ammonia coagulant, 40-44 parts of water, 0-5 parts of a light metal expanding agent and 0-6 parts of a non-ionic polymer fluid loss agent.According to the invention, the frozen ground region negative-temperature well cementation cement slurry is good in rheological property, can be cured within 3 h at a temperature of -18 DEG C, has a24-h compressive strength of up to 6 MPa, can effectively solve the problems that cement is not cured and has no strength, the well cementation quality of the low-temperature frozen ground region is poor, and even well cementation operation cannot be completely conducted due to liquid-phase segregation ice condensation of the conventional cement slurry in a negative temperature environment, and meets the well cementation construction requirements of frozen ground regions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Well-cementing and self-healing cement slurry for oil-gas field

The invention relates to well-cementing and self-healing cement slurry for an oil-gas field, which is suitable for the field of oil well cementation. The well-cementing and self-healing cement slurry comprises the following additives percentage by weight: 2-4% of fluid loss agent, 5-40% of self-healing component, 0.2-1.0% of stabilizing agent, 0.5-2.0% of dispersing agent, 0.3-1.0% of de-foaming agent, and 0.03-0.5% of retarding agent by taking the weight of cement as benchmark. A preparation method of the well-cementing and self-healing cement slurry is as follows: controlling the water cement ratio to be 0.44, uniformly mixing the additives at a low shearing speed, weighing a certain amount of cement, adding into slurry preparation liquid, and mixing with API (American petroleum institute) standards to obtain the well-cementing and self-healing cement slurry. The well-cementing and self-healing cement slurry has the characteristics of low water loss, adjustable thickening time, gas channeling prevention and excellent impervious performance and the like, has the functions of crack prevention and self healing, and remarkably improves the mechanical property of the cement.

