Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

608 results about "Acoustic property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic properties. Water is an excellent conductor of sound, considerably better than air. The attenuation of sound by absorption and conversion to other energy forms is a function of sound frequency and the properties of water.

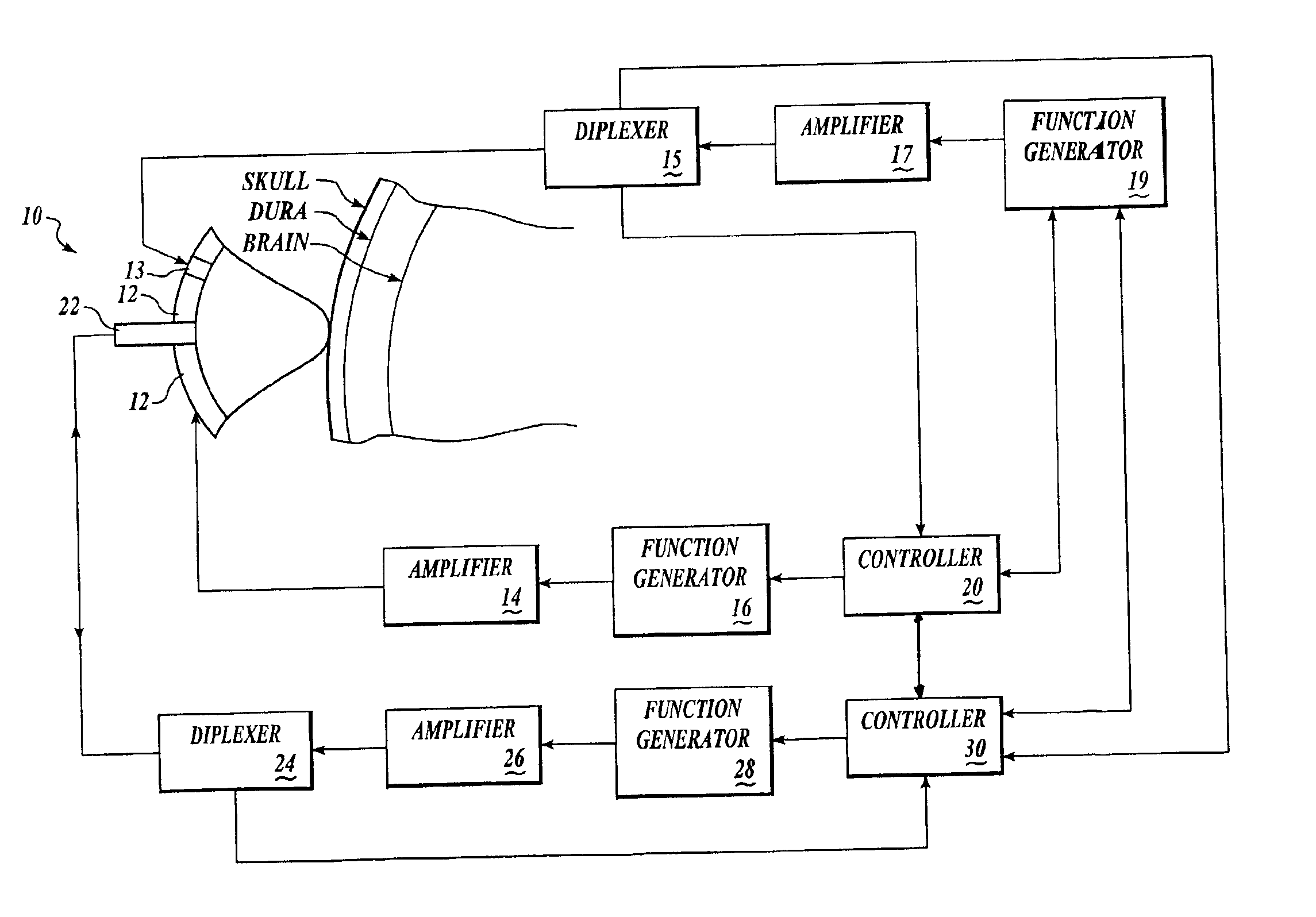

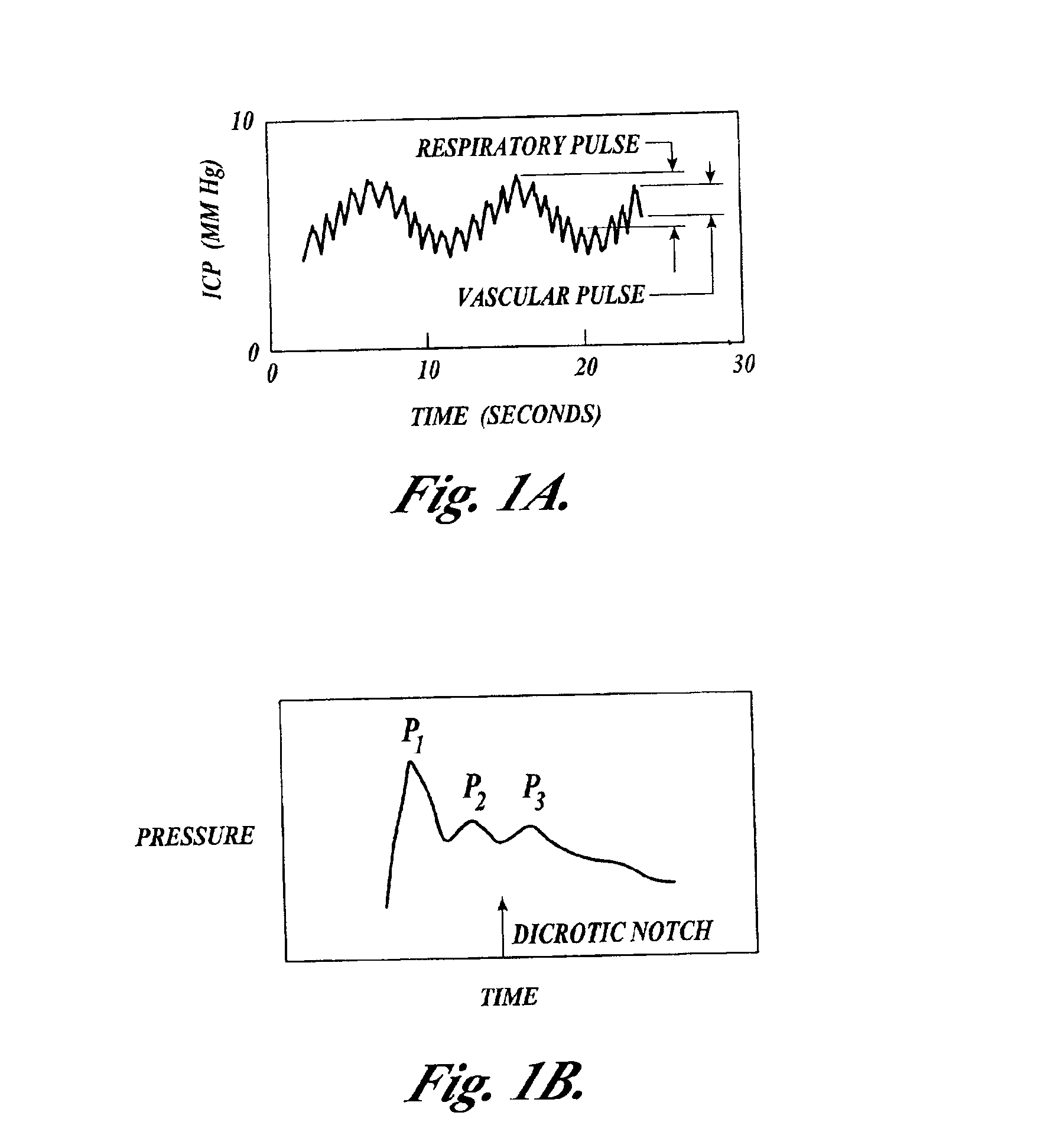

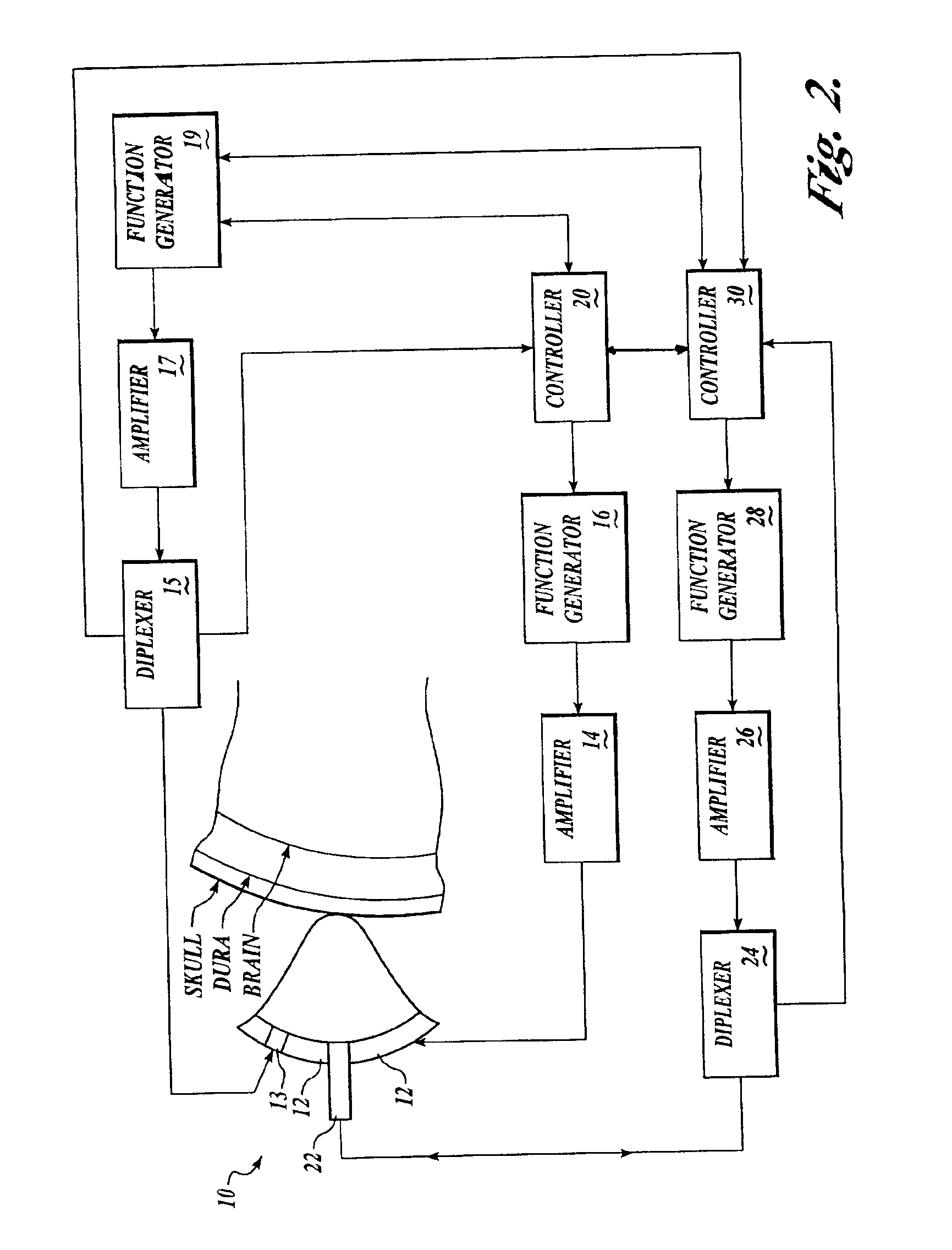

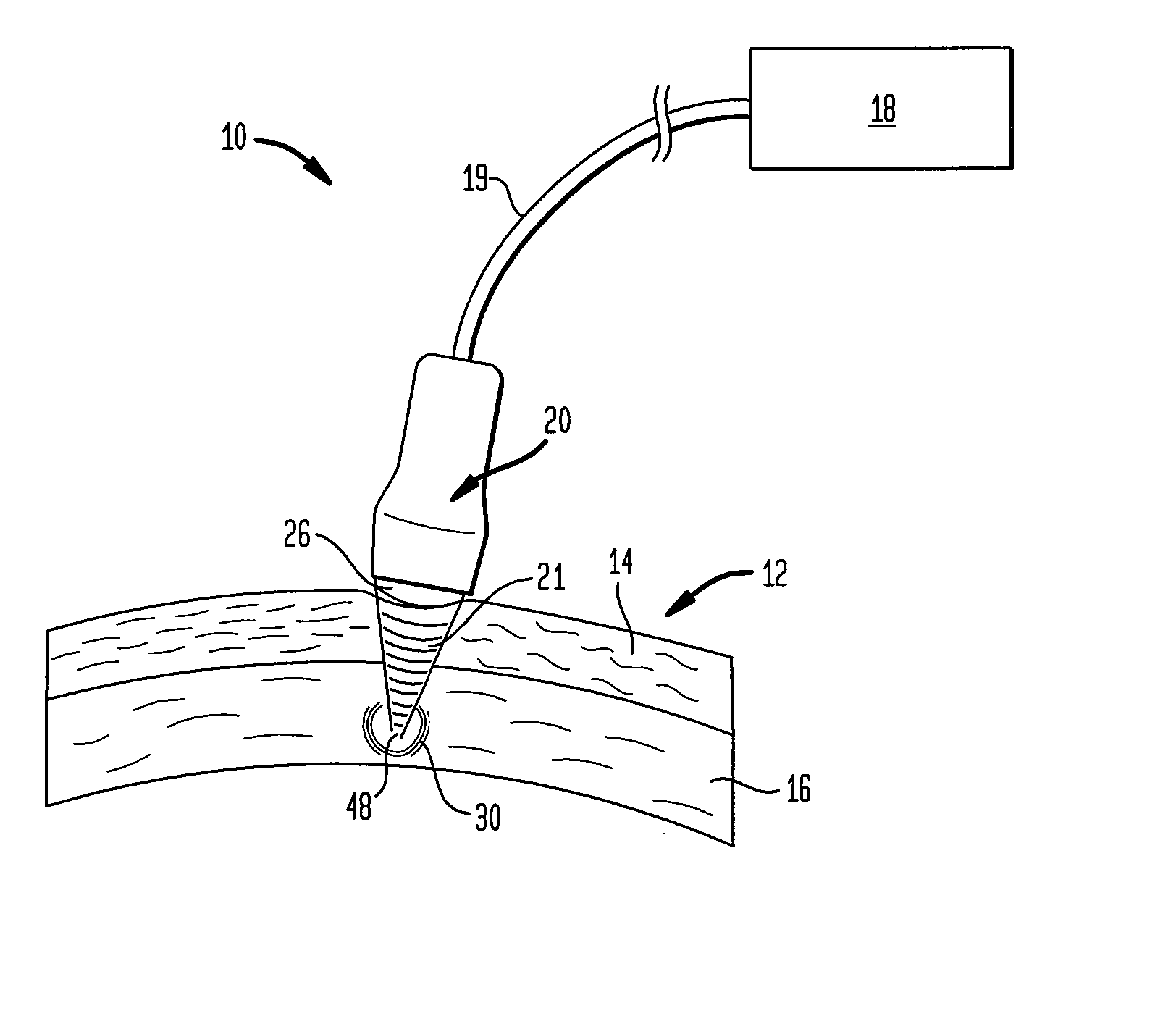

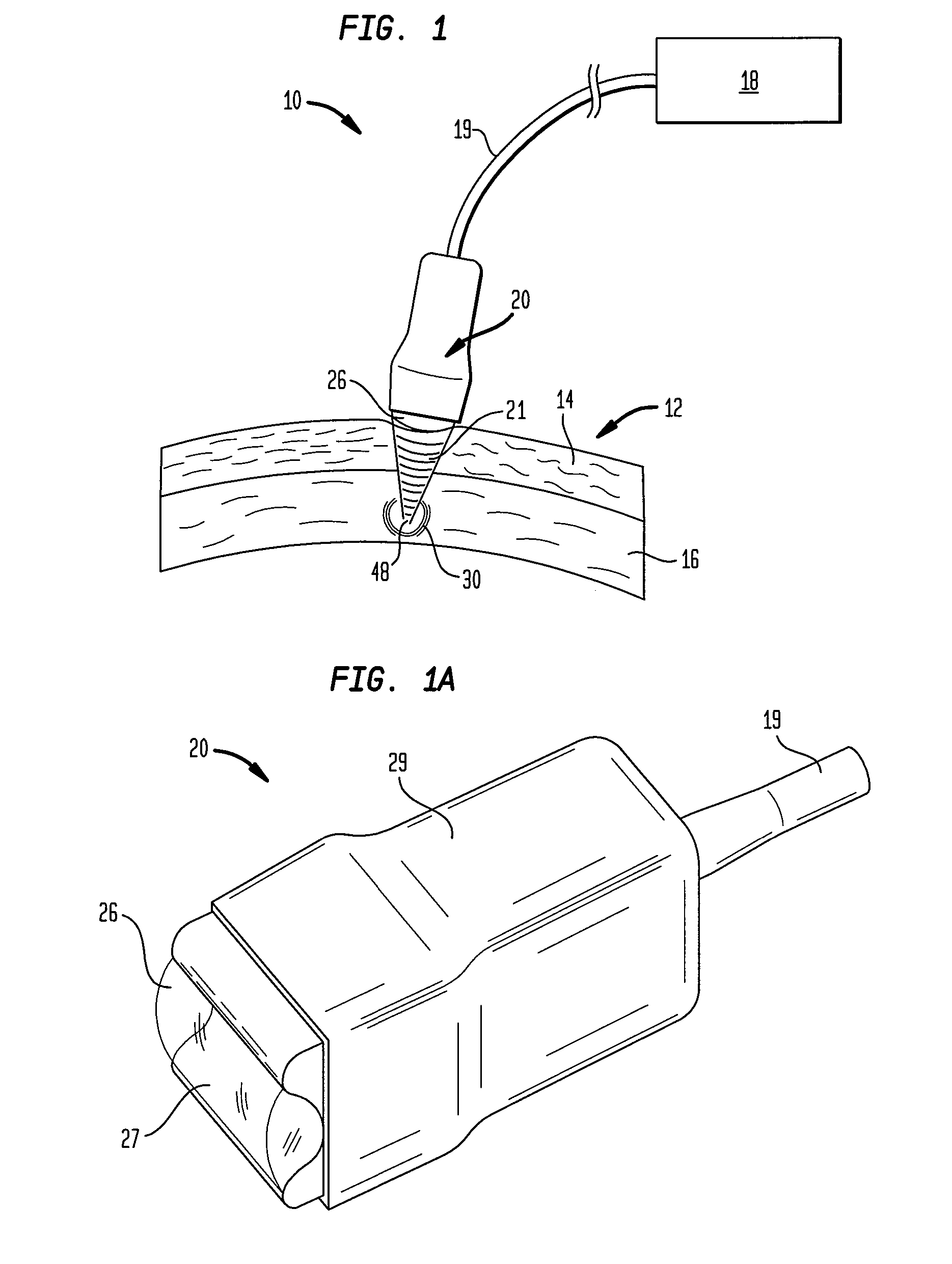

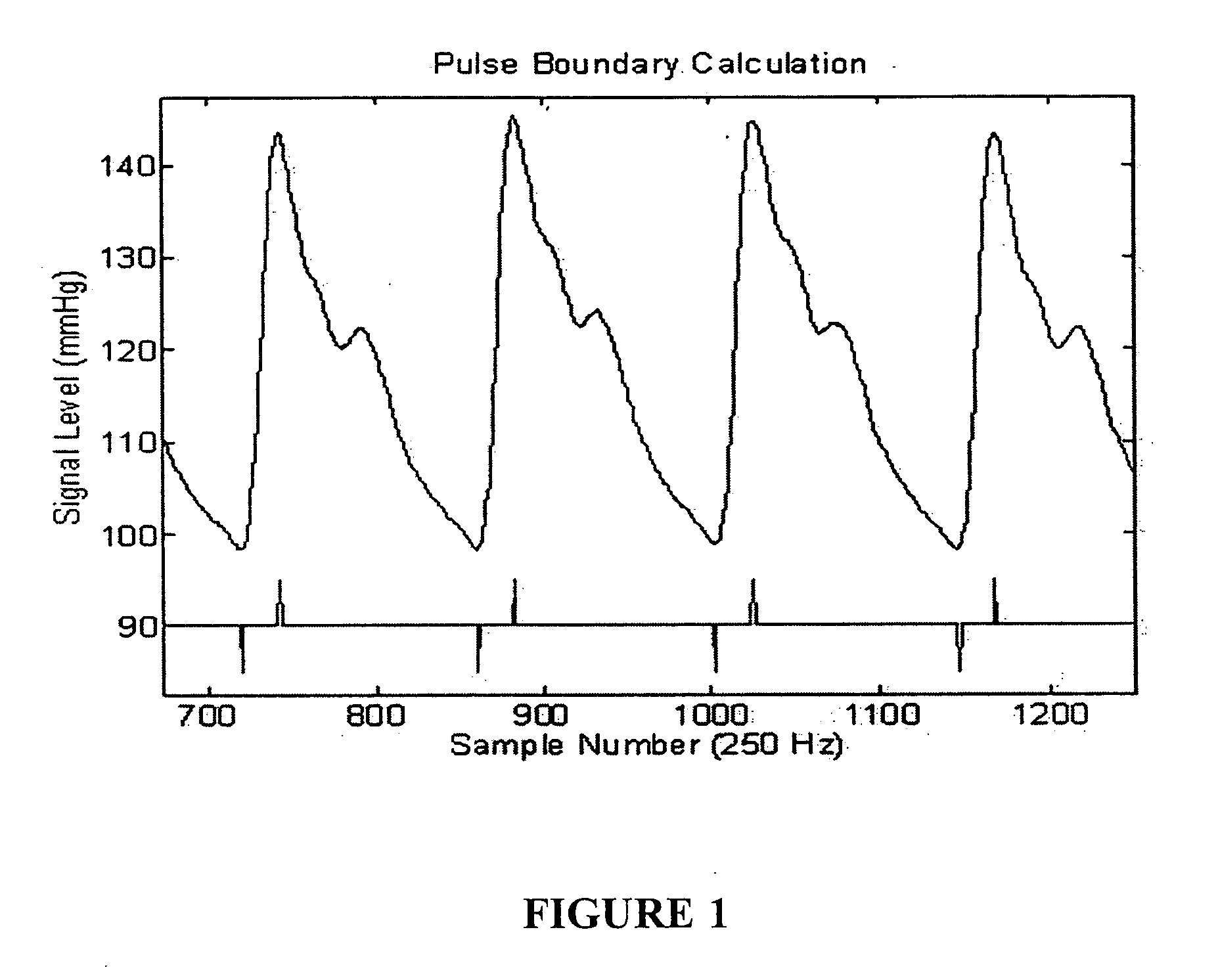

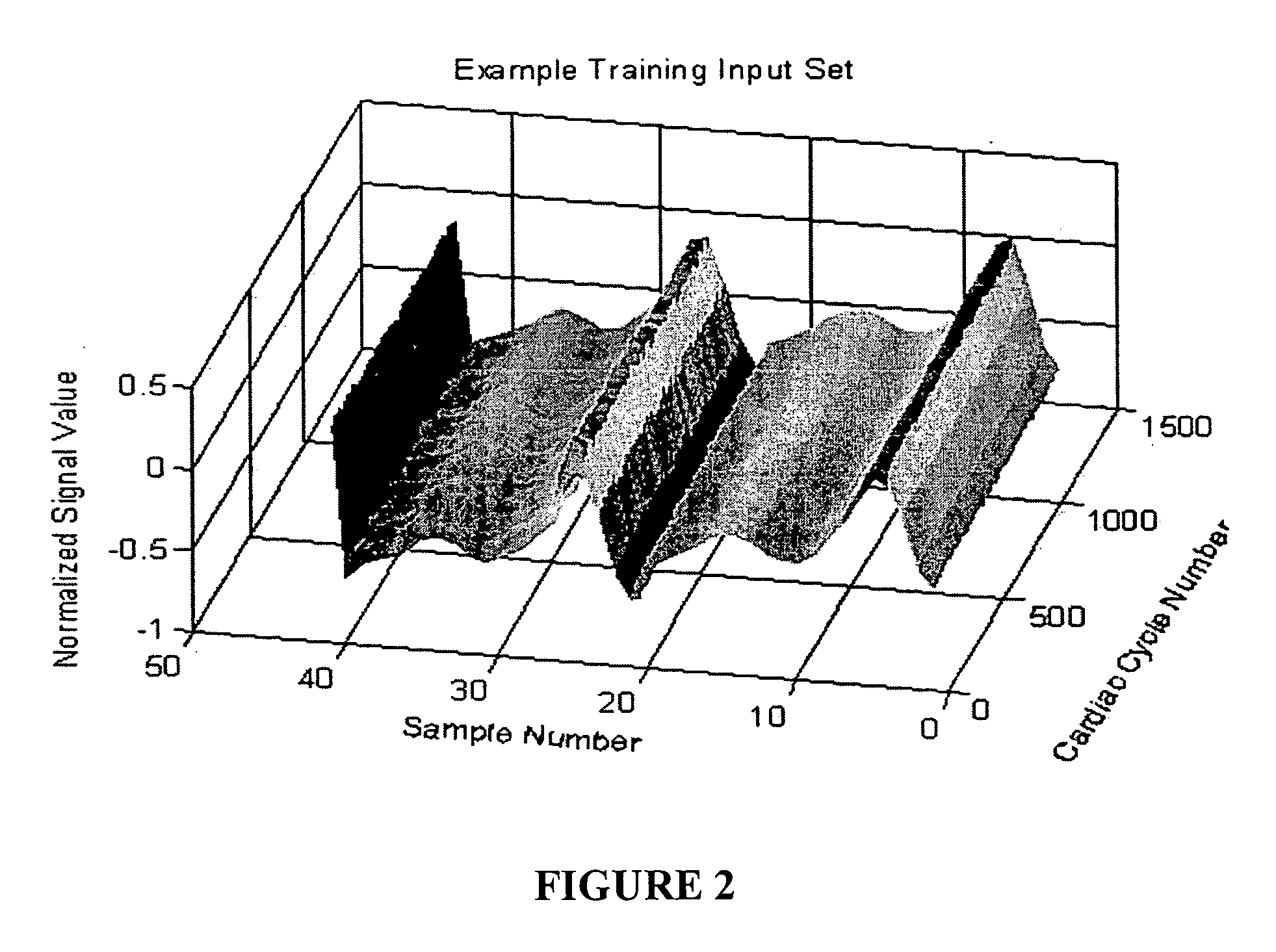

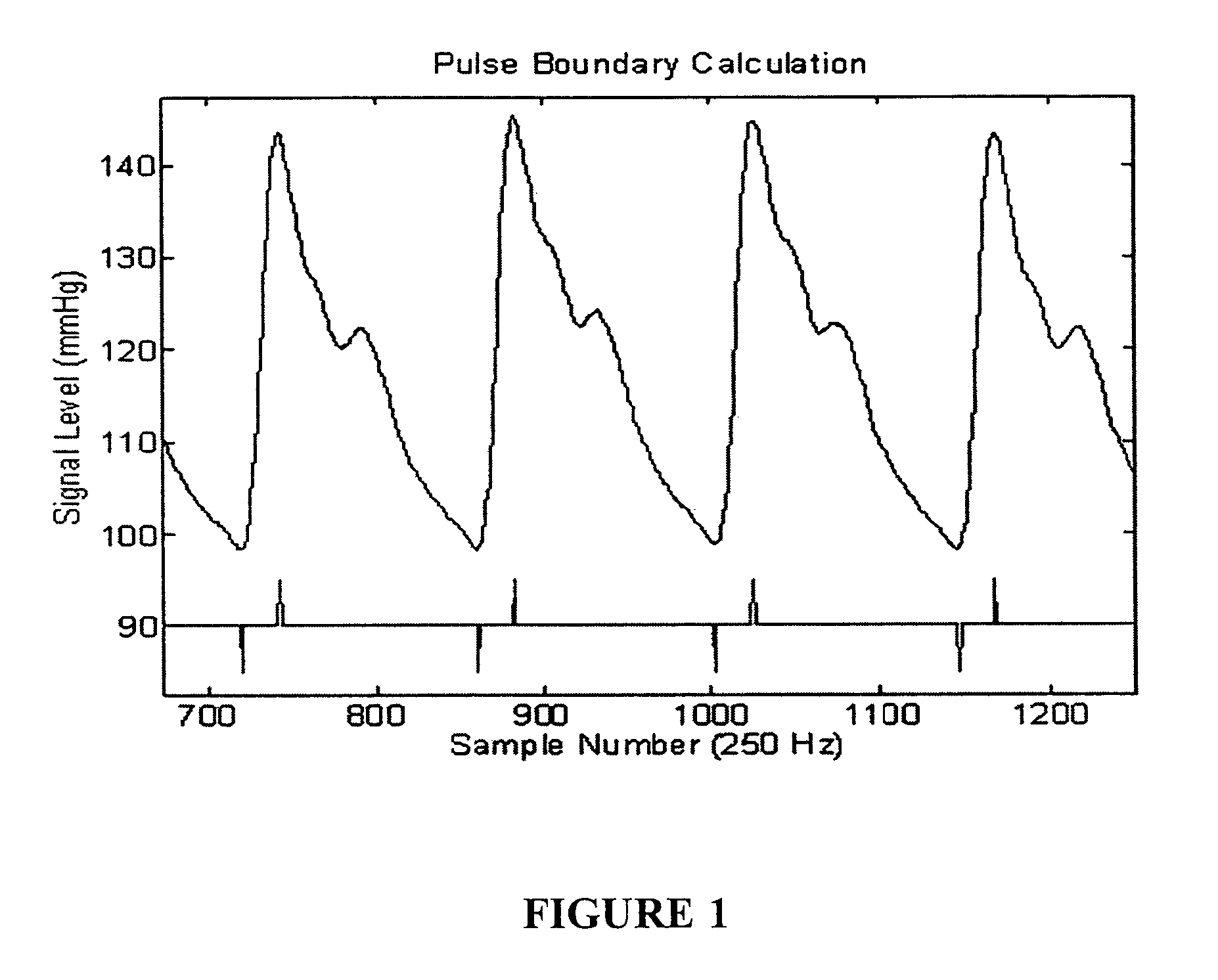

Systems and methods for making noninvasive physiological assessments

InactiveUS6875176B2Improve accuracySensitive highOrgan movement/changes detectionSurgeryDiseaseNon invasive

