Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Polybenzimidazole fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

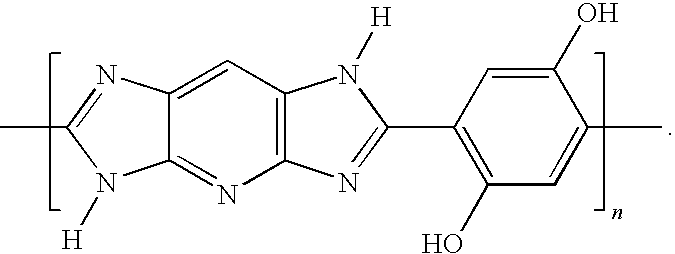

Polybenzimidazole (PBI, short for poly[2,2’-(m-phenylen)-5,5’-bisbenzimidazole]) fiber is a synthetic fiber with a very high decomposition temperature and doesn't exhibit a melting point. It has exceptional thermal and chemical stability and does not readily ignite. It was first discovered by American polymer chemist Carl Shipp Marvel in the pursuit of new materials with superior stability, retention of stiffness, toughness at elevated temperature. Due to its high stability, polybenzimidazole is used to fabricate high-performance protective apparel such as firefighter's gear, astronaut space suits, high temperature protective gloves, welders’ apparel and aircraft wall fabrics. Polybenzimidazole has been applied as a membrane in fuel cells.

Fabric for protective garments

ActiveUS20060035553A1Specific weightImproves the wearer's comfortSynthetic resin layered productsMulti-ply fabricsCarbon fibersMetal fibers