Owner:古莱特科技股份有限公司

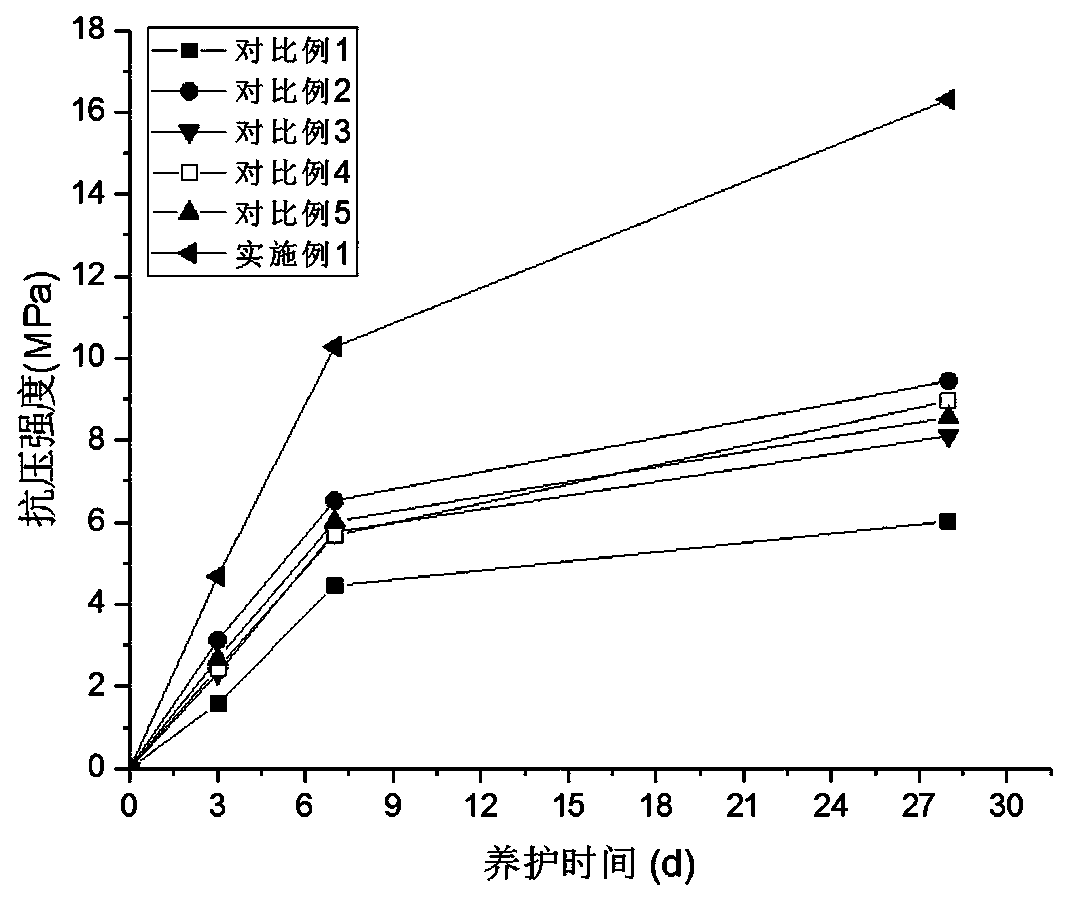

Ultrahigh-strength tough cement paste system for well cementation as well as preparation and application thereof

The invention provides an ultrahigh-strength tough cement slurry system for well cementation and preparation and application thereof. The ultrahigh-strength tough cement slurry system for well cementation comprises the following raw materials: 100 parts by weight of cement, 20-40 parts by weight of a high-temperature reinforcing material, 0.5-6 parts by weight of an inorganic toughening material, 0.5-4 parts by weight of a suspension stabilizer, 2-6 parts by weight of micro silicon, 0.5-1.5 parts of a dispersing agent, 2-6 parts of a fluid loss agent, 1-8 parts of a retarder, 0.2-1 part of a defoaming agent and 40-60 parts of clear water. The cement paste system is good in flowability and sedimentation stability, low in water loss, adjustable in thickening time and wide in adaptive temperature range; the set cement has the characteristics of ultrahigh strength and the like, well cementation requirements of deep shale gas, high-temperature deep wells and the like can be well met, set cement strength decline caused by high-temperature strength can be avoided, and the service lifetime of an oil-gas well can be further prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