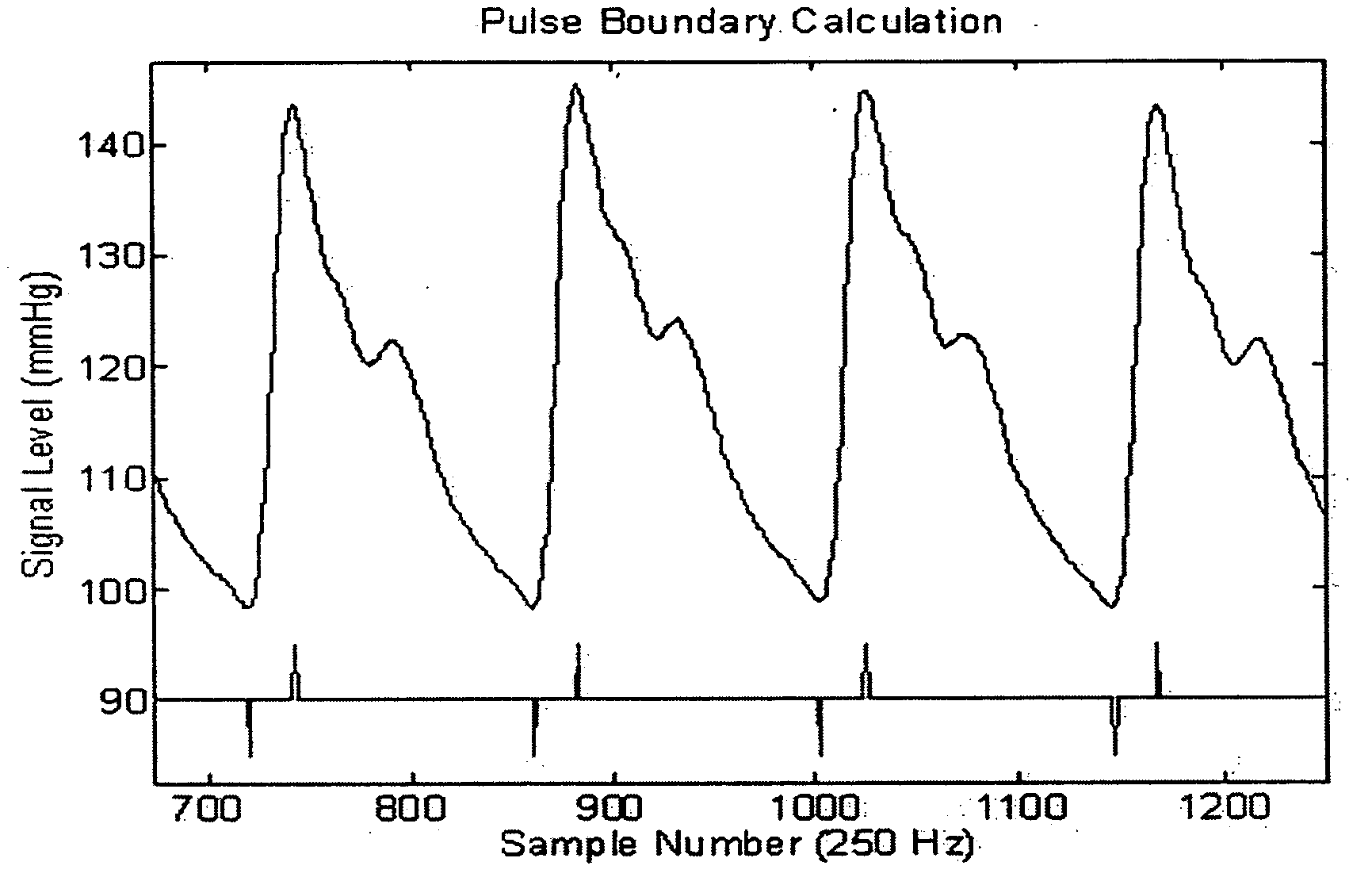

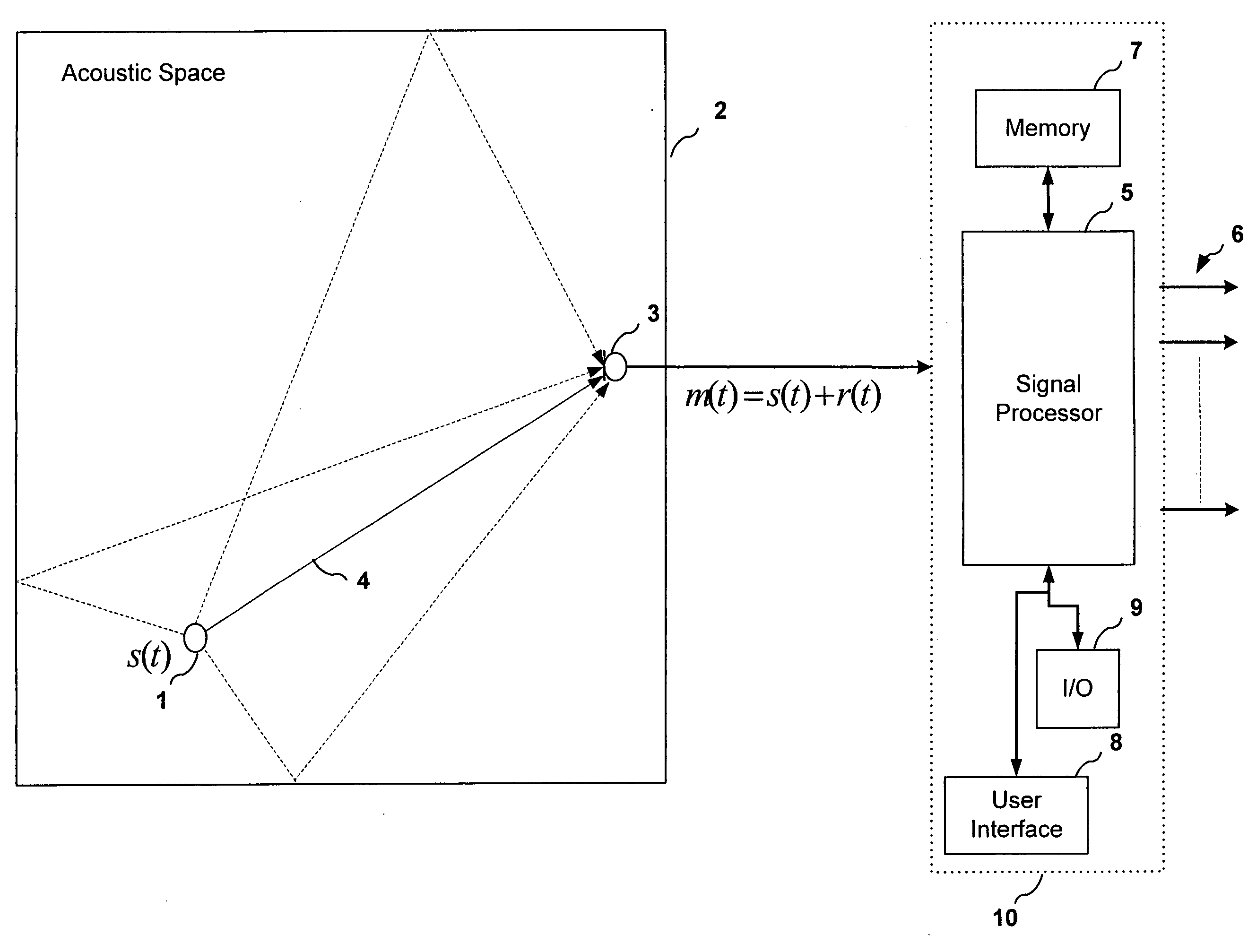

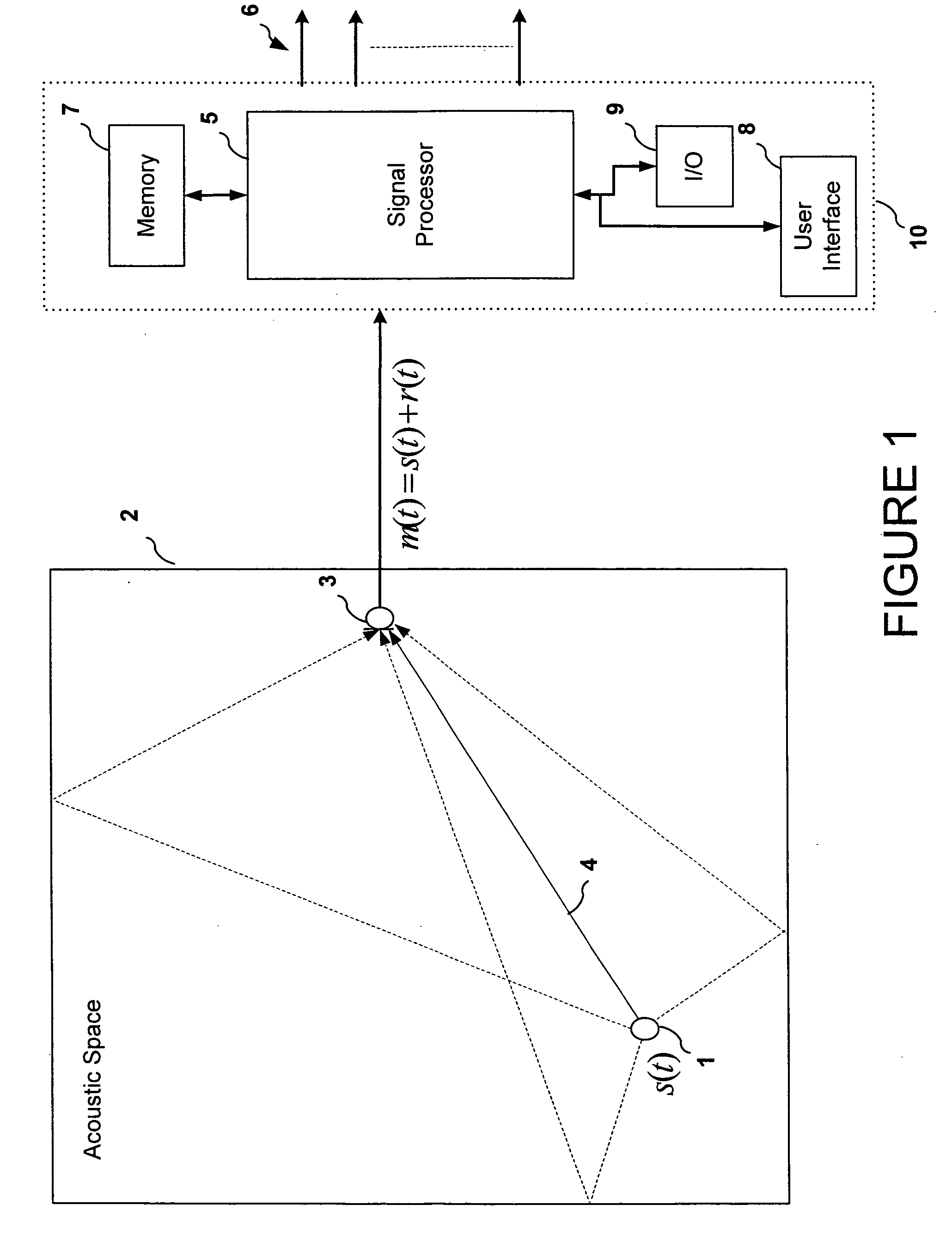

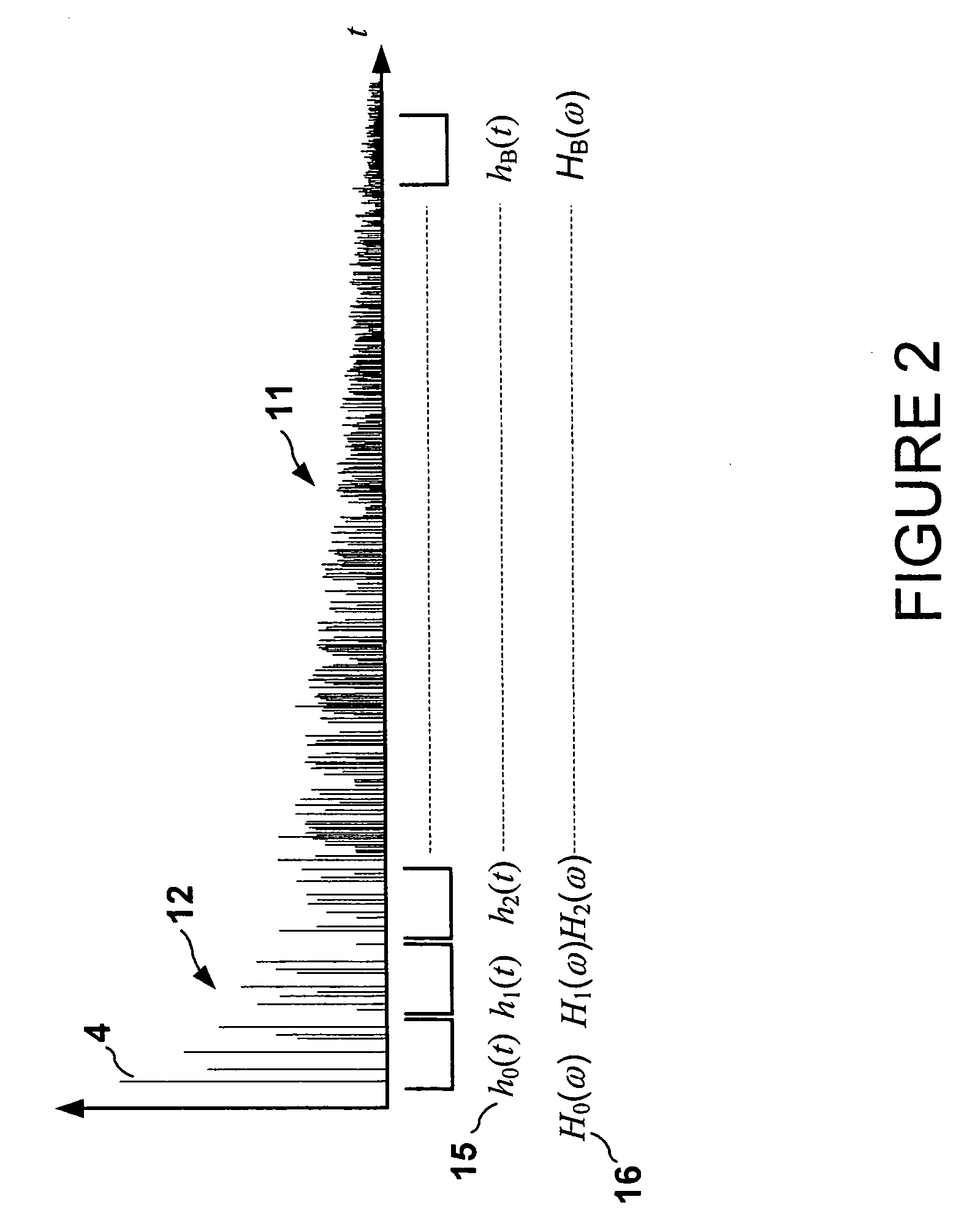

Systems and methods for assessment of tissue properties, noninvasively, by acquiring data relating to at least one aspect of intrinsic and / or induced tissue displacement, or associated biological responses, are provided. Data relating to tissue displacement and associated biological changes may be acquired by detecting acoustic properties of tissue using ultrasound interrogation pulses, preferably in a scatter or Doppler detection mode. Based on this data, tissue properties are assessed, characterized and monitored. Specific applications for systems and methods of the present invention include non-invasive assessment and monitoring of intracranial pressure (ICP), arterial blood pressure (ABP), CNS autoregulation status, vasospasm, stroke, local edema, infection and vasculitus, as well as diagnosis and monitoring of diseases and conditions that are characterized by physical changes in tissue properties. Methods and systems for localizing physiological condition(s) and / or biological response(s), such as pain, by targeting and selectively probing tissues using the application of focused ultrasound are also provided.

Owner:PHYSIOSONICS

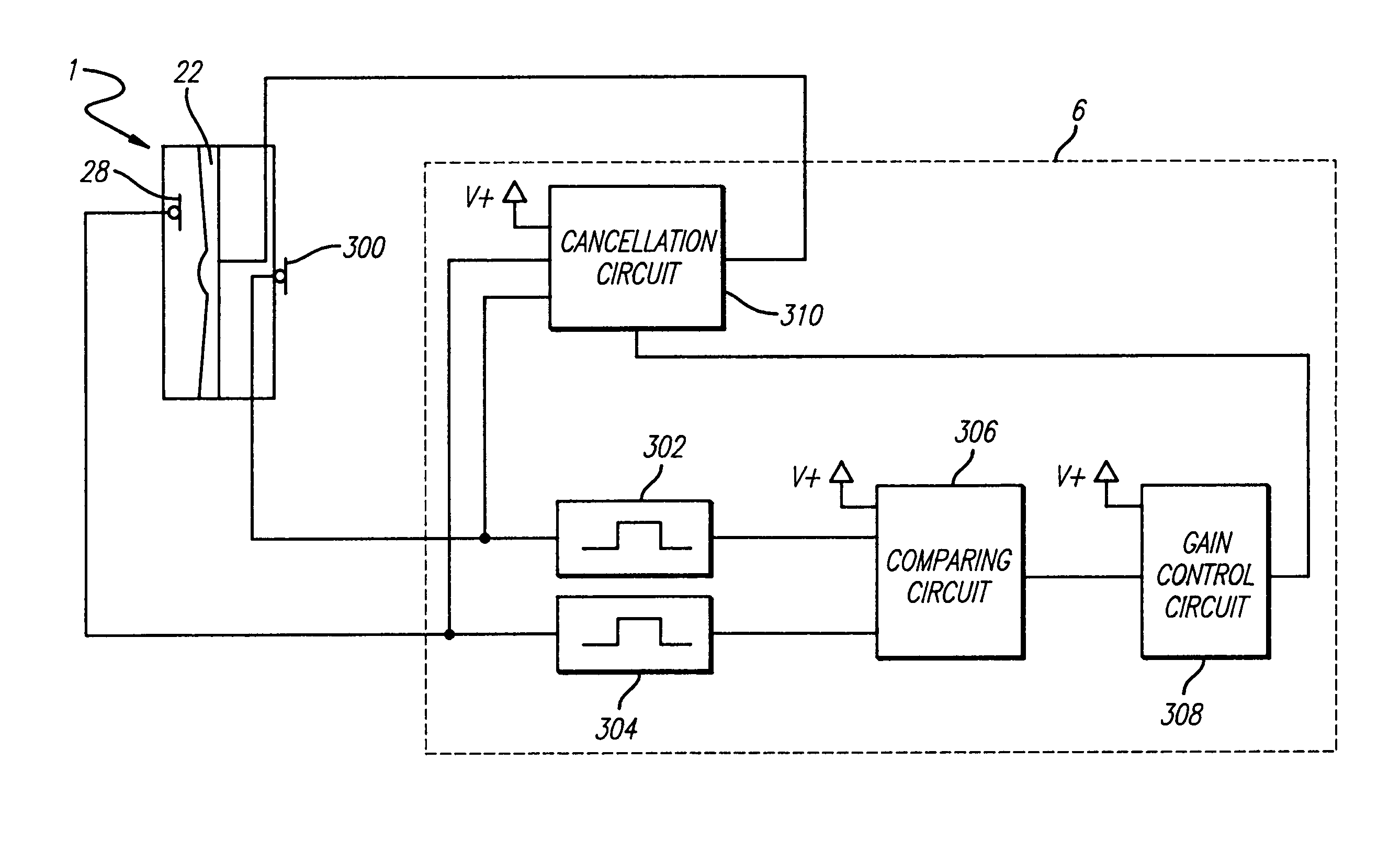

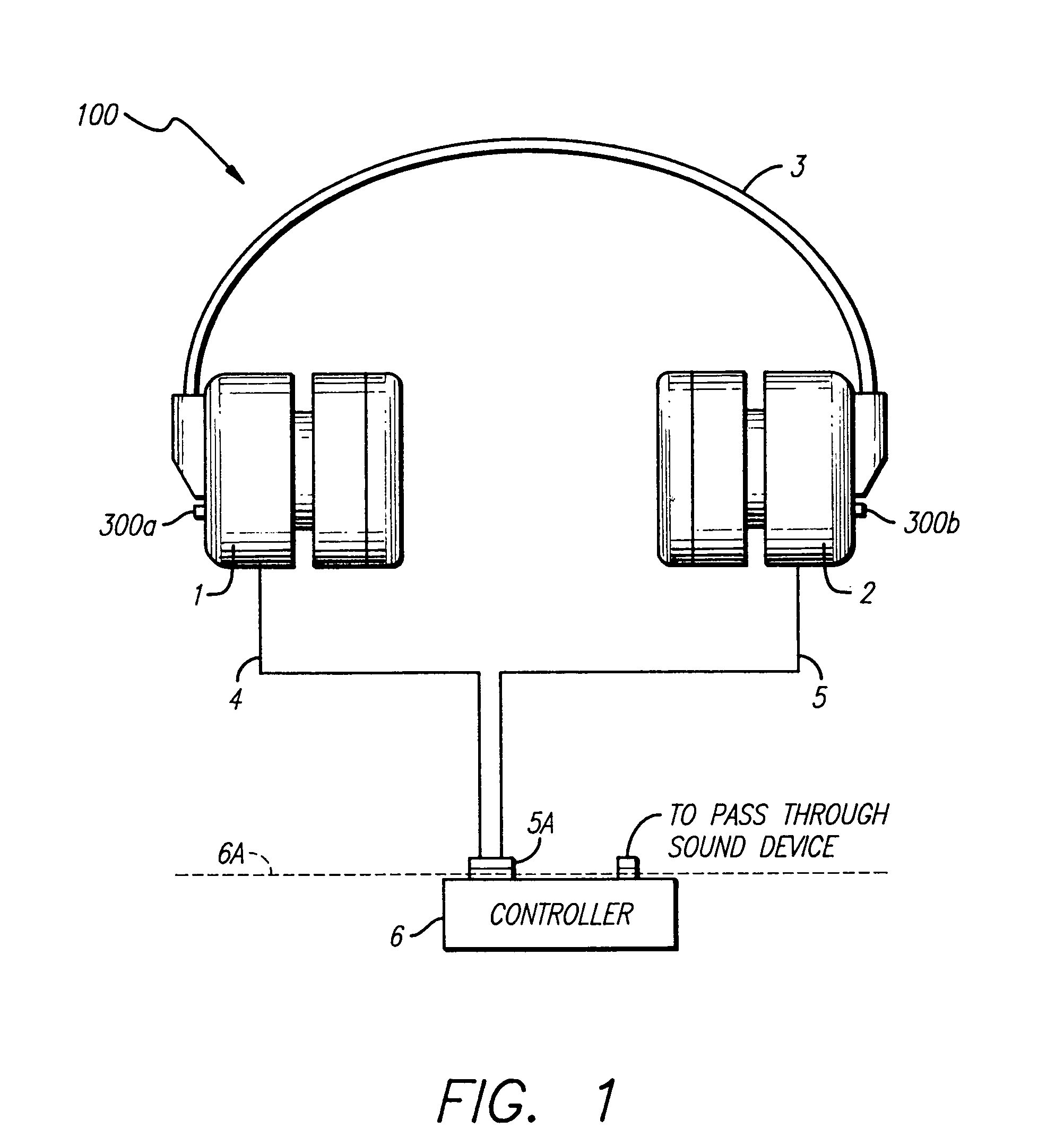

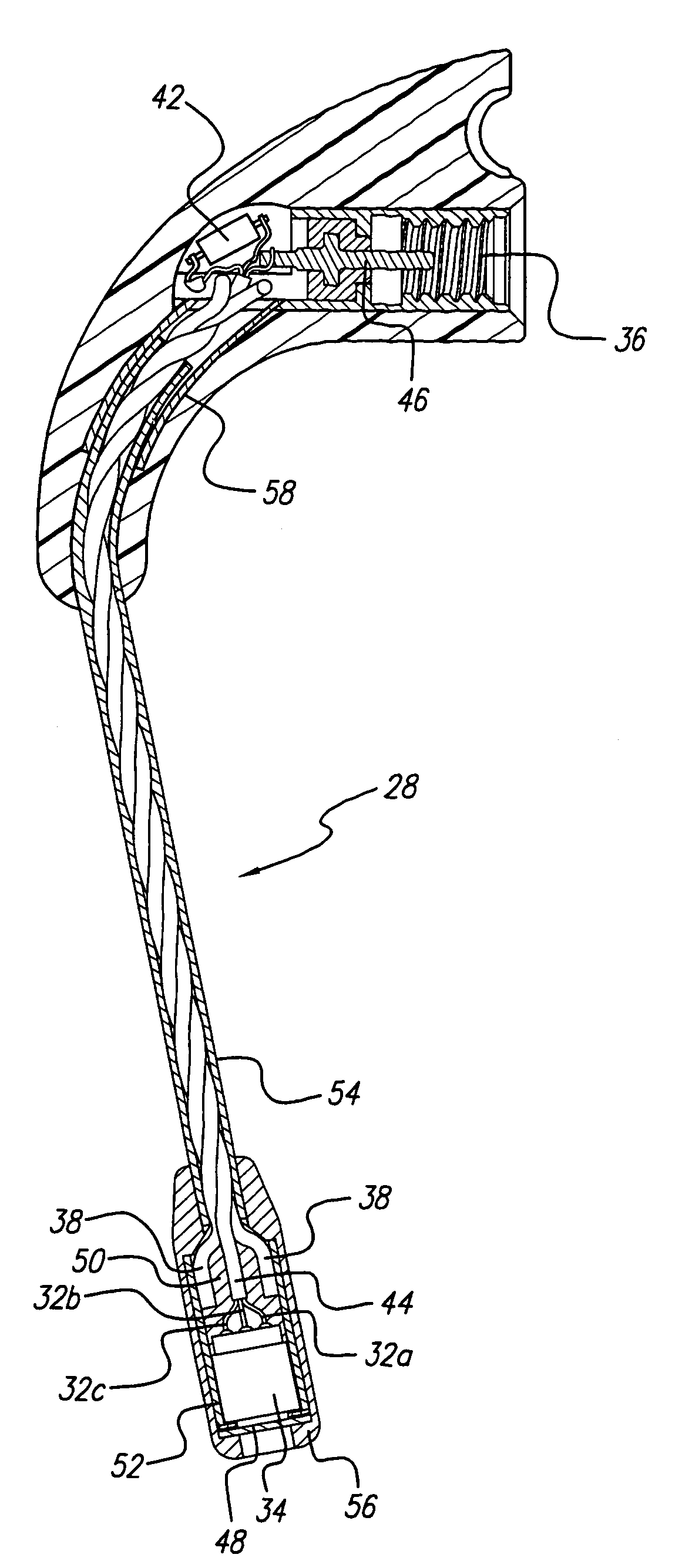

Variable gain active noise canceling system with improved residual noise sensing

InactiveUS6118878AReduce the possibilityCancellation system retains its effectiveness across its bandwidthNoise generationSound producing devicesInstabilityEngineering

An active noise cancellation system includes a series of features for more effective cancellation, greater reliability, and improved stability. A particular feature adapted for headset systems includes locating a residual microphone radially offset from the center of a sound generator to detect a signal more similar to that incident upon the eardrum of the user. In addition, an open back headset design includes perforations on the side of the headset instead of the back, so that the perforations are less susceptible to inadvertent blockage. The system also includes a mechanism for detecting changes in the acoustic characteristics of the environment that may be caused, for example, by pressure exerted upon the earpieces, and that may destabilize the cancellation system. The system automatically responds to such changes, for example, by reducing the gain or the frequency response of the system to preserve stability. The system further includes other methods for detecting imminent instability and compensating, such as detecting the onset of signals within enhancement frequencies characteristic of the onset of instability, and adjusting the gain or frequency response of the system or suppressing the enhanced signals. The system further includes a mechanism for conserving battery life by turning the system off when sound levels are low, or adjusting the power supply to the system to correspond to the current power requirements of the system.

Owner:NOISE CANCELLATION TECH

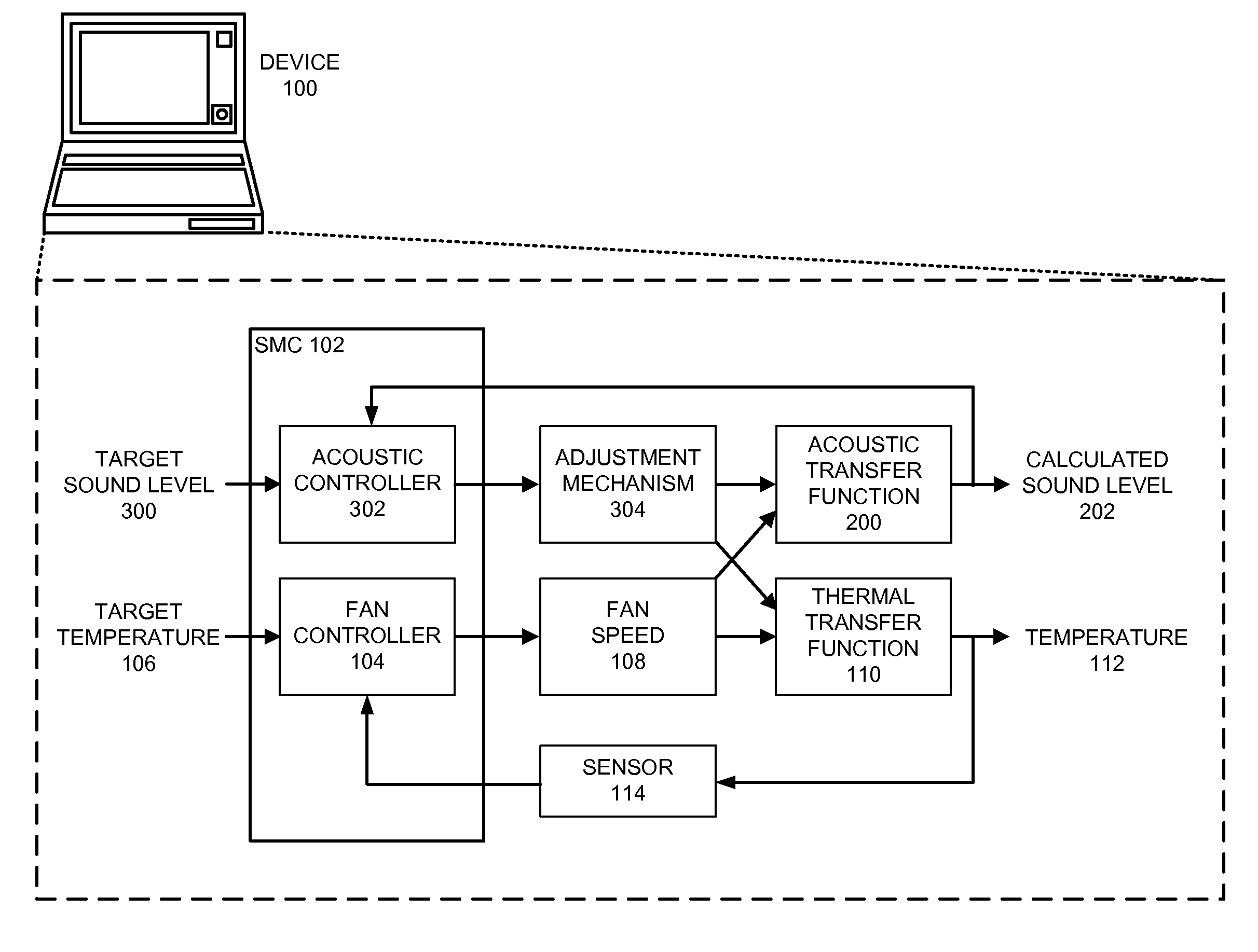

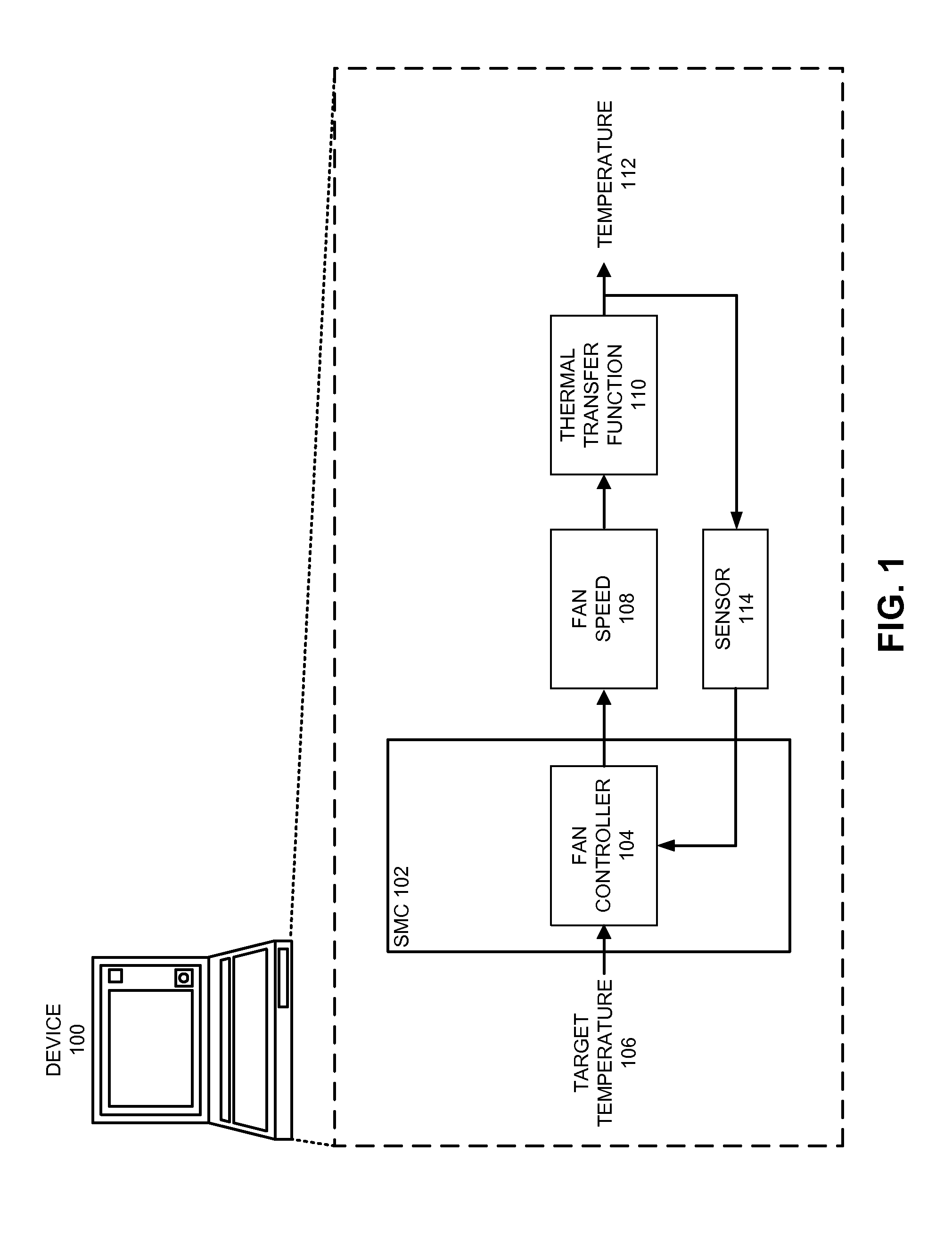

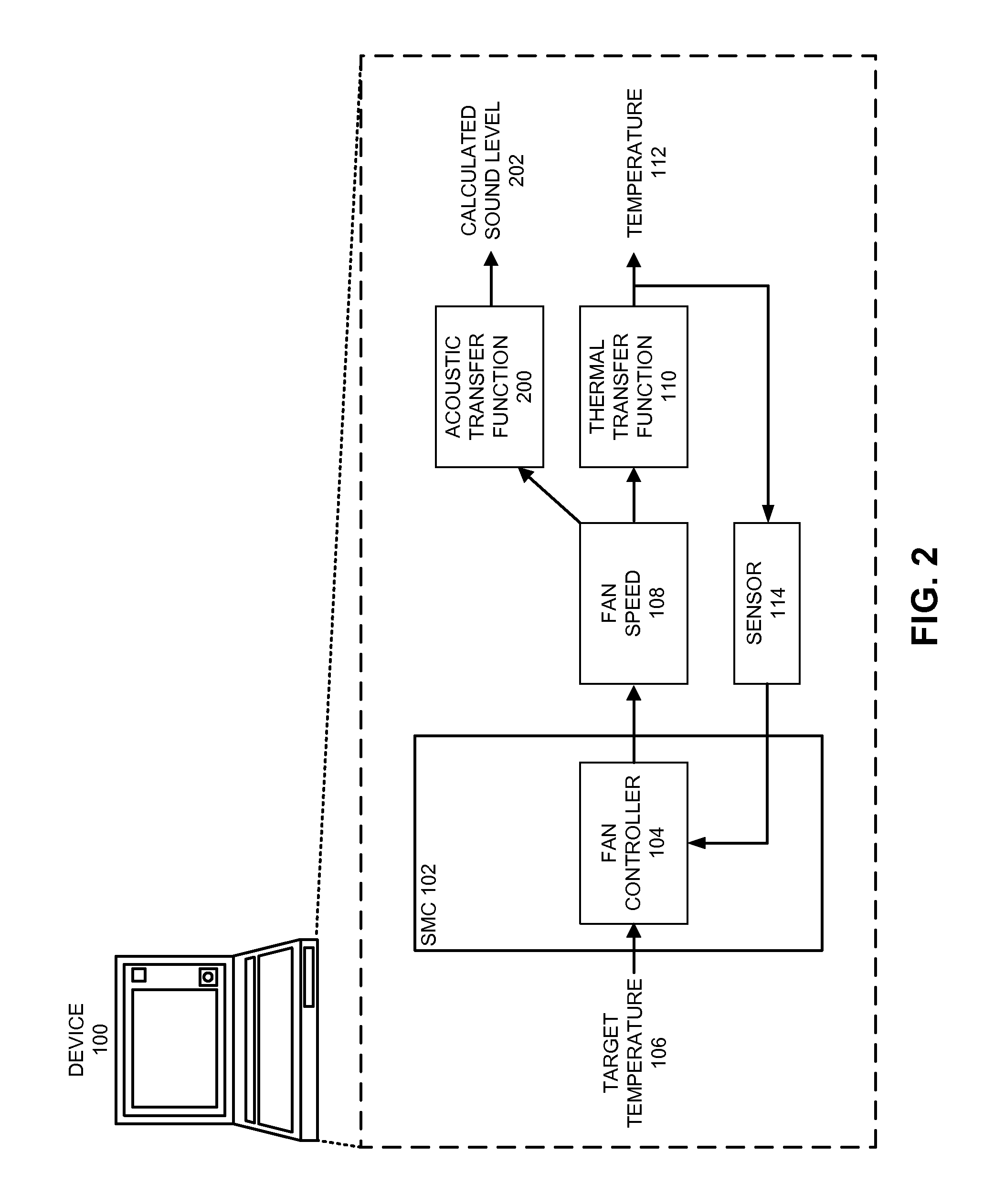

Managing acoustic noise produced by a device

One embodiment of the present invention provides a system that manages the acoustic noise produced by a device. During operation, the system receives a set of acoustic characteristics for the device. The system then uses these acoustic characteristics to estimate the acoustic noise being generated by the device. Next, the system uses the estimated acoustic noise to adjust a setting in the device to manage the acoustic noise produced by the device.