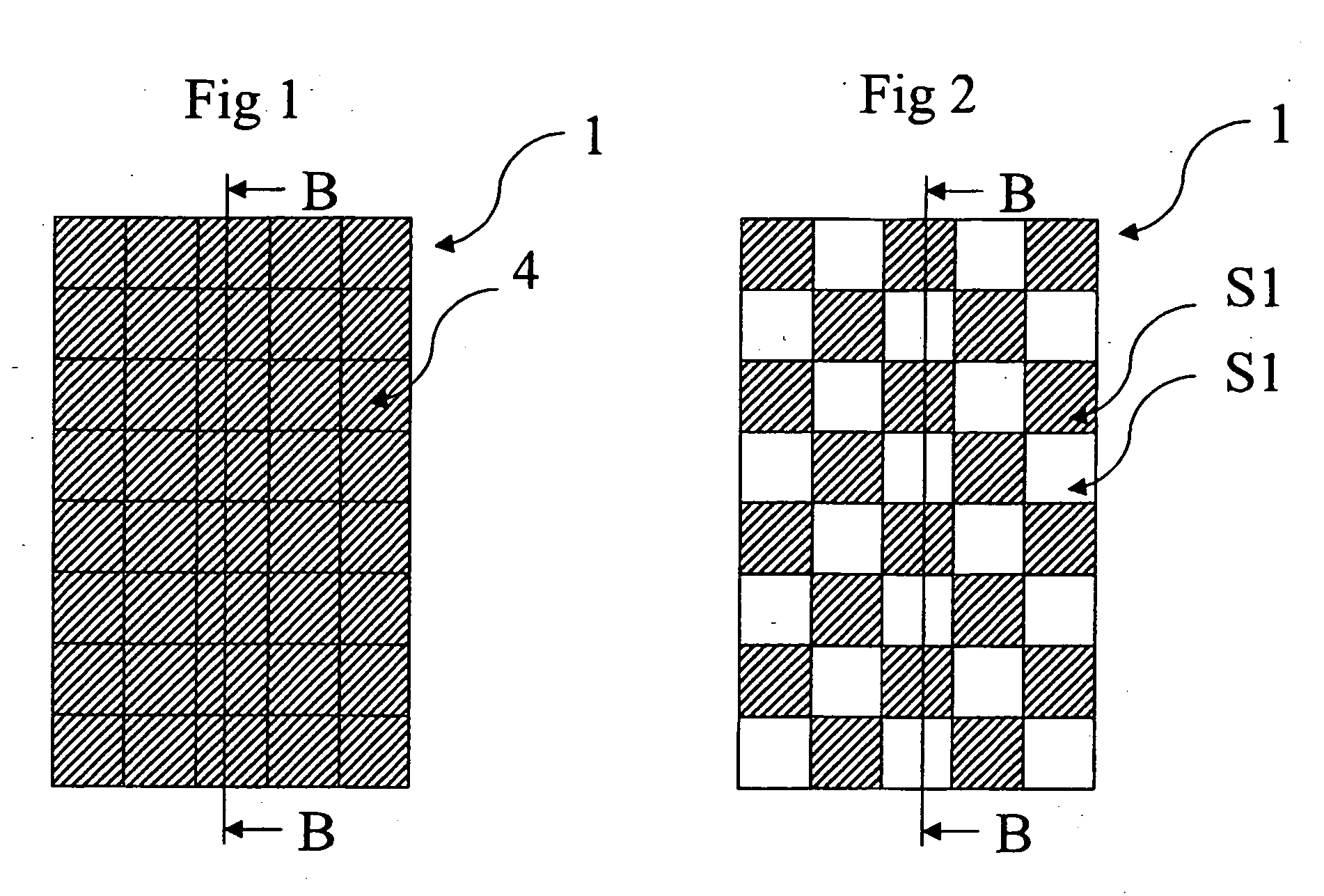

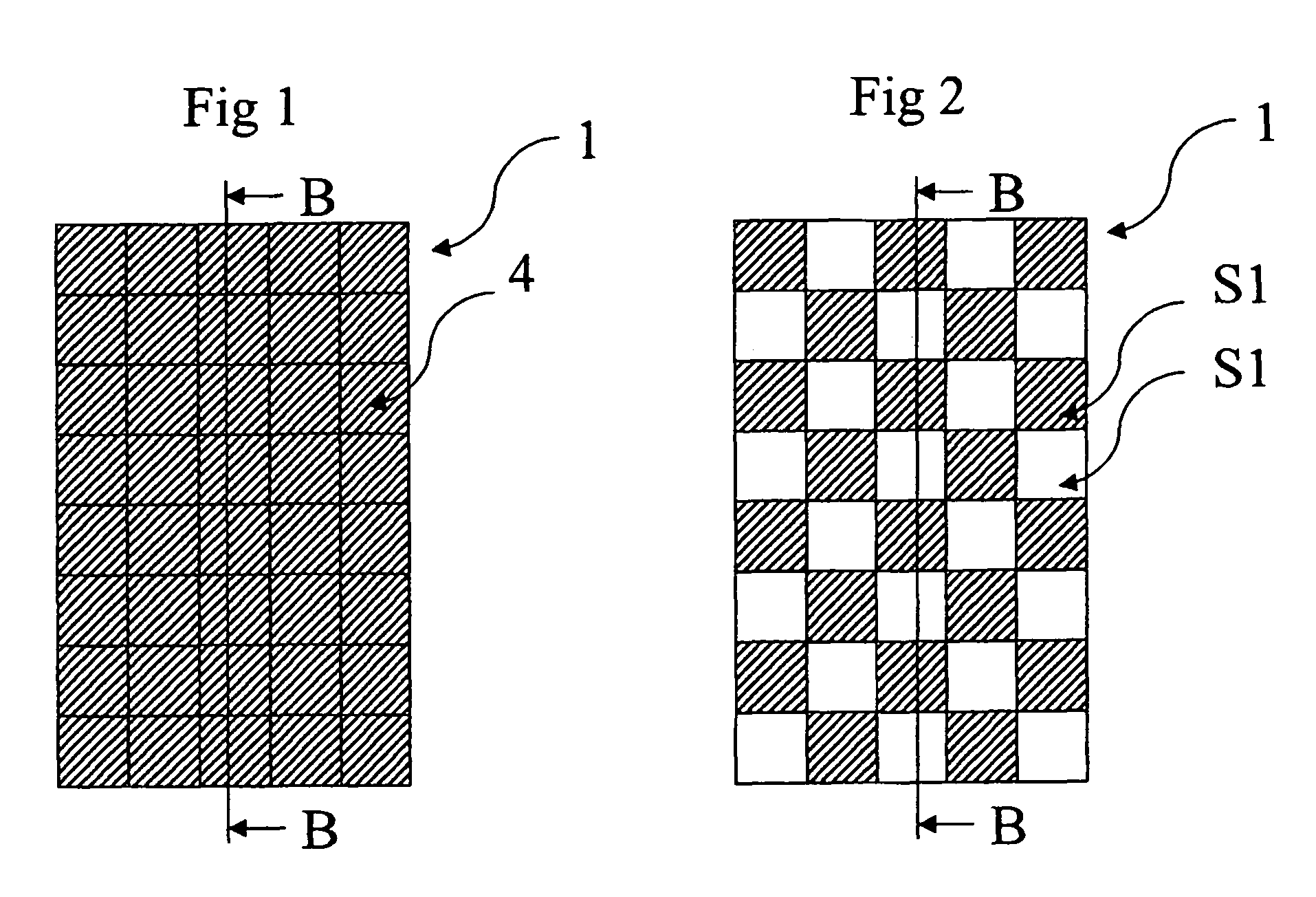

The present invention relates to a heat, flame, and electric arc resistant fabric (1) for use as single or outer layer of protective garments. The fabric (1) of the invention comprises at least two separate single plies which are assembled together at predefined positions so as to build pockets (4). The fabric (1) of the invention is made of materials independently chosen from the group consisting of aramid fibers and filaments, polybenzimidazol fibers and filaments, polyamidimid fibers and filaments, poly(paraphephenylene benzobisaxazole) fibers and filaments, phenol-formaldehyde fibers and filaments, melamine fibers and filaments, natural fibers and filaments, synthetic fibers and filaments, artificial fibers and filaments, glass fibers and filaments, carbon fibers and filaments, metal fibers and filaments, and composites thereof. Due to its peculiar structure, the fabric (1) according to the present invention can have a specific weight which is considerably lower than that of known fabrics having comparable mechanical and thermal properties.

Owner:DUPONT SAFETY & CONSTR INC

Fabric for protective garments

ActiveUS7932194B2Specific weightImproves the wearer's comfortSynthetic resin layered productsMulti-ply fabricsCarbon fibersMetal fibers

Owner:DUPONT SAFETY & CONSTR INC

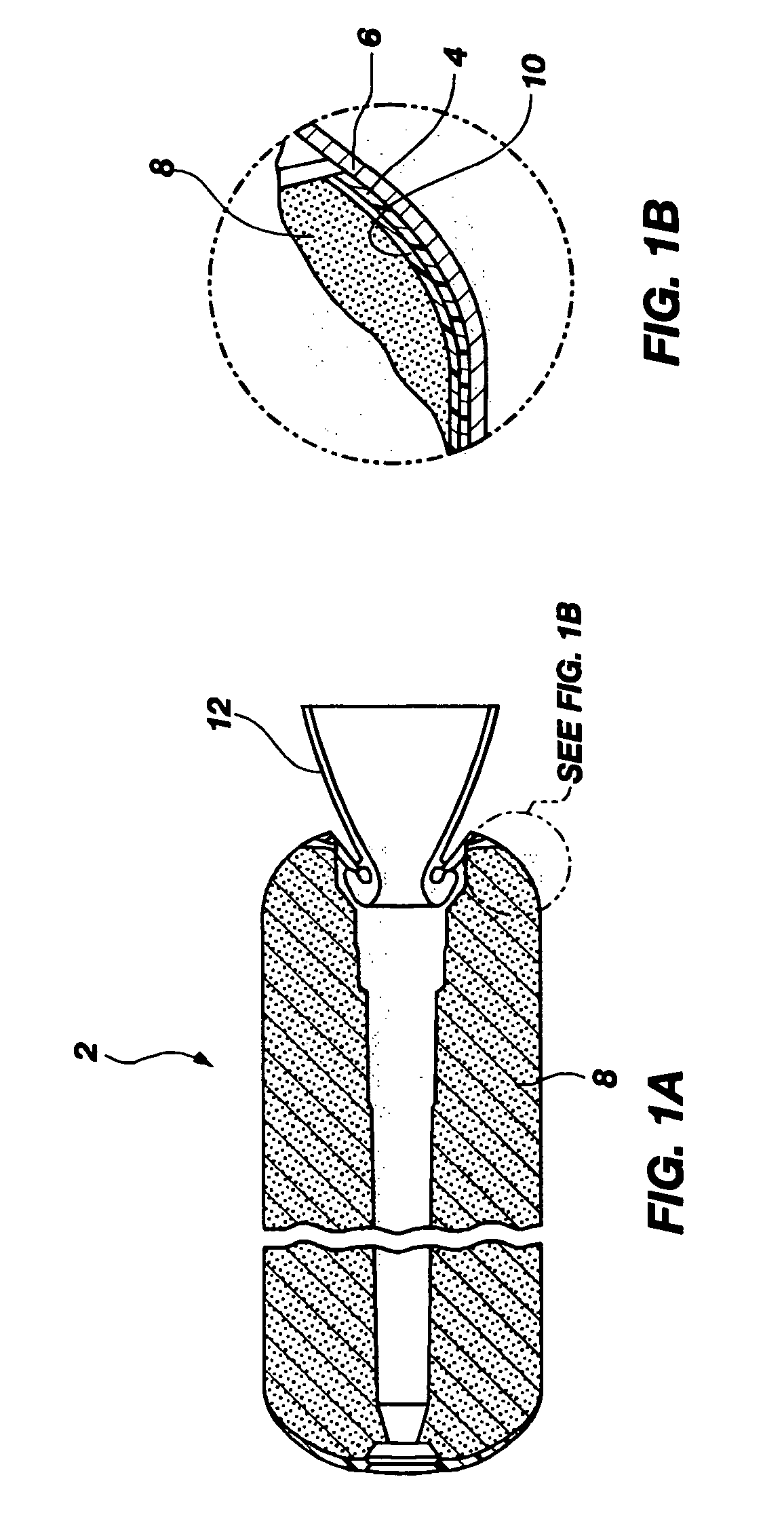

Basalt fiber and nanoclay compositions, articles incorporating the same, and methods of insulating a rocket motor with the same

ActiveUS20070261385A1Other chemical processesRocket engine plantsBasalt fiberPolybenzimidazole fiber