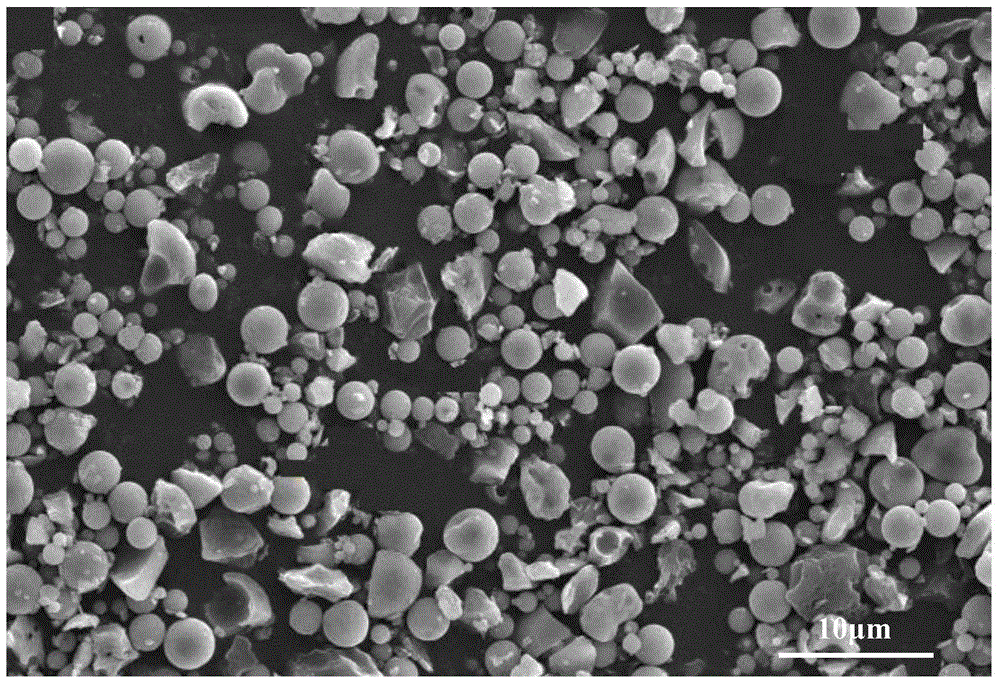

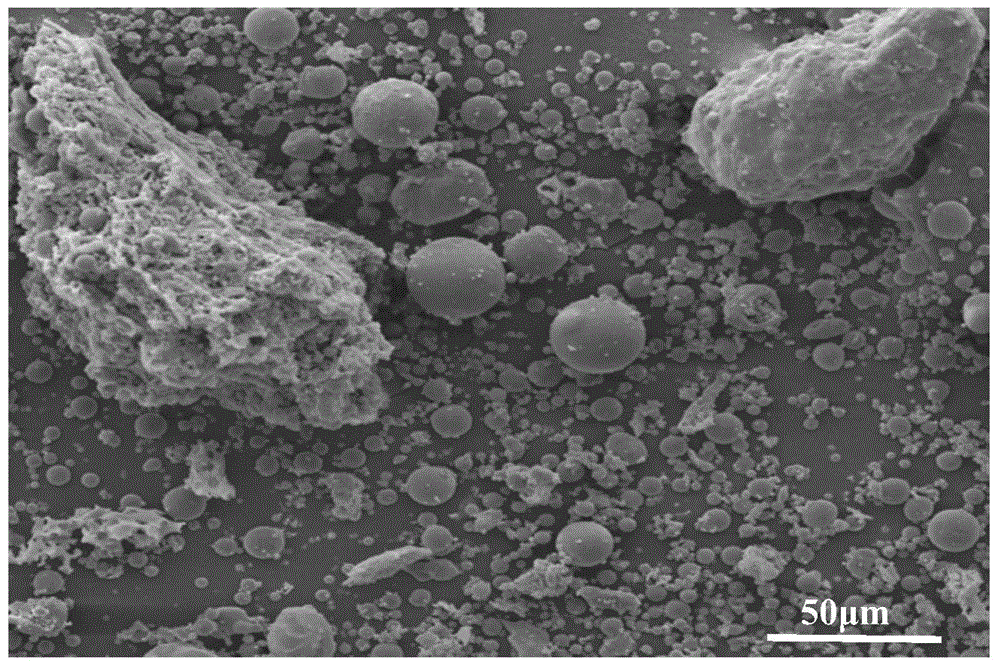

Composite lightening material for well cementation, preparation method of composite lightening material, deep well composite cement paste and application of composite cement paste

ActiveCN104419391ASimple manufacturing processImprove pressure bearing capacityDrilling compositionSealing/packingWell cementingCement paste

The invention discloses a composite lightening material which comprises the following components in parts by weight: 100 parts of coal ash, 10-15 parts of expanding materials and 5-10 parts of toughening materials, wherein the particle size range of the coal ash is 5-10 microns. The invention also relates to a preparation method of the composite lightening material, and the preparation method comprises the following steps: i) carrying out smashing and ball milling on the coal ash through an overhang roll mill, classifying the smashed and ball-milled coal ash through a classifier, and collecting the coal ash with the particle size range of 5-10 microns after the classification to obtain modified coal ash; and ii) mixing the modified coal ash obtained in the step i) with the expanding materials and the toughening materials according to the proportion so as to obtain the composite lightening material. Meanwhile, the invention also discloses deep well composite cement paste and an application of the composite cement paste in well cementing of oil / gas wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