Owner:APPLE INC

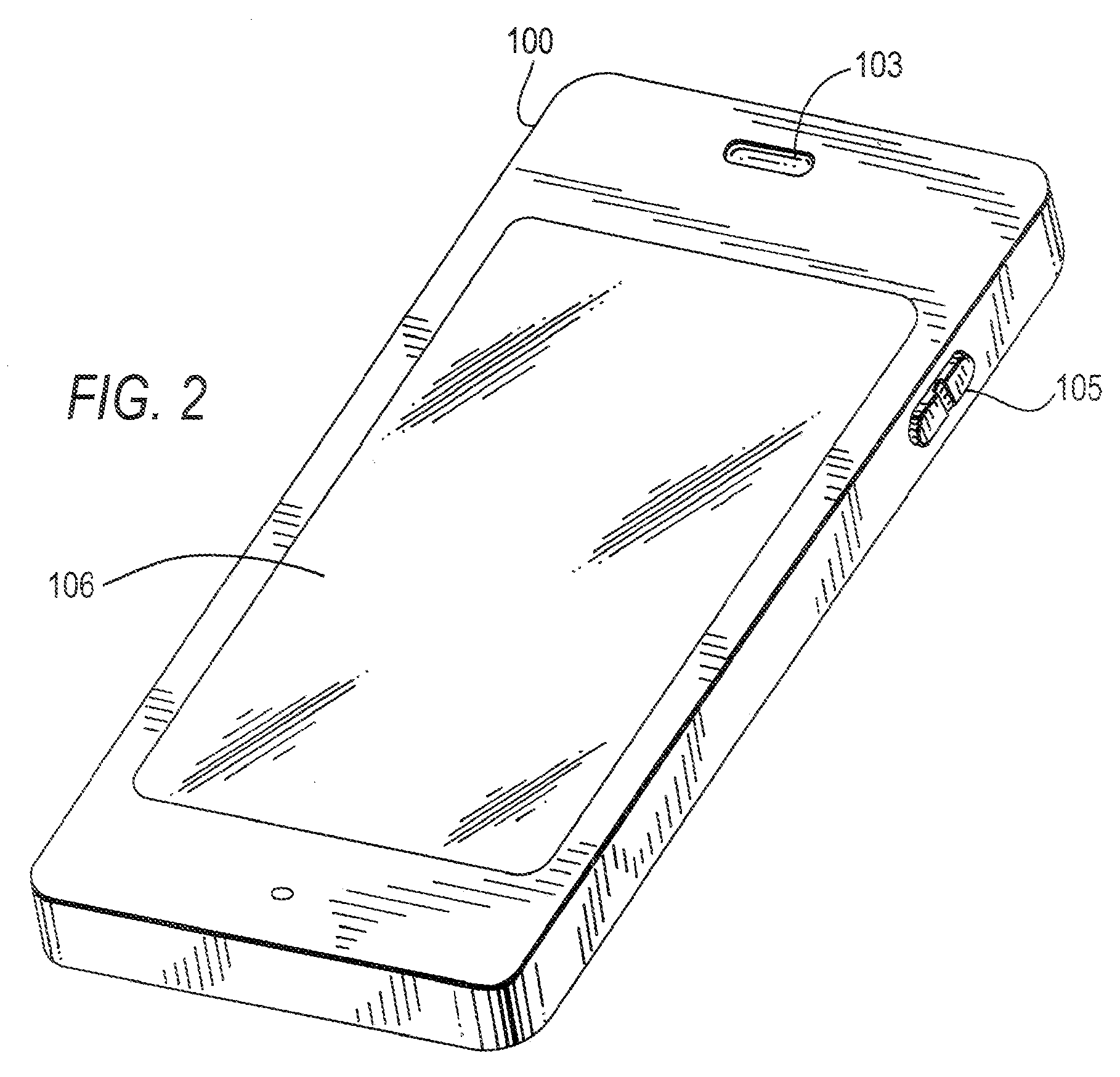

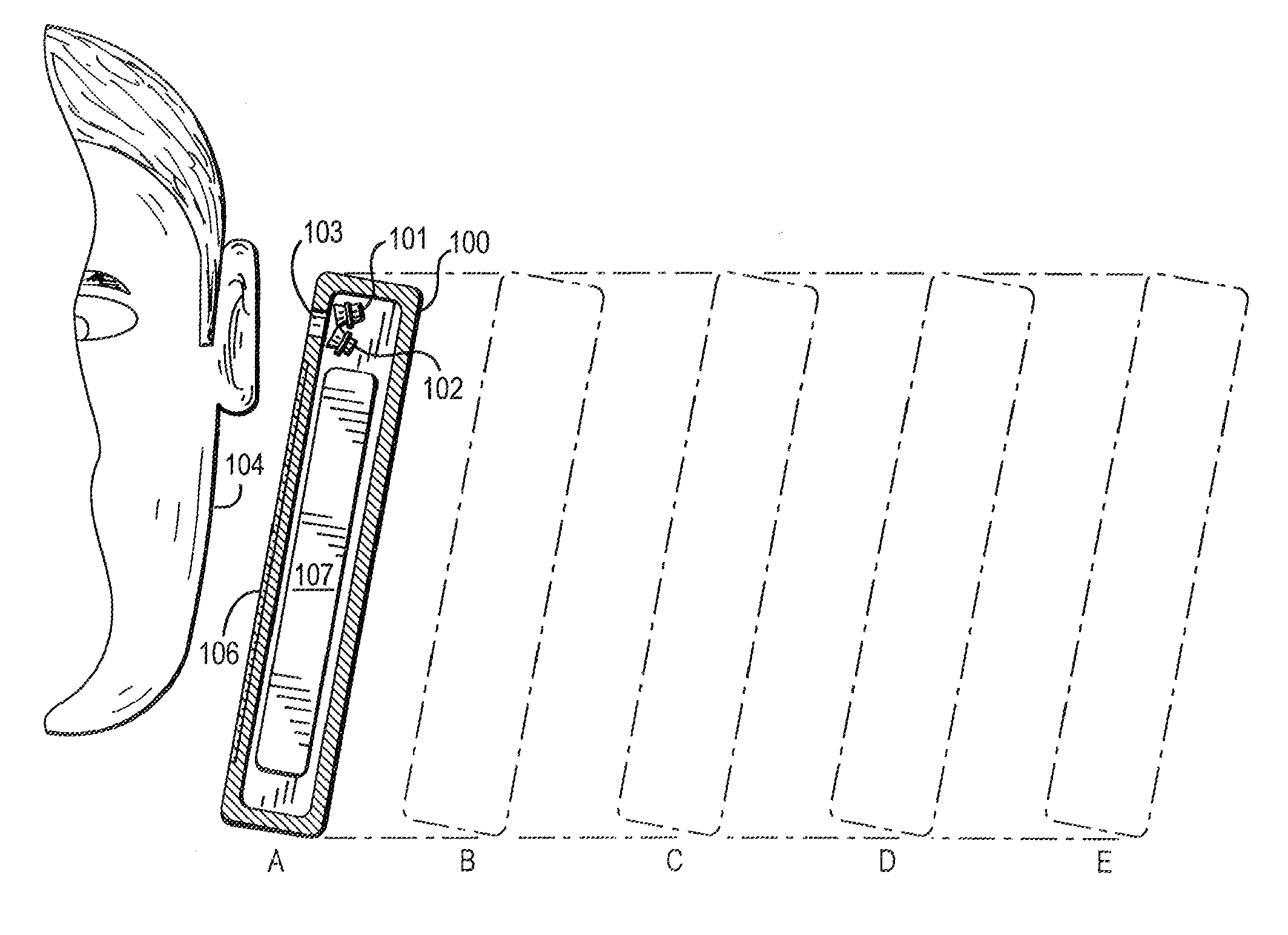

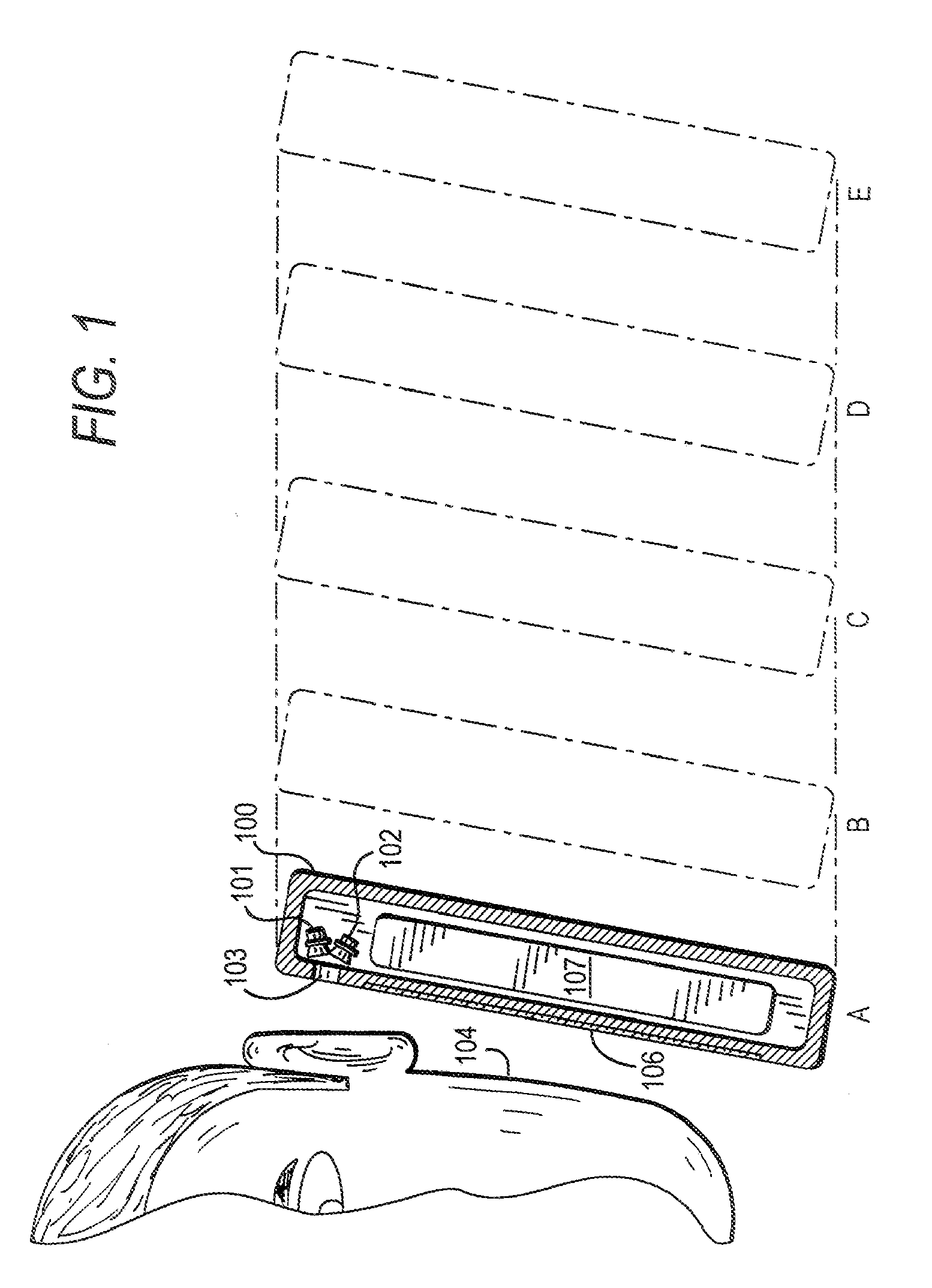

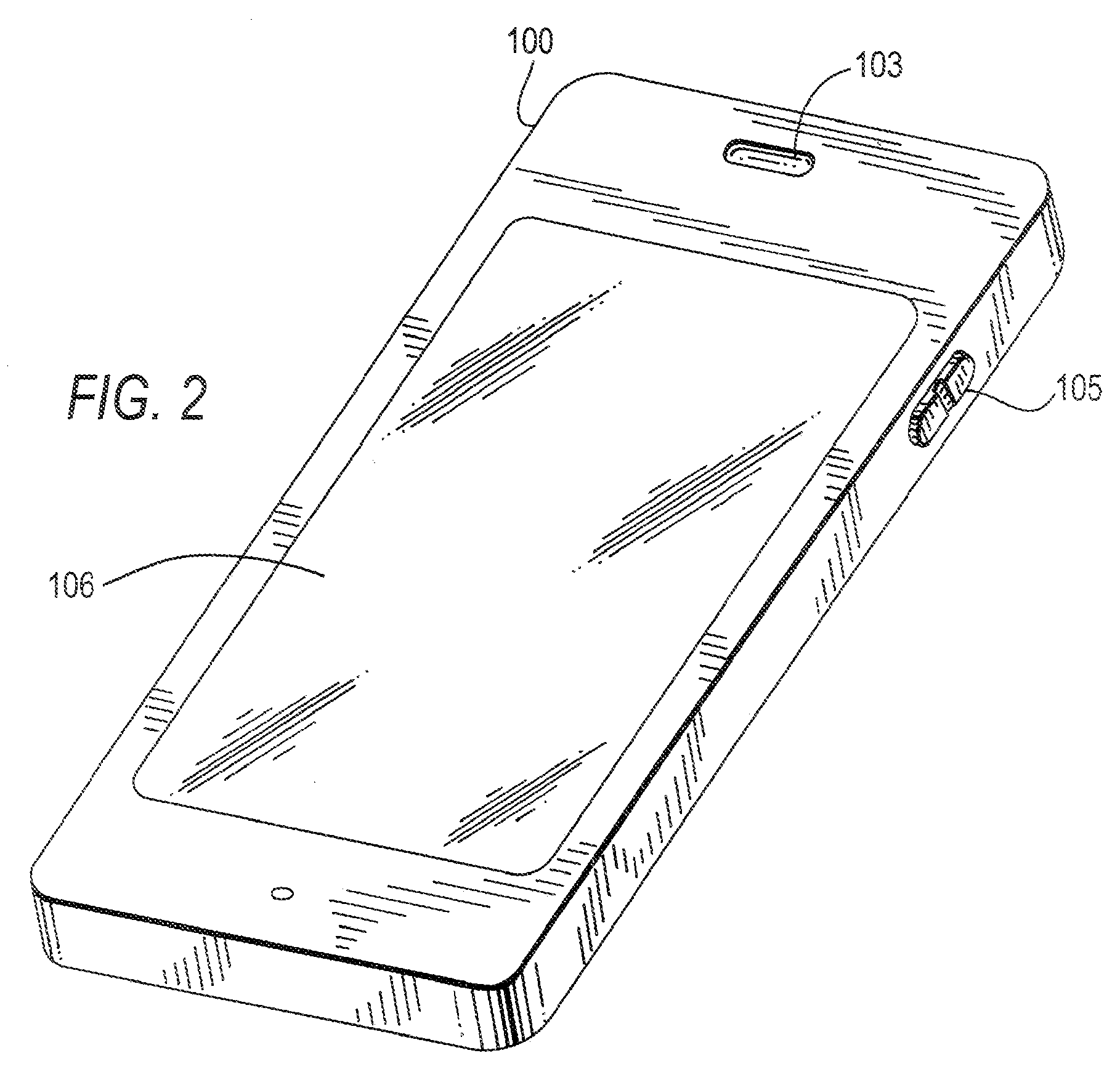

Adjustment of acoustic properties based on proximity detection

One or more acoustic transducers of a device may be adjusted based on automatic detection of device proximity to the user. In a mobile telephone, when the user is using the receiver and holding the telephone against his / her ear, if the telephone detects that the user has moved the telephone further from his / her ear, the telephone will raise the receiver volume. Similarly, if the user is using the speaker, the telephone will adjust the speaker volume as user distance from the telephone changes. In another embodiment the telephone may fade between the receiver and the speaker. Volume is not the only acoustic property that could be adjusted according to user proximity. Frequency response is another property that could be adjusted, such as using appropriate electronic filtering, or by turning on another transducer that is not otherwise being used.

Owner:APPLE INC

Multi-focal treatment of skin with acoustic energy

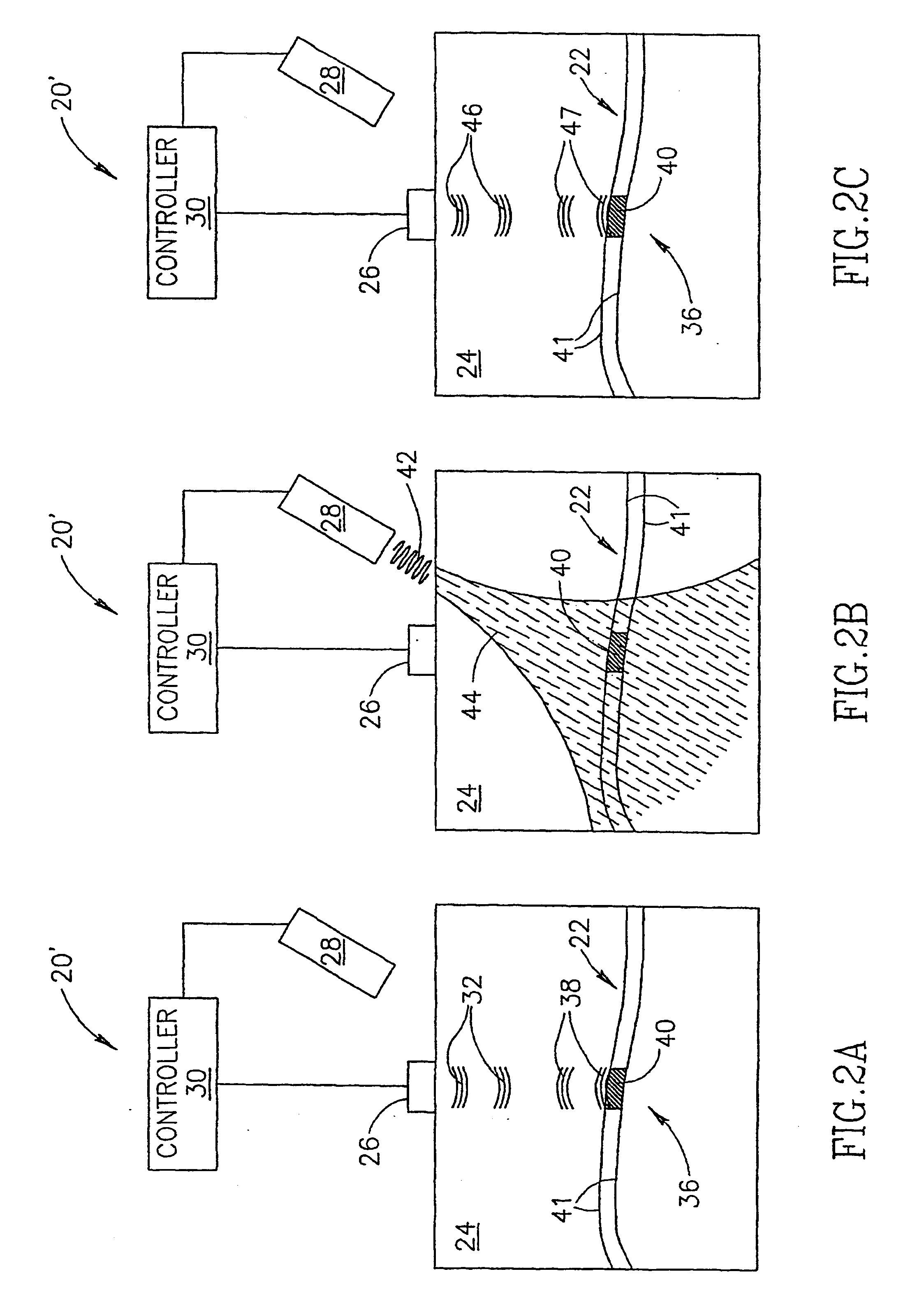

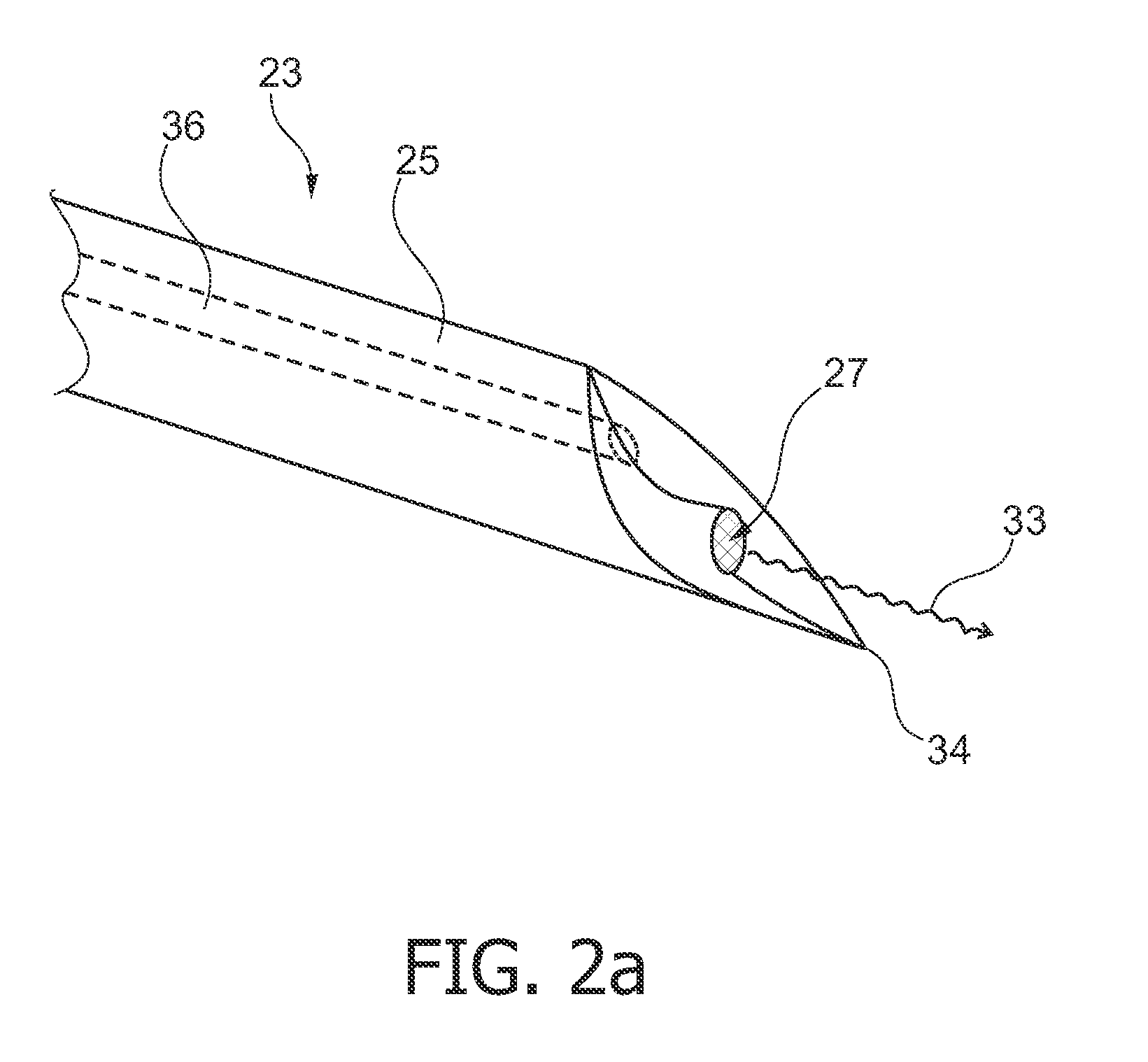

InactiveUS20080027328A1Reduce the possibilityIncrease contrastUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyFocal treatmentWavefront

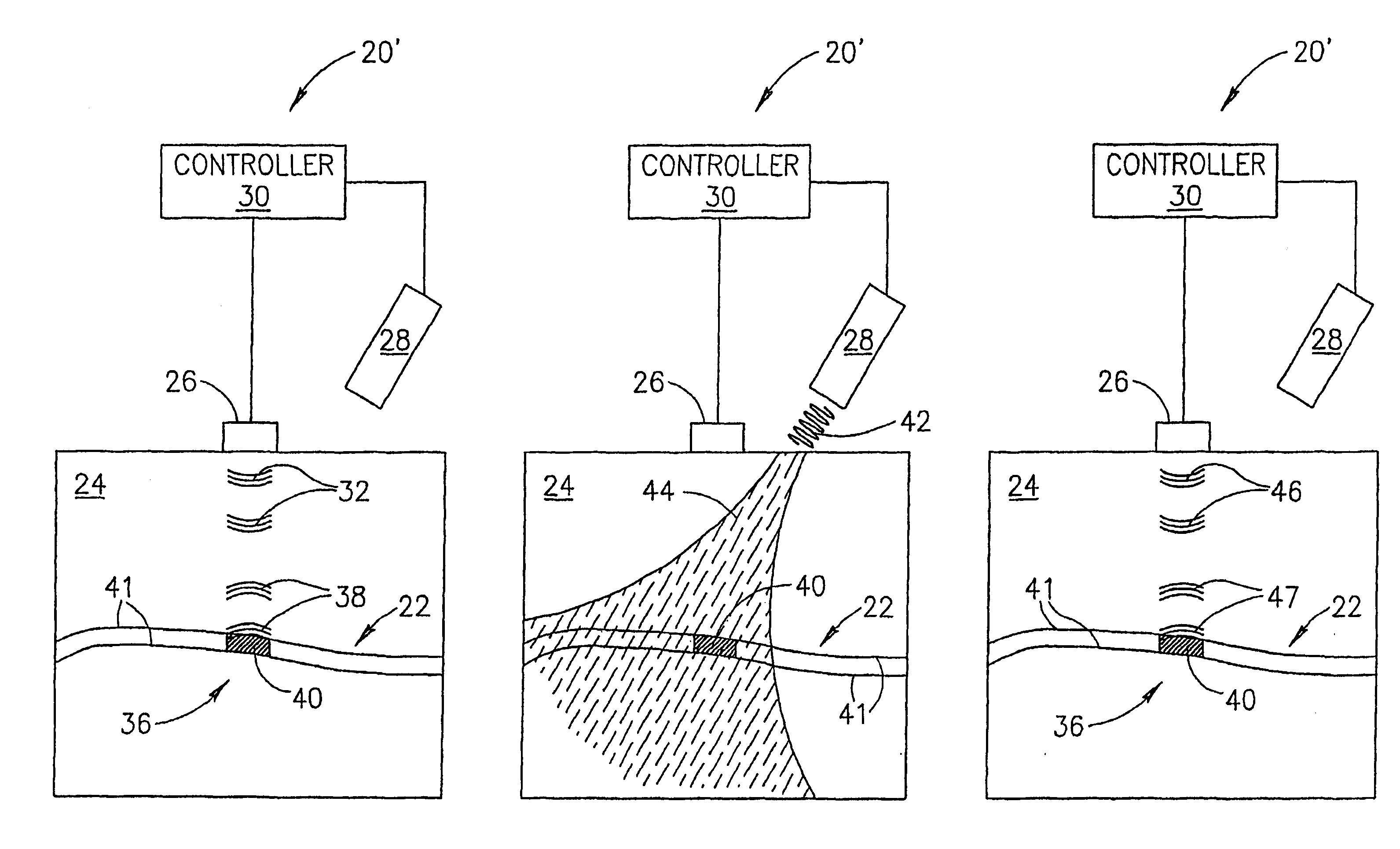

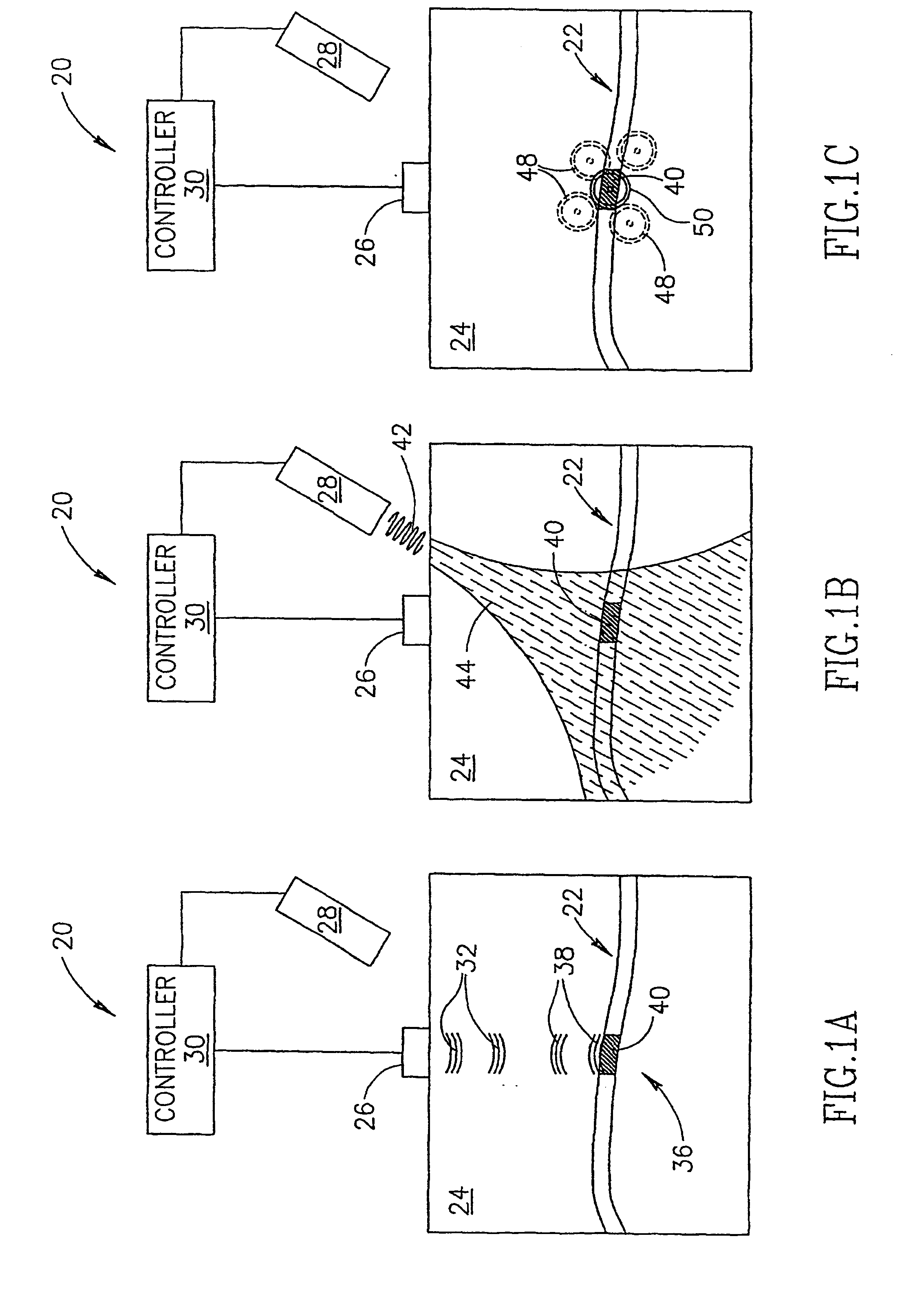

Methods and apparatus are disclosed for applying acoustic energy to the skin. Acoustic waveguides with elements of varying thickness or shape are disclosed which deliver energy to more than one depth below a surface of the skin substantially simultaneously. The invention is especially useful with devices that focus ultrasound energy by condensing a propagating wavefront. The invention compensates for the mismatch in acoustic properties of the device's waveguide and the biological tissue that typically cause portions of the collapsing wavefront to lag behind other portions and, thereby, limit the focusing capabilities of acoustic treatment devices.