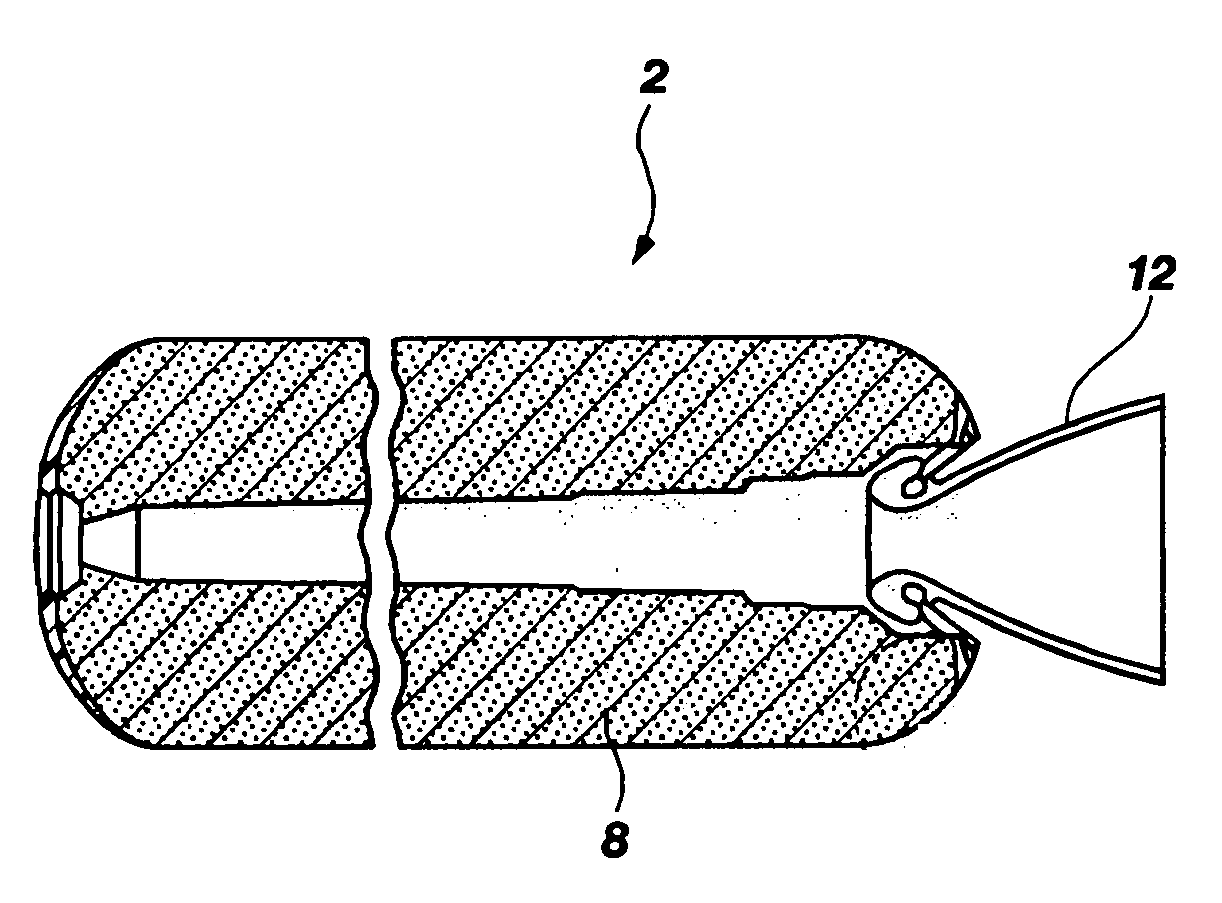

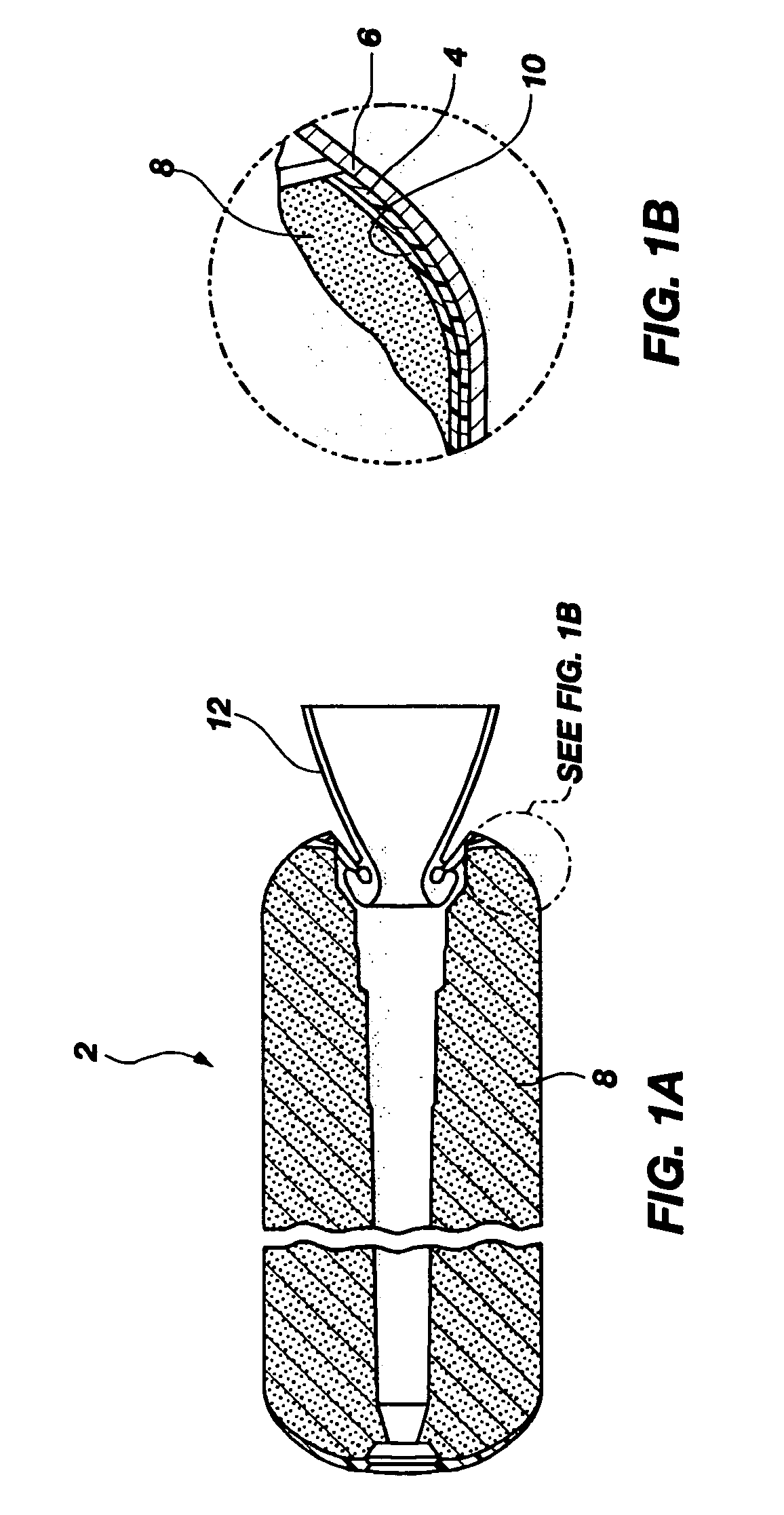

An insulation composition that comprises at least one nitrile butadiene rubber, basalt fibers, and nanoclay is disclosed. Further disclosed is an insulation composition that comprises polybenzimidazole fibers, basalt fibers, and nanoclay. The basalt fibers may be present in the insulation compositions in a range of from approximately 1% by weight to approximately 6% by weight of the total weight of the insulation composition. The nanoclay may be present in the insulation compositions in a range of from approximately 5% by weight to approximately 10% by weight of the total weight of the insulation composition. Rocket motors including the insulation compositions and methods of insulating a rocket motor are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

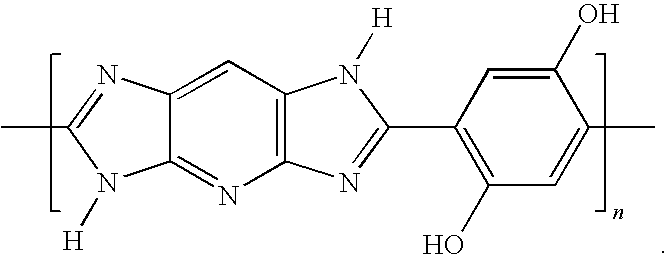

Composite fiber membrane and preparing method and application thereof

ActiveCN106894162AGood dimensional stabilityImprove heat resistanceElectro-spinningNon-woven fabricsFiberNetwork structure