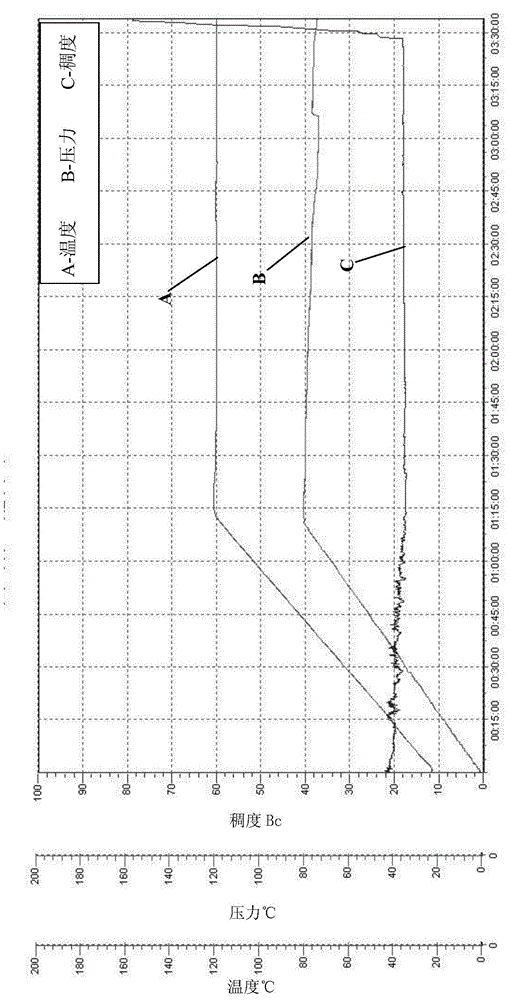

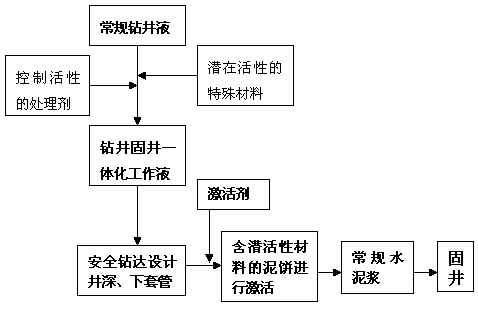

Drilling and solidifying integrated working fluid for improving two-interface cementation quality, and application method thereof

PendingCN110257027AAvoid secondary pollutionFavorable protectionFlushingDrilling compositionWorking fluidContinuous integration

The invention discloses a drilling and solidifying integrated working fluid for improving two-interface cementation quality, and an application method thereof, wherein the integrated working fluid comprises, by weight, 100 parts of a drilling fluid, 5-15 parts of a composite latent active cementing material, a suitable amount of a pH value adjuster for controlling the pH value of the integrated working fluid at 7-11 during drilling, and a suitable amount of an alkaline activator for controlling the pH value of the integrated working fluid at more than 12 during well cementing. According to the present invention, the mud cake formed by the drilling fluid and the solidified body of the cell cementing fluid are converted into the continuous integration by the high-strength active material, wherein the continuous integration is the drilling fluid during the drilling, and the mud cake containing the latent active material can be activated and solidified under the activation of the activator after the drilling is completed and the bushing is arranged so as to eliminate the sandwich cake effect and effectively improve the two-interface cementation quality; and the remaining drilling fluid after the completion of the well cementing can be solidified in situ, and the drilling and cementing integrated technology meets the drilling requirements of well depth of 5000 m, temperature of 150 DEG C and formation pressure of 2.0 g / cm<3>.

Owner:胜利油田胜华实业有限责任公司 +1

Modified polybenzimidazole fiber reinforcement cement paste system

ActiveCN108793900AGood chemical stabilityAvoid the disadvantages of failureFibre typesUltrasonic/sonic fibre treatmentFiberTemperature resistance

The invention discloses a modified polybenzimidazole fiber reinforcement cement paste system. The system comprises the following components in parts by weight: 100 parts of high sulfate resistance grade-G oil well cement, 0.2 to 3.0 parts of modified polybenzimidazole fiber, 0 to 40 pars of quartz sand, 0.5 to 2.5 parts of a dispersant, 1.0 to 6.0 parts of a fluid loss agent, 0.2 to 3.0 parts of aretarder, and 38 to 70 parts of water. The modified polybenzimidazole fiber is performed by performing surface modification on the polybenzimidazole fiber as follows: firstly, performing oxidation treatment on the polybenzimidazole fiber, then, performing low temperature plasma treatment on the polybenzimidazole fiber, and finally, performing coupling treatment on the polybenzimidazole fiber. Feinforcement cement paste has the characteristics of high tensile strength, breaking strength and low elasticity modulus, the modified polybenzimidazole fiber is high in temperature resistance capacityand good in dispersibility in cement paste, set cement is excellent in mechanical property, and the system has important application value for improving the cementing quality of high temperature deepwells and shale gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