Owner:JULIA THERAPEUTICS

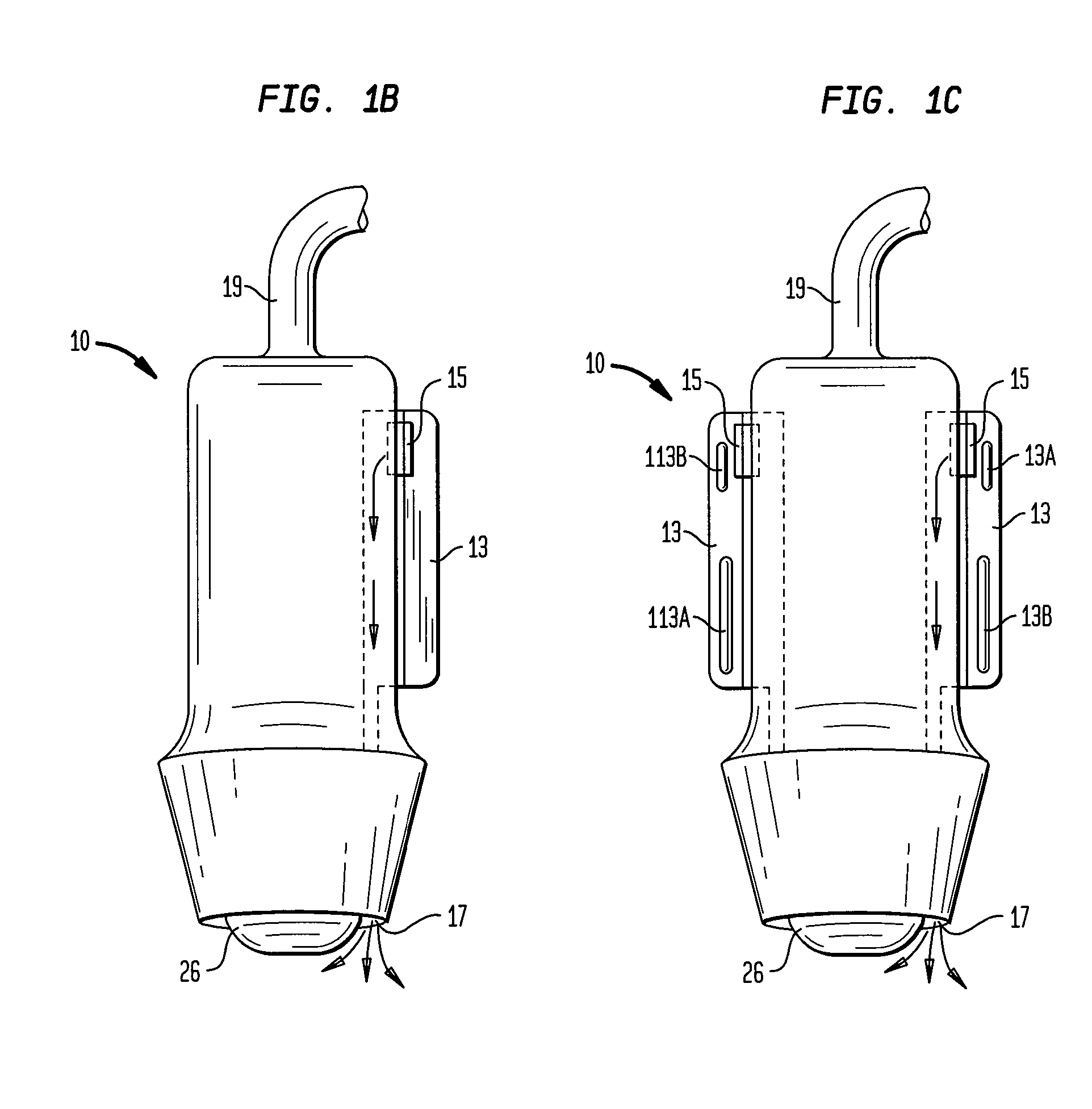

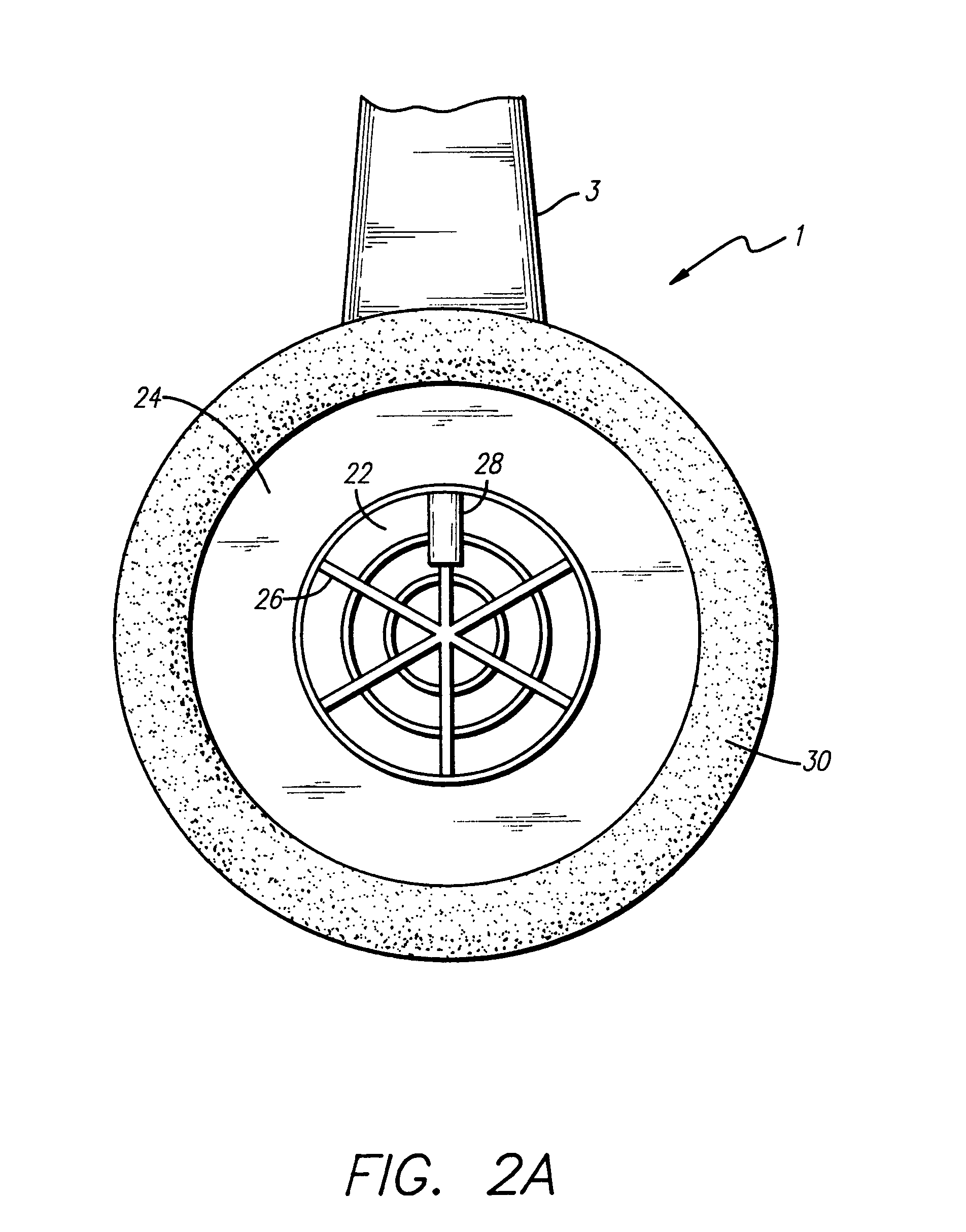

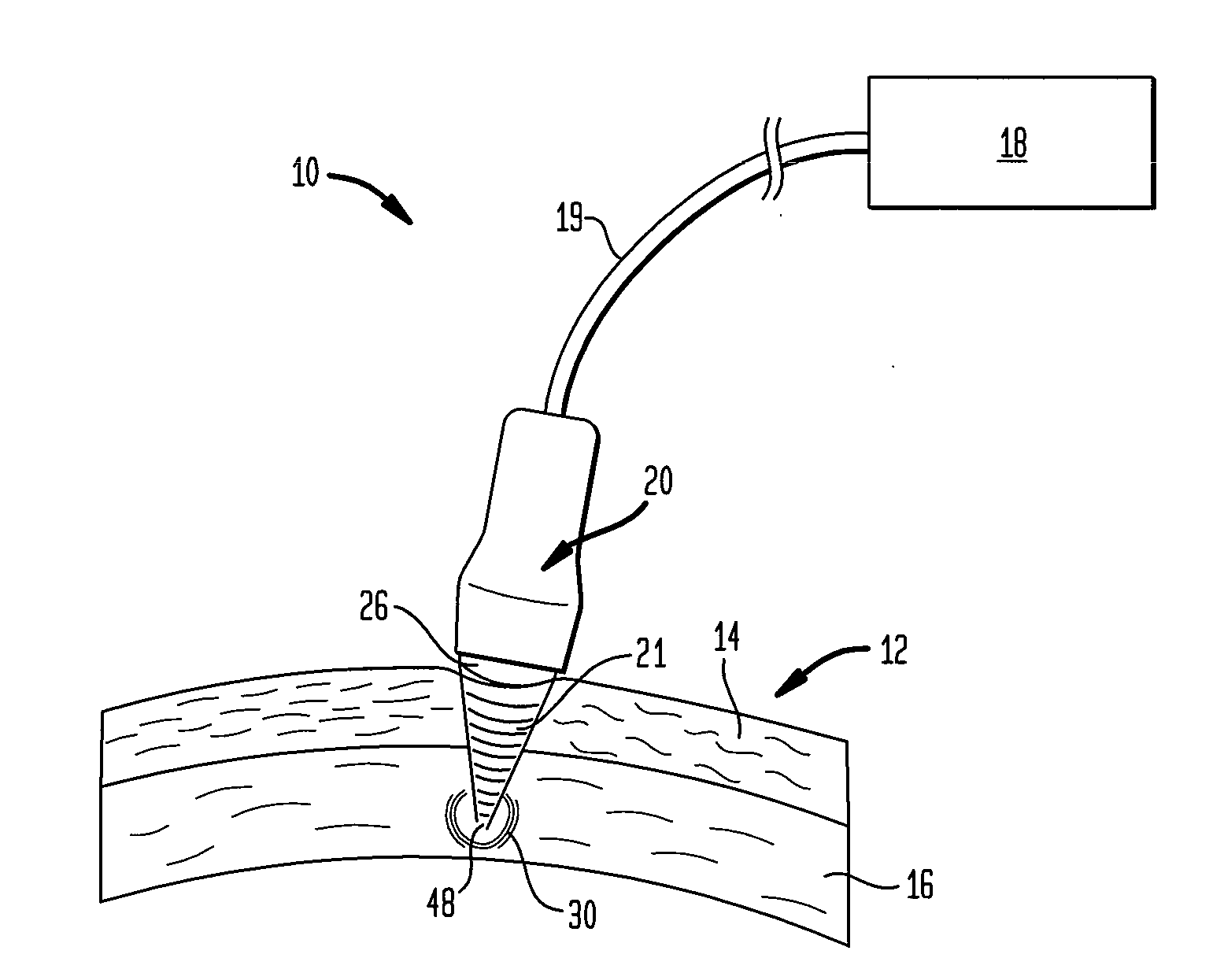

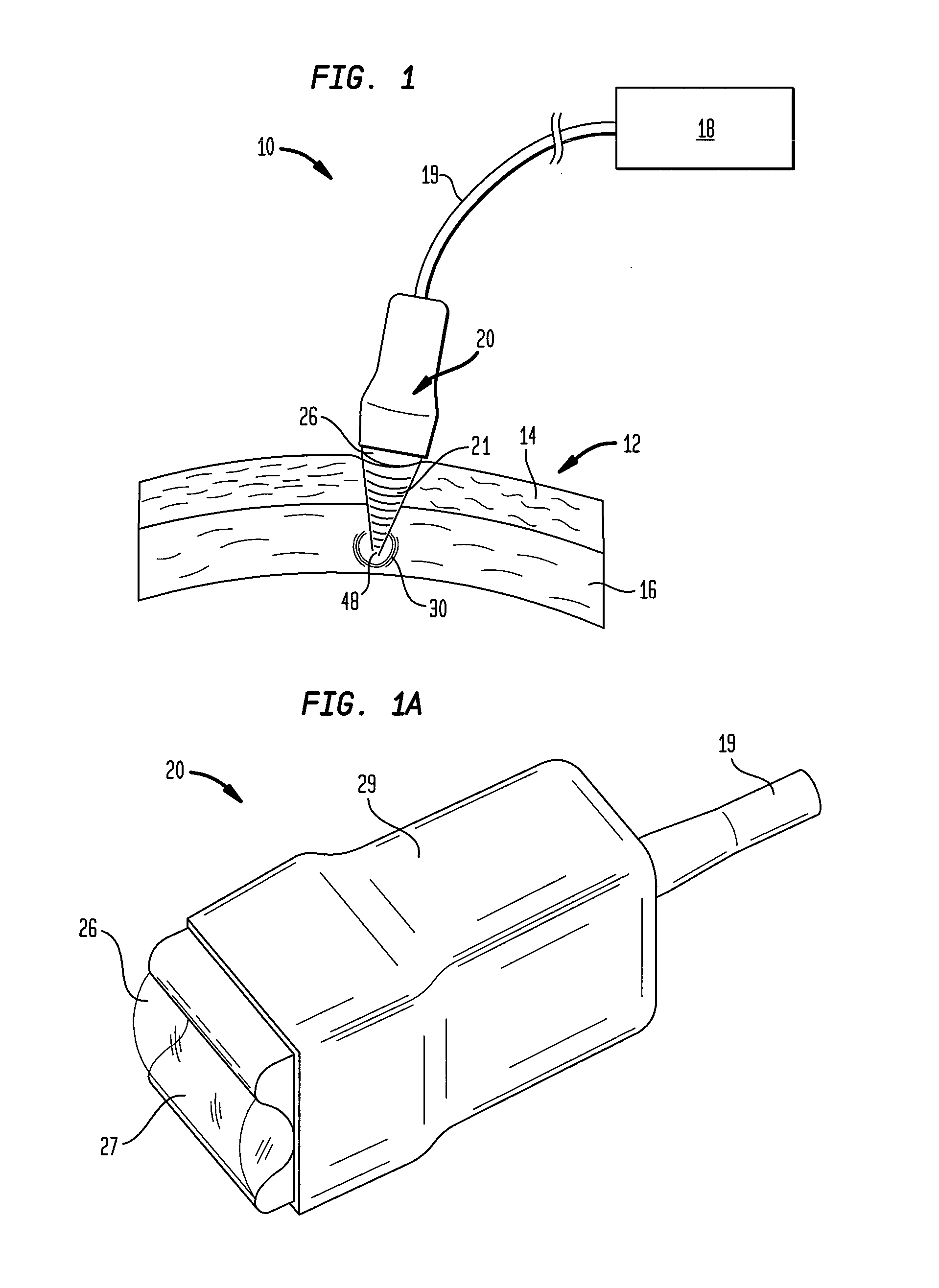

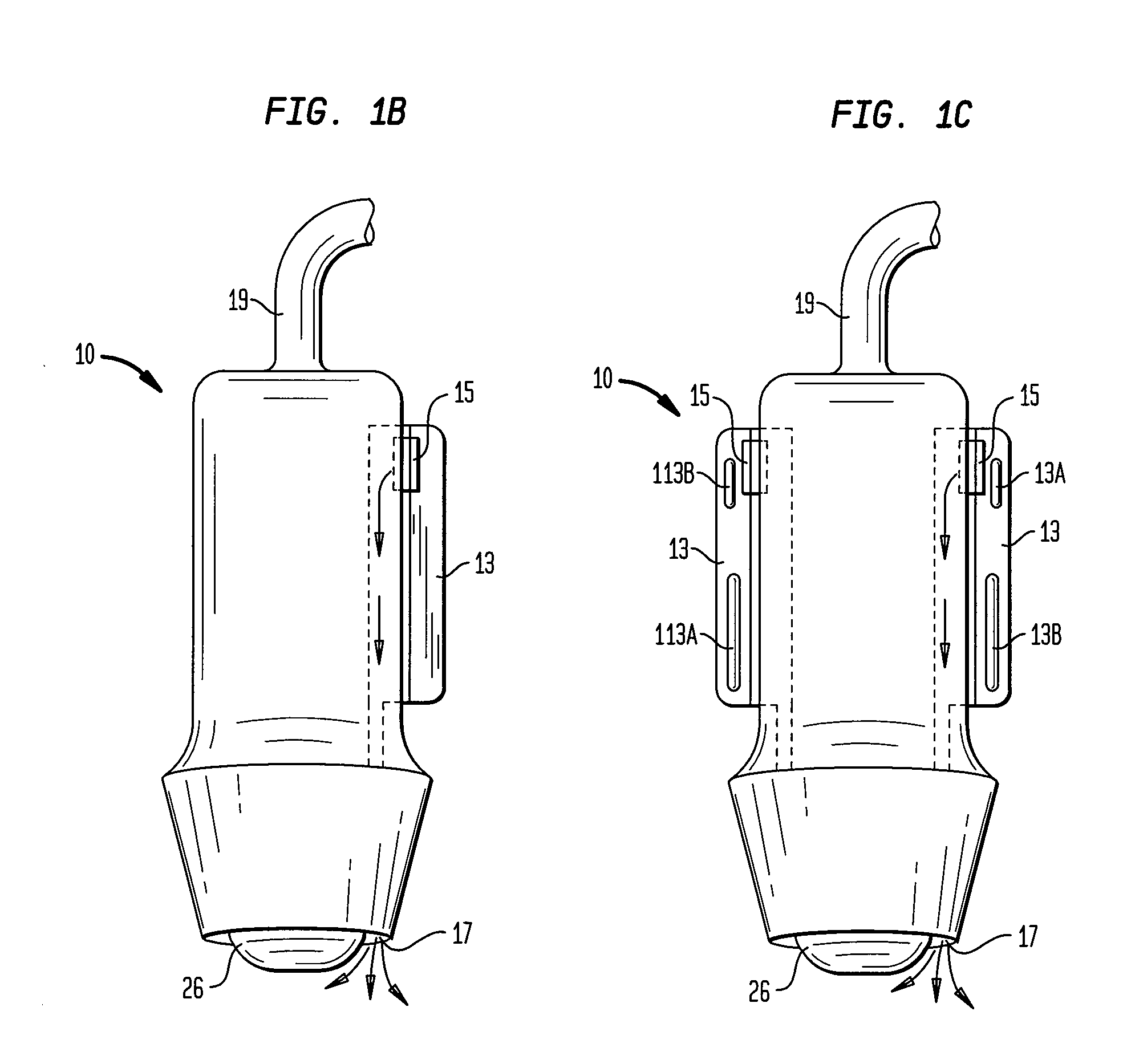

Systems and methods for determining intracranial pressure non-invasively and acoustic transducer assemblies for use in such systems

InactiveUS20050015009A1Accurate assessmentAccurate monitoringMedical data miningDiagnostics using vibrationsSound sourcesCentral sulcus artery

Systems and methods for determining ICP based on parameters that can be measured using non-invasive or minimally invasive techniques are provided, wherein a non-linear relationship is used to determine ICP based on one or more variable inputs. The first variable input relates to one or more properties of a cranial blood vessel and / or blood flow, such as acoustic backscatter from an acoustic transducer having a focus trained on a cranial blood vessel, flow velocity in a cranial blood vessel, and the like. Additional variables, such as arterial blood pressure (ABP), may be used in combination with a first variable input relating to one or more properties of a cranial blood vessel, such as flow velocity of the middle cerebral artery (MCA) to derive ICP using a non-linear relationship. Methods and systems for locating target areas based on their acoustic properties and for acoustic scanning of an area, identification of a target area of interest based on acoustic properties, and automated focusing of an acoustic source and / or detector on a desired target area are also provided. Acoustic transducer assemblies are described.

Owner:PHYSIOSONICS +1

Variable gain active noise cancelling system with improved residual noise sensing

InactiveUS7103188B1Less instabilityImprove Noise CancellationEar treatmentHearing device active noise cancellationInstabilityEngineering

An active noise cancellation system includes a series of features for more effective cancellation, greater reliability, and improved stability. A particular feature adapted for headset systems includes locating a residual microphone radially offset from the center of a sound generator to detect a signal more similar to that incident upon the eardrum of the user. In addition, an open back headset design includes perforations on the side of the headset instead of the back, so that the perforations are less susceptible to inadvertent blockage. The system also includes a mechanism for detecting changes in the acoustic characteristics of the environment that may be caused, for example, by pressure exerted upon the earpieces, and that may destabilize the cancellation system. The system automatically responds to such changes, for example, by reducing the gain or the frequency response of the system to preserve stability. The system further includes other methods for detecting imminent instability and compensating, such as detecting the onset of signals within enhancement frequencies characteristic of the onset of instability, and adjusting the gain or frequency response of the system or suppressing the enhanced signals. The system further includes a mechanism for conserving battery life by turning the system off when sound levels are low, or adjusting the power supply to the system to correspond to the current power requirements of the system.

Owner:NCT GROUP

Treatment of skin with acoustic energy

InactiveUS20060184071A1Lower capability requirementsCompensation DistortionUltrasound therapySurgeryFocus ultrasoundWavefront

Methods and apparatus are disclosed for applying acoustic energy to the skin whereby the wavefront can be controlled to confine the focused energy to a desired subsurface region. Acoustic waveguides are disclosed which compensate for distortions that otherwise occur when a focused acoustic beam crosses a boundary, such as the transition from a treatment device to a target region of skin. The invention is especially useful with devices that focus ultrasound energy by condensing a propagating wavefront. The invention compensates for the mismatch in acoustic properties of the device's waveguide and the biological tissue that typically cause portions of the collapsing wavefront to lag behind other portions and, thereby, limit the focusing capabilities of acoustic treatment devices.

Owner:JULIA THERAPEUTICS

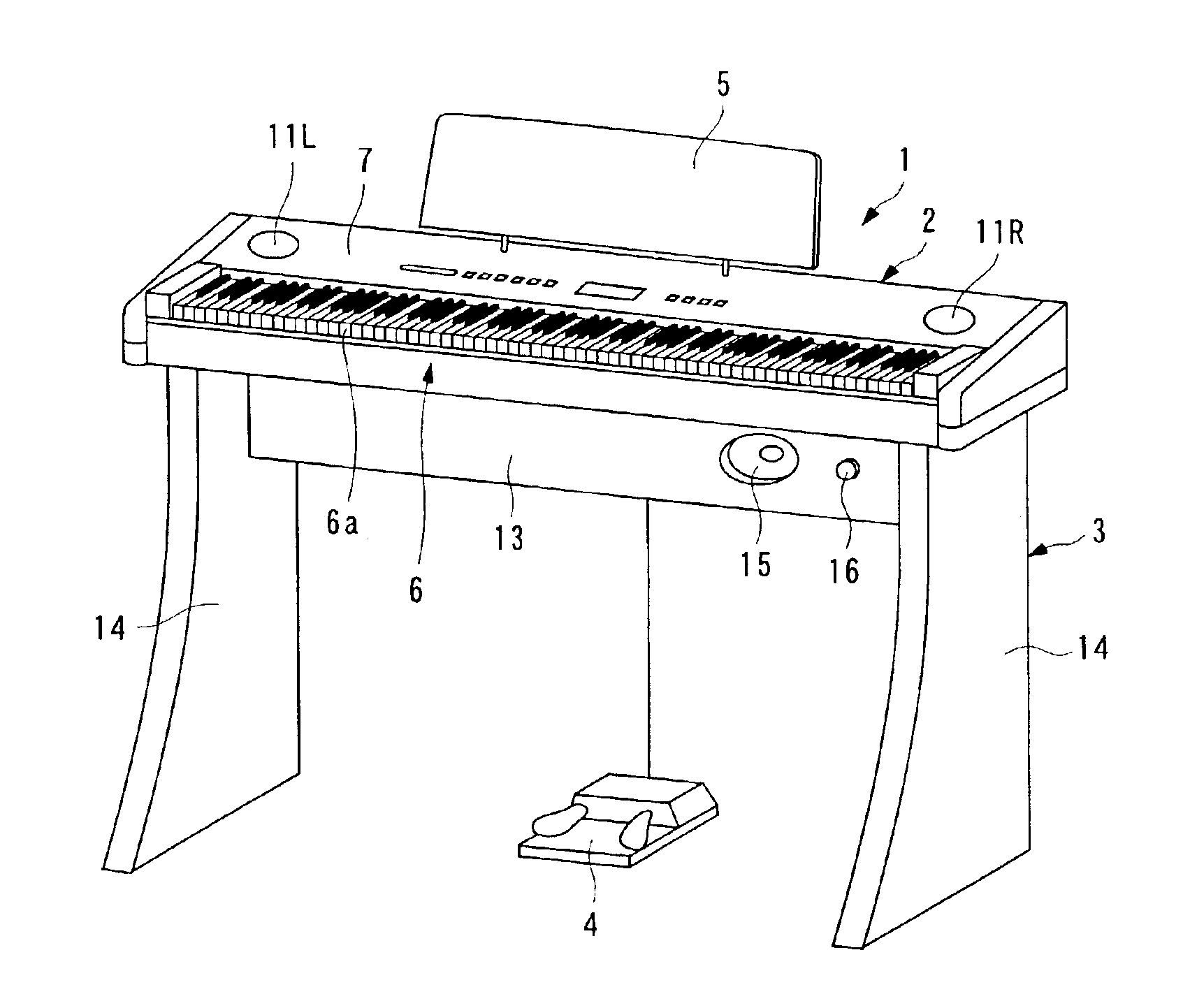

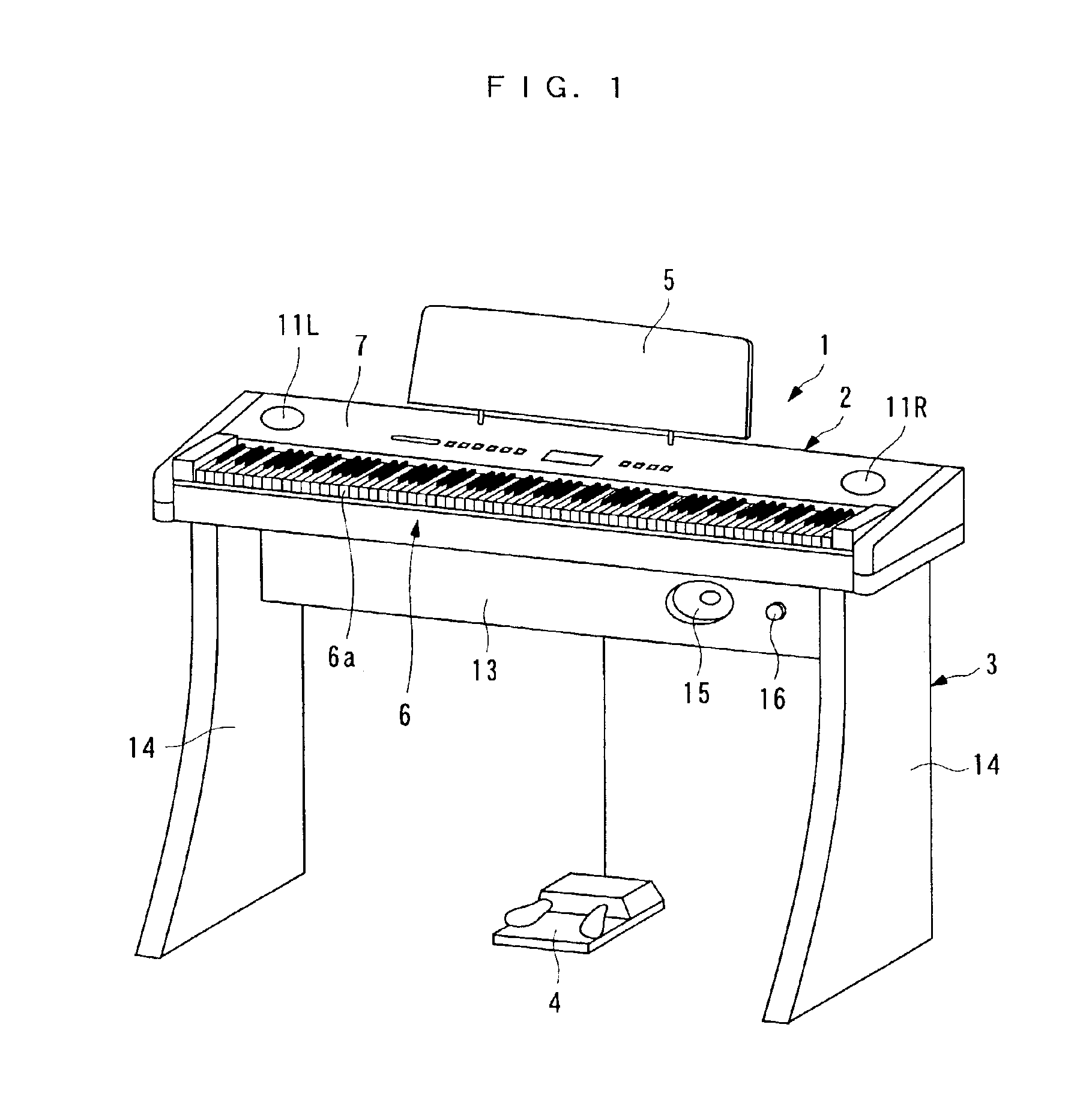

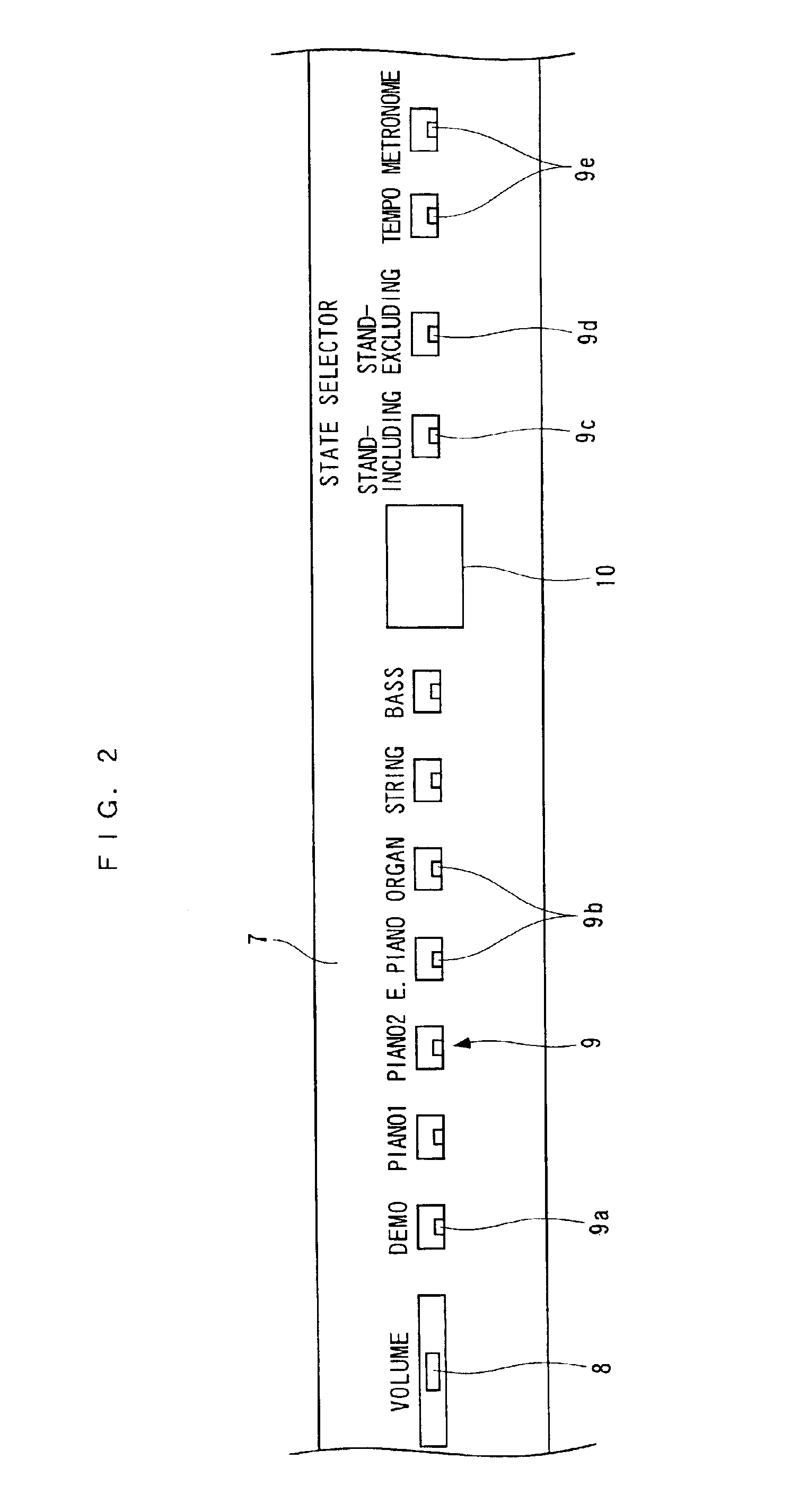

Acoustic control system for electronic musical instrument

InactiveUS6916980B2Optimize layoutAvailable spaceElectrophonic musical instrumentsTransducer casings/cabinets/supportsPianoControl system

An acoustic control system for an electronic musical instrument, which can obtain optimal acoustic characteristics irrespective of whether or not a low range speaker is attached to a body thereof. A piano body has high range and mid range speakers. A low range speaker is removable from the body. A stand-excluding switch designates a first speaker-use mode for using the high range and mid range speakers alone, and a stand-including switch designates a both speaker-use mode for using both the high range and mid range speakers and the low range speaker. A ROM stores stand-excluding and stand-including factors for setting acoustic characteristics in the two modes, respectively. A CPU reads one of the factors, which corresponds to the mode designated by the stand-excluding or stand-including switch. A tone generator circuit generates a musical tone signal to be reproduced in one of the modes, based on the read factor.

Owner:KAWAI MUSICAL INSTR MFG CO

System for modifying an acoustic space with audio source content

An audio signal processing system is configured to separate an audio signal into a dry signal component and one or more reverberant signal components. The dry signal component and the reverberant signal components can be separately modified and then recombined to form a processed audio signal. Alternatively, the dry signal component may be combined with an artificial reverberation component to form the processed audio signal. Modification of the reverberation signal component and generation of the artificial reverberation component may be performed in order to modify the acoustic characteristics of an acoustic space in which the audio signal is driving loudspeakers. The audio signal may be a pre-recorded audio signal or a live audio signal generated inside or outside the acoustic space.

Owner:HARMAN INT IND INC

Photoacoustic assay and imaging system

InactiveUS6846288B2High measurement accuracyPath lengthUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesAssayLength wave

A method for assaying a component of a localized region of interest in a body comprising: illuminating the region with at least one pulse of radiation having a wavelength at which the radiation is absorbed by the component to generate a change in an acoustic property of the region; transmitting ultrasound so that it is incident on the region; measuring at least one effect of the change on the incident ultrasound; using the measured at least one effect to determine an absorption coefficient for the radiation in the region; and using the determined absorption coefficient to determine concentration of the component in the region.

Owner:PHC HLDG CORP

Gel dispensers for treatment of skin with acoustic energy

InactiveUS20080146970A1Lower capability requirementsCompensation DistortionUltrasound therapySurgeryWavefrontAcoustic energy

Methods and apparatus are disclosed for dispensing fluid in an apparatus for applying acoustic energy to the skin. Acoustic waveguides are disclosed which compensate for distortions that otherwise occur when a focused acoustic beam crosses a boundary, such as the transition from a treatment device to a target region of skin. The invention is especially useful with devices that focus ultrasound energy by condensing a propagating wavefront. The invention compensates for the mismatch in acoustic properties of the device's waveguide and the biological tissue that typically cause portions of the collapsing wavefront to lag behind other portions and, thereby, limit the focusing capabilities of acoustic treatment devices.