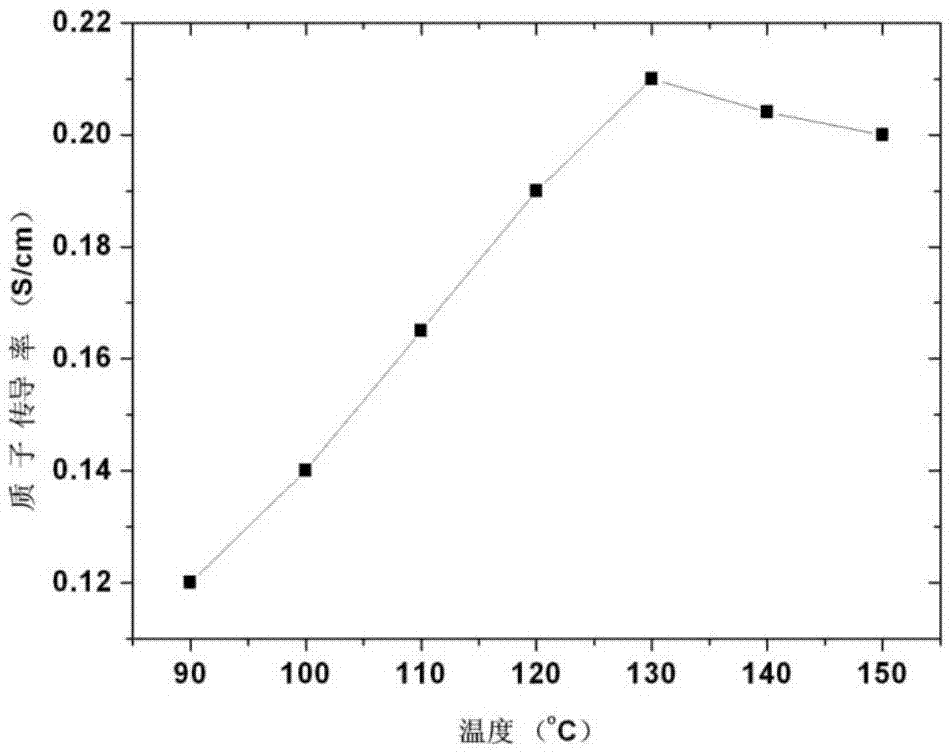

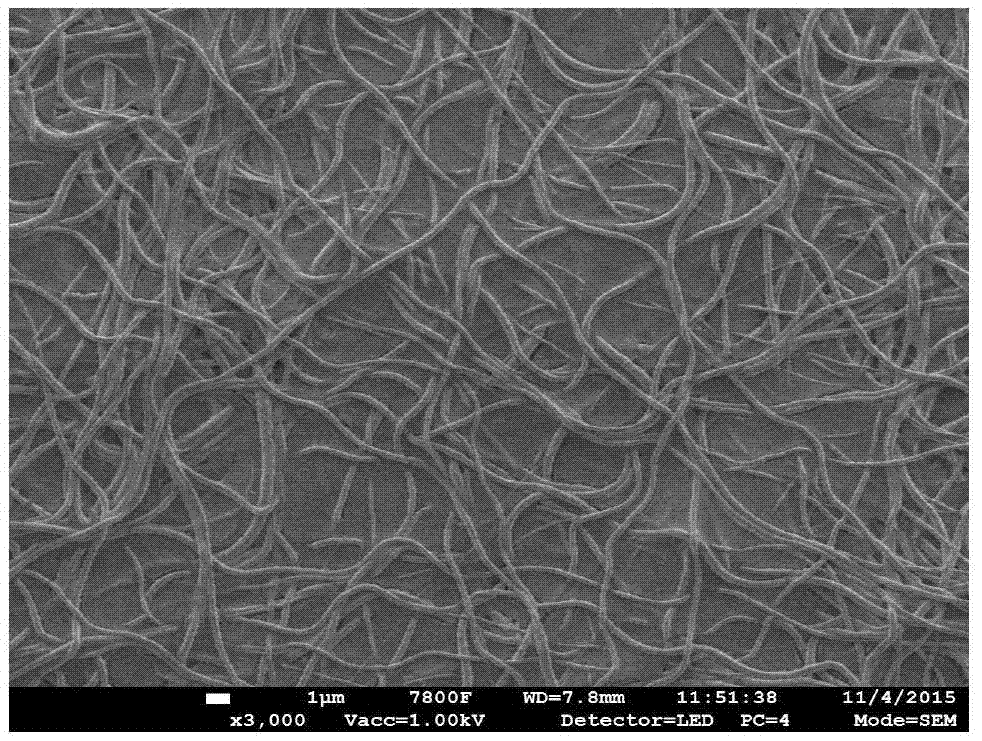

The invention discloses a composite fiber membrane. The composite fiber membrane is formed by one or two above of polybenzimidazole polymerized by one of a PBI unit and one or two above of a supporting polymer; polybenzimidazole fibers and supporting polymer fibers are microscopically of interpenetration interweaving network structures, and nodes are arranged between interwoven fibers; the molecular weight of the polybenzimidazole is 6 ten thousand to 20 ten thousand; the molecular weight of the supporting polymer is 2 ten thousand to 100 ten thousand; the quality content of the supporting polymer in a composite fiber proton exchange membrane is 5 wt.% to 80 wt.%. The proton conduction capacity is provided for PBI by doping phosphoric acid, and when the thickness of an electrolyte membrane is low, and the proton conductivity is high, the proton conduction efficiency is highest. Descending of the mechanical strength of the membrane can be caused when the proton conduction efficiency is improved by adding the doping content of the phosphoric acid and reducing the thickness of the membrane. For solving contradictions between the mechanical strength and the thickness of the membrane, an effective way that the supporting polymer fibers with the good mechanical strength are led into the membrane is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of heat-preservation and heat-insulation tent composite fabric

PendingCN110481105AImprove thermal insulationImprove mechanical propertiesFibre typesSynthetic resin layered productsFiberThermal insulation

The invention relates to a preparation method of a heat-preservation and heat-insulation tent composite fabric, and belongs to the technical field of textile fabrics. Polyimide modified silicon dioxide aerogel is used as a coating, a fabric prepared from polyurethane modified polybenzimidazole fibers is used as base cloth, the coating is coated between the two layers of base cloth, and the heat-preservation and heat-insulation tent composite fabric is prepared through hot pressing and has good weather resistance, flame retardance, water resistance, ultraviolet resistance and other functions. The polybenzimidazole fiber has outstanding high temperature resistance and good waterproof performance; the silicon dioxide aerogel has the obvious characteristics of a nanometer material; good optical performance, sound absorption performance, chemical stability, environmental protection performance and excellent heat preservation and heat insulation performance are realized; polyimide has good mechanical property and flexibility and low thermal conductivity, and the prepared film has good flexibility and can be bent and folded, so that the polyimide modified silicon dioxide aerogel has goodmechanical property and thermal insulation property.

Owner:肖时云

Nano vermiculite modified composite sound absorbing material and preparation method thereof

The invention discloses a nano vermiculite modified composite sound absorbing material. The material is prepared from the following raw materials in parts by weight: 100-120 parts of barite powder, 50-60 parts of ceramsite, 40-50 parts of nano vermiculite, 80-90 parts of polyvinyl acetate emulsion, 55-65 parts of modified tree ashes, 15-20 parts of aluminium hydroxide, 20-30 parts of polybenzimidazole fibers, 10-20 parts of nanocarbon, 20-30 parts of EVA (ethylene-vinyl acetate copolymer), 15-20 parts of CPE (chlorinated polyethylene), 5-10 parts of HIPS (high impact polystyrene), 5-8 parts of diisobutyl phthalate, 4-6 parts of decabromodiphenyl ether, 2-3 parts of zinc stearate and 1-2 parts of tribasic lead sulfate. The material has the beneficial effects that the problem of developing and researching the sound absorbing material urgently is solved and the novel sound absorbing material which meets the requirements, can stand the tests of harsh environments and has the advantages of high tensile strength, high elongation, high breaking strength, good sound absorbing effect and the like is prepared.

