High-temperature-resistant composite paper and preparation method thereof

A composite paper and high-temperature-resistant technology, which is applied in the field of paper product processing, can solve the problems of unable to meet production needs and low heat-resistant temperature, and achieve good promotion and application value, low quality loss rate, and reduce import dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

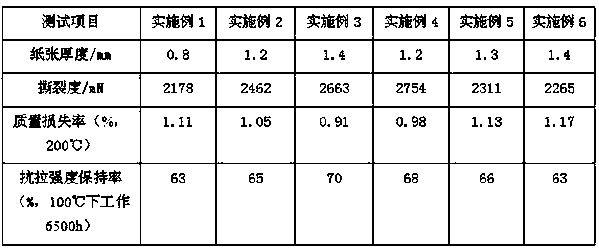

Examples

Embodiment 1

[0029] A kind of high temperature resistant composite paper, which has 4 layers from bottom to top, the first layer is a parchment layer with a thickness of 0.3mm, the second layer is an alumina layer with a thickness of 0.1mm, and the third layer is a polycarbonate layer with a thickness of 0.2mm The ester layer and the fourth layer are fiber layers composed of polybenzimidazole fibers and polyarylethersulfone fibers with a thickness of 0.2 mm.

[0030] The preparation method of above-mentioned high temperature resistant composite paper comprises the following steps:

[0031] (1) Pretreatment of the parchment paper layer: spread the parchment paper on the thin steel plate;

[0032](2) Preparation of bauxite layer: drying, calcining, grinding, and crushing bauxite into 100 meshes to obtain bauxite powder, adding adhesive to the bauxite powder, the adhesive is acrylate adhesive, stirring and mixing at 400r / min for 10min , the mass ratio of adhesive to bauxite powder is 20:80, ...

Embodiment 2

[0036] A kind of high temperature resistant composite paper, with 4 layers from bottom to top, the first layer is a parchment layer with a thickness of 0.4mm, the second layer is an alumina layer with a thickness of 0.2mm, and the third layer is a polycarbonate layer with a thickness of 0.3mm The ester layer and the fourth layer are fiber layers composed of polybenzimidazole fibers and polyarylethersulfone fibers with a thickness of 0.3 mm.

[0037] The preparation method of above-mentioned high temperature resistant composite paper comprises the following steps:

[0038] (1) Pretreatment of the parchment paper layer: spread the parchment paper on the thin steel plate;

[0039] (2) Preparation of bauxite layer: drying bauxite, calcining, grinding, crushing bauxite into 120 meshes to obtain bauxite powder, adding adhesive to the bauxite powder, the adhesive is epoxy resin adhesive, stirring and mixing at 450r / min 15min, the mass ratio of the adhesive to the alumina powder is 2...

Embodiment 3

[0043] A kind of high temperature resistant composite paper, which has 4 layers from bottom to top, the first layer is a parchment paper layer with a thickness of 0.4mm, the second layer is an alumina layer with a thickness of 0.2mm, and the third layer is a polycarbonate layer with a thickness of 0.4mm The ester layer and the fourth layer are fiber layers composed of polybenzimidazole fibers and polyarylethersulfone fibers with a thickness of 0.4 mm.

[0044] The preparation method of above-mentioned high temperature resistant composite paper comprises the following steps:

[0045] (1) Pretreatment of the parchment paper layer: spread the parchment paper on the thin steel plate;

[0046] (2) Preparation of bauxite layer: Dry bauxite, calcinate, grind, and crush it into 140 meshes to obtain bauxite powder, add adhesive to the bauxite powder, the adhesive is epoxy resin adhesive and polyurethane adhesive, mixed at 500r / Stir and mix at min speed for 20min. The mass ratio of ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com