Owner:JULIA THERAPEUTICS

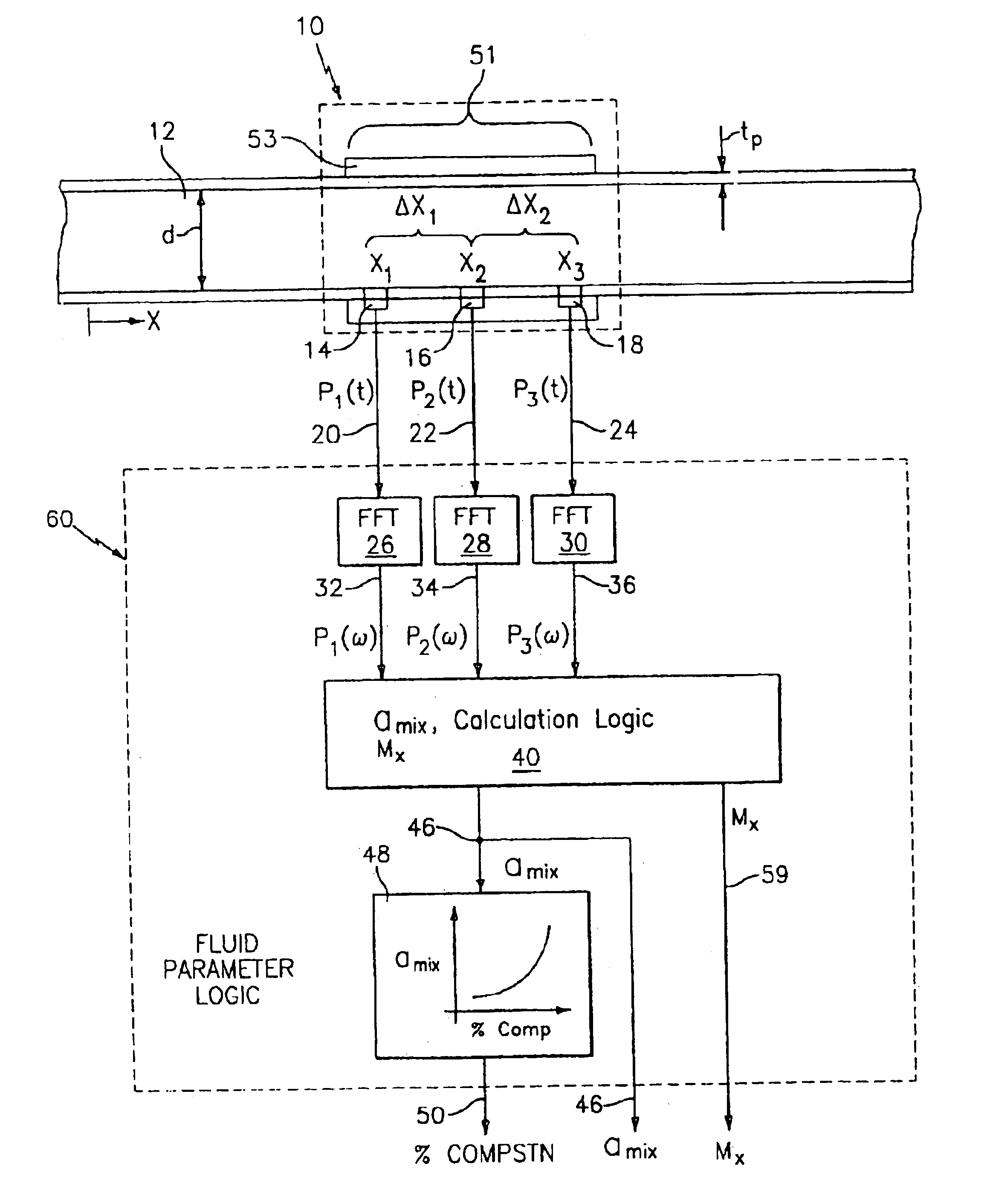

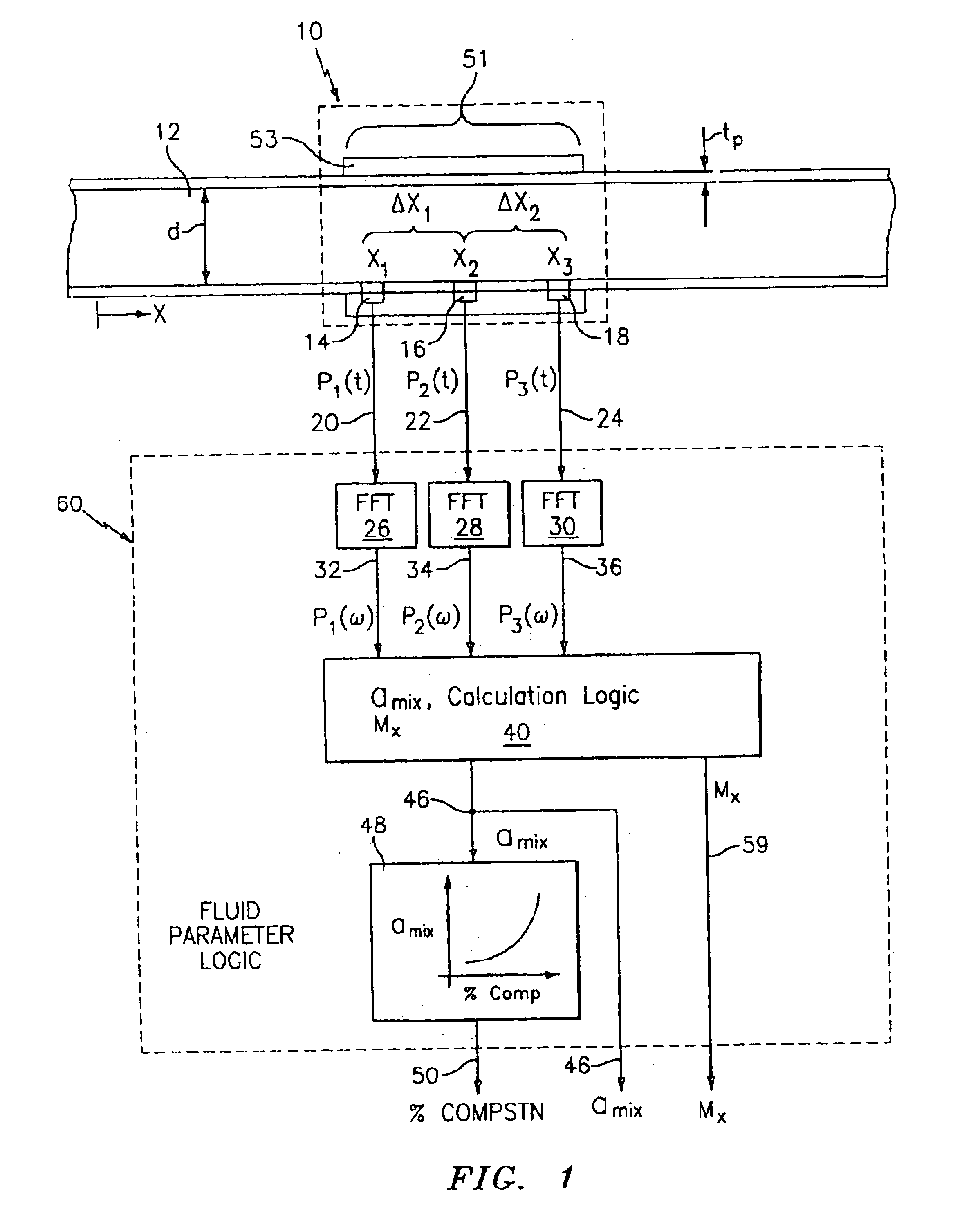

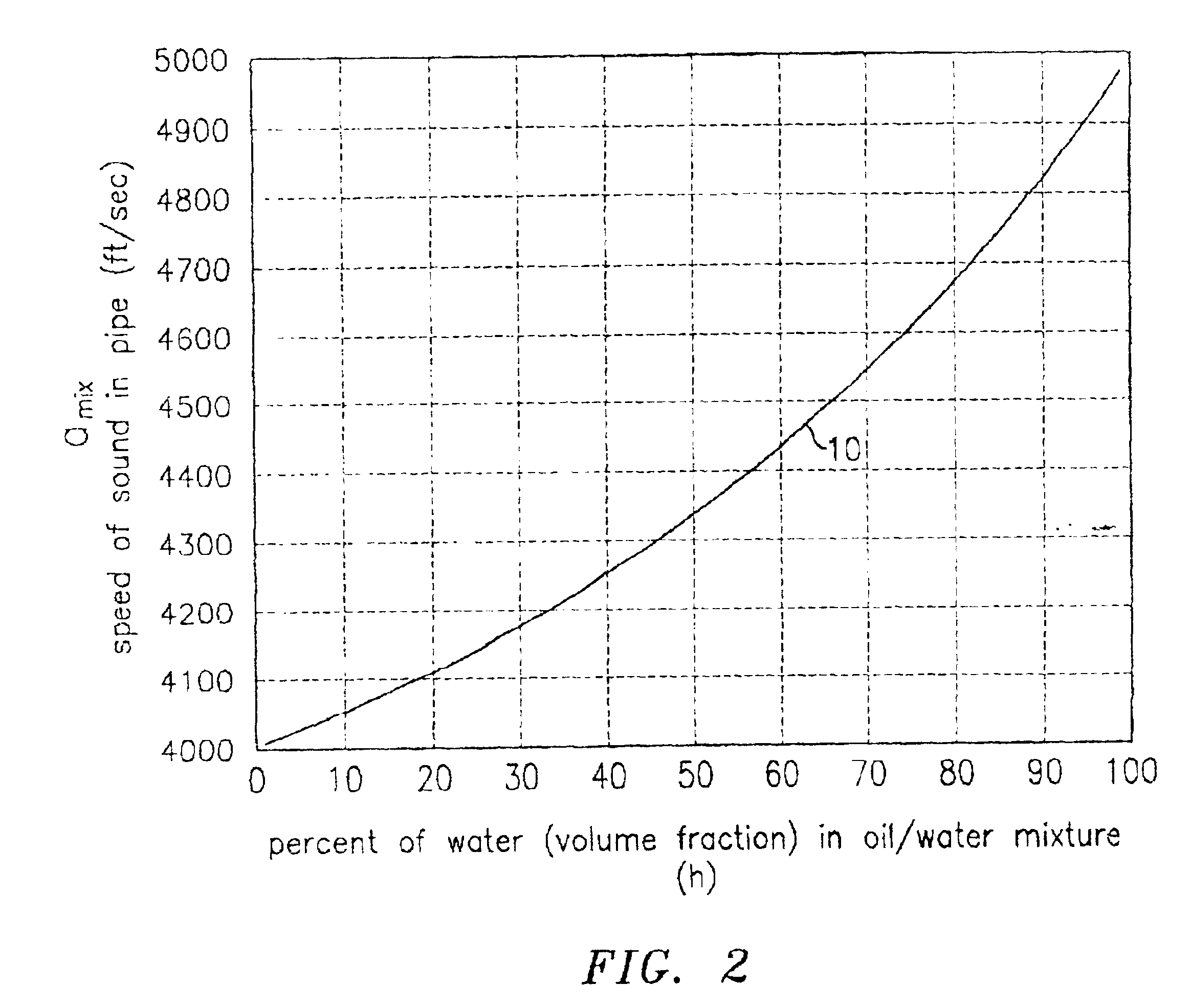

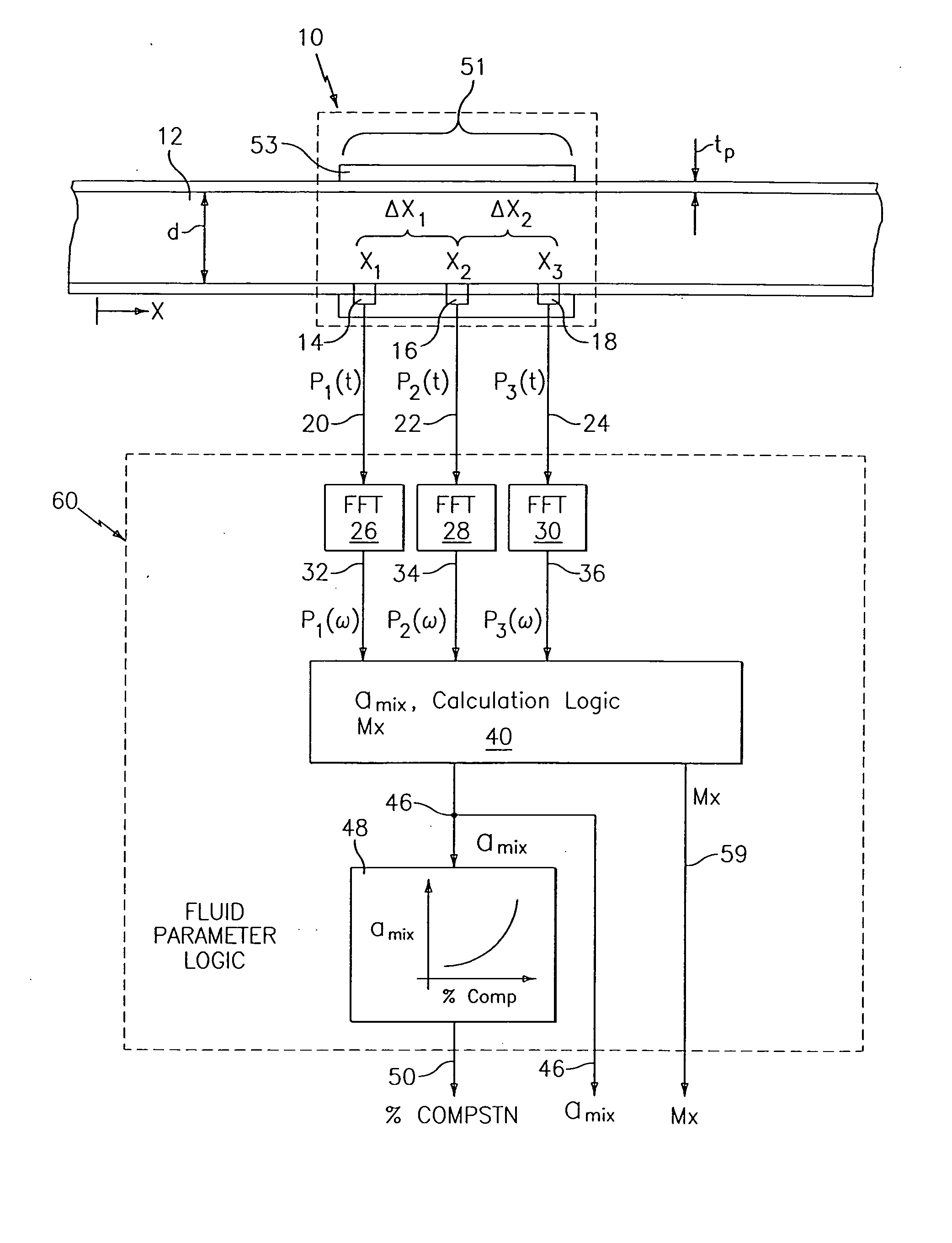

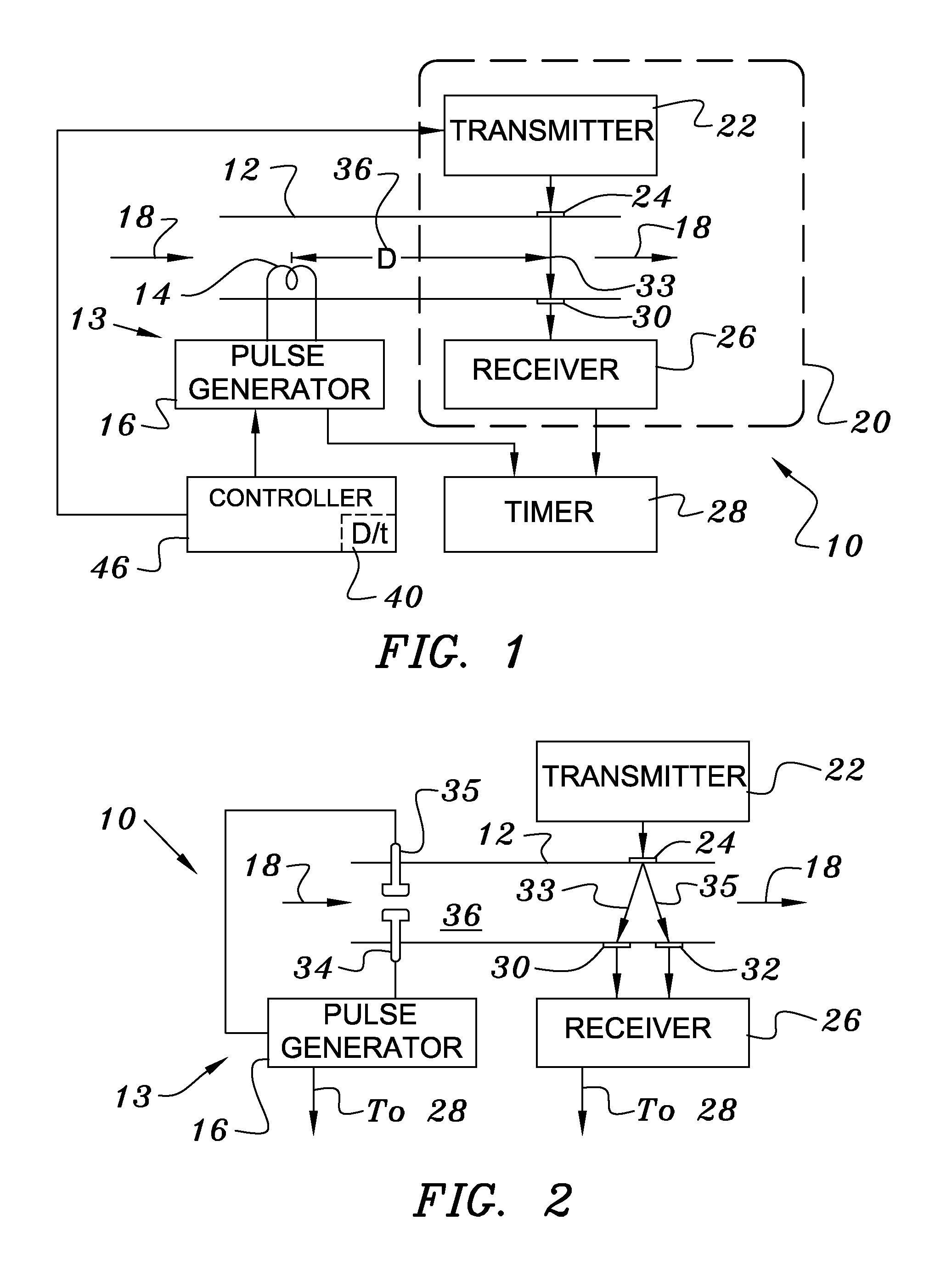

Fluid parameter measurement in pipes using acoustic pressures

InactiveUS6862920B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWater fraction

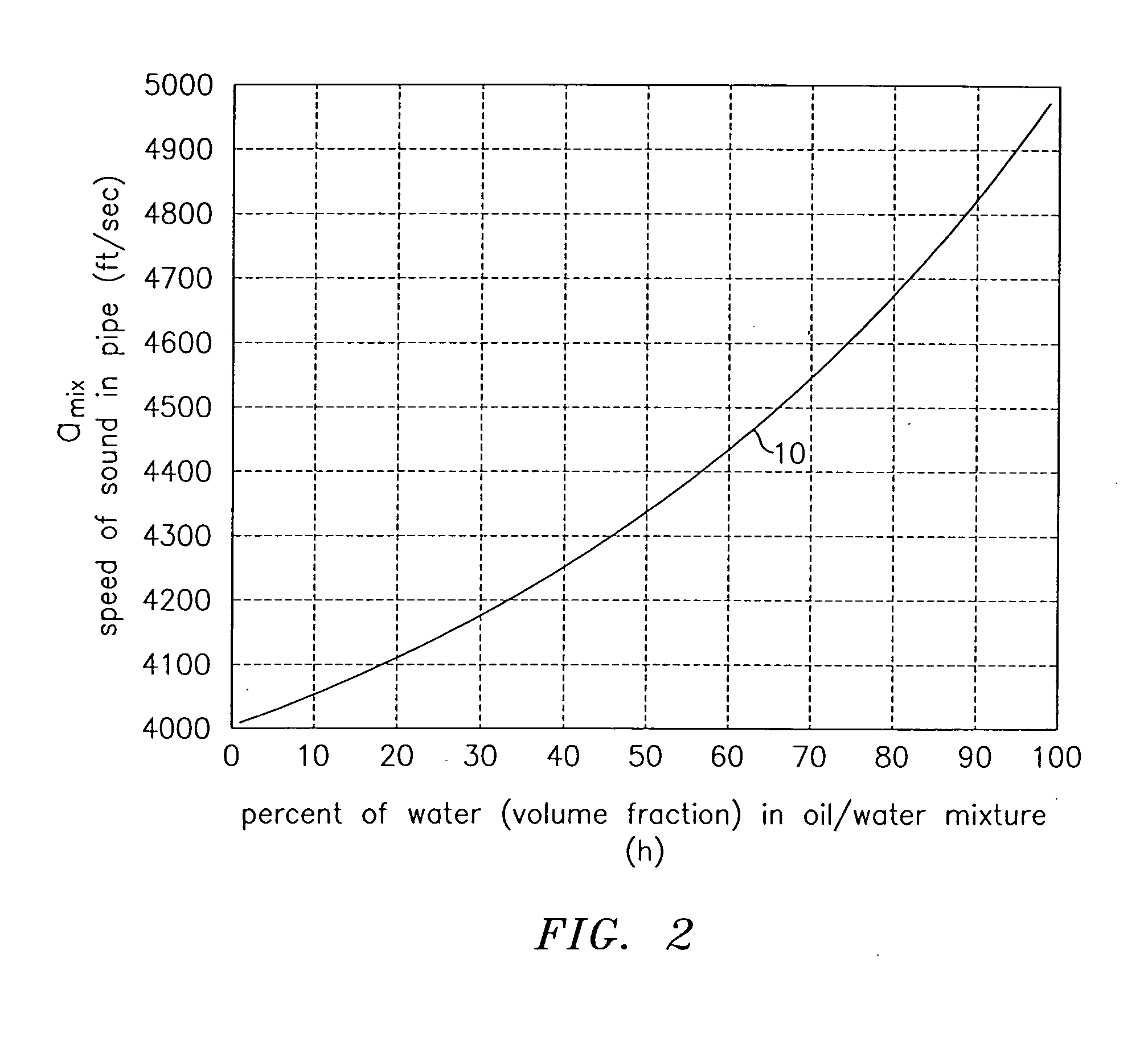

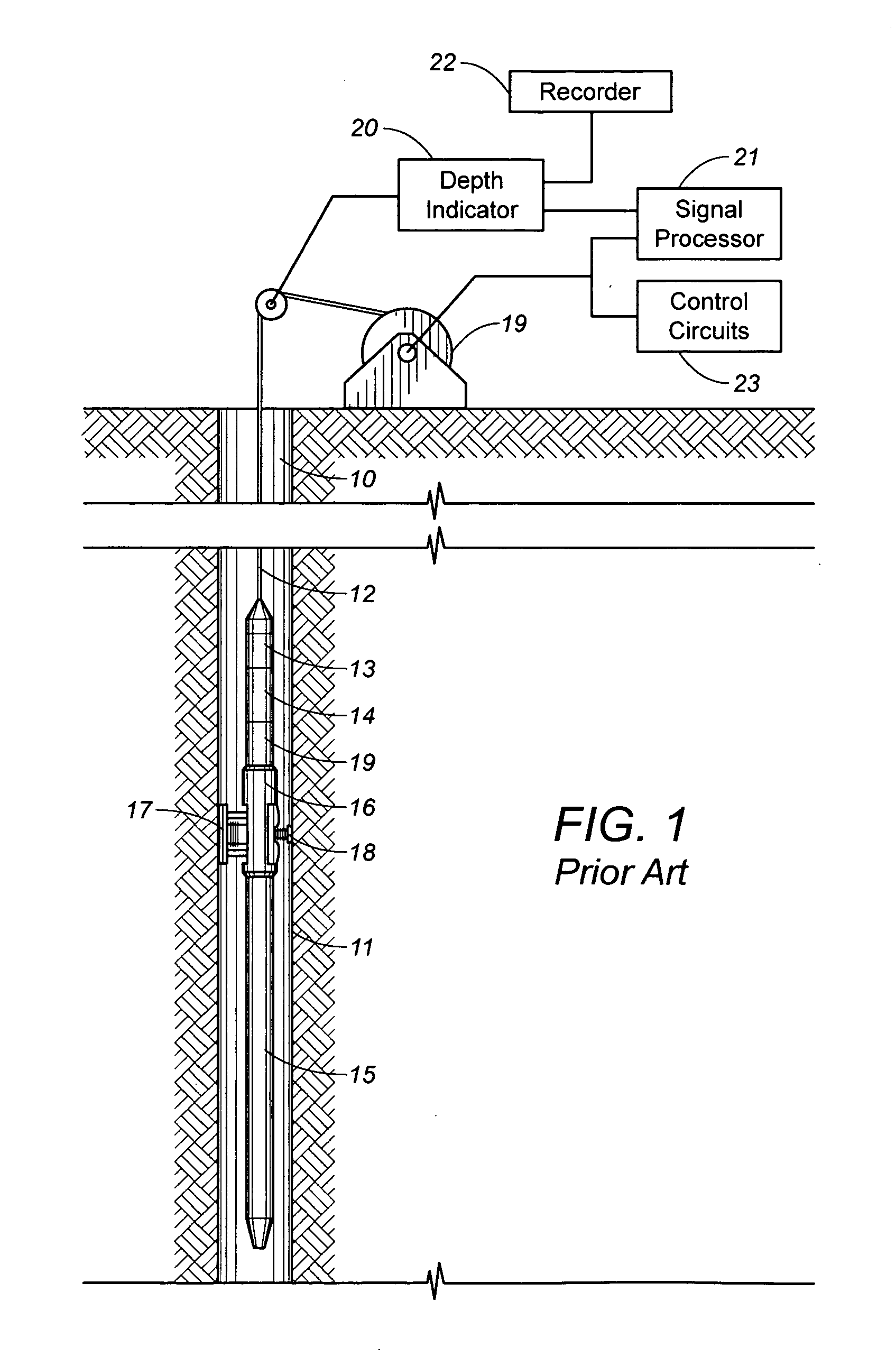

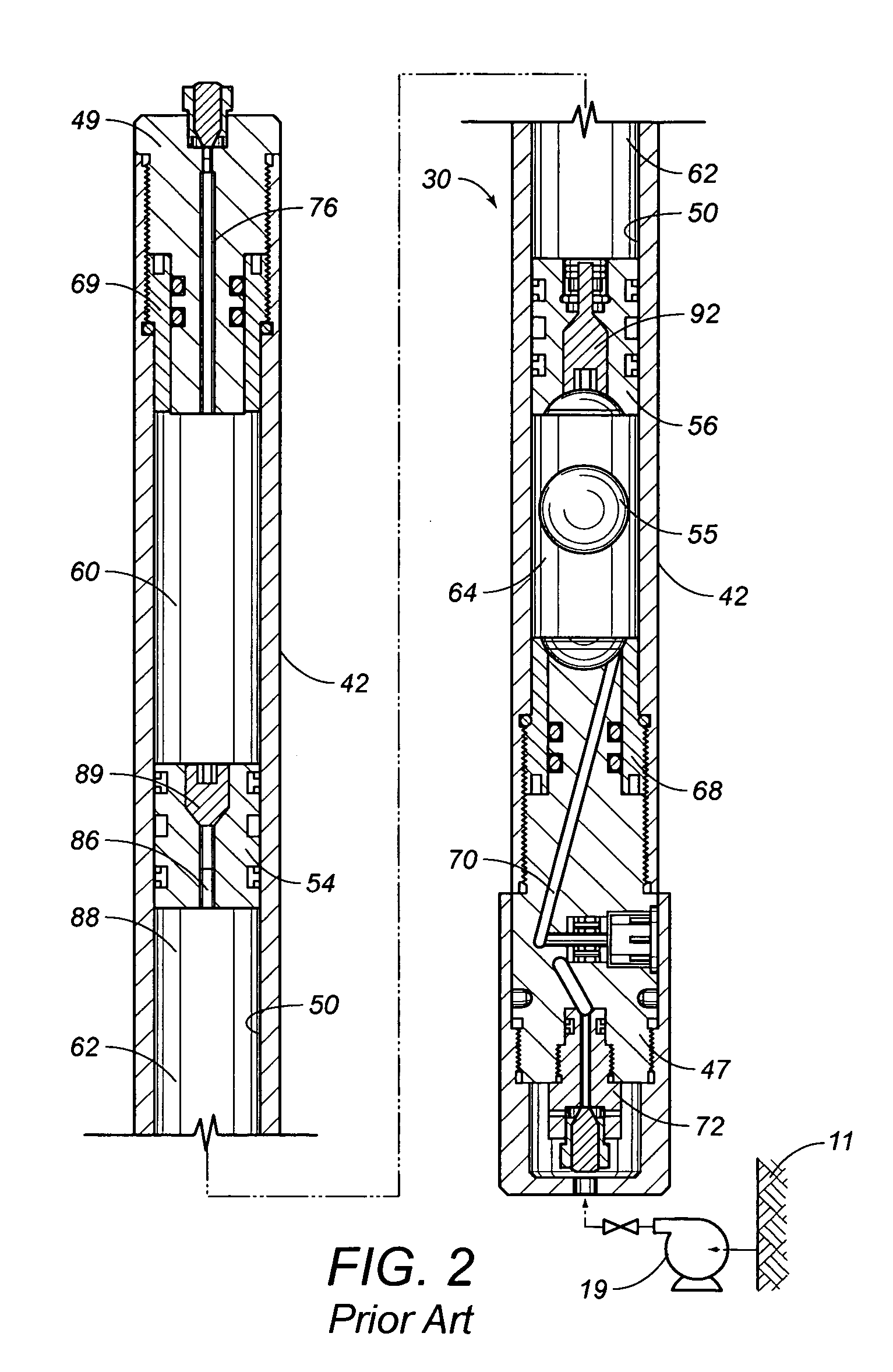

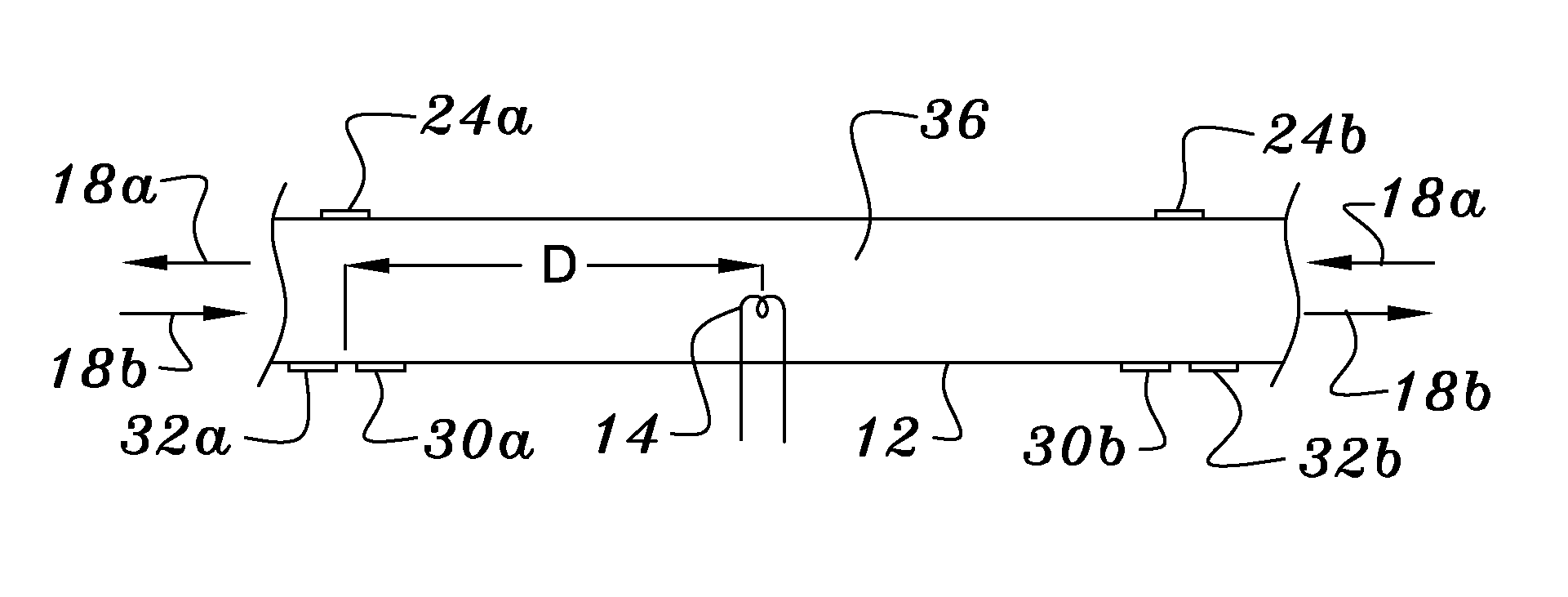

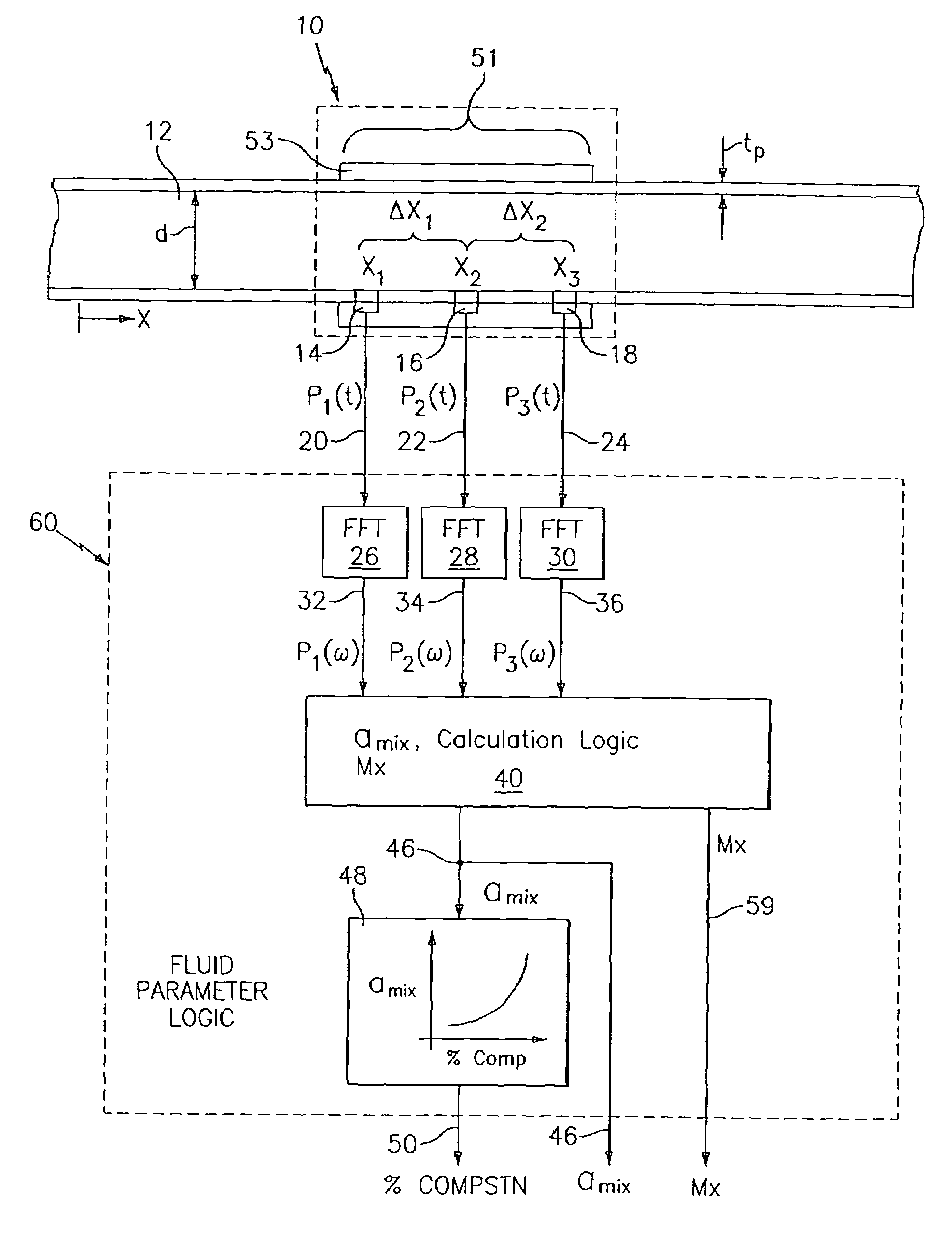

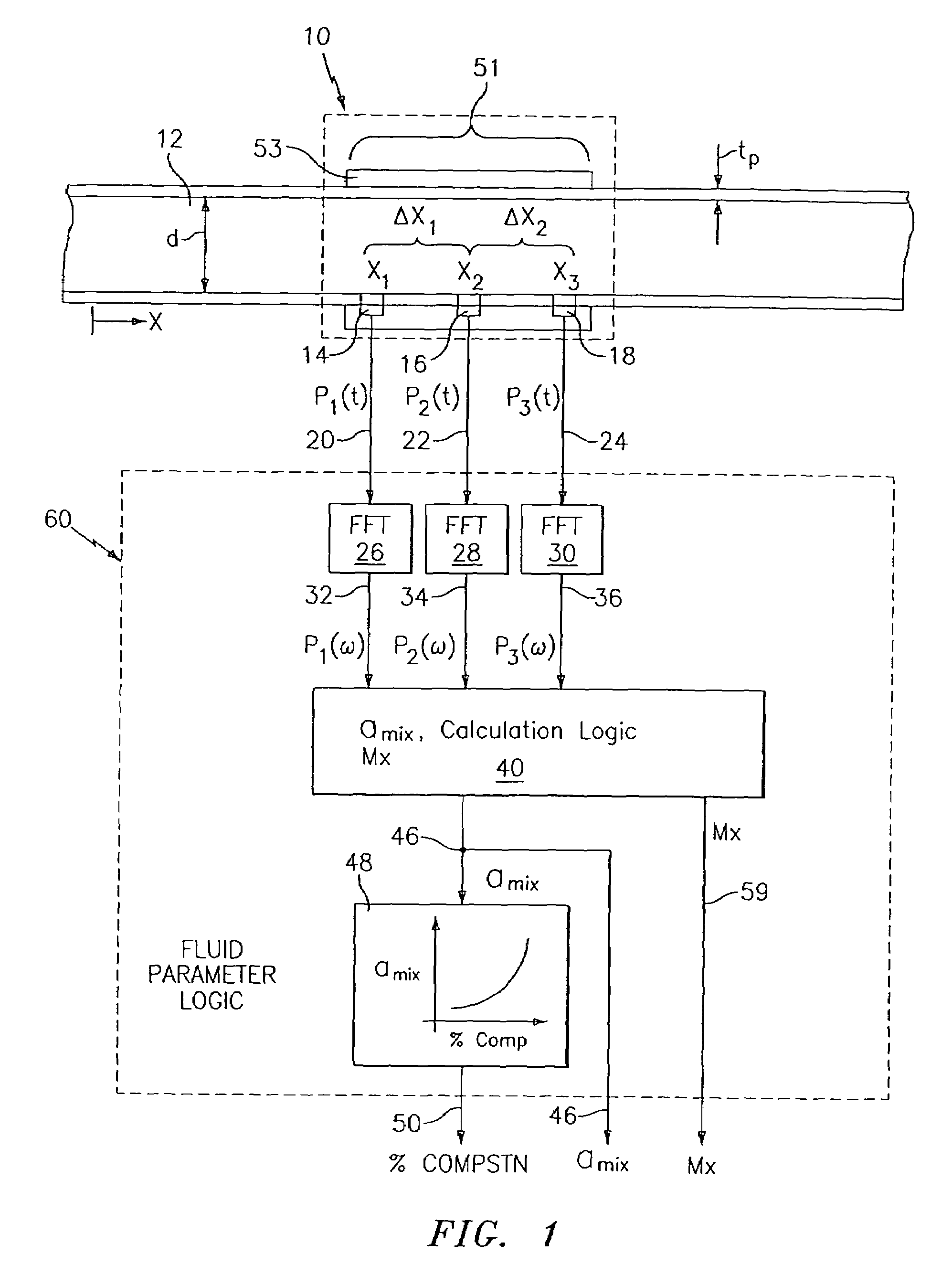

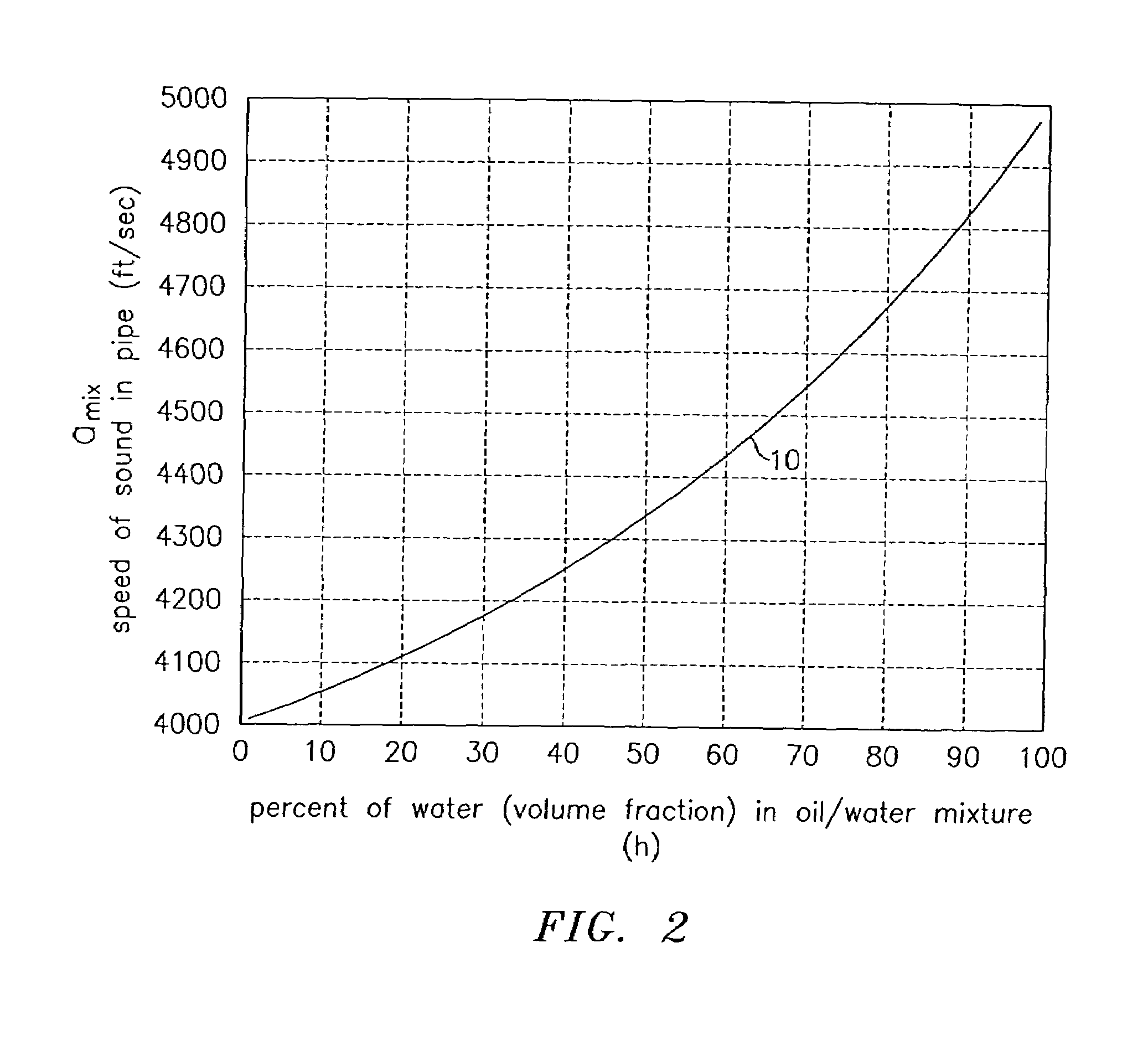

At least one parameter of at least one fluid in a pipe is measured using a spatial array of acoustic pressure sensors placed at predetermined axial locations along the pipe 12. The pressure sensors provide acoustic pressure signals, which are provided to a signal processing system that determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques. Numerous spatial array processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to another logic system that calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture or fluid which is related to the sound speed amix. The signal processing system may also determine the Mach number Mx of the fluid. The acoustic pressure signals measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus are more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system.