Owner:芜湖跃飞新型吸音材料股份有限公司

Basalt fiber and nanoclay compositions, articles incorporating the same, and methods of insulating a rocket motor with the same

An insulation composition that comprises at least one nitrile butadiene rubber, basalt fibers, and nanoclay is disclosed. Further disclosed is an insulation composition that comprises polybenzimidazole fibers, basalt fibers, and nanoclay. The basalt fibers may be present in the insulation compositions in a range of from approximately 1% by weight to approximately 6% by weight of the total weight of the insulation composition. The nanoclay may be present in the insulation compositions in a range of from approximately 5% by weight to approximately 10% by weight of the total weight of the insulation composition. Rocket motors including the insulation compositions and methods of insulating a rocket motor are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

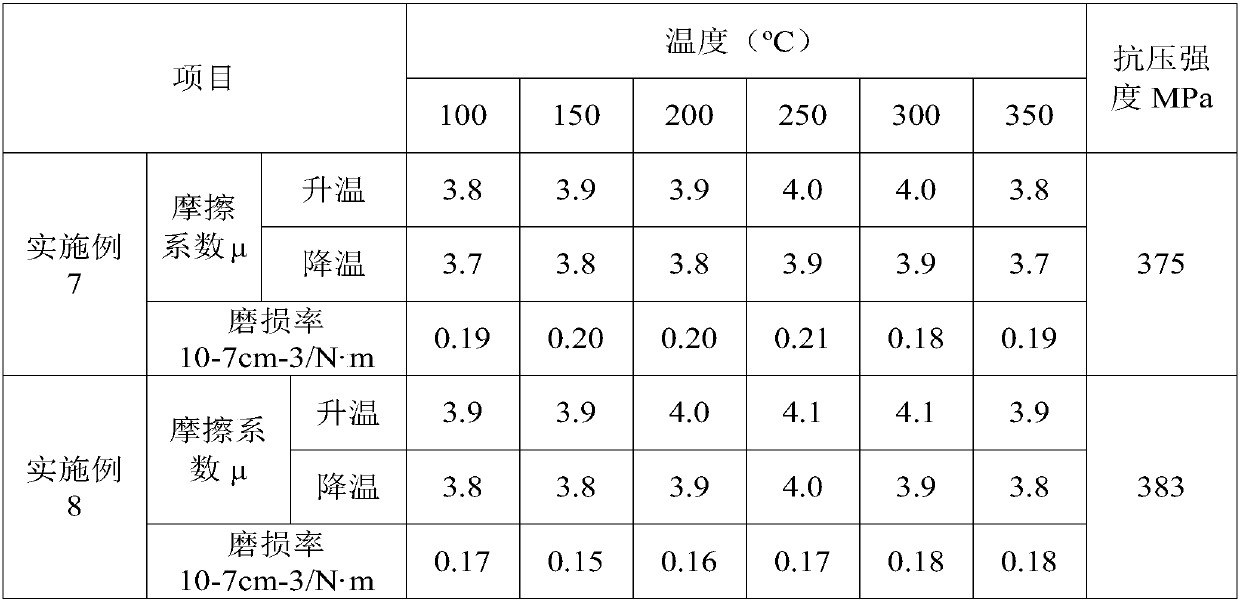

Brake pad friction material composition and preparation method thereof, and brake pad

ActiveCN107676413AGood toughening effectIncrease coefficient of frictionOther chemical processesFriction liningHeat stabilityMullite

Owner:麻莲莲

PET (polyethylene terephthalate) fiber/polybenzimidazole fiber composite sound absorption cotton and preparation method thereof

InactiveCN102978831AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPolymer science

The invention discloses PET (polyethylene terephthalate) fiber / polybenzimidazole fiber composite sound absorption cotton, which comprises the following raw materials in parts by weight: 70-80 parts of PET fiber, 40-50 parts of polybenzimidazole fiber, 10-15 parts of emulsifiers OP-40, 5-10 parts of peregal O-25, 80-100 parts of PP (propene polymer), 30-40 parts of ABS (acrylonitrile butadiene styrene), 15-20 parts of titanium dioxide, 10-15 parts of modified diatomite, 2-3 parts of stearic acid, 5-8 parts of di-iso-octyl sebacate, 4-6 parts of antimonous oxide, 2-3 parts of glyceryl monostearate, 1-2 parts of phenyl triethoxysilane, 2-3 parts of zinc stearate, 1-2 parts of dibasic lead phosphite, 0.5-1.5 parts of anti-aging agents MB, and 1-2 parts of antioxidant 168. The sound absorption cotton prepared by the method has the advantages of excellent appearance evenness, even thickness, soft hand feel, excellent product bonding degree, strong tensile property, excellent sound absorption performance, excellent flame retardant efficiency and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Basalt fiber chenille yarn

The invention discloses basalt fiber chenille yarn which comprises two strands of center yarn and camlet, wherein the camlet is made of basalt fiber or blended yarn formed by the combination of the basalt fiber and one or more of quartz glass fiber, high silica glass fiber, aluminum silicate fiber, polyamide-imide fiber, polyether-ether-ketone fiber, polyphenylene sulfide fiber, polysulfone amide fiber, poly-p-phenylenebenzobisoxazole fiber, polybenzimidazole fiber, polytetrafluoroethylene fiber, polyimide fiber and aramid fiber, and the two strands of center yarn are twisted together to clamp the camlet between the two strands of center yarn. The basalt fiber chenille yarn has the advantages that the basalt fiber is purely inorganic, resistant to high temperature, high in strength, good in heat dissipation performance and air permeability, resistant to mildew and moth, free of static electricity, and capable of restraining the growth of bacteria in an unique way and resisting ultraviolet penetration effectively, and the manufactured basalt chenille yarn is even in yarn levelness, high in spinnability, and soft with the basalt fiber serving as the camlet.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Efficient automobile filter paper and preparation method thereof

InactiveCN102899967AImprove adsorption capacityImprove filtering effectPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberDecabromodiphenyl ether

The invention discloses an efficient automobile filter paper and a preparation method thereof. The efficient automobile filter paper is composed of the following raw materials, by weight: 70-80 parts of softwood pulp, 20-30 parts of polybenzimidazole fiber, 10-20 parts of quartz glass fiber, 2-5 parts of modified bentonite, 1-3 parts of nanometer calcium, 2-4 parts of diatomaceous earth, 1-2 parts of nanometer titania, 0.5-0.8 part of decabromodiphenyl ether, 2-3 parts of modified polyvinyl acetate emulsion, 0.5-1 part of glycerol triglyceride, 0.5-1 part of a silane coupling agent KH550, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of polyethylene imine. The filter paper prepared by the invention has advantages of good water permeability, large filtering area, small maximum pore size, high filtration precision, strong durability, high temperature resistance, high tensile strength and good water resistance, has filtering efficiency reaching 99.99%, stable performance index at room temperature and high temperature, and good temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

Garments Comprising a Flexible High Thermal Performance Outer Shell Fabric of Polybenzimidazole and Polypyridobisimidazole Fibers

This invention concerns a flame-resistant garment having an outer shell fabric comprising 5 to 50 parts by weight of a polypyridobisimidazole fiber having an inherent viscosity of greater than 20 dl / g and 50 to 95 parts by weight of polybenzimidazole fiber.