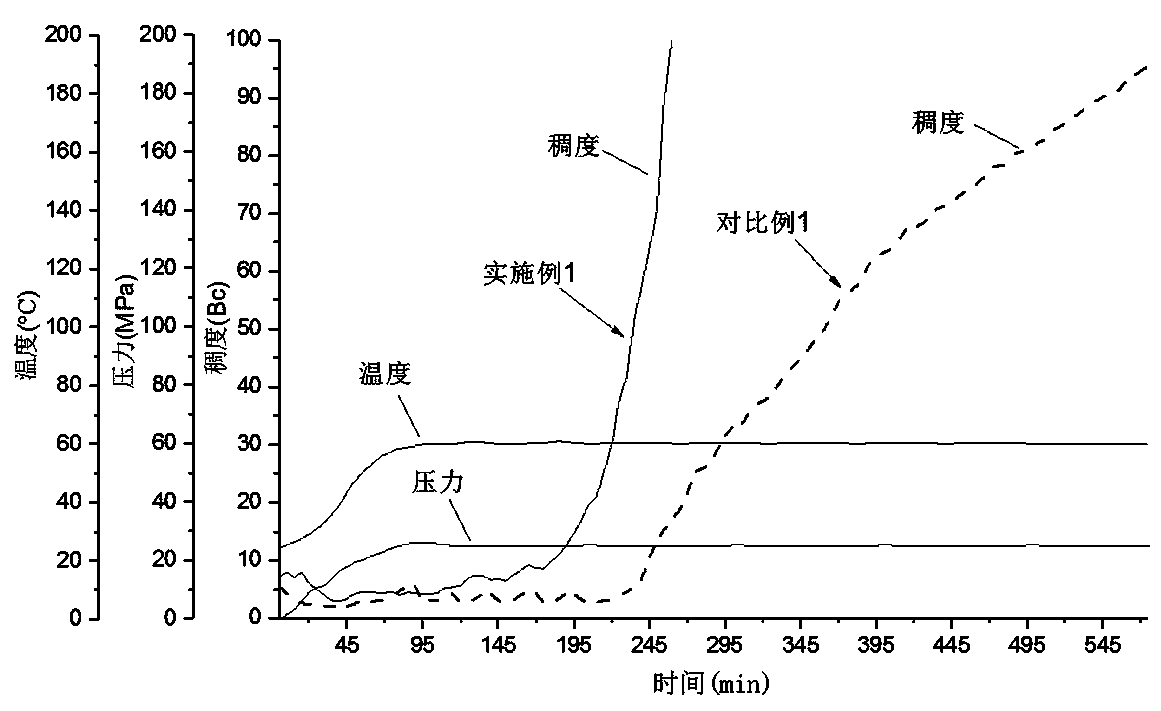

High temperature resistant toughening retarder

ActiveCN103396775AThickening time adjustableGood settlement stabilityDrilling compositionBoric acidMechanical property

The invention discloses a high temperature resistant toughening retarder. A preparation method of the high temperature resistant toughening retarder comprises the following steps of: (1) smashing sepiolite, soaking by water, stirring and clarifying, then filtering, washing, drying, smashing, levigating and screening; adding the sepiolite powder into a nitric acid, sulfuric acid or hydrochloric acid solution, stirring for 3-8 hours, then washing with deionized water to be neutral, and filtering; roasting for 2-4 hours at 100-200 DEG C, and then calcining for 2-3 hours at 600 DEG C; (2) uniformly mixing borax and boric acid at a mass ratio of 1.2-4:6-8.8, slowly pouring into water, and stirring for 5-15 minutes; (3) adding the processed sepiolite into the mixed solution of borax and boric acid, stirring for 2-4 hours so as to prepare the mixed liquor of sepiolite, boric acid and borax; (4) spray-drying. According to the high temperature resistant toughening retarder, components with delayed coagulation effect are released slowly, and the sensitive degree of cement to the retarder is lowered, so that set cement has good mechanical property at low temperature, and also can play a delayed coagulation role at high temperature without affecting the mechanical property.