Owner:WEATHERFORD TECH HLDG LLC

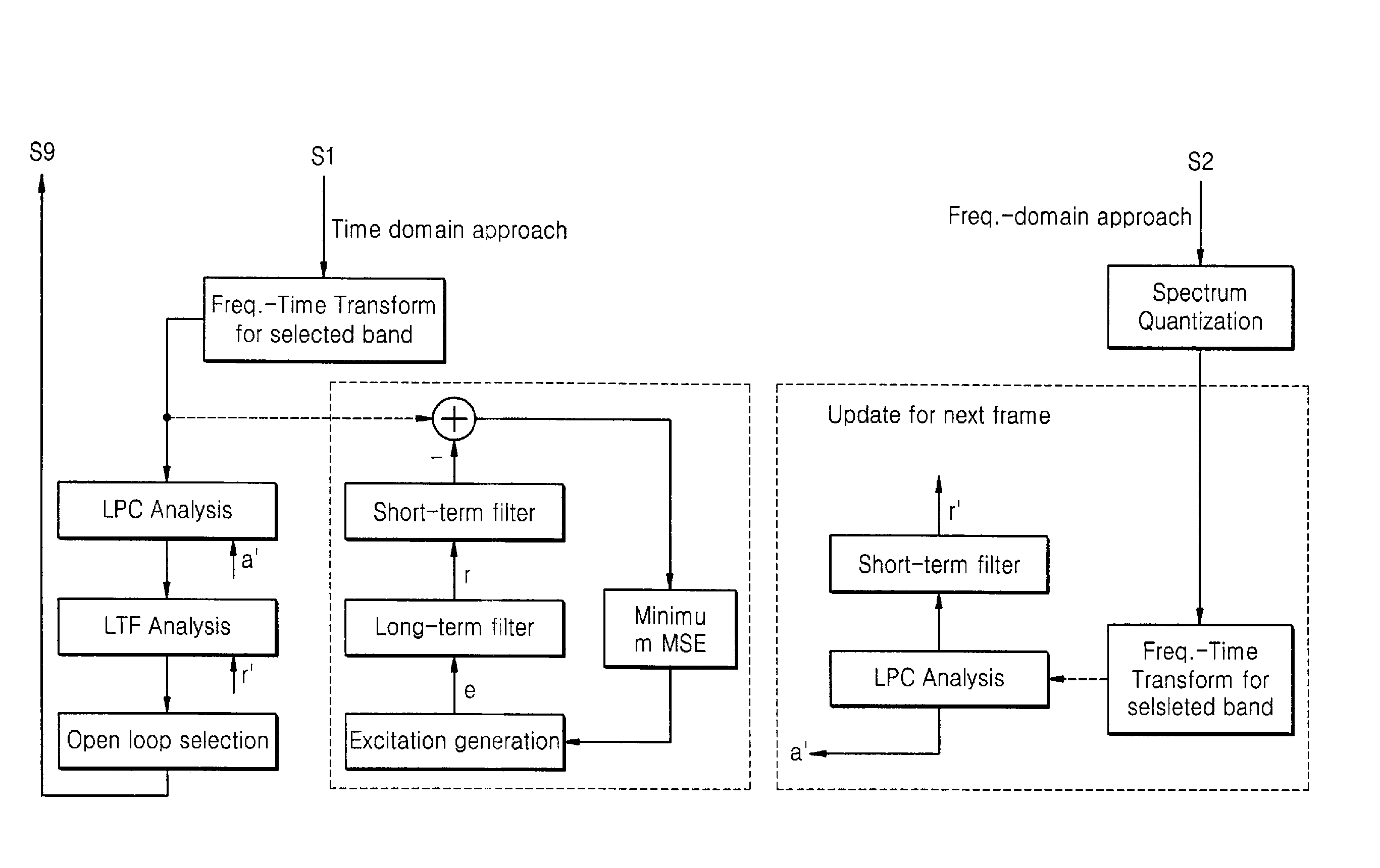

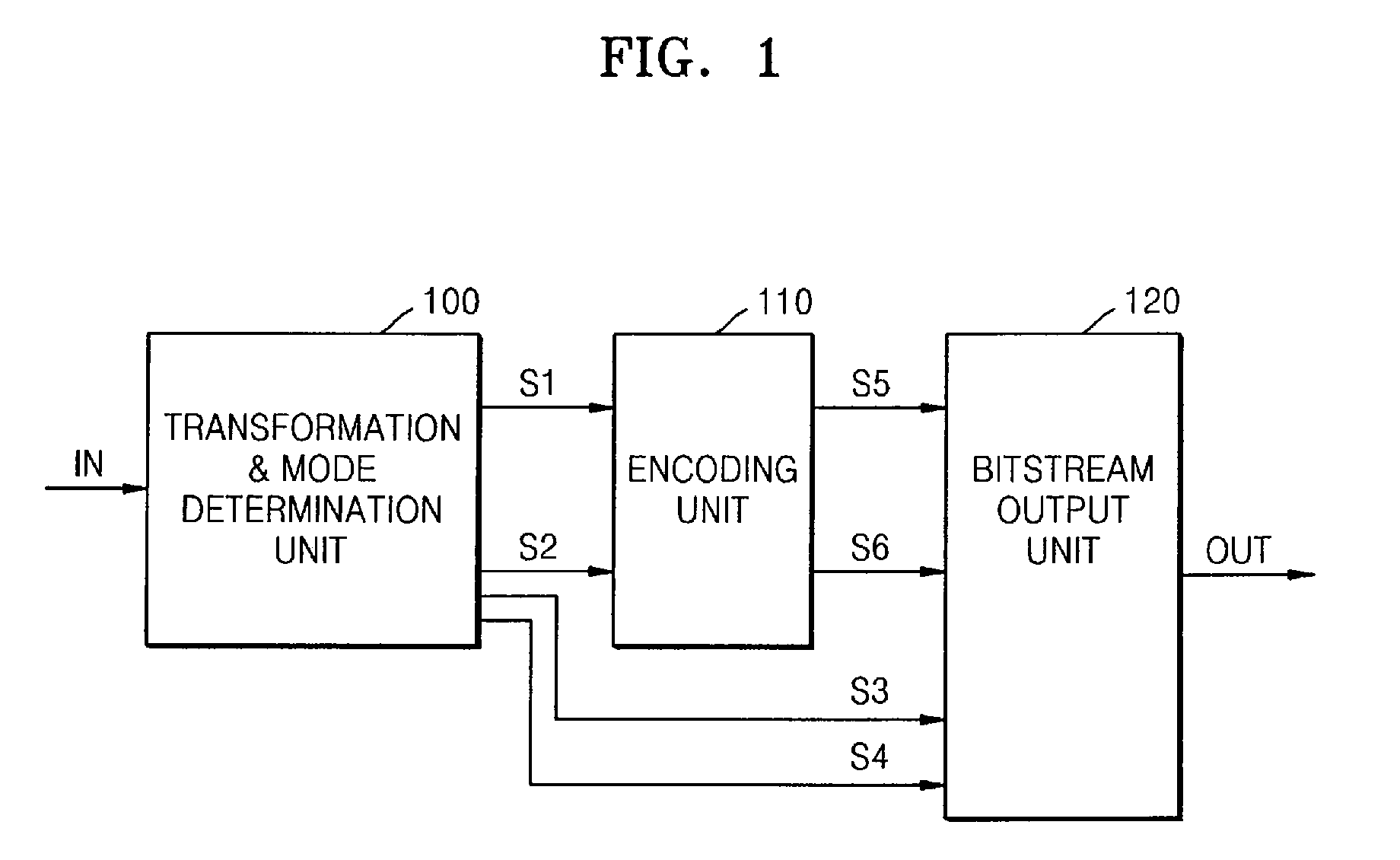

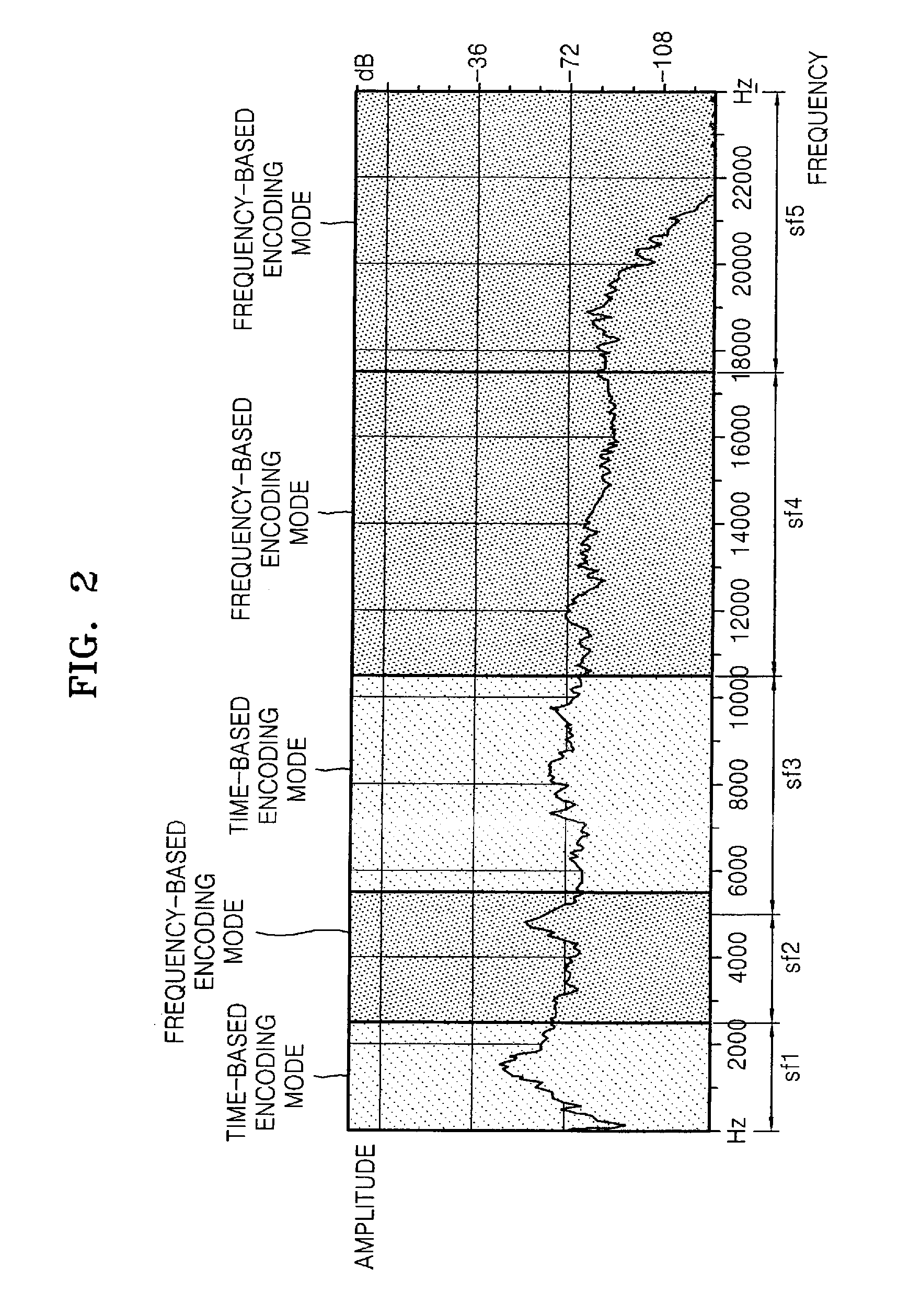

Adaptive time/frequency-based audio encoding and decoding apparatuses and methods

InactiveUS20070106502A1Improve compression efficiencySpeech analysisDigital computer detailsEngineeringProcessing element

Adaptive time / frequency-based audio encoding and decoding apparatuses and methods. The encoding apparatus includes a transformation & mode determination unit to divide an input audio signal into a plurality of frequency-domain signals and to select a time-based encoding mode or a frequency-based encoding mode for each respective frequency-domain signal, an encoding unit to encode each frequency-domain signal in the respective encoding mode, and a bitstream output unit to output encoded data, division information, and encoding mode information for each respective frequency-domain signal. In the apparatuses and methods, acoustic characteristics and a voicing model are simultaneously applied to a frame, which is an audio compression processing unit. As a result, a compression method effective for both music and voice can be produced, and the compression method can be used for mobile terminals that require audio compression at a low bit rate.

Owner:SAMSUNG ELECTRONICS CO LTD

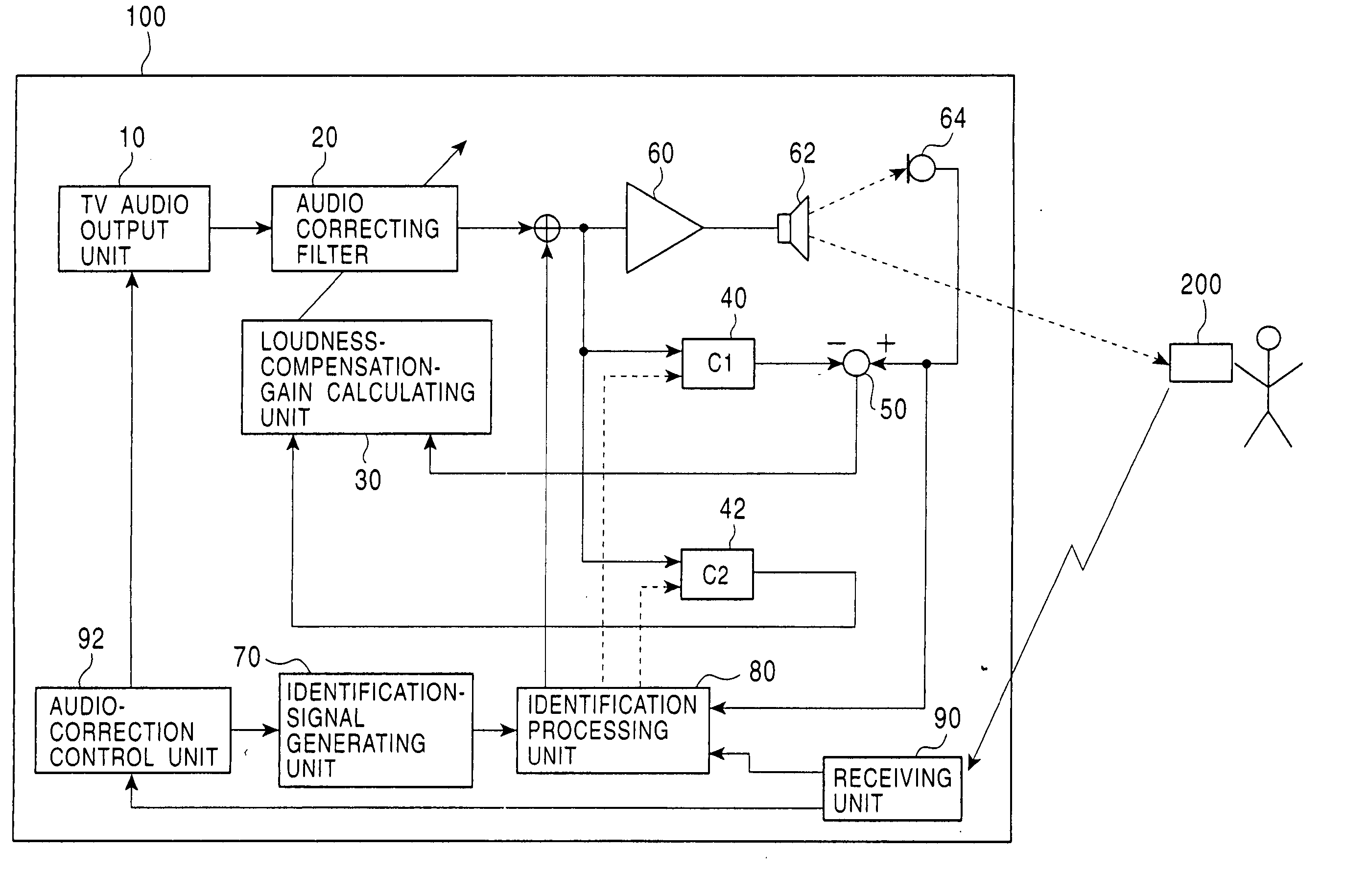

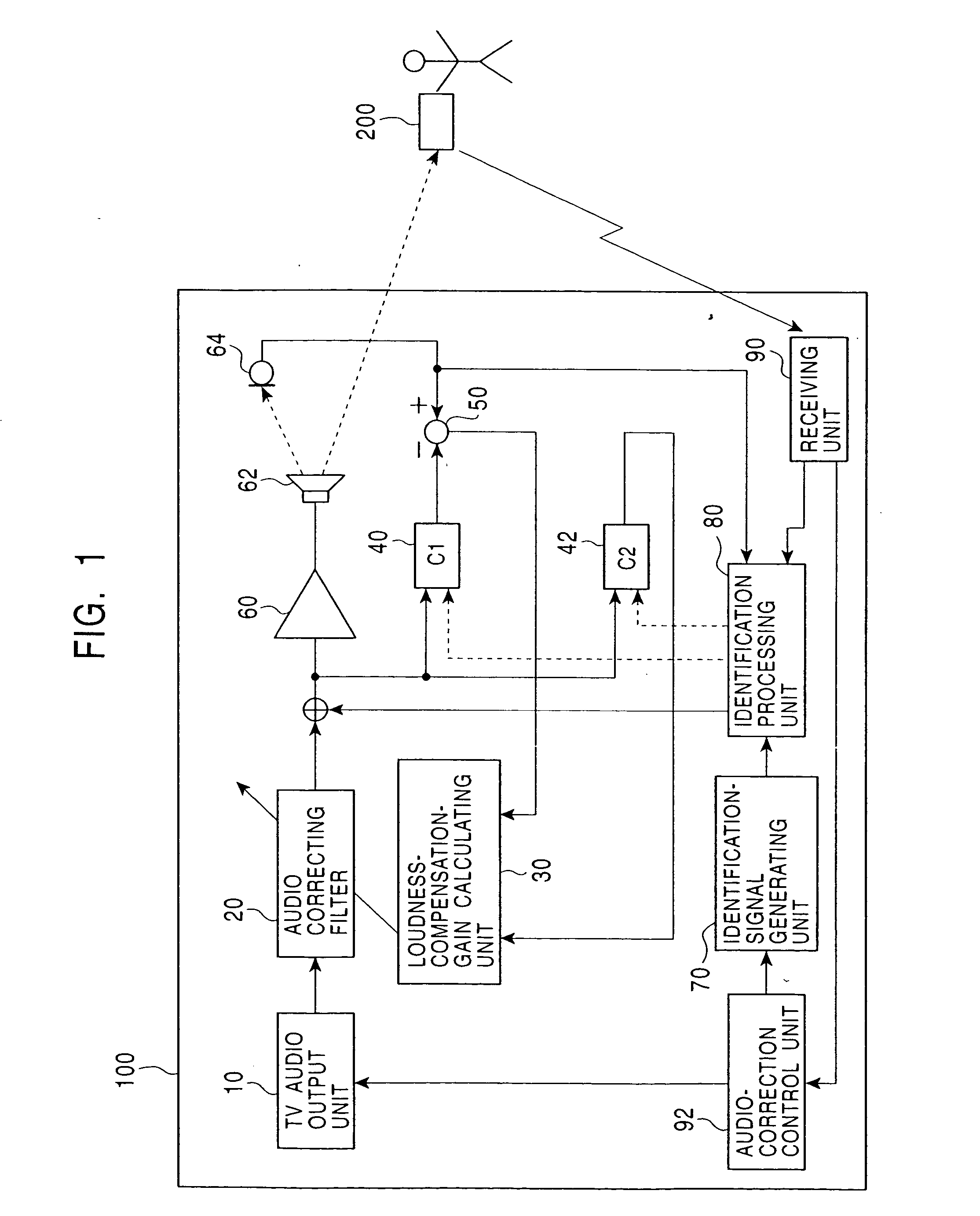

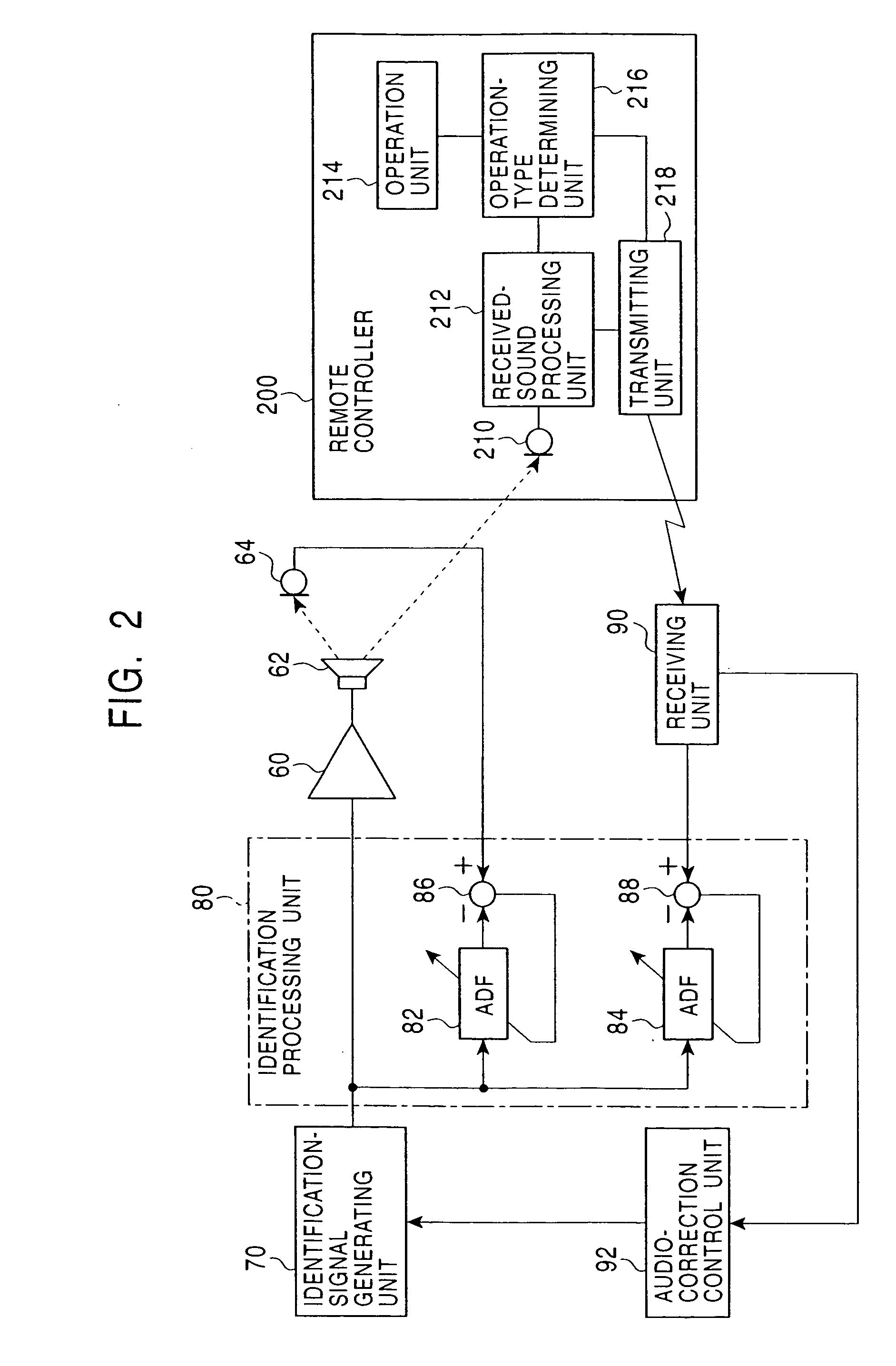

Audio correcting apparatus

InactiveUS20050013443A1Accurate sound pressure levelListen clearlyTelevision system detailsAdaptive networkEnvironmental noiseLoudspeaker

An audio correcting apparatus includes a speaker provided on a television apparatus, a microphone provided on a remote controller, an identifying unit which identifies an acoustic characteristic from the speaker to the microphone, and an acoustic characteristic setting unit having the acoustic characteristic. A signal obtained by allowing an audio signal input to the speaker to pass through the acoustic characteristic setting unit, and a signal representing ambient noise are input to an audio-correcting filter and a loudness-compensation-gain calculating unit. Based on both signals, the sound pressure level of sound output from the speaker is corrected so that the sound output from the speaker is clearly heard when reaching the user without being affected by the ambient noise.

Owner:ALPINE ELECTRONICS INC

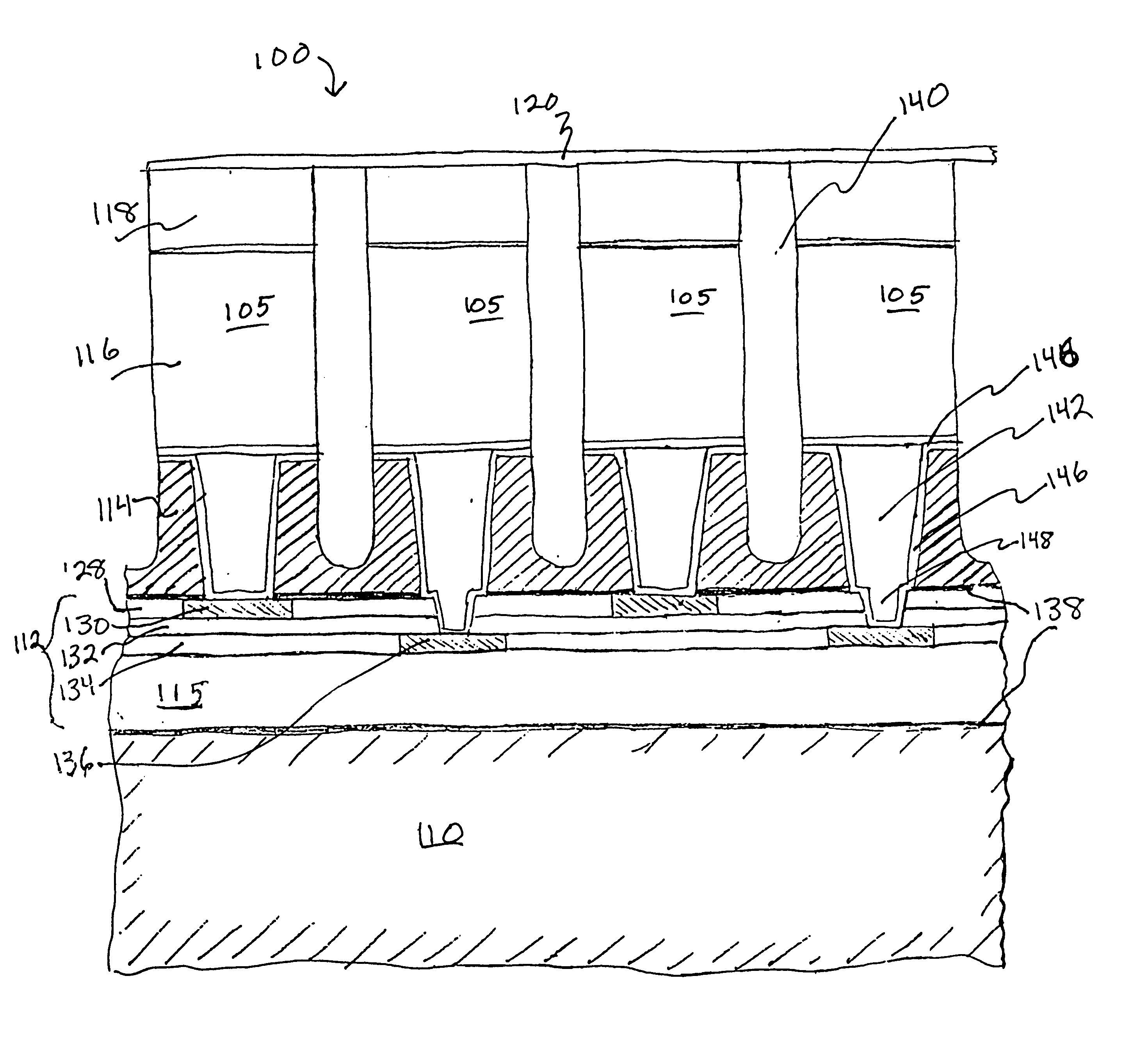

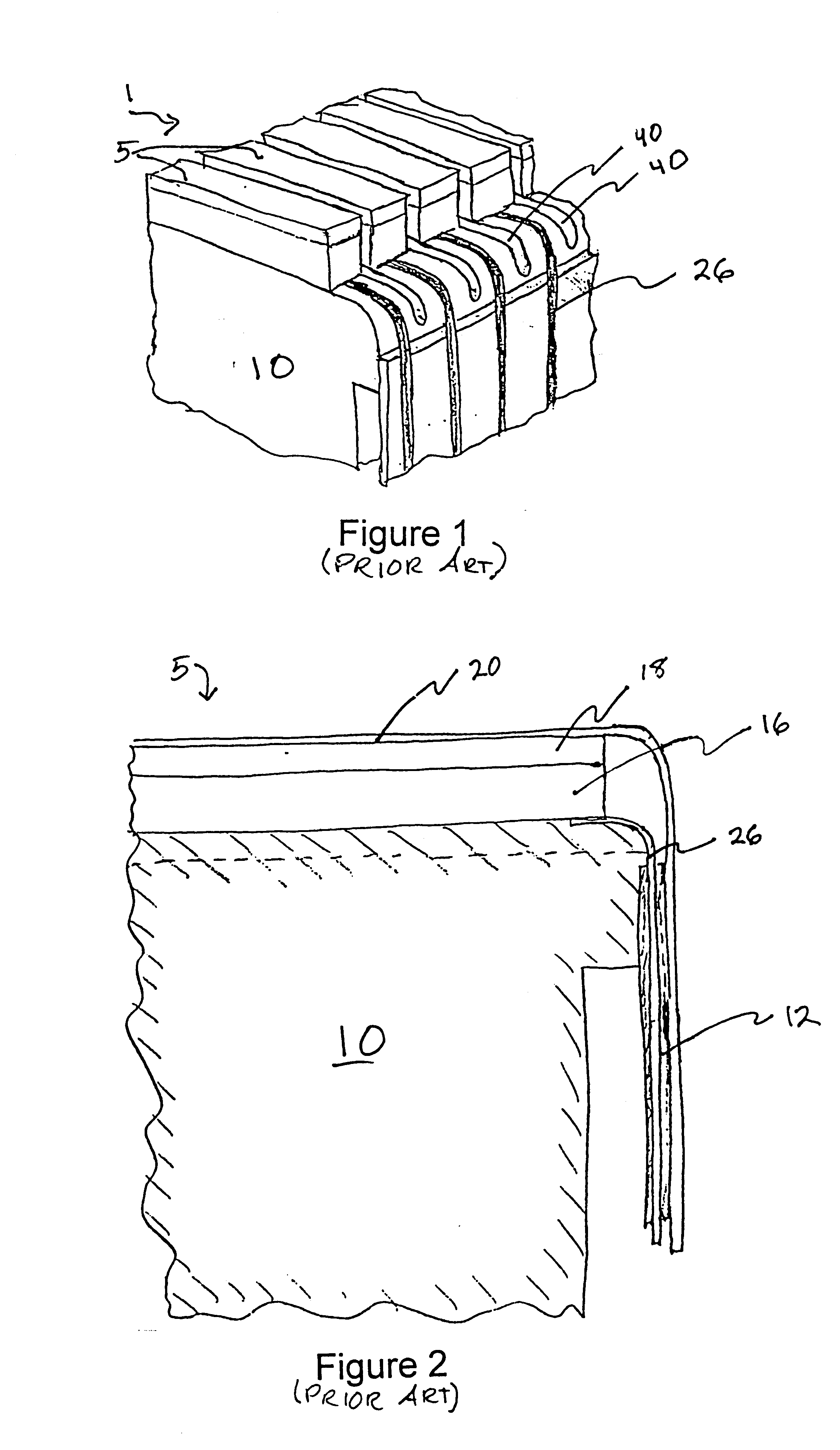

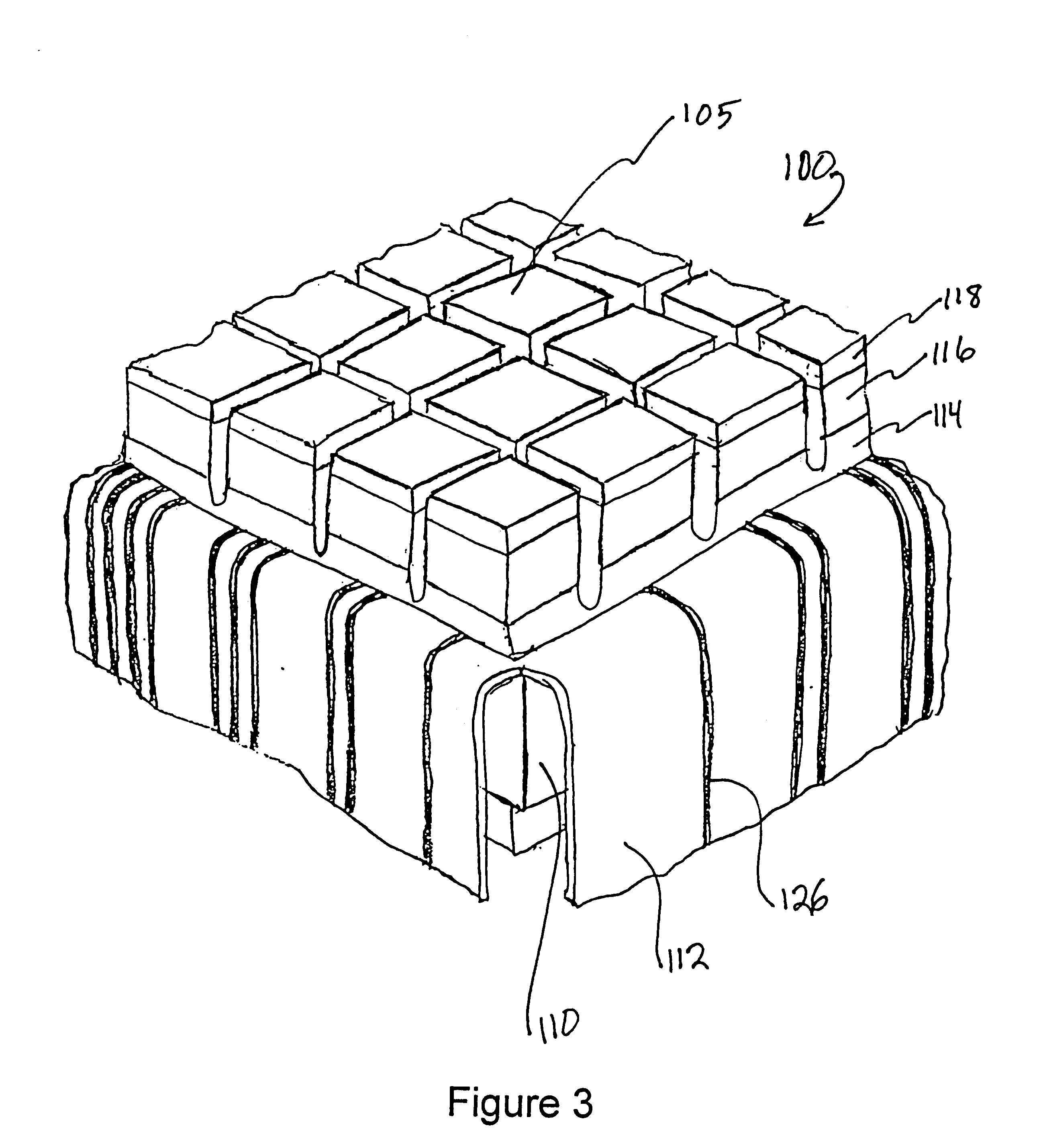

Two-dimensional ultrasound phased array transducer

InactiveUS6894425B1Easy to manufactureReduce crosstalkPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationFlexible circuitsInterface layer