Owner:EI DU PONT DE NEMOURS & CO

Modified polybenzimidazole fiber reinforcement cement paste system

ActiveCN108793900AGood chemical stabilityAvoid the disadvantages of failureFibre typesUltrasonic/sonic fibre treatmentFiberTemperature resistance

The invention discloses a modified polybenzimidazole fiber reinforcement cement paste system. The system comprises the following components in parts by weight: 100 parts of high sulfate resistance grade-G oil well cement, 0.2 to 3.0 parts of modified polybenzimidazole fiber, 0 to 40 pars of quartz sand, 0.5 to 2.5 parts of a dispersant, 1.0 to 6.0 parts of a fluid loss agent, 0.2 to 3.0 parts of aretarder, and 38 to 70 parts of water. The modified polybenzimidazole fiber is performed by performing surface modification on the polybenzimidazole fiber as follows: firstly, performing oxidation treatment on the polybenzimidazole fiber, then, performing low temperature plasma treatment on the polybenzimidazole fiber, and finally, performing coupling treatment on the polybenzimidazole fiber. Feinforcement cement paste has the characteristics of high tensile strength, breaking strength and low elasticity modulus, the modified polybenzimidazole fiber is high in temperature resistance capacityand good in dispersibility in cement paste, set cement is excellent in mechanical property, and the system has important application value for improving the cementing quality of high temperature deepwells and shale gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Heat-resistant ageing-resistant sound-absorbing cotton and preparation method thereof

InactiveCN105220493AReasonable structureGood sound absorptionFibre typesPolyesterAbsorption capacity

The invention discloses heat-resistant ageing-resistant sound-absorbing cotton. The heat-resistant ageing-resistant sound-absorbing cotton is prepared from, by weight, 40-60 parts of polyester fibers, 5-10 parts of polybenzimidazole fibers, 10-15 parts of poly(m-phenylene isophthalamide)fibers, 10-15 parts of ES fibers, 3-5 parts of ceramic fibers, 0.1-0.2 part of butylated hydroxytoluene, 3-5 parts of spindle oil, 2-4 parts of barite powder, 1-2 parts of silane coupling agents KH-550, 0.2-0.4 part of pentaerythritol oleate and 10-15 parts of composite resin. The sound-absorbing cotton has better full frequency sound absorption capacity, the acoustic property is obvious promoted, good heat resistance and ageing resistance are achieved, the use property is good, the service life is long, the application range is wide, and the practicability is high.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Garments comprising a flexible high thermal performance outer shell fabric of polybenzimidazole and polypyridobisimidazole fibers

Owner:EI DU PONT DE NEMOURS & CO

Fiber-reinforced bituminous waterproof sheet material

InactiveCN105038269AMolecular cross-linking increasedImprove surface strengthBuilding insulationsAluminateEpoxy

The invention discloses a fiber-reinforced bituminous waterproof sheet material which comprises the following raw materials in parts by weight: 81-90 parts of bitumen, 0.5-1 part of allylsulfocarbamide, 0.6-1 part of ethyl naphthol, 2-3 parts of calcium aluminate, 2-3 parts of polybenzimidazole fiber, 1-2 parts of coconut charcoal fiber, 2-3 parts of tetrahydrofurfuryl alcohol, 1-2 parts of barium metaborate, 3-4 parts of polystyrene, 25-30 parts of diatomite, 0.1-0.2 part of dicumyl peroxide, 20-30 parts of hydroxyl silicone oil, 30-40 parts of a 6% NaOH solution, 6-10 parts of alkali lignin, 2-3 parts of epoxy chloropropane and 6-8 parts of petroleum ether. According to the fiber-reinforced bituminous waterproof sheet material, provided by the invention, alkali lignin is subjected to epoxidation treatment, the crosslinking degree of lignin molecules is increased, and then polystyrene and fibers are subjected to hybrid modification, therefore the surface strength and the water-resisting property of the modified material are improved, and the insulativity, the mechanical property, the heat stability and the adhesiveness of finished products are further improved when the modified material is further mixed with epoxidized lignin.

Owner:BENGBU NANZI INSTR

Basalt fiber chenille circular weaving machine weaving filter bag

InactiveCN105274699AHigh temperature resistantHigh strengthDispersed particle filtrationWoven fabricsYarnGlass fiber

The invention discloses a basalt fiber chenille circular weaving machine weaving filter bag. The filter bag is a basalt fiber chenille weaving filter bag woven by a circular weaving machine. A basalt fiber chenille yarn comprises two parts of a core yarn and camlet. The material of the camlet is basalt fibers or a combined yarn of the basalt fibers with one or more selected from quartz glass fibers, high silica glass fibers, alumina silicate fibers, polyamide-imide fibers, PEEK fibers, polyphenylene sulfide fibers, polysulfone amide fibers, polyparaphenylene benzo dual-oxazole fibers, polybenzimidazole fibers, Teflon fibers, polymide fibers, and aramid fibers. The core yarn is two strands of yarns. After twisting the core yarns, the camlet is clamped between the two core yarns. A round filter bag woven by a six-shuttle circular weaving machine does not have weft weak points, the angle between a longitude fiber and a latitude fiber is 90 DEG. When filtering wind pressure is relatively large, a problem of breaking of weak points on the weft direction is not prone to occur.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of heat-resistant PVC (polyvinyl chloride) pipe

InactiveCN107805357AGood mechanical propertiesStable heat resistancePolyvinyl chlorideMechanical property

The invention discloses a preparation method of a heat-resistant PVC (polyvinyl chloride) pipe. The preparation method includes the operation steps: (1) mixing PVC resin and tetrabutylammonium fluoride, heating mixture to reach the temperature of 68-72 DEG C, uniformly mixing and stirring the mixture after completely melting of the tetrabutylammonium fluoride, and cooling the mixture to reach indoor temperature to prepare modified PVC resin; (2) mixing, stirring and heating polybenzimidazole fibers, polytetrafluoroethylene resin and acetaldehyde ammonia trimers, adding aluminum borate and zirconium oxide when the temperature reaches 80 DEG C, continuing to keep temperature and mix mixture for 15-20 minutes, and cooling the mixture to reach the indoor temperature to prepare heat-resistant agents; (3) adding the modified PVC resin, calcium-zinc stabilizers, the heat-resistant agents and calcium carbonate into a extruding machine, and performing extrusion molding, cooling and sizing to obtain the heat-resistant PVC pipe. The preparation method is stable in production process, continuous mass production can be achieved, the prepared PVC pipe is excellent in mechanical property and particularly has excellent heat resistance, and the quality of the PVC pipe is greatly improved.

Owner:安徽金昊天塑胶科技发展有限公司

Antiflaming blended fabric and preparation method thereof

InactiveCN110284325AImprove flame retardant performanceGood adhesionFlame-proof filament manufactureHeat resistant fibresFiberDecabromobiphenyl ether

The invention discloses an antiflaming blended fabric. The antiflaming blended fabric is obtained through padding of a gray fabric in antiflaming treating liquid; the gray fabric is obtained through blending weaving of following raw materials, wherein the raw materials comprise, by weight, 36-40 parts of chinlon fibers, 12-16 parts of polytetrafluoroethylene fibers, 6-8 parts of polybenzimidazole fibers and 3-7 parts of coconut fibers. The antiflaming blended fabric is obtained through padding of the gray fabric in the antiflaming treating liquid and has good antiflaming performance; the antiflaming treating liquid takes 2,4-diamido-6-(3,3,3-tribromo propyl)-1,3,5-triazine and decabromodiphenyl ether which cooperate with each other as an antiflaming agent, the antiflaming performance of the antiflaming treatment liquid is improved, sulfated castor oil improves the permeability, and the performance of attachment of the antiflaming treating liquid to the gray fabric is improved; by adding bisphenol A unsaturated polyester, the attachment force of the antiflaming agent is further improved.