Owner:SOUTHWEST PETROLEUM UNIV

Low-temperature high-strength oil-gas well plugging agent

InactiveCN111363527ARapid increase in intensityExcellent water impact resistanceDrilling compositionAqueous solubilityCalcium carbonate

The invention discloses a low-temperature high-strength oil-gas well plugging agent, and relates to the technical field of petroleum drilling materials. The low-temperature high-strength oil-gas wellplugging agent is prepared from the following raw materials in percentage by mass: 70 to 90 percent of an inorganic gel material, 0 to 0.5 percent of a fiber toughening agent, 1 to 20 percent of a filling material, 1 to 5 percent of an expanding agent, 0.1 to 0.3 percent of a flocculating agent and 0.05 to 0.2 percent of a retarder, wherein the inorganic gel material is sulphoaluminate cement, thefiber length of the fiber toughening agent is less than 12cm, the filling material is calcium carbonate powder and the retarder is a composition of boric acid and D-sodium gluconate. The sulphoaluminate clinker, the active admixture, the water-soluble organic material and other raw materials are adopted, so that the plugging agent has the characteristics of high hour strength development speed, high underwater impact resistance, high acid solubility and good thixotropic property at 10-60 DEG C under a specific ratio, and the plugging purpose is achieved by utilizing the characteristics of theplugging agent.

Owner:JIAHUA SPECIAL CEMENT

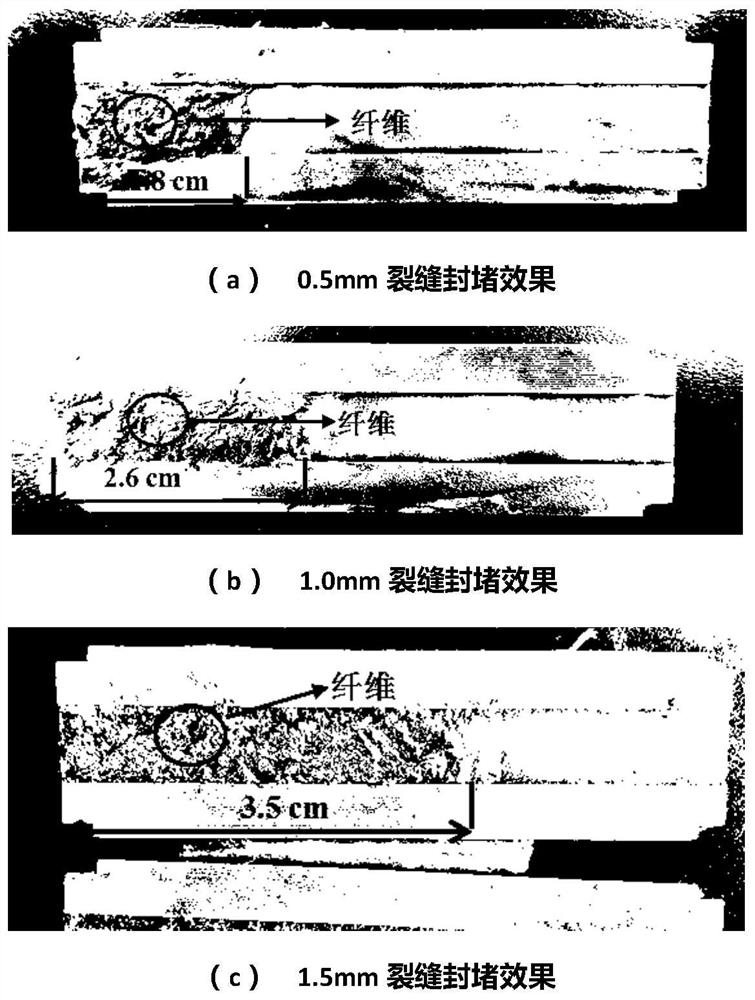

Well cementing cement paste suitable for coal bed methane and preparation method thereof

InactiveCN112456873AIncrease fiber loadingHigh impact strengthSolid waste managementDrilling compositionFiberPhysical chemistry