A two-dimensional ultrasound phased array transducer includes an acoustic backing, a first circuit, which may be a flexible circuit disposed over the acoustic backing or a ground plane, an acoustically absorptive interface layer disposed over the flexible circuit, and a piezoelectric layer disposed over the interface layer. A matching layer may be disposed over the piezoelectric layer, and a second circuit, which may be a ground plane or a flexible circuit, may be disposed over the matching layer. The piezoelectric layer and the matching layer are diced by forming kerfs extending through these layers and at least partially into the interface layer. Extending the kerfs into the interface layer reduces cross-talk between elements, electrically isolates the elements, and facilitates manufacturing by reducing the precision required in controlling the depth of the cut. The acoustically absorptive interface layer may have acoustic properties similar to the backing material and may be formed of the same material as the backing material. Electrical interconnection between the piezoelectric elements and the first circuit is provided through the interface layer. The electrical connection may be formed by laser drilled vias in the interface layer, coated with gold or another suitable material.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

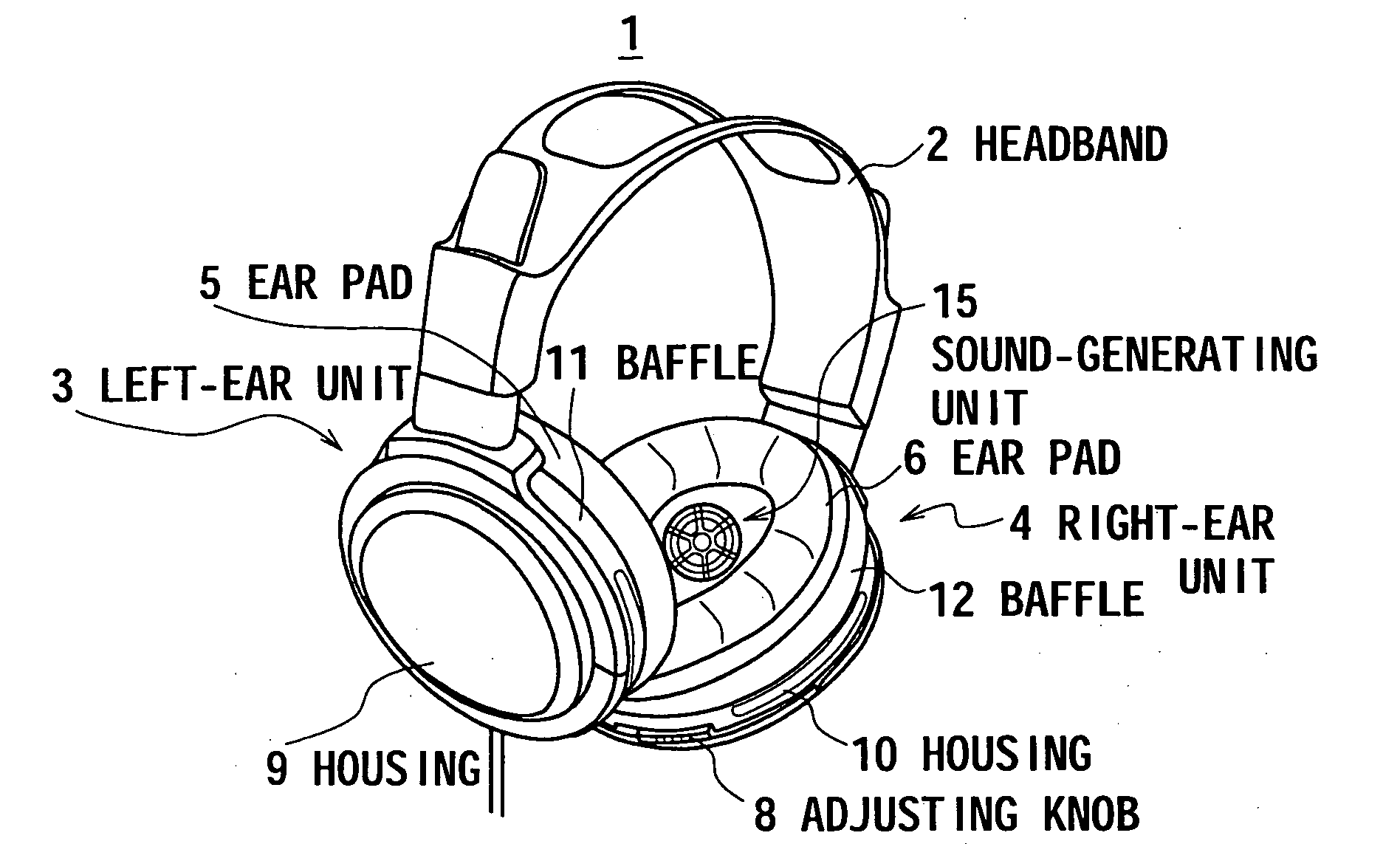

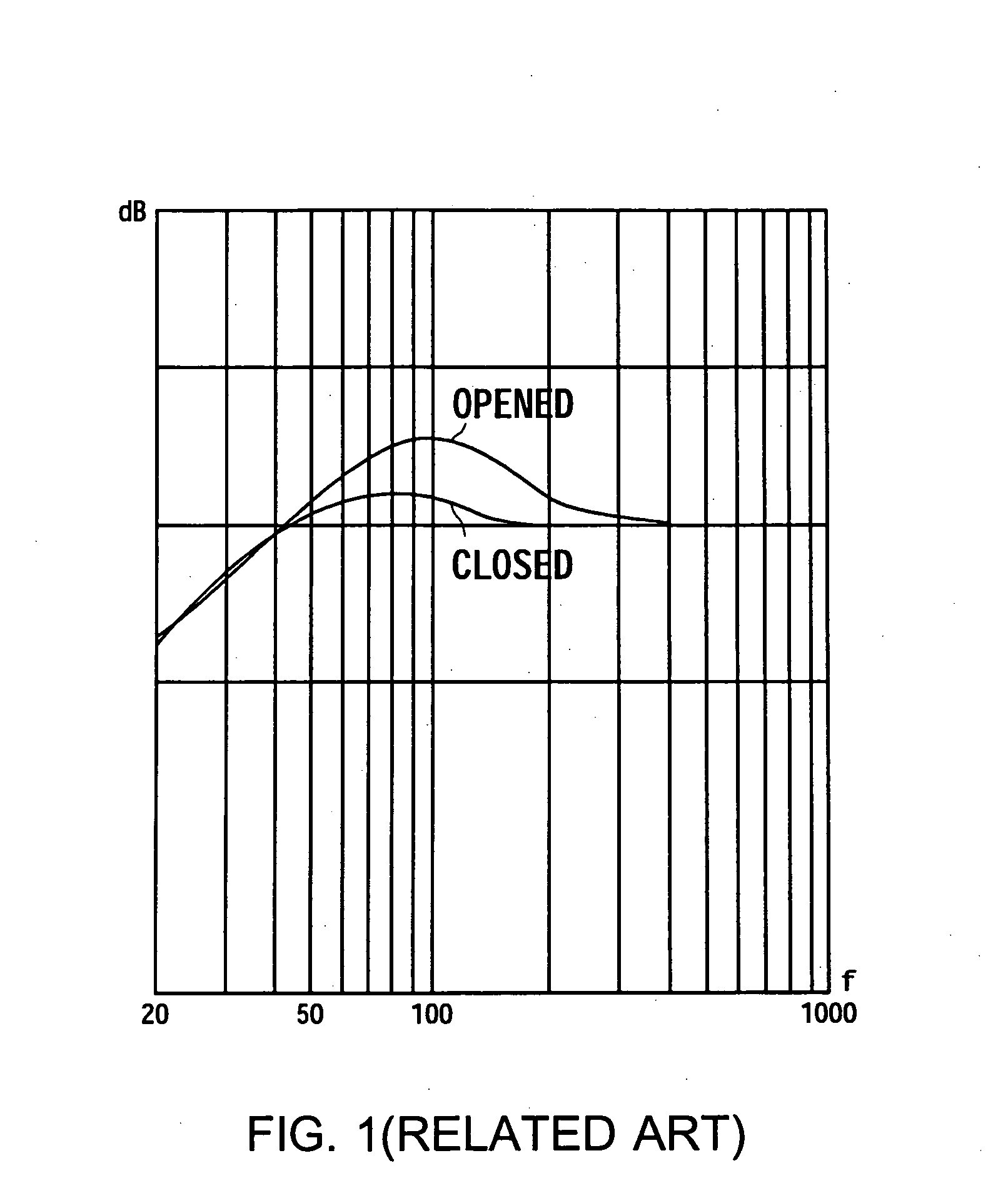

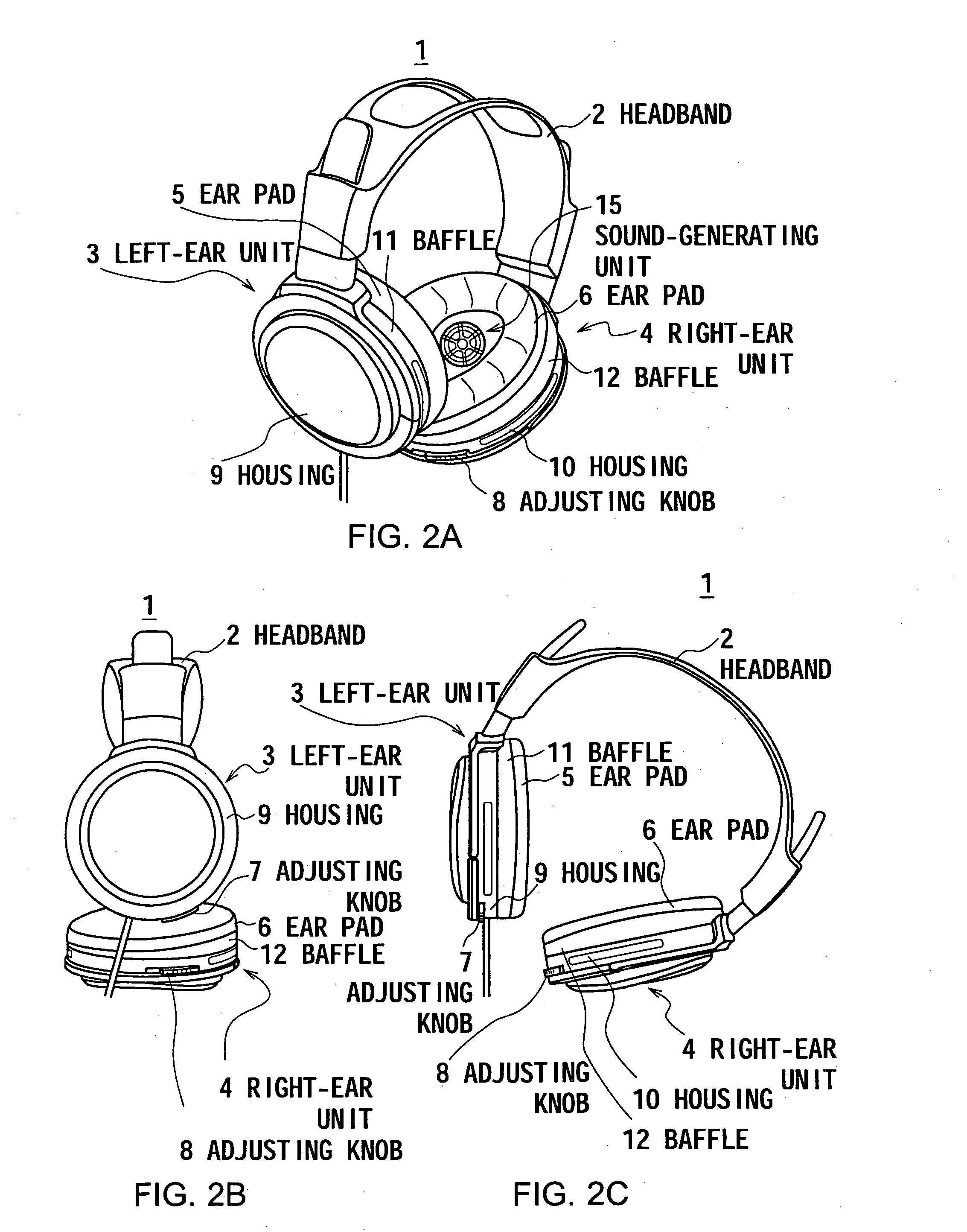

Headphone apparatus

InactiveUS20060104471A1Easy to changeEasy to operateHeadphones for stereophonic communicationSupra/circum aural earpiecesAcoustic propertyEngineering

A headphone apparatus the acoustic characteristics of which can be easily changed in accordance with the type of content the user wants to listen to. An adjusting knob provided on the housing of the headphone apparatus is moved, closing an opening made in a baffle. As a result, an acoustic space defined by the inner side of the baffle and an ear pad is more closed, thus increasing the level of low-frequency components of the sound generated by a sound-generating unit. Hence, the acoustic characteristics of the apparatus can be easily changed as the user desires.

Owner:SONY CORP

Golf club head providing enhanced acoustics

InactiveUS7056228B2Enhanced sound and feel characteristicHigh CORGolfing accessoriesGolf clubsGolf BallBiomedical engineering

An golf club head is provided, having enhanced sound and feel characteristics. The club head has a hollow main body including a ball-striking face, a sole, a crown, a hosel, and a side portion extending rearwardly from the face. The body further includes a heel region adjacent to the hosel and a toe region opposing the heel region, and it defines a volume of at least 100 cc. The club head further includes a stiffening member disposed within the body and attached to both the sole and the crown. The member is spaced apart from the striking face and disposed within the body in a region having a first zone extending less than half the distance from the heel region to the toe region and a second zone extending less than half the distance from a rearmost point, thereby forming a local stiffness zone in the body to influence vibration modes and acoustic properties of the club head in a prescribed manner.

Owner:TAYLOR MADE GOLF

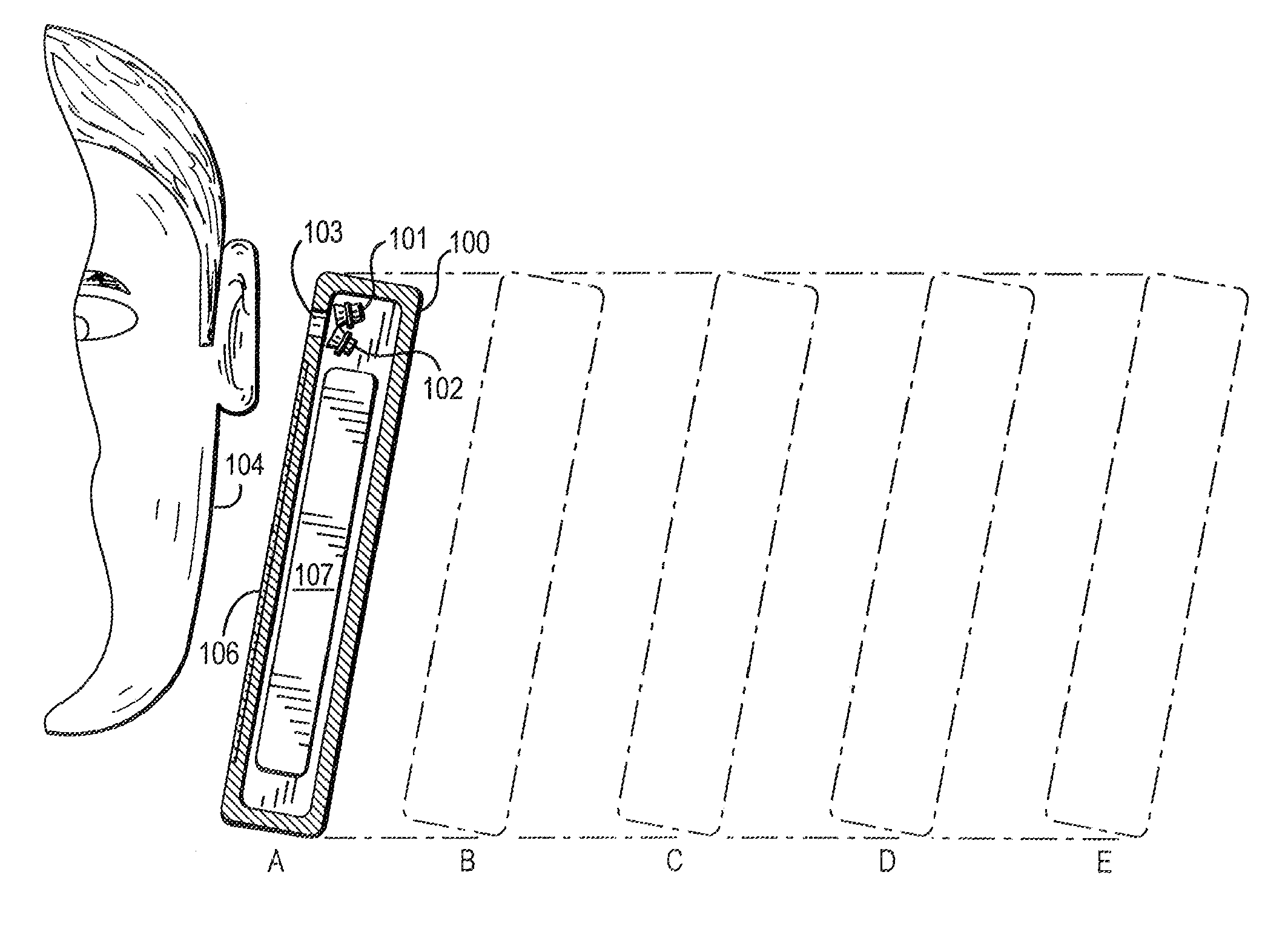

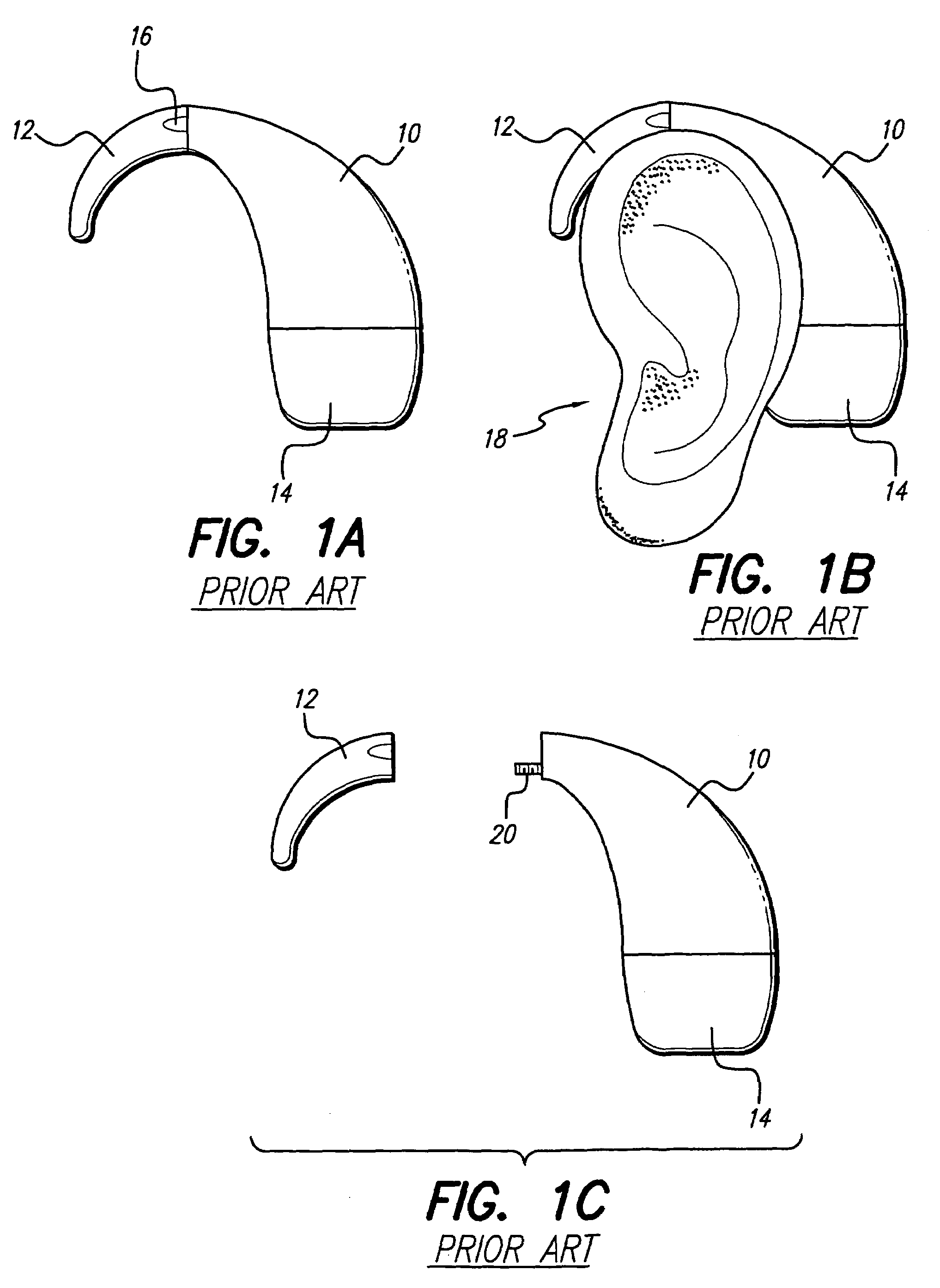

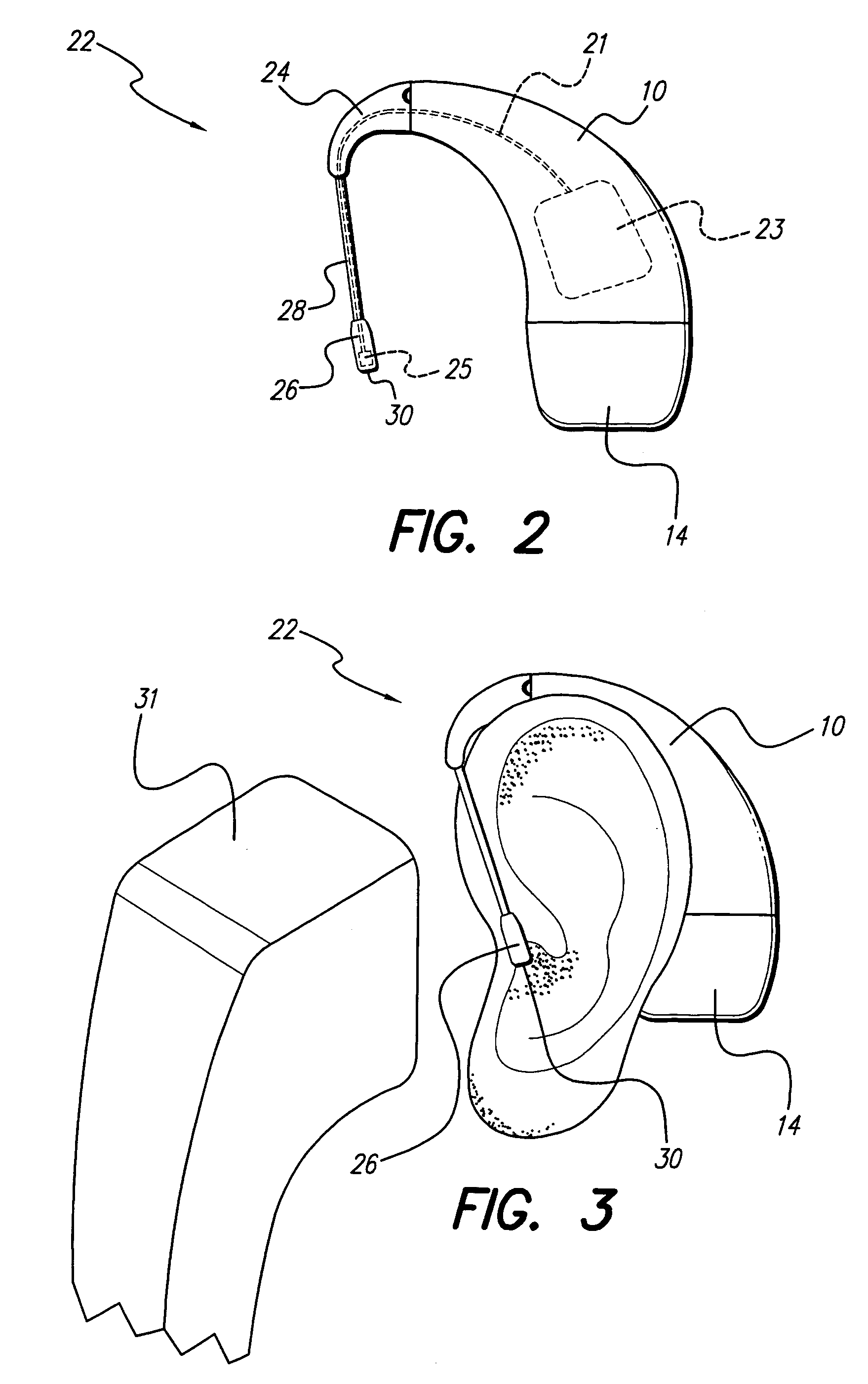

In the ear auxiliary microphone for behind the ear hearing prosthetic

InactiveUS7106873B1Improve responseEnhanced couplingElectrotherapyImplantable hearing aidsCouplingEngineering

An In The Ear (ITE) microphone improves the acoustic response of a Behind The Ear (BTE) Implantable Cochlear Stimulation (ICS) system during telephone use. An acoustic seal provided by holding a telephone earpiece against the ear provides improved coupling of low frequency (up to about 1 KHz) sound waves, sufficient to overcome losses due to the near field acoustic characteristics common to telephones. In a preferred embodiment, the ITE microphone is connected to a removable ear hook of the BTE ICS system by a short bendable stalk.

Owner:ADVANCED BIONICS AG

Voice coder with two microphone system and strategic microphone placement to deter obstruction for a digital communication device

ActiveUS20110144984A1Reduce signal to noise ratioFacilitate communicationTransducer detailsSpeech analysisSignal qualitySignal-to-noise ratio (imaging)

The present invention provides a voice coder for voice communication that employs a multi-microphone system as part of an improved approach to enhancing signal quality and improving the signal to noise ratio for such voice communications, where there is a special relationship between the position of a first microphone and a second microphone to provide the communication device with certain advantageous physical and acoustic properties. In addition, the communication device can have certain physical characteristics, and design features. In a two microphone arrangement, the first microphone is located in a location directed toward the speech source, while the second microphone is located in a location that provides a voice signal with significantly lower signal-to-noise ratio (SNR).

Owner:XENOGENIC DEV LLC

Photoacoustic assay and imaging system

InactiveUS20050085725A1High measurement accuracyPath lengthEnergy modified materialsBlood flow measurement devicesAssayLength wave

A method for assaying a component of a localized region of interest in a body comprising: illuminating the region with at least one pulse of radiation having a wavelength at which the radiation is absorbed by the component to generate a change in an acoustic property of the region; transmitting ultrasound so that it is incident on the region; measuring at least one effect of the change on the incident ultrasound; using the measured at least one effect to determine an absorption coefficient for the radiation in the region; and using the determined absorption coefficient to determine concentration of the component in the region.

Owner:GLUCON

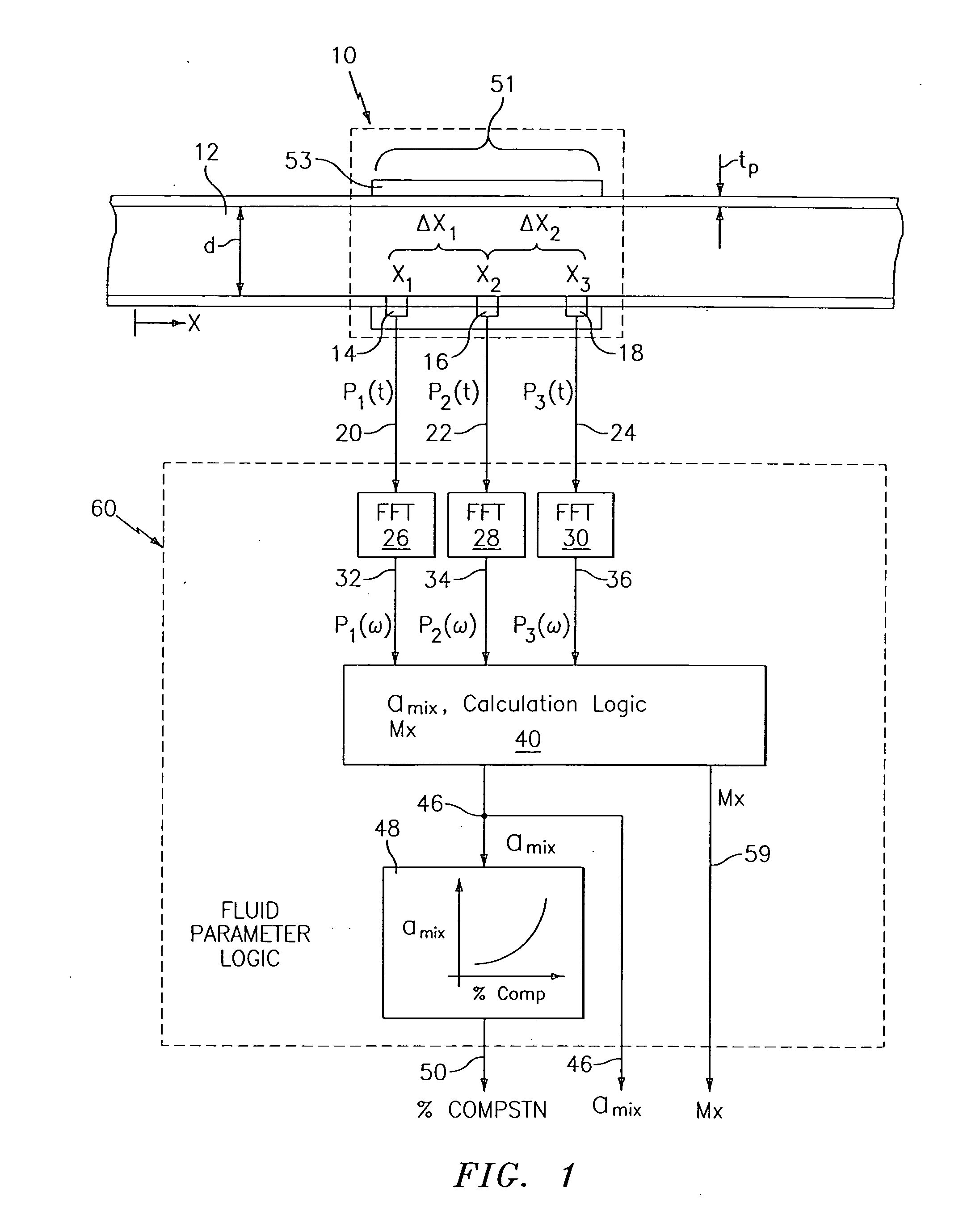

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

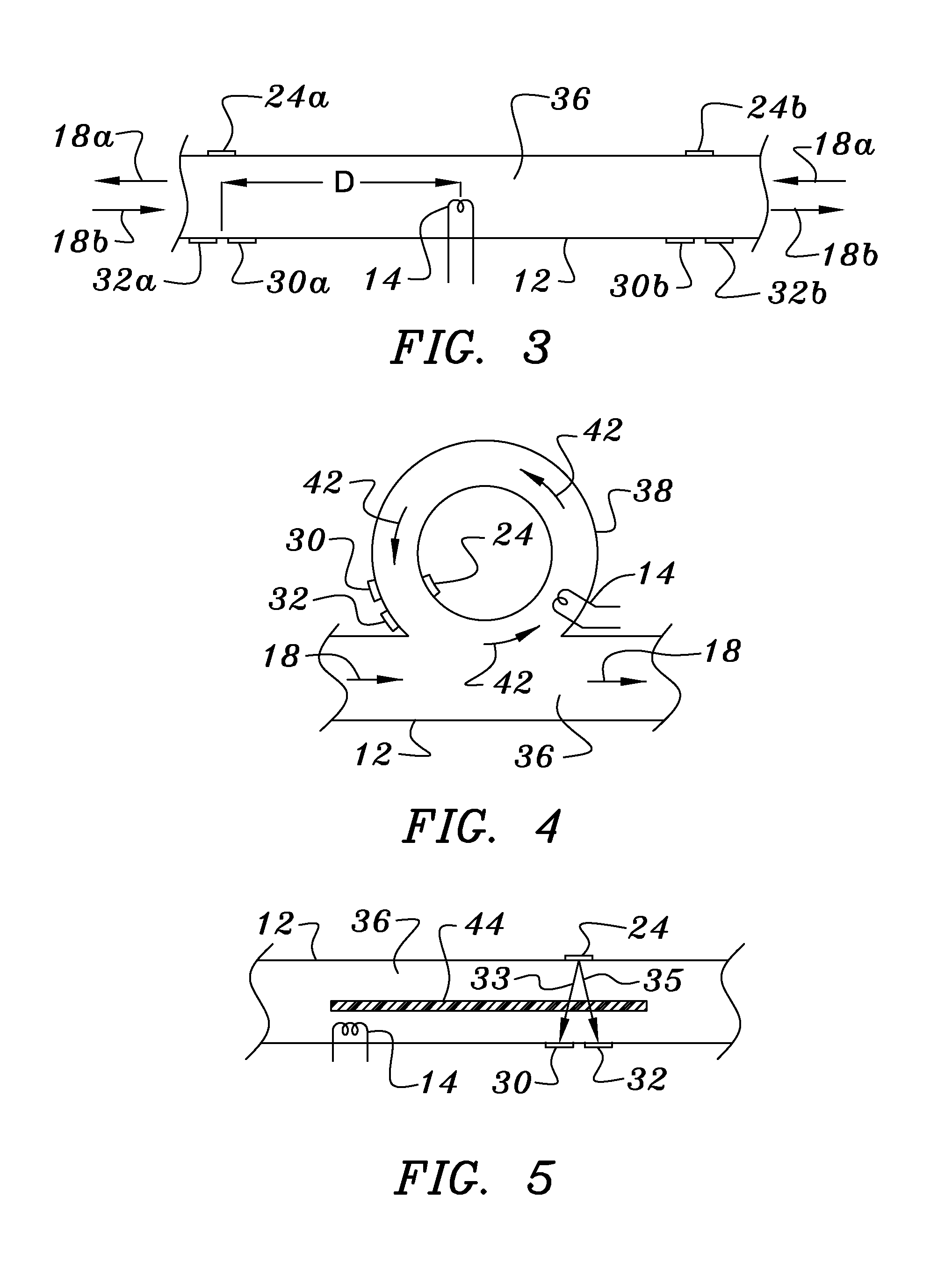

Apparatus and methods for acoustically determining fluid properties while sampling

ActiveUS20050223808A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcoustic propertyTransmitter

An apparatus and methods for acoustically analyzing a fluid sample and determining one or more properties of the sample are disclosed by the present invention. The apparatus comprises a chamber, a transmitter positioned within the chamber for transmitting an acoustic signal through the fluid, a reflector movably positioned within the fluid inside the chamber for reflecting the acoustic signal, and a receiver positioned within the chamber for detecting reflections of the acoustic signal. The methods employ the use of a transmitter, a reflector movably positioned within the fluid inside the chamber, and a receiver to characterize the fluid sample based on one or more of its acoustic properties.