Owner:南通北岸纺织科技有限公司

Basalt fiber chenille knitted fabric

The invention discloses a basalt fiber chenille knitted fabric. The basalt fiber chenille knitted fabric is formed by crocheting basalt fiber chenille yarns through knitting equipment, wherein the basalt fiber chenille yarns comprise core yarns and camlet, the camlet is made from basalt fibers or a combination yarn of basalt fibers and one or more of quartz glass fibers, high silica glass fibers, aluminum silicate fibers, polyamide-imide fibers, polyether-ether-ketone fibers, polyphenylene sulfide fibers, polysulfoneamide fibers, poly(p-phenylene benzobisoxazole) fibers, polybenzimidazole fibers, polytetrafluoroethylene fibers, polyimide fibers and aramid fibers; each core yarn is formed by two piled yarns, and the camlet is clamped between every two core yarns which are twisted. The basalt fiber chenille knitted fabric processed by a knitting machine has the advantages that space gaps among the yarns are large, air resistance is small, and thus the air filtering efficiency can be improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Multifunctional durable blending chemical fiber

InactiveCN105970389AHigh temperature resistantRadiation resistantYarnPolyvinyl alcoholOptoelectronics

The invention discloses a multifunctional and durable blended chemical fiber, which is formed by blending and weaving a first fiber, a second fiber and a third fiber, the first fiber is cupro ammonia fiber, and the second fiber is made of polytetrafluoroethylene Vinyl fiber and polypropylene fiber are blended and woven, and the third fiber is blended and woven from polyvinyl formal fiber and polybenmidazole fiber, and the weight percentages of the components in the second fiber are respectively: The polytetrafluoroethylene fiber accounts for 46%-55%, the polypropylene fiber accounts for 45%-54%, and the weight percentages of each component in the third fiber are respectively: the polyvinyl formal fiber accounts for 29% -38%, the polybenzimidazole fiber accounts for 62%-71%. The invention has the characteristics of high temperature resistance, radiation resistance, corrosion resistance, high strength, moisture absorption and ventilation.

Owner:太仓市璜泾镇佳梦化纤厂

Eva emulsion heat radiating coating and preparation method therefor

InactiveCN105111835AImprove impact resistanceImprove corrosion resistanceAnti-corrosive paintsDimethyl methylphosphonateCopper sulfate

The present invention discloses an Eva emulsion heat radiating coating. The Eva emulsion heat radiating coating is prepared from the following raw materials in parts by weight: 2-4 parts of calcium fluoride, 6-10 parts of an Eva emulsion, 12-15 parts of a styrene and maleic anhydride copolymer, 6-10 parts of propargyl alcohol, 90-100 parts of tetrahydrofuran, 4-7 parts of graphene, 16-20 parts of nano silicon dioxide, 700-800 parts of dimethylformamide, 4-5 parts of sodium nitride, 0.04-0.05 part of aluminium trichloride, 1.6-2 parts of a 2-3% sodium ascorbate solution, 1.8-2 parts of a 2-3% copper sulfate solution, 120-130 parts of high density polyethylene, 0.7-1 part of ricinoleic acid, 3-4 parts of dimethyl Methylphosphorate, 2-3 parts of diphenyl silandiol, 0.7-1 part of ammonium molybdate, 1-2 parts of polybenzimidazole fiber and 0.4-0.5 part of a silane coupling agent KH560. According to the present invention, by adding the Eva emulsion, the compatibility of materials among resin can be improved, the dispersibility of particles is improved, and the heat-conducting and heat radiating effect is improved.

Owner:BENGBU TIMES ELECTRONICS

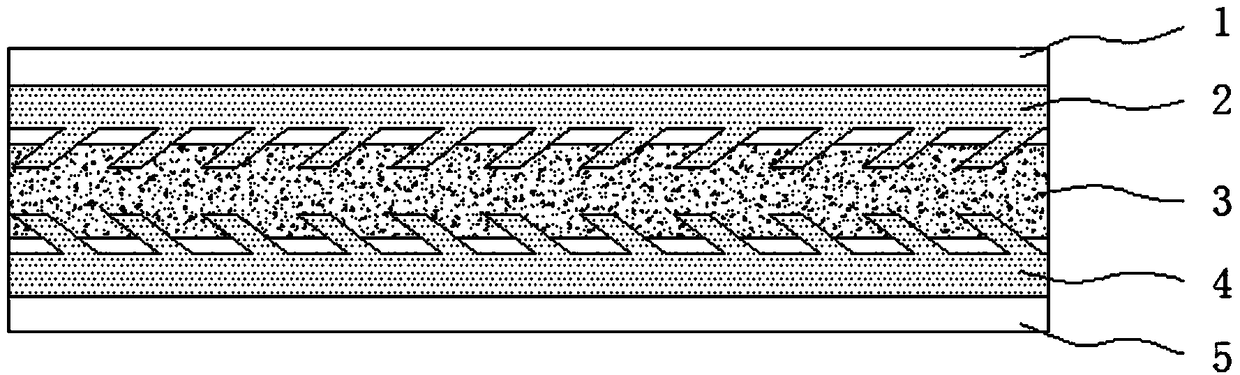

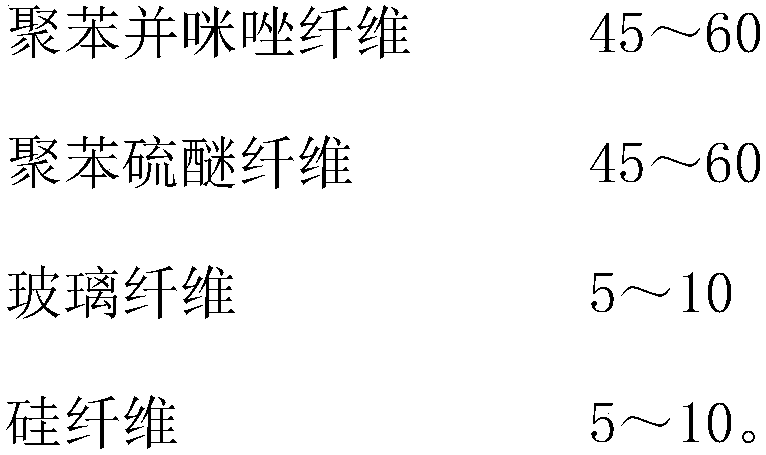

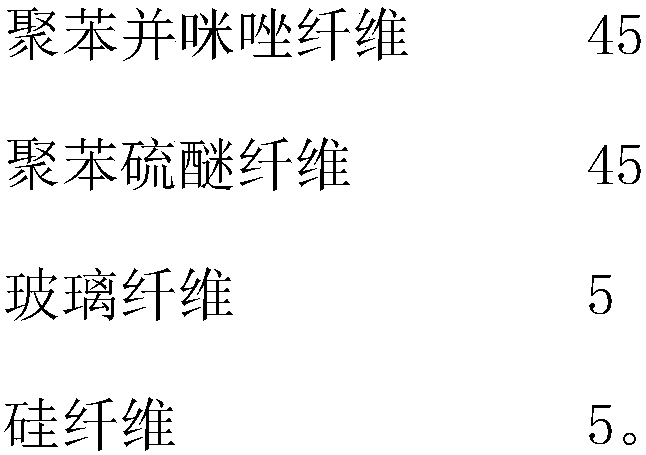

Inorganic or organic nano composite material for protective suit and preparation method thereof

InactiveCN108215379AIncrease elasticityHigh breaking strengthLaminationLamination apparatusActivated carbonBreaking strength

The invention discloses an inorganic or organic nano composite material for a protective suit and a preparation method thereof and relates to the technical field of biomedical high molecular materials. The inorganic or organic nano composite material is composed of the following five layers of structures from top to bottom: a waterproof layer, a nano composite material, a fiber layer, a hot melt adhesive thin film and a contact layer. According to the inorganic or organic nano composite material disclosed by the invention, the waterproof layer, the nano composite material, the fiber layer, thehot melt adhesive thin film and the contact layer are compounded and molded in sequence, so that the prepared composite material has advantages of a traditional material and also has the advantages of high elasticity and high breaking strength; meanwhile, the fiber layer comprises polybenzimidazole fibers, polyphenylene sulfide fibers, glass fibers and silicon fibers and has the advantage of highflame-retarding strength; meanwhile, the nano composite material comprises nano-grade activated carbon and an antibacterial agent and has the effects of sterilizing and disinfecting, and absorbing harmful substances.