The invention provides well cementing cement paste suitable for coal bed methane. Compared with the prior art, a multi-size-fraction leaking stoppage material, an active filler and a resin material are added into the cement paste to form a leaking stoppage type cement paste system, in the multi-size-fraction leaking stoppage material, the first-stage particle leaking stoppage material serves as asupporting material, and the bridging effect can be achieved to support cracks; gaps are filled with a second-stage particle leaking stoppage material, cement particles and the like to form a leakingstoppage frame, and a hydrophilic fiber leaking stoppage material can form a fiber grid structure in a crack, so that the stability of a cement paste leaking stoppage structure is improved; a resin cementing material is used for further enhancing the mutual cementing among the crack surface, the leaking stoppage material and the cement; therefore, the compactness of the leaking stoppage structureis improved through multistage filling of the bridges, the elasticity, the nano materials and the cement particles, and meanwhile, the addition amounts of the modified multi-size-fraction leaking stoppage material, the active filler and the resin material are adjusted, so that the combined action of the modified multi-size-fraction leaking stoppage material, the active filler and the resin material has a remarkable synergistic effect on the leaking stoppage performance of the cement paste.

Owner:CHINA UNITED COALBED METHANE +1

Low temperature magnesium oxysulfide thermosetting resin cementitious system and preparation method thereof

InactiveCN109536144AHigh strengthEasy to adjust the densityDrilling compositionSlurryMaterials science

The invention relates to a low temperature magnesium oxysulfide thermosetting resin cementitious system and a preparation method thereof, and relates to the field of oil-gas well cementing. The low temperature magnesium oxysulfide thermosetting resin cementitious system has good slurry rheological property and is prone to well cementing construction. By use of a thermosetting resin cementitious material, the elasticity modulus of a consolidator can be effectively reduced, the elasticity of the consolidator is increased, and the impact resistance is improved. The density, rheology, curing time,consolidator strength and other properties of the thermosetting resin system can be further improved or controlled by cooperative use with a magnesium oxysulfide skeleton material. With use of good cementing properties of thermosetting resin, magnesium oxysulfide and metals and the expansion characteristics of magnesium oxide, the cementing strength of a first interface and a second interface canbe improved. While the basic requirements of well cementing engineering are met, the problems of vulnerability and poor cementing of oil well cement can also be solved, and the related shortcomings of oil well cement are overcome. The low temperature magnesium oxysulfide thermosetting resin cementitious system provides a new choice for the field and has broad application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