Owner:SHELL OIL CO

Thermal pulsed ultrasonic flow sensor

InactiveUS7270015B1Practical size limitationSmall sizeVolume/mass flow measurementDiagnostic recording/measuringAcoustic transmissionTransducer

In thermal pulse flow measurements a relatively small bolus of flowing fluid is heated or cooled and the time required for the bolus to move downstream a known distance is measured. In many fluids, changing the temperature changes the acoustic transmission properties of the bolus from those of the rest of the fluid, so the bolus can be detected when it intersects an acoustic beam. The use of an acoustic beam or beams, which are usually defined between acoustic transmitting receiving transducers, typically provides a high frequency carrier which is modulated by the change in acoustic properties of the bolus when it passes between the two transducers. When compared to conventional thermal measurements, this acoustic approach provides faster response times and can thus be used for measuring higher flow rates.

Owner:ONICON INC

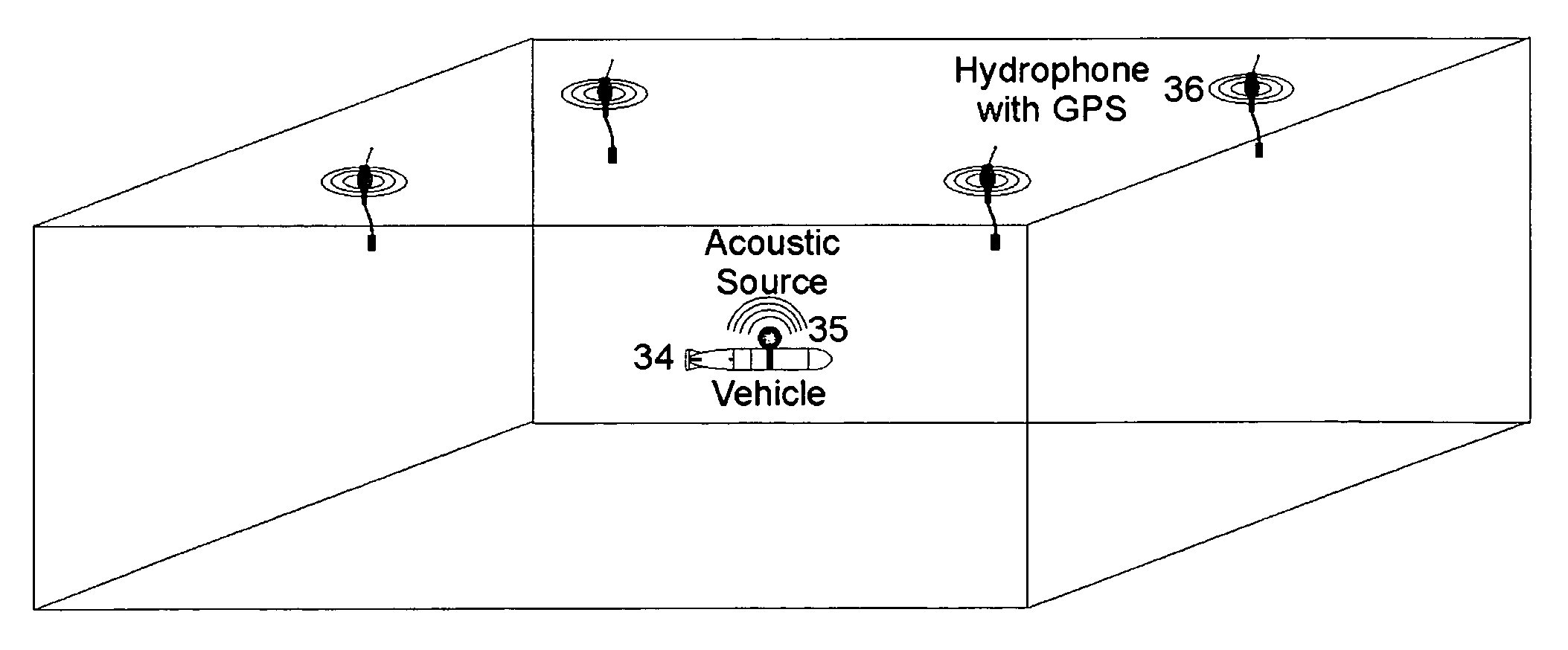

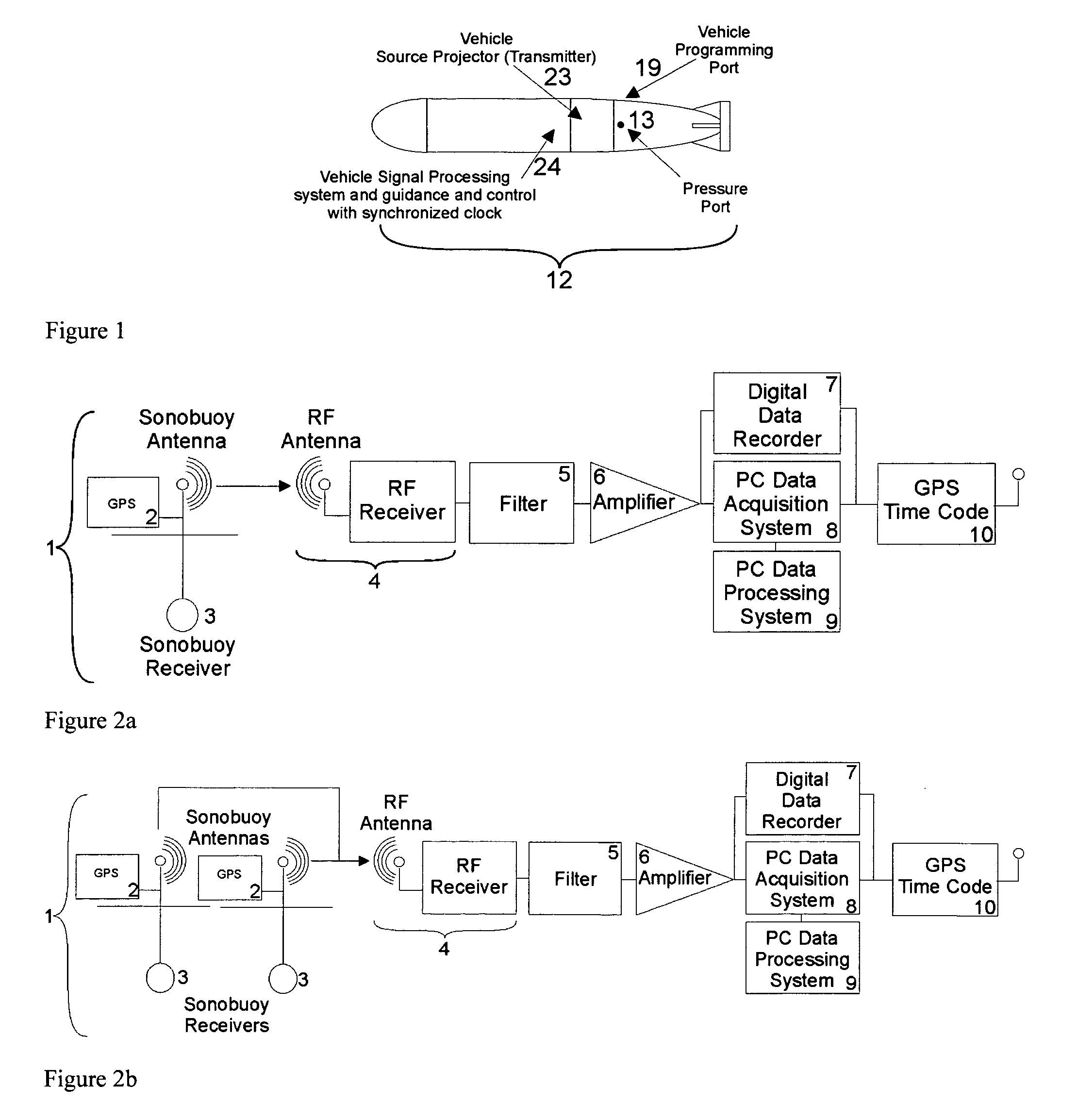

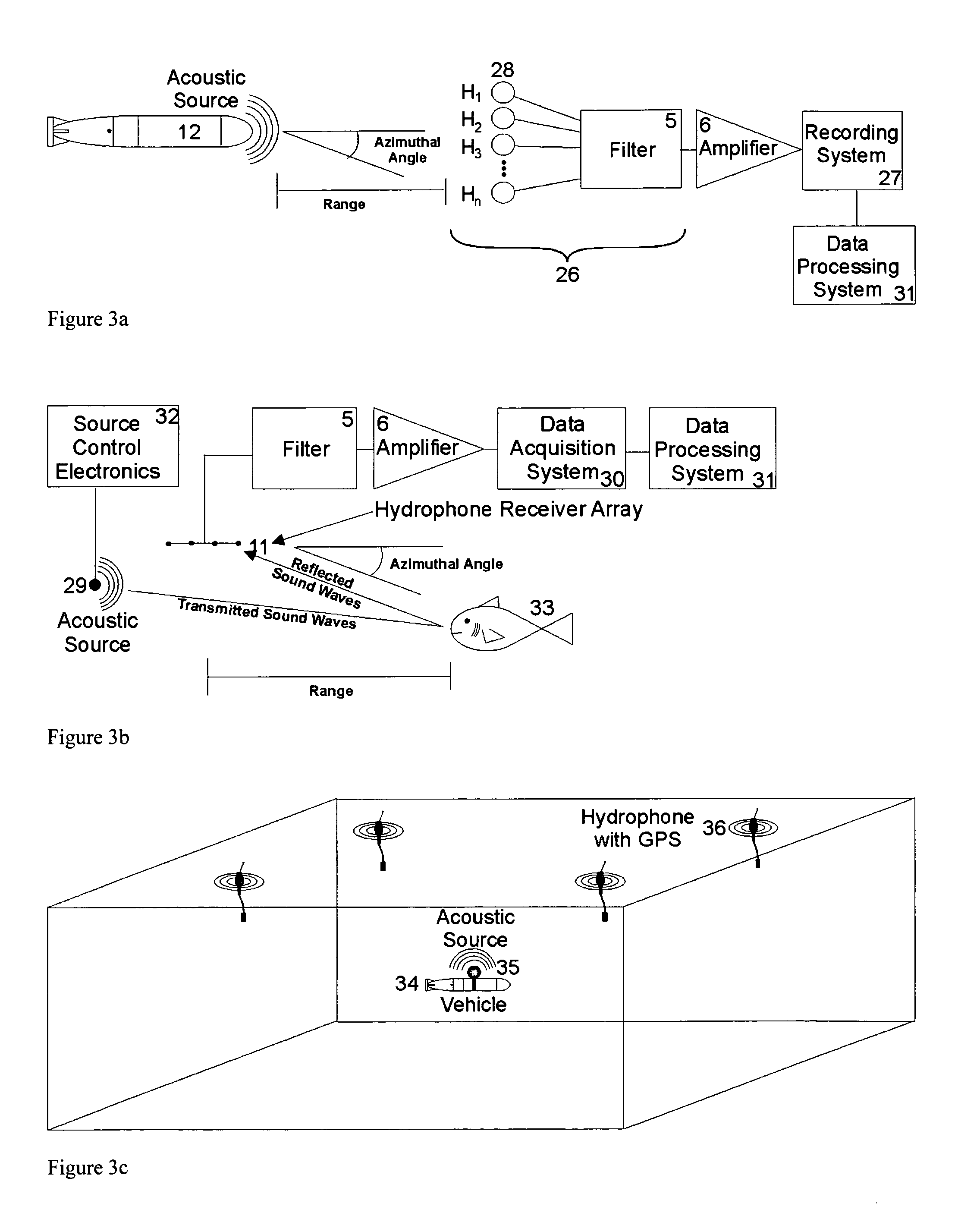

Methods of and systems for continually measuring the range between mobile underwater vehicles carrying acoustical signal transmitters and remotely deployed synchronized underwater acoustical receivers provided with signal processing for continually determining such range during the underwater moving of the vehicle, and for measuring acoustic underwater transmission loss, geoacoustical properties and for other purposes

ActiveUS20080165617A1Improve practicalitySonic/ultrasonic/infrasonic transmissionAcoustic wave reradiationOcean bottomContinuous measurement

Invention relates to a novel method of and system for ranging between an acoustic source carried on an unmanned or autonomous undersea mobile vehicle (UUV or AUV) and preferably a plurality of hydrophone receivers remotely deployed from the vehicle in predetermined patterns, generally suspended from sonobuoys equipped with above-the-sea relay radio transmitting antennas, and with time synchronization provided amongst the source and the receivers, wherein the time delay from the transmissions of the source is measured by utilizing special signal processing, enabling range to be measured in close to real time by determining the product of the sound velocity and the measured time delay, and with the process continually and periodically being repeated throughout the duration of the vehicle run. Given the range, the system may then be used to measure the acoustical properties of and / or receiver system performance in the sea or other water body, such as transmission or propagation loss TL, channel impulse response, bottom geoacoustic properties, source level, receiver sensitivity calibration, sonar operator readiness and sonar receiver performance and the like. Further, in situ measured data can be assimilated with models to enable more accurate prediction of the ocean environment than could be obtained from either individually.

Owner:OCEAN ACOUSTICAL SERVICES ADN INSTR SYST OASIS INC

Methods for determining intracranial pressure non-invasively

InactiveUS7547283B2Medical data miningDiagnostics using vibrationsSound sourcesCentral sulcus artery

Systems and methods for determining ICP based on parameters that can be measured using non-invasive or minimally invasive techniques are provided, wherein a non-linear relationship is used to determine ICP based on one or more variable inputs. The first variable input relates to one or more properties of a cranial blood vessel and / or blood flow, such as acoustic backscatter from an acoustic transducer having a focus trained on a cranial blood vessel, flow velocity in a cranial blood vessel, and the like. Additional variables, such as arterial blood pressure (ABP), may be used in combination with a first variable input relating to one or more properties of a cranial blood vessel, such as flow velocity of the middle cerebral artery (MCA) to derive ICP using a non-linear relationship. Methods and systems for locating target areas based on their acoustic properties and for acoustic scanning of an area, identification of a target area of interest based on acoustic properties, and automated focusing of an acoustic source and / or detector on a desired target area are also provided. Acoustic transducer assemblies are described.

Owner:PHYSIOSONICS +1

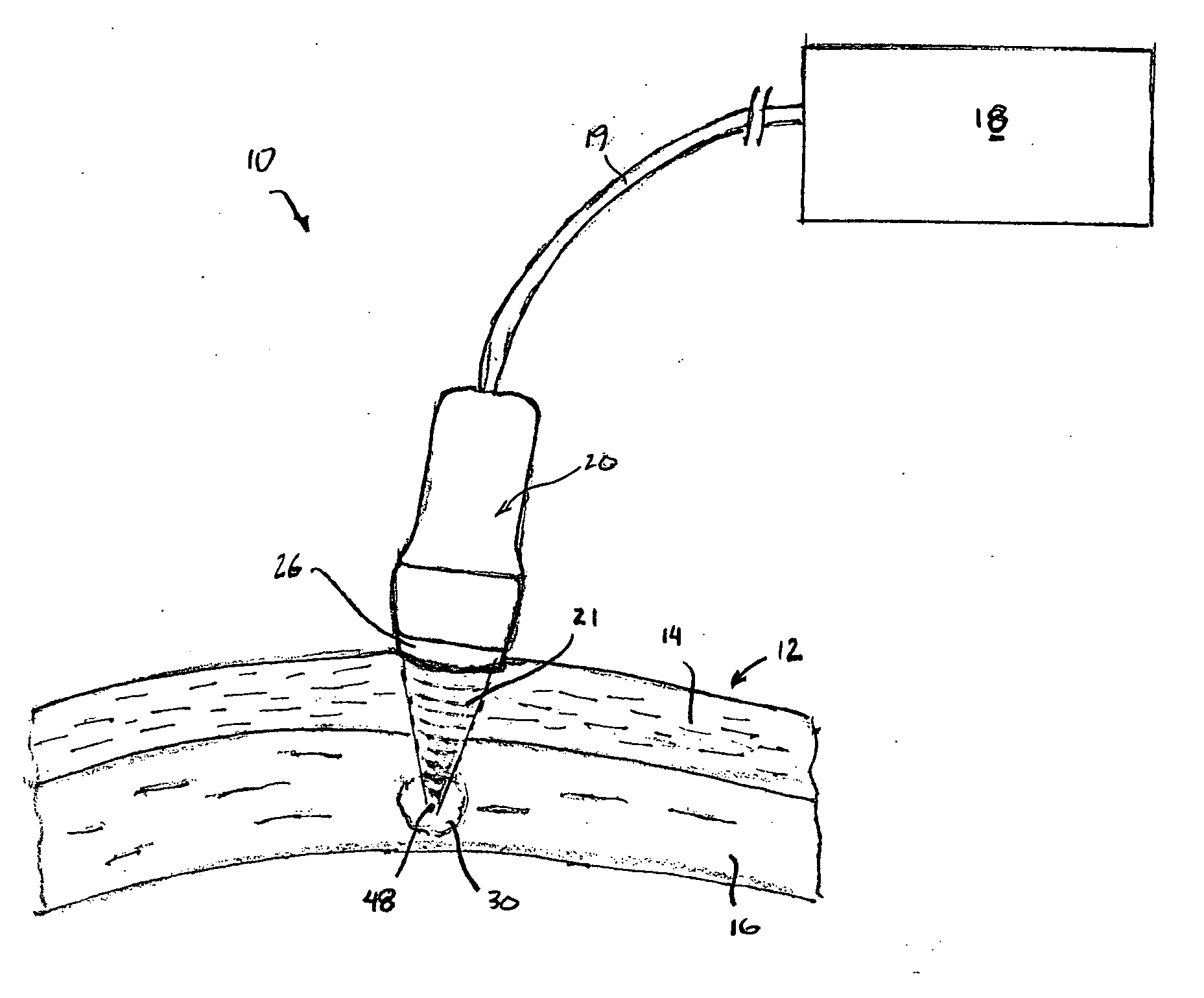

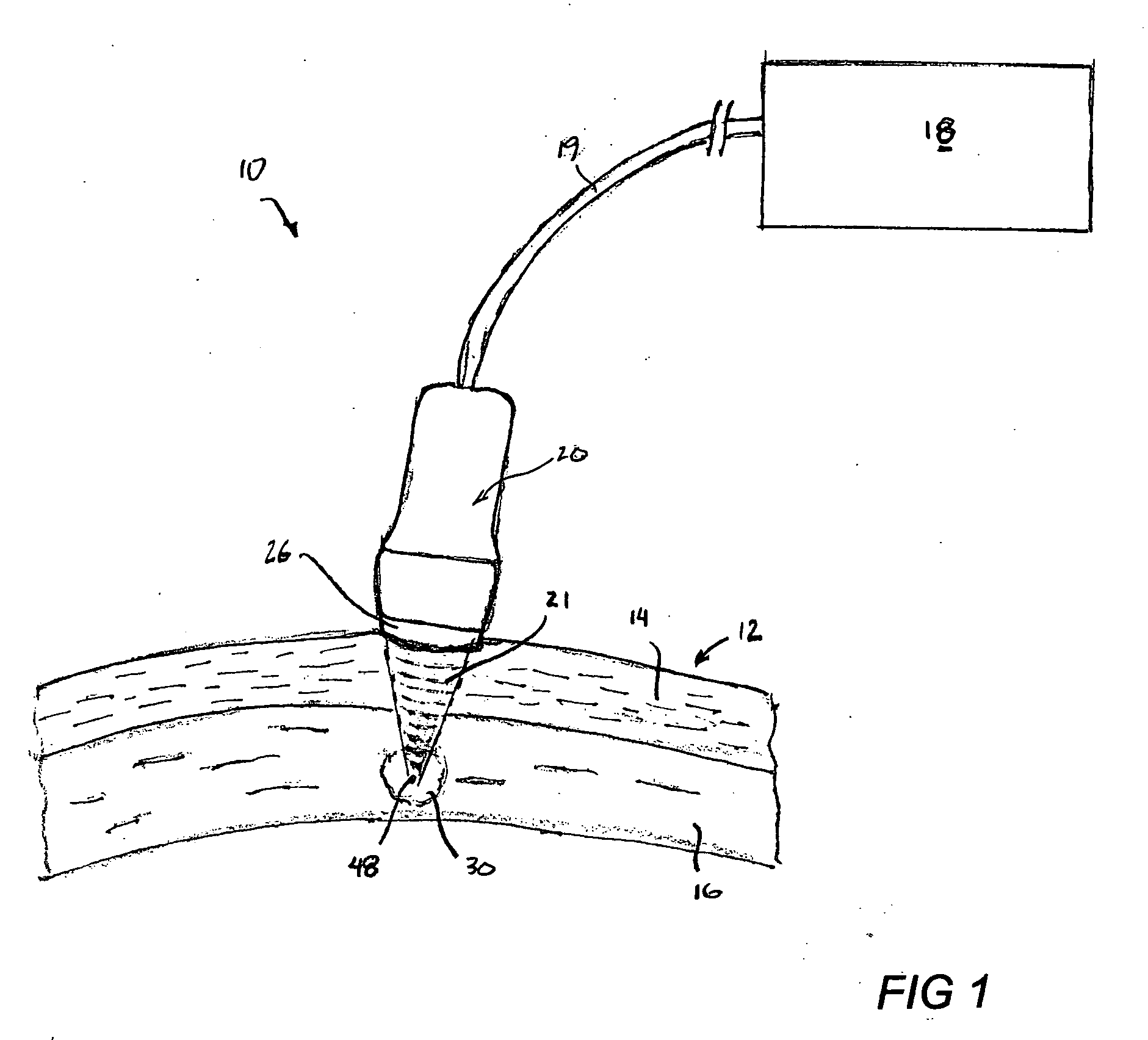

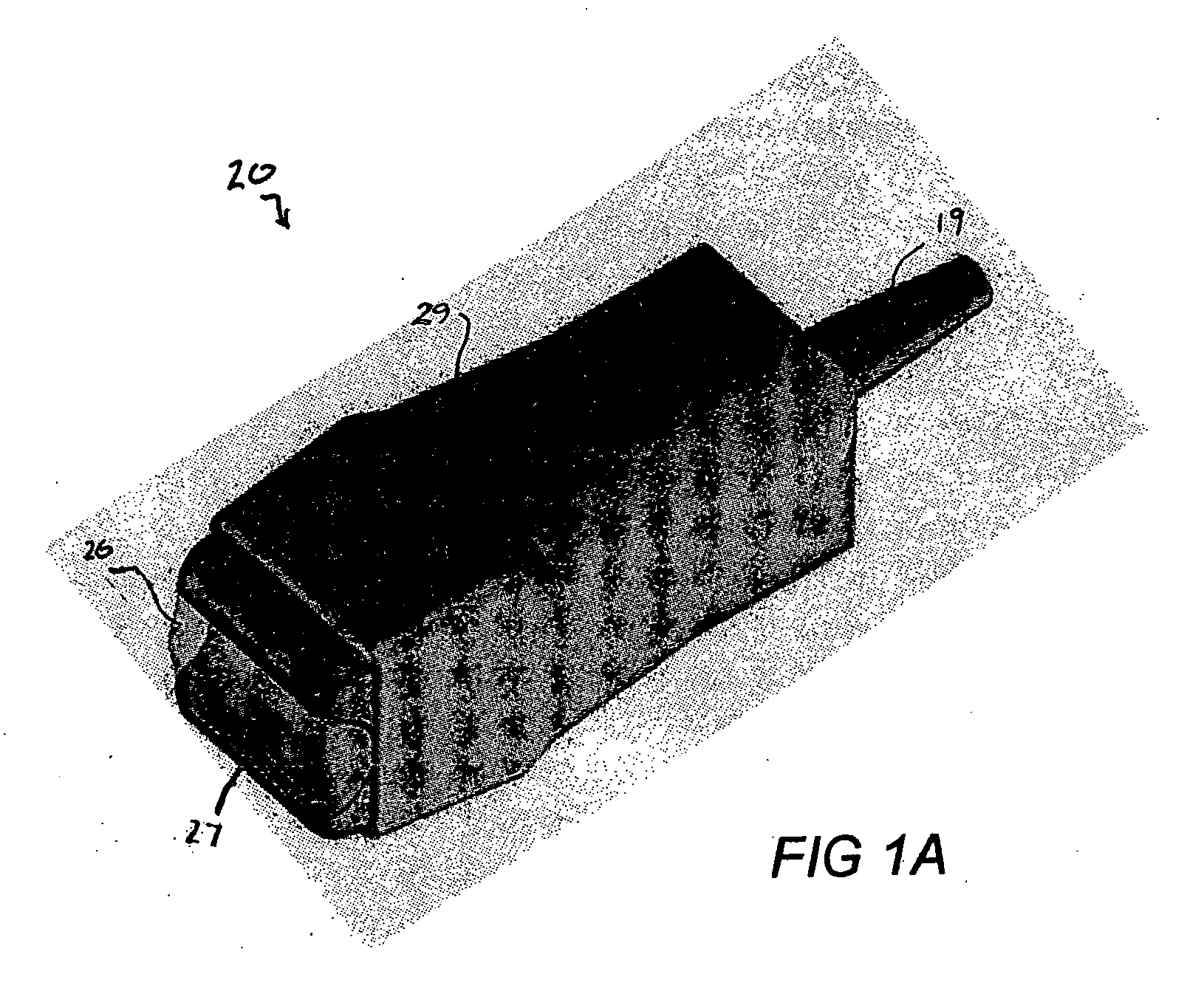

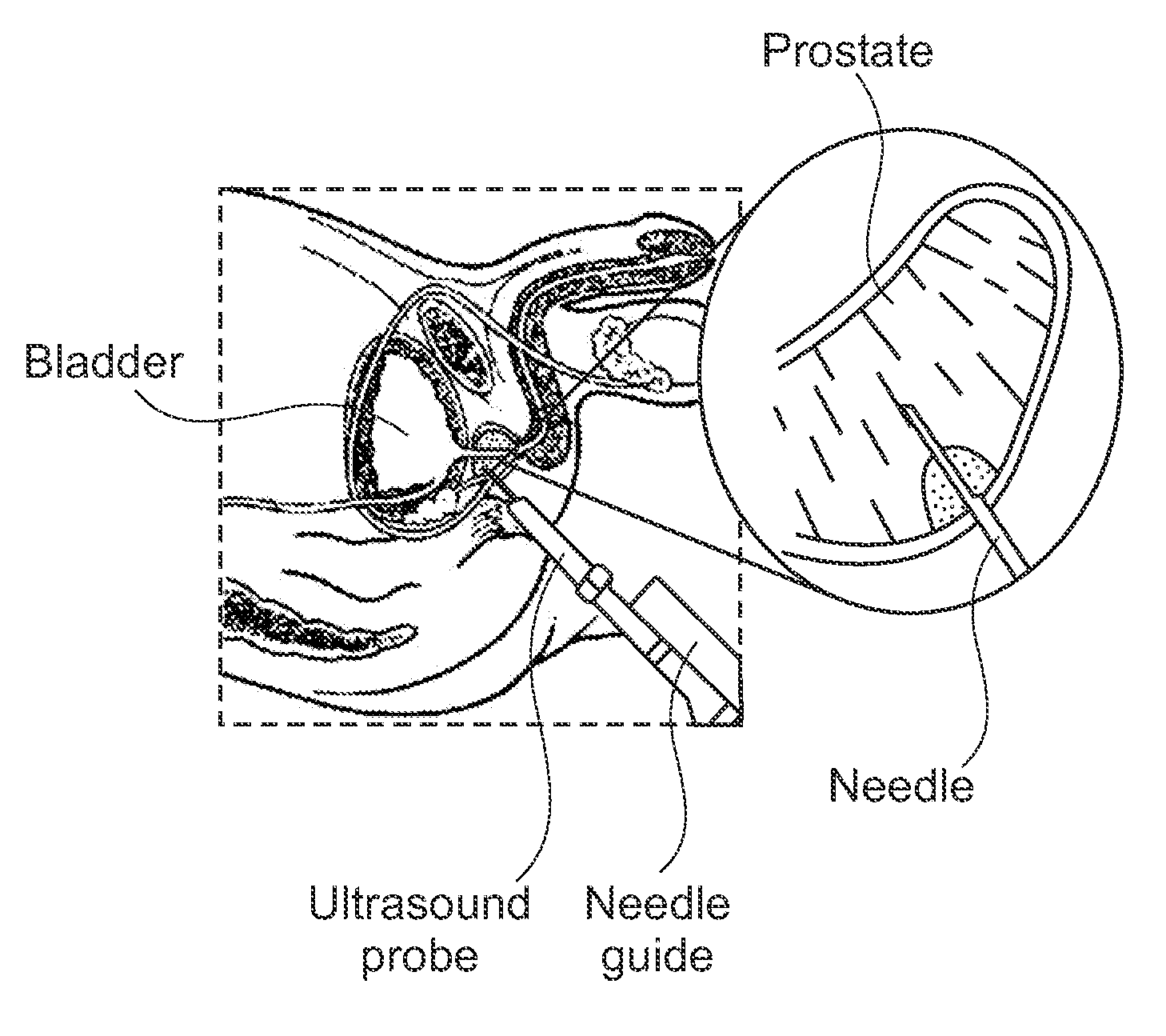

Biopsy device with acoustic element

InactiveUS20110066073A1Continuous measurementStrong absorption capacitySurgical needlesVaccination/ovulation diagnosticsRadiologyTransducer

The invention relates to a biopsy device, particularly a biopsy device comprising a shaft with a transducer element for providing information about acoustic properties of a material to be analysed, a system of positioning a biopsy device and a method for positioning a biopsy device. The biopsy device may be adapted to take biopsies of different regions of the 5 human body for excluding or detecting abnormalities as cancerous lesions. The biopsy device may be used to measure acoustic properties of the material while inserting the tip portion of the biopsy device into the material to be analysed. The biopsy device may further allow measurement based on elastography.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Adjustment of acoustic properties based on proximity detection

ActiveUS20100046766A1Increase air volumePosition data use in hearing devicesSignal processingTransducerLoudspeaker

One or more acoustic transducers of a device may be adjusted based on automatic detection of device proximity to the user. In a mobile telephone, when the user is using the receiver and holding the telephone against his / her ear, if the telephone detects that the user has moved the telephone further from his / her ear, the telephone will raise the receiver volume. Similarly, if the user is using the speaker, the telephone will adjust the speaker volume as user distance from the telephone changes. In another embodiment the telephone may fade between the receiver and the speaker. Volume is not the only acoustic property that could be adjusted according to user proximity. Frequency response is another property that could be adjusted, such as using appropriate electronic filtering, or by turning on another transducer that is not otherwise being used.

Owner:APPLE INC

Speech recognition

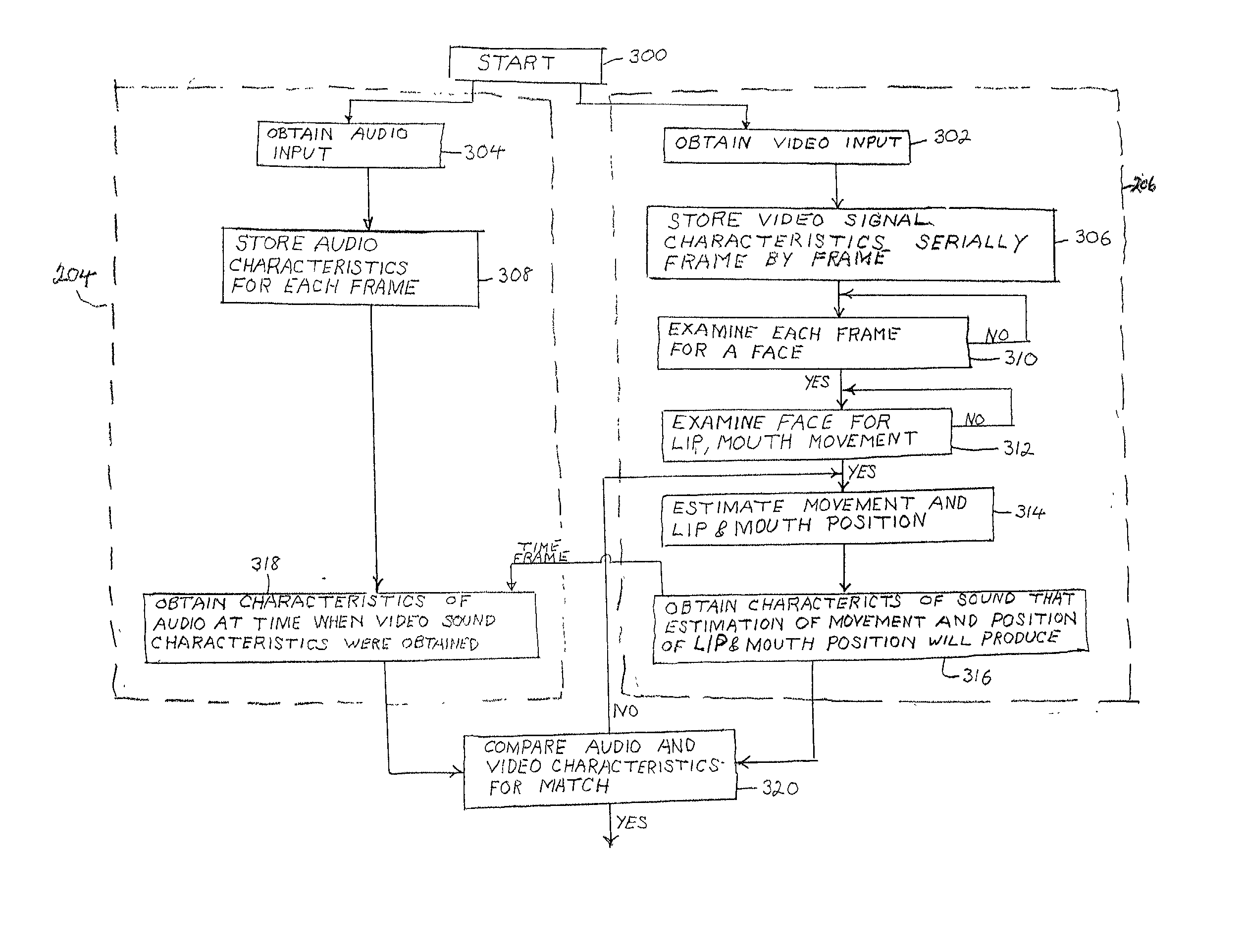

A method and apparatus for automatically controlling the operation of a speech recognition system without requiring unusual or unnatural activity of the speaker by passively determining if received sound is speech of the user before activating the speech recognition system. A video camera and microphone are located in a hand-held device. The video camera records a video image of the speaker's face, i.e., of speech articulators of the user such as the lips and / or mouth. The recorded characteristics of the articulators are analyzed to identify the sound that the articulators would be expected to make, as in "lip reading". A microphone concurrently records the acoustic properties of received sound proximate the user. The recorded acoustic properties of the received sound are then compared to the characteristics of speech that would be expected to be generated by the recorded speech articulators to determine whether they match. If so, then the received sound is identified as having emanated from the user the speech recognition system is operated to perform speech recognition of the received sound.

Owner:AVAYA TECH CORP

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS6988411B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSound pressure

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com