Owner:合肥普尔德医疗用品有限公司

Elastic cushioning rubber material and preparation method thereof

The invention discloses an elastic anti-buffer rubber material, which is composed of the following raw materials in parts by weight: magnesium oxide 0.1-0.3, zinc oxide 1-2, accelerator TMTD 0.8-1, sulfur 1-2, anti-aging Agent AW1-2, tributyl citrate 7-9, buffer additive 5-7, medical stone powder 2-4, ethylene glycol monobutyl ether 4-6, propylene glycol alginate 1-2, polybenzimidazole Fiber 3-4, oxidized polyethylene wax 2-4, 8-hydroxyquinoline copper 0.7-1, silane coupling agent KH5600.1-0.2, butadiene rubber 100-140, wollastonite powder 10-12, dodecane Base trimethyl ammonium chloride 0.7-1; The present invention adopts polyurethane thermoplastic elastomer as the main body of the anti-buffer material, which not only has good impact strength, but also can improve various mechanical properties of finished rubber and improve weather resistance. The anti-buffer rubber material invented has good flexibility and high resilience, and can be used as a variety of safety protection buffer materials. It has no volatilization of toxic and harmful components, and is safe and reliable.

Owner:宁波远欣石化有限公司

High-cost performance alcohol-based foundry coating and preparation method thereof

InactiveCN104289664AReduce manufacturing costImprove performance indicatorsFoundry mouldsFoundry coresFoundryFiber

The invention discloses a high-cost performance alcohol-based foundry coating. The high-cost performance alcohol-based foundry coating is characterized by being prepared from the following raw materials in parts by weight: 75-90 parts of emery, 2.3-4.5 parts of silica gel powder, 4.1-6.2 parts of asbestos powder, 3-5 parts of attapulgite, 1.2-3.1 parts of E12 epoxy resin, 2.4-3.6 parts of phenolic resin, 1-2 parts of polybenzimidazole fiber, 0.4-0.7 parts of coco fatty acid diethanol amide, 0.7-0.9 parts of butadiene styrene rubber, 12-15 parts of shrimp shell, 11-13 parts of flaxseed meal, 1-3 parts of rosin, 45-60 parts of ethanol and 2-4 parts of auxiliaries. According to the high-cost performance alcohol-based foundry coating, the shrimp shell and the flaxseed meal are added to the raw materials after being specially treated, so that the production cost of the coating is reduced and various performance indexes of the coating are also increased; the obtained coating has the advantages of high cost performance, high-temperature resistance, good suspension property and the like, and is suitable for large-scale industrial production.

Owner:TONGLING RELY TECH

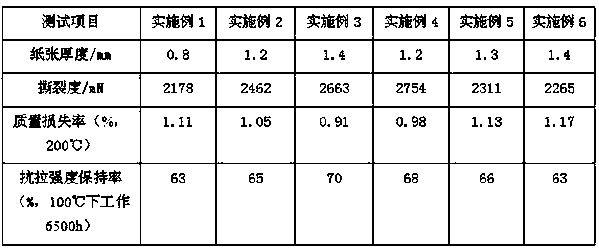

High-temperature-resistant composite paper and preparation method thereof

ActiveCN107587388AImprove high temperature resistanceImprove mechanical propertiesSpecial paperSynthetic resin layered productsFiberLoss rate

The invention provides high-temperature-resistant composite paper and a preparation method thereof and relates to the technical field of paper product processing. The composite paper comprises four layers from bottom to top, wherein the first layer is a parchment layer, the second layer is an alumina layer, the third layer is a polycarbonate layer, and the fourth layer is a fiber layer formed by mixing polybenzimidazole fiber with polyether sulphone fiber. The prepared high-temperature-resistant composite paper with the four-layer composite structure has good high temperature resistance and mechanical performance, is not prone to damage, has small mass loss rate (less than 1.17%) at the high temperature of 200 DEG C and can still keep higher tensile strength retention rate up to 70% afterworking at 100 DEG C for 6,500 h. The prepared composite paper has good promotion and application value, production of paper for non-traditional machining is further promoted, and import dependence isreduced.

Owner:湖北夷盟包装材料有限公司

Preparation method of high-temperature-resistant filtering material

ActiveCN111804063AImprove high temperature resistanceHigh filtration precisionHuman health protectionDispersed particle filtrationTriethoxysilaneBasalt fiber

The invention discloses a preparation method of a high-temperature-resistant filtering material and belongs to the technical field of filtering and dedusting materials. The method comprises the stepsof 1) mixing, 2) opening, 3) lapping, 4) needling, 5) dipping and 6) film covering. The mixing process comprises: uniformly mixing basalt fibers and polybenzimidazole fibers according to a weight ratio of (3-4): (1-2), and the dipping process comprises: padding the needled felt in the treatment liquid, wherein the pick-up rate is 29-33%, drying at the temperature of 190-220 DEG C, baking at the temperature of 250-320 DEG C, controlling the drying and baking speed to be 4-5m / min, and rolling, wherein the treatment liquid is prepared from the following components in percentage by mass: 15 to 26percent of polytetrafluoroethylene dispersion liquid, 2 to 6 percent of dimethyl diphenyl polysiloxane, 0.7 to 3 percent of 3-aminopropyltriethoxysilane, 0.5 to 1 percent of Tween and the balance of water. The filtering material has good high temperature resistance, can resist the temperature of 280-295 DEG C for a long time, can resist the temperature of 320 DEG C instantaneously, and has the service life of 2 years or longer.

Owner:山东兴国新力环保科技股份有限公司

Garments Comprising High Strength Extreme Thermal Performance Outer Shell Fabric of Polybenzimidazole and Polypyridobisimidazole Fibers

This invention concerns a flame-resistant garment having an outer shell fabric comprising 50 to 95 parts by weight of a polypyridobisimidazole fiber having an inherent viscosity of greater than 20 dl / g and 5 to 50 parts by weight of polybenzimidazole fiber.

Owner:EI DU PONT DE NEMOURS & CO

High-temperature resistant fiber blended fabric

InactiveCN104195724AImprove wearing safetyImprove high temperature resistanceWoven fabricsYarnFiberMetallurgy

The invention discloses a high-temperature resistant fiber blended fabric. The high-temperature resistant fiber blended fabric is formed by blending polybenzimidazole fibers, poly-p-phenylene terephthamide fibers, boron nitride fibers and polyamide-imide fibers in a woven mode, and comprises, by weight, 13% to 17% of the polybenzimidazole fibers, 25% to 29% of the poly-p-phenylene terephthamide fibers, 10% to 14% of the boron nitride fibers and 40% to 52% of the polyamide-imide fibers. The high-temperature resistant fiber blended fabric is formed by blending the four fabric fibers including the polybenzimidazole fibers, the poly-p-phenylene terephthamide fibers, the boron nitride fibers and the polyamide-imide fibers in the woven mode, and the fabric formed in the woven mode has the excellent high-temperature resistance, the excellent chemical corrosion resistance, the excellent tensile strength and the excellent abrasion resistance, and is high in wearing safety performance and low in production cost.

Owner:陈朝阳

Basalt fiber chenille woven fabric

The invention discloses a basalt fiber chenille woven fabric woven by basalt fiber chenille yarns through weaving equipment. The basalt fiber chenille yarns comprise core wires and camlets. The camlets are made of basalt fiber or combination yarns made of the basalt fiber and one or more of silica glass fiber, high silica glass fiber, aluminum silicate fiber, polyamide-imide fiber, polyether-ether-ketone fiber, polyphenylene sulfide fiber, polysulfone base amide fiber, polyp-phenylene benzobisthiazole fiber, polybenzimidazole fiber, polytetrafluroethylene fiber, polyimide fiber and aramid fiber. The core wires are two piled yarns. After the core wires are twisted, the camlets are placed between the core wires. The processing method for the basalt fiber chenille woven fabric by the weaving equipment is the most traditional method and includes an included angle 90 degrees between latitudinal and longitudinal directions. Various equipment is suitable to produce the basalt fiber chenille woven fabric with huge quantity and lowest production cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com