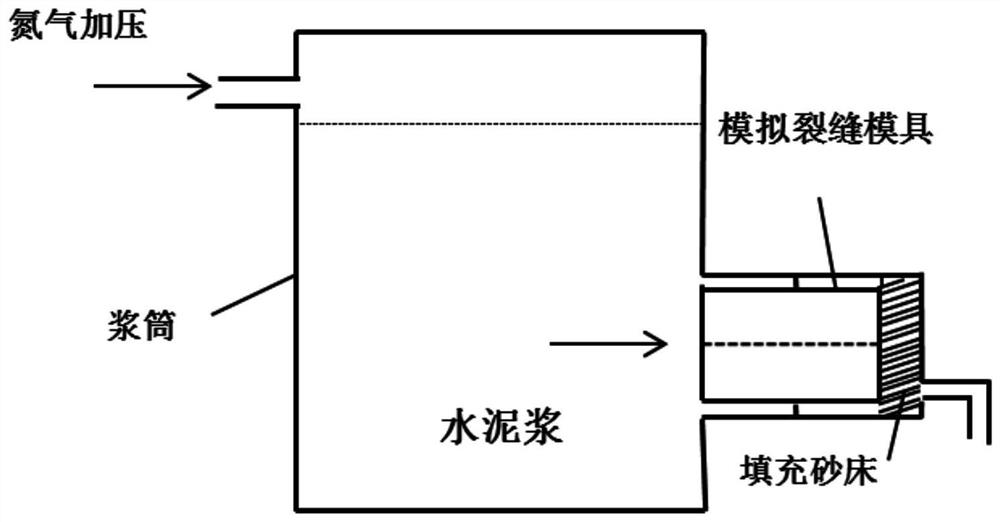

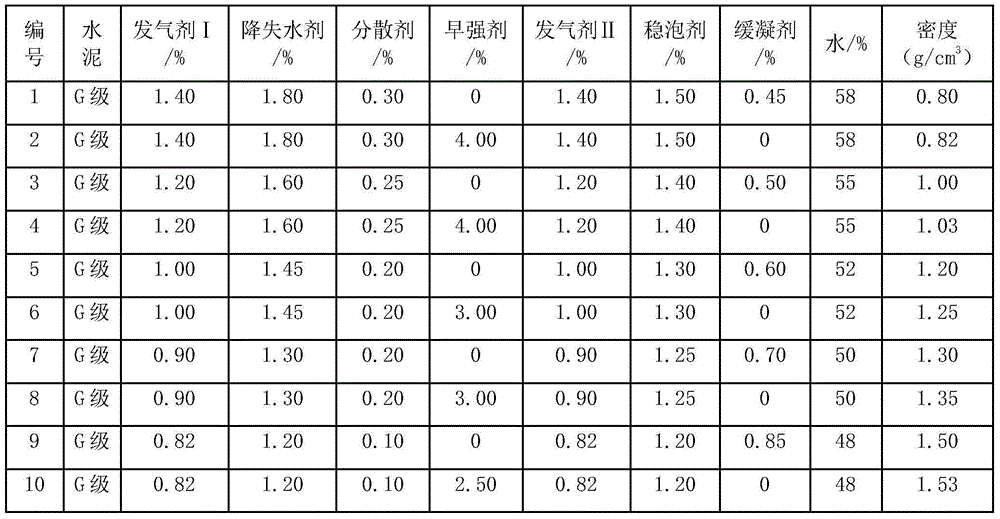

Foam cement slurry system and composition

ActiveCN103525387BFast dissolutionHigh nitrogen rateDrilling compositionCeramicwareFoaming agentNitrogen

The invention provides a novel chemical nitrogen-charge foam cement slurry, mainly solves the problems that the density is high and the stability is poor in a conventional chemical nitrogen-charge foam cement slurry, and is applicable to the field of oil and gas well cementing. The novel chemical nitrogen-charge foam cement slurry system comprises the components in parts by weight as follows: 100 parts of oil well cement, 0.5-2.0 parts of a foaming agent I, 0.5-2.0 parts of a foaming agent II, 0.7-2.5 parts of a foam stabilizing agent, 1.0-10 parts of a fluid loss agent, 1.0-1.5 parts of powder, 0.3-1.0 part of a retarder, 1.0-4.0 parts of an early strength agent and 48-70 parts of water. The density of the chemical nitrogen-charge foam cement slurry can be adjusted in a range of 0.80-1.50 g / cm <3>, the slurry is applicable to oil and gas well cementing operations in a range of 10-95 GEG C and has the advantages of simple site operation and foam cement cost reduction, the problems of low pressure leakiness and formation cementing leakage can be effectively solved, pollution of the cement slurry to an oil and gas production layer is reduced, and the application prospect is wide.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of retarder used for oil gas well cementing operation, retarder and application

PendingCN107814876AAvoid induced decompositionDecomposition rate is stableDrilling compositionIonChemistry

The invention discloses a preparation method of a retarder used for oil gas well cementing operation, the retarder and an application. The preparation method comprises the following steps: (1) adding2-acrylamido-2-sodium methallyl sulfonate into deionized water and stirring to dissolve, wherein the use amount of the deionized water is 1-3 times of 2-acrylamido-2-sodium methallyl sulfonate; addingan NaOH solution to regulate the pH value of the system to 9-12; (2) adding itaconic acid to the solution obtained in the step (1), heating in thermostatic waterbath till reaching 40-60 DEG C, and keeping for 10-30min, wherein the mass ratio of 2-acrylamido-2-sodium methallyl sulfonate to itaconic acid is (73-75):(25-27); (3) slowly dripping an initiator solution to the solution obtained in step(2); slowly heating to 50-90 DEG C while dripping, and continuing reaction for 2-5h after dripping is completed, so as to obtain a liquid product; and (4) participating by alcohol, drying and smashingthe liquid product obtained in step (3) so as to obtain a product which is white powder. The retarder is small in adding amount, high in application temperature and large in temperature resistant scope span.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com